The E Factor in Pharmaceutical Chemistry: From Oil Refining to Sustainable API Synthesis

This article explores the critical application of Sheldon's Environmental (E) Factor—a metric of process waste—across chemical manufacturing scales, from bulk petrochemicals to high-value Active Pharmaceutical Ingredients (APIs).

The E Factor in Pharmaceutical Chemistry: From Oil Refining to Sustainable API Synthesis

Abstract

This article explores the critical application of Sheldon's Environmental (E) Factor—a metric of process waste—across chemical manufacturing scales, from bulk petrochemicals to high-value Active Pharmaceutical Ingredients (APIs). Targeted at researchers and drug development professionals, it examines foundational principles, methodological applications in green chemistry, strategies for troubleshooting and optimizing synthetic routes, and comparative validation against other sustainability metrics. The synthesis provides a roadmap for integrating E Factor analysis into pharmaceutical R&D to drive more sustainable and economically viable processes.

Defining the E Factor: A Cross-Industry Metric for Waste and Sustainability

The E Factor, conceived by Roger A. Sheldon in the early 1990s, emerged as a pivotal metric to quantify the environmental impact of chemical processes. Its development was driven by the growing need for a simple, yet powerful, tool to assess the "greenness" of chemical manufacturing across industries. The core premise is that the ideal chemical process should generate minimal waste, with the bulk of reactants incorporated into the final product. The E Factor provides a straightforward measure of this efficiency, catalyzing the principles of Green Chemistry.

The fundamental equation is defined as:

E = (Total waste generated in kg) / (Total product generated in kg)

Where "Total waste" encompasses all non-product outputs, including by-products, spent reagents, solvents, process aids, and energy-generation by-products (when significant). Water is typically excluded from the calculation due to its high mass, except when its use or contamination is a critical issue.

The E Factor Spectrum: From Bulk Chemicals to Pharmaceuticals

The E Factor's utility is most apparent when comparing its values across different sectors of the chemical industry, highlighting intrinsic process inefficiencies and environmental burdens. The following table summarizes typical E Factor ranges.

Table 1: E Factor Values Across Chemical Industries

| Industry Sector | Typical E Factor Range (kg waste / kg product) | Key Drivers of Waste Generation |

|---|---|---|

| Oil Refining | < 0.1 | Large-scale, continuous, highly optimized processes; water is main co-product. |

| Bulk Chemicals | < 1 - 5 | Large-tonnage production, catalytic processes, but stoichiometric inorganic reagents are common. |

| Fine Chemicals | 5 - 50 | Multi-step batch processes, functional group protection/deprotection, varied reagents. |

| Pharmaceuticals (API) | 25 - 100+ | Complex multi-step synthesis, low atom economy, extensive purification, high solvent usage. |

| Biotechnology/Research | Often >> 100 | Small-scale reactions, excess reagents for yield optimization, extensive chromatography. |

Core Equation and Detailed Calculation Methodology

An accurate E Factor calculation requires a detailed process mass inventory. The following experimental protocol outlines the steps for determination.

Experimental Protocol: Determination of Process E Factor

Objective: To calculate the E Factor for a given chemical synthesis or manufacturing process.

Materials & Reagents:

- Analytical balance (high precision)

- Detailed process flow diagram

- Inventory of all input materials (mass)

- Measurement of all output streams (mass)

Procedure:

- Define System Boundaries: Clearly define the start and end points of the process (e.g., from raw material charging to isolated, dried product).

- Mass Input Tabulation: Record the mass (kg) of every material introduced into the reaction and work-up stages. This includes all reactants, catalysts, solvents, and any process aids (e.g., filter aids, drying agents).

- Mass Output Tabulation: Precisely measure the mass (kg) of the isolated, purified final product (with specified purity, e.g., >98%). Collect and quantify all other output streams, including:

- Aqueous waste streams

- Organic waste (spent solvents, mother liquors)

- Solid waste (used catalysts, filtration residues, by-products)

- Emissions (if captured; otherwise, estimated from mass balance)

- Perform Mass Balance: Verify the data by checking: Σ(Mass Inputs) ≈ Σ(Mass Outputs). Significant discrepancies indicate measurement errors or unaccounted losses/emissions.

- Calculate Total Waste: Total Waste (kg) = Σ(Mass of All Outputs) - Mass of Product.

- Compute E Factor: Apply the core equation: E = Total Waste (kg) / Mass of Product (kg).

- Report: Report the E Factor value alongside the defined system boundaries and any notable assumptions (e.g., exclusion of process water).

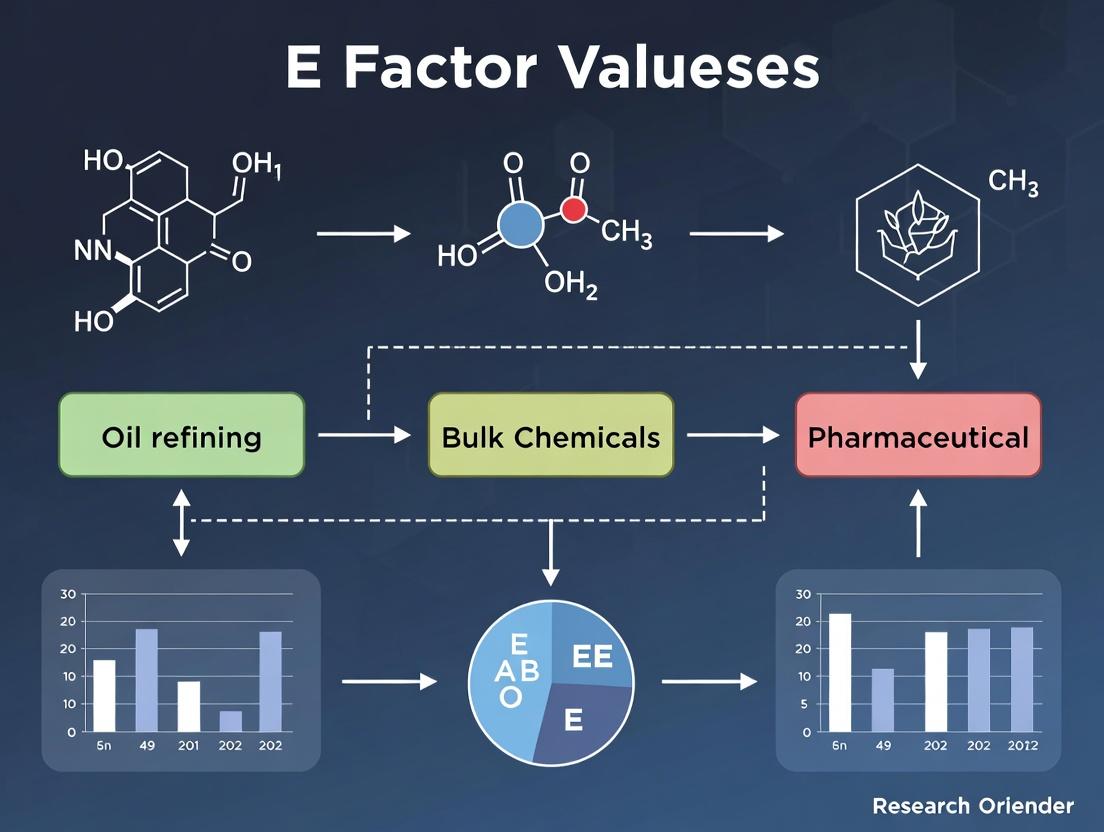

Visualizing the E Factor Calculation and Industrial Context

The logical flow of the E Factor calculation and its relationship to process efficiency is depicted in the following diagram.

The Scientist's Toolkit: Essential Reagents and Materials for E Factor-Conscious Research

Moving from traditional synthesis towards processes with lower E Factors requires specific tools and reagents. The following table details key research solutions.

Table 2: Research Toolkit for Optimizing E Factor

| Reagent / Material Category | Example(s) | Primary Function in Reducing E Factor |

|---|---|---|

| Catalysts (Heterogeneous) | Immobilized enzymes, polymer-supported reagents, metal-on-solid catalysts | Enable easy recovery, reuse, and minimize metal contamination in waste streams. |

| Alternative Solvents | Water, supercritical CO₂, bio-derived solvents (e.g., 2-MeTHF, Cyrene), ionic liquids | Replace volatile, hazardous, and mass-intensive organic solvents, simplifying recovery and reducing toxicity. |

| Atom-Economical Reagents | Olefin metathesis catalysts, C-H activation catalysts, cascade reaction reagents | Maximize the incorporation of reactant atoms into the final product, minimizing by-product formation. |

| Process Analytical Technology (PAT) | In-line IR/Raman spectroscopy, automated sampling systems | Allows real-time monitoring and precise control of reaction endpoints, reducing excess reagent use and reprocessing. |

| Continuous Flow Systems | Microreactors, packed-bed flow reactors | Enhance heat/mass transfer, improve safety with hazardous reagents, reduce solvent volume, and enable precise reaction control. |

| Alternative Energy Sources | Microwave, ultrasound, mechanochemical (ball mill) equipment | Can accelerate reactions, improve yields/selectivity, and sometimes enable solvent-free conditions. |

Sheldon's E Factor remains a cornerstone metric in Green Chemistry, providing an unambiguous measure of process waste efficiency. Its stark revelation of the waste intensity of pharmaceuticals and fine chemicals has driven significant research into catalytic methods, solvent substitution, and process intensification (e.g., flow chemistry). Modern applications extend the principle to include environmental quotient (EQ) and life cycle assessment (LCA) for a more holistic view. For researchers and drug development professionals, targeting a lower E Factor is synonymous with developing more sustainable, cost-effective, and environmentally responsible chemical processes.

The E Factor, defined as the ratio of the mass of waste produced to the mass of the desired product, is a pivotal metric in assessing the environmental impact of chemical processes. This whitepaper provides an in-depth technical comparison of E Factors across three distinct industrial sectors: oil refining, bulk chemicals, and fine chemicals/pharmaceuticals. The analysis is framed within the context of a broader thesis on the fundamental economic and operational drivers that dictate these values, underscoring the intrinsic relationship between molecular complexity, process intensity, and environmental efficiency.

Quantitative E Factor Data Across Sectors

The E Factor spectrum reveals orders-of-magnitude differences, reflecting the varying process complexities and purification requirements.

Table 1: Comparative E Factors and Key Characteristics

| Sector | Typical E Factor Range | Scale (Annual Tonnage) | Key Drivers of Waste |

|---|---|---|---|

| Oil Refining | <0.1 | 10^6 - 10^8 | Energy consumption, catalyst regeneration, minimal purification. |

| Bulk Chemicals | 1 - 5 | 10^4 - 10^6 | Stoichiometric reagents, moderate purification, solvent use. |

| Fine Chemicals/Pharmaceuticals | 25 - 100+ | 10 - 10^3 | Multi-step synthesis, complex purification, high solvent volumes. |

Table 2: Representative Process Details and Associated Waste

| Sector / Example Product | Typical Steps | Major Waste Components | Approx. Solvent Mass per kg API (Pharma) |

|---|---|---|---|

| Oil Refining / Gasoline | 1-2 (Distillation, Cracking) | Spent catalysts, sludge, CO₂ from energy. | N/A (minimal) |

| Bulk / Ethylene | 1 (Steam Cracking) | Tars, spent caustic wash, CO₂. | N/A (minimal) |

| Pharma / API (Typical) | 6-12+ | Solvents (DMF, DMSO, THF), reagents, by-products, packaging. | 50 - 150 kg |

Detailed Methodologies and Experimental Protocols

Protocol for Determining E Factor in a Pharmaceutical Process

A standardized methodology for calculating the "Process Mass Intensity" (PMI), a related metric, is recommended by the American Chemical Society Green Chemistry Institute Pharmaceutical Roundtable (ACS GCI PR).

- System Boundary Definition: Define the "cradle-to-gate" boundary, starting from purchased materials to the isolated Active Pharmaceutical Ingredient (API).

- Mass Accounting: Accurately weigh all input materials (reagents, solvents, catalysts, processing aids) for a single batch.

- Product Mass: Record the mass of the dried, purified final API product.

- Waste Calculation: Calculate total waste mass as: Total Input Mass - Mass of API.

- E Factor Calculation: Compute E Factor = Total Waste Mass / Mass of API.

- Solvent Contribution: A critical sub-calculation is the solvent E Factor: Mass of Solvents Used / Mass of API.

Protocol for Life Cycle Inventory (LCI) in Oil Refining

For a more comprehensive environmental assessment, a simplified LCI for a refinery can be conducted.

- Functional Unit: Define the basis (e.g., 1 MJ of energy output from gasoline, or 1 kg of refined product).

- Data Collection: Gather operating data for a specified period (e.g., one month):

- Inputs: Mass of crude oil, mass of catalysts, volume of water, energy (natural gas, electricity).

- Outputs: Mass of all saleable products (gasoline, diesel, etc.).

- Non-Product Outputs: Mass of spent catalyst, sludge from wastewater treatment, CO₂ emissions from on-site combustion (calculated from fuel usage).

- Allocation: Allocate waste and emissions to different co-products using an appropriate method (e.g., energy content, mass).

- E Factor Calculation: For a specific product stream: E Factor = (Allocated Waste + Allocated Emissions Mass) / Mass of Product.

Visualizing the E Factor Spectrum and Workflows

The E Factor Industrial Spectrum

Diagram 1: E Factor Industrial Scale-Complexity Trade-off

Typical Pharmaceutical API Synthesis Workflow

Diagram 2: Pharma API Synthesis Waste Generation Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Pharmaceutical Process Research & Green Metrics Analysis

| Item / Reagent Solution | Function / Purpose | Key Consideration for E Factor |

|---|---|---|

| Alternative Solvent Guides (e.g., CHEM21) | Provides ranked lists of safer, greener solvents to replace problematic ones (e.g., DMF, DCM). | Directly reduces solvent waste mass and toxicity. |

| Supported Reagents (Silica, Polymer-bound) | Immobilizes reagents, simplifying workup (filtration) and reducing aqueous waste. | Eliminates extraction steps, reduces solvent use for purification. |

| Flow Chemistry Systems | Enables continuous processing with superior heat/mass transfer and safer handling of intermediates. | Reduces solvent volume, improves yield, minimizes scale-up waste. |

| Process Analytical Technology (PAT) | In-line sensors (IR, Raman) for real-time monitoring of reaction endpoints and purity. | Prevents over-processing, reduces failed batches, and optimizes yields. |

| Catalytic Reagents (e.g., Pd/C, Enzymes) | Replaces stoichiometric oxidants/reductants (e.g., metals, borohydrides). | Drastically reduces inorganic salt waste and improves atom economy. |

| Green Metrics Software (e.g., iChemE Calculator) | Automates calculation of E Factor, PMI, Atom Economy, and other sustainability metrics. | Essential for quantitative comparison and optimization of synthetic routes. |

The E Factor spectrum starkly illustrates the environmental efficiency gradient from simple, large-scale hydrocarbon processing to complex, small-scale molecule synthesis. The core thesis is that the high E Factors in pharmaceuticals are not merely a function of industry maturity but are intrinsically linked to the molecular complexity demanded by biological activity and the rigorous purification standards required for human therapeutics. The path toward sustainability in fine chemicals and pharmaceuticals lies in adopting the methodologies outlined in this guide: rigorous metric tracking, solvent and reagent substitution, and the integration of innovative technologies like flow chemistry and catalysis to mimic the efficiency of bulk chemical processes while retaining the precision of molecular synthesis.

Within the broader landscape of industrial chemical synthesis, the Environmental Factor (E Factor)—defined as the mass ratio of waste to desired product—reveals stark contrasts across sectors. While oil refining and bulk chemicals operate with E Factors typically below 5, the pharmaceutical industry consistently exhibits E Factors ranging from 25 to over 100. This whitepaper analyzes the technical and regulatory drivers behind this disparity, focusing on molecular complexity, multi-step purification, and the stringent requirements of drug approval.

Comparative Analysis of Industrial E Factors

The following table summarizes E Factors across key industries, highlighting the outlier status of pharmaceuticals.

Table 1: E Factor Comparison Across Industries

| Industry Sector | Typical E Factor Range | Key Drivers |

|---|---|---|

| Oil Refining | <0.1 | Integrated, catalytic processes; high-volume, simple molecules. |

| Bulk Chemicals | <1 to 5 | Optimized continuous processes; tolerance for minor impurities. |

| Fine Chemicals | 5 to 50 | Increased complexity, batch processes, need for higher purity. |

| Pharmaceuticals (API Manufacturing) | 25 to 100+ | Multi-step synthesis, complex purification, regulatory compliance, rapid process development. |

Core Technical Drivers of High Pharma E Factor

Molecular Complexity & Multi-Step Synthesis

Active Pharmaceutical Ingredients (APIs) are structurally complex, often featuring chiral centers, heterocycles, and sensitive functional groups. This necessitates long synthetic sequences (often 8-15 steps) with inherently low atom economy. Each step involves reagents, solvents, and protective groups, the majority of which become waste.

Intensive Purification & Isolation Protocols

Regulatory mandates for ultra-high purity (>99.0% for APIs) demand rigorous purification after each critical step. Techniques like chromatography, recrystallization, and distillation generate substantial solvent and solid waste.

Table 2: Waste Contribution of Common Purification Techniques

| Technique | Primary Waste Stream | Typical Solvent Use per kg API (L) |

|---|---|---|

| Column Chromatography | Spent silica, solvent | 100 - 1000+ |

| Recrystallization | Mother liquor, washes | 50 - 200 |

| Distillation | High-boiling residues | Varies widely |

Regulatory & Quality Drivers

Good Manufacturing Practice (GMP) requirements prioritize process validation, consistency, and patient safety over waste minimization. Changes to a validated process are costly and require regulatory re-approval, disincentivizing post-approval green chemistry optimization. Furthermore, the use of highly hazardous reagents is often mandated to ensure specific stereochemical outcomes or to avoid potential mutagenic impurities.

Experimental Protocol: Evaluating E Factor in a Typical API Step

This protocol details the measurement of E Factor for a single chemical transformation in API synthesis.

Title: Gravimetric Analysis of Process Step E Factor

Objective: To quantify the mass of waste generated per unit mass of product for a defined synthetic step (e.g., a Suzuki-Miyaura coupling followed by isolation).

Materials & Reagents:

- Starting materials (aryl halide, boronic acid).

- Catalyst (Palladium complex, e.g., Pd(PPh3)4).

- Base (e.g., K2CO3).

- Solvents (Toluene, Ethanol, Water for reaction; Ethyl Acetate, Hexanes for workup/purification).

- Silica gel for chromatography.

- Standard laboratory glassware and equipment (round-bottom flasks, separatory funnel, rotary evaporator, chromatographic column).

Procedure:

- Reaction: Charge the aryl halide (1.0 equiv), boronic acid (1.2 equiv), Pd catalyst (0.02 equiv), and base (2.0 equiv) into a flask. Add degassed toluene/ethanol/water solvent mixture (10 mL per mmol of limiting reagent). Heat at 80°C under N2 for 12 hours.

- Work-up: Cool the reaction mixture. Dilute with ethyl acetate (50 mL) and transfer to a separatory funnel. Wash with water (2 x 30 mL) and brine (1 x 30 mL). Dry the organic layer over anhydrous MgSO4, filter, and concentrate via rotary evaporation to yield a crude solid.

- Purification: Purify the crude material by flash column chromatography on silica gel (eluent: gradient of ethyl acetate in hexanes). Combine pure fractions and concentrate to obtain the isolated product.

- Weighing & Calculation:

- Weigh the isolated, dry product (MassP).

- Record the mass of all input materials excluding solvents used in excess for extraction/washing (MassR).

- Step E Factor = (MassR - MassP) / Mass_P

- For a complete process E Factor, include all solvents, silica gel, and consumables in the waste mass.

The Scientist's Toolkit: Key Reagents for API Synthesis & Analysis

Table 3: Essential Research Reagent Solutions in Pharmaceutical Development

| Reagent/Material | Function in API Development | Typical Use Case |

|---|---|---|

| Palladium Catalysts (e.g., Pd(dppf)Cl2) | Facilitate key C-C/C-N bond formations (cross-couplings). | Suzuki, Heck, Buchwald-Hartwig reactions in core structure assembly. |

| Chiral Resolution Agents (e.g., L-Tartaric Acid) | Separate enantiomers to obtain the therapeutically active stereoisomer. | Resolution of racemic mixtures during early-phase development. |

| High-Performance Liquid Chromatography (HPLC) Grade Solvents | Provide ultra-high purity for analytical testing and final purification. | Assay and impurity profiling of API batches to meet regulatory specs. |

| Silica Gel (40-63 μm) | Solid support for chromatographic purification of intermediates. | Flash column chromatography to remove by-products and unreacted starting materials. |

| Genotoxic Impurity (GTI) Standards | Analytical reference materials to monitor and control mutagenic impurities. | Validated analytical methods per ICH M7 guideline compliance. |

Visualizing the Drivers of Pharmaceutical E Factor

Diagram 1: Drivers of Pharmaceutical E Factor

The pharmaceutical industry's exceptionally high E Factor is an inherent consequence of its mission to deliver structurally complex, ultra-pure, and rigorously safe therapeutics. While oil refining and bulk chemical sectors optimize for volumetric efficiency and atom economy, drug manufacturing is driven by patient safety, regulatory compliance, and speed to market, often at the expense of environmental efficiency. Advancements in continuous manufacturing, biocatalysis, and analytical quality by design (QbD) offer pathways to reduce this waste burden without compromising quality, representing the frontier of sustainable pharmaceutical engineering.

The E Factor (Environmental Factor), introduced by Roger A. Sheldon, is a cornerstone metric in green chemistry, defined as the mass ratio of waste to desired product (kg waste/kg product). While invaluable, the E Factor's focus on mass alone is a critical limitation. It assigns equal weight to benign waste (e.g., NaCl, H₂O) and highly hazardous materials. This whitepaper reframes waste assessment within the thesis of E Factor progression—from oil refining (E ~0.1) to bulk chemicals (E ~1-5) to pharmaceuticals (E ~25-100+) and research activities (E >>100)—by introducing the Environmental Quotient (EQ) and Waste Hazard as essential complementary metrics.

EQ = E Factor × Q where Q is an empirically determined unfriendliness quotient that accounts for the nature of the waste (toxicity, persistence, bioaccumulation, etc.).

This guide provides a technical framework for researchers, especially in drug development, to move beyond mass-based metrics and implement hazard-aware environmental impact assessments.

Quantitative Data: E Factors and Hazard Classifications

The following tables synthesize current data on E Factors and propose a hazard multiplier (Q) framework for common waste streams.

Table 1: Typical E Factors Across Chemical Industries

| Industry Sector | Typical E Factor Range | Primary Waste Components |

|---|---|---|

| Oil Refining | 0.1 - 0.3 | Spent catalysts, acidic gases, metal oxides. |

| Bulk Chemicals | <1 - 5 | Inorganic salts (NaCl, Na₂SO₄), process water, organic by-products. |

| Fine Chemicals | 5 - 50 | Solvents (DMF, THF), metal complexes, halogenated organics. |

| Pharmaceuticals (API) | 25 - >100 | Complex solvents (DCM, DMF, NMP), chromatography eluents, heavy metal reagents. |

| Medicinal Chemistry (Research) | 100 - 1000+ | High-boiling solvents, excess reagents, reaction quenches in small volumes. |

Table 2: Proposed Hazard Multiplier (Q) for Common Waste Classes

| Waste Hazard Class | Description & Example Compounds | Proposed Q Value | Rationale |

|---|---|---|---|

| Innocuous (Q=1) | Water, NaCl, Na₂SO₄, CaCO₃, cellulose. | 1 | Benign, easily treated or disposed. |

| Low Hazard (Q=1-10) | Short-chain alcohols (MeOH, EtOH), acetic acid, acetone. | 2-5 | Some energy recovery potential, low toxicity. |

| Moderate Hazard (Q=10-100) | Halogenated solvents (DCM, CHCl₃), aromatic hydrocarbons (toluene, xylene), bases (pyridine). | 25-50 | Toxic, requires specialized recovery or treatment. |

| High Hazard (Q=100-1000) | Heavy metal salts (Pd, Cr, As), cyanides, persistent bioaccumulative toxins (PBTs), genotoxic impurities. | 100-1000 | Severe environmental and health impact, costly destruction. |

Experimental Protocols for Determining EQ in Pharmaceutical Research

Protocol 3.1: Lifecycle Inventory for a Representative API Synthesis Step

Objective: To calculate the precise E Factor and EQ for a Pd-catalyzed cross-coupling step in drug candidate synthesis.

Methodology:

- Mass Balance: On a 10 mmol scale reaction, record exact masses of all inputs:

- Substrates: Aryl halide (2.12 g), boronic acid (1.83 g).

- Catalyst/Reagents: Pd(PPh₃)₄ (115 mg, 1 mol%), K₂CO₃ (2.76 g, 2.0 equiv).

- Solvent: Toluene (30 mL) and Water (10 mL).

- Work-up/Isolation: 2M HCl (20 mL), Ethyl acetate (3 × 30 mL), MgSO₄ (2 g), silica gel (10 g) for flash chromatography, hexane/ethyl acetate eluents (500 mL total).

Product Isolation: Isolate pure product by flash chromatography. Record final dry mass of product (e.g., 2.15 g).

Waste Calculation:

- Aqueous Waste: Combine all aqueous layers (reaction water, acid quench, aqueous washes). Calculate mass.

- Organic Waste: Combine all spent organic fractions from chromatography and filtrates. Evaporate solvent to determine mass of non-volatile residues.

- Solid Waste: Weigh spent silica gel, MgSO₄, and filter papers.

Hazard Assessment & Q Assignment: Classify each waste stream using safety data sheets (SDS) and GHS classifications. Assign a Q value:

- Spent Toluene/Hexane: Halogen-free organic solvent waste (Moderate Hazard): Q=30.

- Aqueous Layer with K+, Pd traces: Heavy metal traces (High Hazard): Q=100.

- Solid Silica Gel with Organics: Mixed organic/inorganic (Low Hazard): Q=5.

Calculation:

- E Factor = (Total mass of inputs - 2.15 g product) / 2.15 g.

- EQ = Σ (Mass of waste stream * i * Qi) / Mass of product.

Protocol 3.2: Solvent Selection Guide Based on EQ

Objective: To compare the EQ of two common amide coupling solvents, DMF and 2-MeTHF, for a standard peptide bond formation.

Methodology:

- Run identical peptide coupling reactions on a 5 mmol scale using HATU as the coupling agent and DIPEA as the base, in parallel with DMF or 2-MeTHF (20 mL each).

- Work up by dilution with water (50 mL) and extraction with EtOAc (3 × 25 mL).

- The aqueous layer contains the spent solvent (DMF is water-miscible; 2-MeTHF forms a separate layer).

- Isolate and weigh the product from the organic phase.

- Waste Stream Analysis: For DMF, the entire aqueous layer is a single waste stream (Q=50, hard to recycle). For 2-MeTHF, the aqueous layer is primarily water (Q=1), and the organic layer can be distilled and reused (Q for fresh solvent credit).

- Calculate and compare the EQ for both processes, highlighting the advantage of a water-immiscible, biodegradable solvent.

Visualization: From E Factor to EQ in API Development

Title: The EQ Calculation Integrates Mass and Hazard

Title: EQ-Driven Sustainable API Development Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Hazard-Reduced Medicinal Chemistry

| Item / Reagent | Function & Green Chemistry Rationale | Hazard Reduction Impact |

|---|---|---|

| 2-Methyltetrahydrofuran (2-MeTHF) | Water-immiscible, biobased solvent for extractions, Grignard reactions. Replaces THF (persistent) and halogenated solvents. | Lowers Q factor; derived from renewable resources. |

| Cyclopentyl methyl ether (CPME) | High-boiling, stable, low-peroxide-formation ether solvent. Alternative to Dioxane (carcinogenic) and DIPE. | Lower toxicity (higher Q allowance) versus traditional ethers. |

| Ethyl Lactate | Biodegradable, renewable aprotic solvent with good solubilizing power. Potential replacement for NMP (reprotoxic) or DMF. | Drastically reduces environmental persistence and toxicity (Q). |

| Immobilized Catalysts (e.g., SiliaCat Pd) | Heterogeneous catalysts on silica support for cross-couplings, hydrogenations. Enable filtration recovery and reuse. | Minimizes heavy metal waste, critical for lowering Q. |

| Polymer-Supported Reagents & Scavengers | For catch-and-release purification or quenching excess reagents (e.g., PS-Trisamine, PS-Isocyanate). | Simplifies workup, reduces solvent volume for extraction/purification, lowering E. |

| Water as a Reaction Medium | For reactions amenable to aqueous conditions (e.g., hydrolysis, biocatalysis). | Q = 1 for the bulk medium, eliminating organic solvent hazard. |

| In-line Analytics (FTIR, PAT) | For real-time reaction monitoring to determine endpoint. | Prevents over-use of reagents/solvents and minimizes by-product formation, optimizing both E and Q. |

The Environmental Factor (E Factor), defined as the ratio of mass of waste to mass of desired product, is a critical metric for assessing the environmental efficiency and sustainability of chemical processes. This whitepaper presents current (2024) benchmark ranges across major chemical sectors, framed within a broader thesis that E Factor values trend dramatically lower as one moves from bulk chemical manufacturing toward targeted pharmaceutical research and production. This progression reflects increasing complexity, regulatory scrutiny, and value per unit mass.

2024 E Factor Benchmarks by Industry Sector

The following table summarizes the latest typical E Factor ranges, highlighting the vast disparity between sectors. Data is synthesized from recent industry reports, green chemistry literature, and corporate sustainability disclosures.

Table 1: Current Typical E Factor Ranges by Industry Sector (2024)

| Industry Sector | Typical E Factor Range (2024) | Key Drivers & Context |

|---|---|---|

| Oil Refining & Bulk Petrochemicals | 0.1 - 0.5 | Highly integrated, continuous, large-scale processes. Waste primarily consists of spent catalysts, inorganic salts, and minor process losses. Focus is on energy efficiency and atom economy. |

| Bulk & Industrial Chemicals | 1 - 5 | Includes fertilizers, polymers, and commodity chemicals. Processes are optimized for cost and scale, with significant aqueous waste streams and by-products. |

| Fine Chemicals | 5 - 50 | Multistep batch processes for complex intermediates. Higher purification requirements and lower volumes than bulk chemicals. |

| Pharmaceuticals (Active Pharmaceutical Ingredient - API Manufacturing) | 25 - 100+ | Complex multi-step syntheses with extensive purification, chromatography, and solvent use per kg of final product. This is the most waste-intensive commercial chemical sector. |

| Pharmaceutical Research (Medicinal Chemistry) | 100 - 1000+ | Laboratory-scale synthesis for discovery and early development. Extremely low yields in exploratory steps, high solvent use for purification (flash chromatography), and single-use materials dominate waste generation. |

Thesis Context: The data in Table 1 empirically supports the central thesis: E Factor increases exponentially with the complexity and specificity of the chemical product. The transition from refinery-scale catalysis (E Factor <<1) to bespoke, multi-gram API synthesis (E Factor ~50) and finally to milligram-scale research (E Factor >>100) maps directly to increasing molecular complexity, regulatory purity demands, and the economic tolerance for waste generation.

Experimental Protocol for Determining E Factor in Pharmaceutical Research

To standardize reporting, researchers should adhere to a detailed protocol. The following methodology is adapted from the ACS GCI Pharmaceutical Roundtable recommendations.

Protocol Title: Standard Operating Procedure for Determining Process E Factor in a Medicinal Chemistry Laboratory

1. Objective: To accurately calculate the total E Factor for a single chemical transformation or a multi-step synthetic sequence to a target compound.

2. Scope: Applicable to all solution-phase synthetic chemistry experiments at the laboratory (mg to g) scale.

3. Definitions:

- Product: The purified target compound, dried to constant weight.

- Waste: All materials used in the reaction and work-up that do not appear in the final product. This includes solvents, reagents, catalysts, aqueous washes, silica gel from chromatography, and consumables (e.g., plasticware for filtration). Note: In laboratory settings, consumables are often omitted but should be noted.

4. Materials & Equipment:

- Analytical balance

- Laboratory notebook

- Waste collection containers (for organic, aqueous, and solid waste)

- Drying apparatus (e.g., vacuum desiccator)

5. Procedure: Step 5.1: Planning & Recording.

- Before starting the experiment, record the exact masses/volumes of all input materials (starting materials, reagents, solvents, catalysts) in the notebook.

Step 5.2: Reaction Execution.

- Carry out the synthesis, work-up, and purification as per the experimental procedure.

Step 5.3: Product Isolation & Quantification.

- Isolate and purify the final product.

- Dry the product to constant weight.

- Accurately record the final mass (in kg) of the pure, dry product (Mass of Product).

Step 5.4: Waste Quantification.

- Method A (Direct Measurement): Collect all waste streams (combined organic layers, aqueous layers, solid residues, used silica gel, etc.) separately. Measure their masses or volumes and convert to mass using known densities where applicable. Sum all waste masses to obtain Total Mass of Waste.

- Method B (Input-Output Calculation - Most Common in Labs): Calculate waste mass indirectly:

- Total Mass of Inputs = Σ (mass of all starting materials, reagents, solvents, catalysts).

- Mass of Product = As measured in 5.3.

- Total Mass of Waste ≈ Total Mass of Inputs − Mass of Product.

- Assumption: This method assumes all inputs not incorporated into the product become waste. It is the most practical for laboratory settings.

Step 5.5: Calculation.

- Calculate the E Factor using the formula:

E Factor = (Total Mass of Waste) / (Mass of Product) - Report the E Factor as a dimensionless number, alongside the method used for waste quantification (A or B).

6. Diagram: E Factor Determination Workflow

Title: Laboratory E Factor Calculation Protocol

The Scientist's Toolkit: Essential Research Reagent Solutions for Green Metrics Analysis

Table 2: Key Tools for E-Factor and Sustainability Assessment in Research

| Tool / Reagent Category | Specific Example(s) | Function in Context of E Factor |

|---|---|---|

| Analytical Balances | Micro (0.001 mg), Semi-micro (0.01 mg), Analytical (0.1 mg) | Critical for accurate mass measurement of both inputs and final product, the foundation of all mass-based green metrics. |

| Green Solvent Selection Guides | ACS GCI Pharmaceutical Roundtable Solvent Guide, CHEM21 Guide | Provides ranked lists of solvents based on safety, health, environmental (E Factor impact) and life-cycle criteria to minimize hazardous waste. |

| Catalysis Kits | Commercially available Pd, Ni, Cu, Organocatalyst libraries | Enables high-atom-economy transformations (e.g., cross-couplings), reducing stoichiometric reagent waste and improving E Factor. |

| Supported Reagents & Scavengers | Polymer-supported reagents, silica-bound scavengers (e.g., for amines, acids) | Facilitates purification without traditional work-up/chromatography, reducing solvent and silica gel waste (major contributors to lab E Factor). |

| Chromatography Alternatives | Automated flash systems, prep-HPLC, recrystallization screening kits | Aims to optimize or replace traditional column chromatography, the single largest source of solvent and solid waste in medicinal chemistry. |

| Process Mass Intensity (PMI) Calculators | Custom Excel sheets, MyGreenLab's PI Calculator | Software tools to automate the calculation of E Factor, PMI, and other related metrics from experimental data. |

Visualizing the Thesis: The E Factor Gradient Across Industries

The following diagram logically maps the relationship between industry characteristics and the resulting E Factor, illustrating the core thesis.

Title: Industry Drivers and Resulting E Factor Ranges

Applying E Factor Analysis to Pharmaceutical Process Development

1. Introduction and Context

The E Factor (Environmental Factor) is a fundamental green chemistry metric, defined as the mass ratio of waste to desired product. It provides a stark, quantitative lens on process efficiency. In a broader thesis on industrial waste, E Factor values reveal a compelling hierarchy: oil refining (~0.1) < bulk chemicals (<1-5) < fine chemicals (5-50) < pharmaceuticals (25-100+). This escalation reflects increasing molecular complexity, multi-step syntheses, and extensive purification in pharmaceutical manufacturing. For researchers and drug development professionals, calculating and minimizing the E Factor is not merely an academic exercise but a critical lever for reducing environmental impact, cost, and supply chain vulnerability. This guide provides a detailed methodology for calculating the E Factor for an Active Pharmaceutical Ingredient (API) synthesis, using a published route as a case study.

2. Case Study: Synthesis of Sildenafil (API)

We will analyze a reported synthetic route to Sildenafil, a well-known API. The calculation focuses on the final API manufacturing steps, excluding earlier production of advanced intermediates.

2.1. Reaction Scheme and Stoichiometry The final steps involve the condensation of a pyrazole carboxylic acid with a sulfonamide intermediate, followed by workup and purification.

2.2. Detailed Experimental Protocol

- Reaction: Charge a reactor with 1.0 kg (1.0 eq, 2.92 mol) of the sulfonamide intermediate. Add 15 L of dichloromethane (DCM) as solvent. Add 0.72 kg (1.05 eq, 3.07 mol) of the pyrazole carboxylic acid. Cool the mixture to 0-5°C. Slowly add 0.67 kg (1.2 eq, 3.50 mol) of N-(3-Dimethylaminopropyl)-N'-ethylcarbodiimide hydrochloride (EDC·HCl) as a coupling agent, maintaining temperature below 10°C. Stir the reaction mixture at 20-25°C for 18 hours.

- Workup: Quench the reaction by adding 10 L of water. Separate the organic layer. Wash the organic layer sequentially with 5 L of 5% aqueous sodium bicarbonate solution and 5 L of brine. Dry the organic layer over anhydrous sodium sulfate (1.0 kg used, subsequently filtered off).

- Isolation: Concentrate the DCM solution under reduced volume to ~3 L. Add 10 L of heptane to precipitate the crude product. Filter and wash the solid with 2 L of heptane.

- Purification: Dissolve the wet crude solid in 20 L of ethyl acetate at 50°C. Cool to 20°C, then further to 0-5°C to crystallize the product. Filter, wash the cake with 2 L of cold ethyl acetate, and dry under vacuum at 50°C for 24 hours to yield 1.05 kg of Sildenafil API as a solid.

3. Mass Inventory and E Factor Calculation

The calculation follows the principle: E Factor = Total Waste Mass (kg) / Product Mass (kg). Waste includes all reagents, solvents, and auxiliary materials not incorporated into the final product. Water from aqueous washes is included. Solvents are accounted for by their total input mass, assuming no recovery/recycling for this batch calculation.

Table 1: Input Mass Inventory for Sildenafil Synthesis (Batch Basis)

| Component | Mass (kg) | Role | Fate/Notes |

|---|---|---|---|

| Sulfonamide Intermediate | 1.00 | Reactant | Incorporated into product |

| Pyrazole Carboxylic Acid | 0.72 | Reactant | Incorporated into product |

| EDC·HCl | 0.67 | Coupling Agent | Consumed, forms urea waste |

| Dichloromethane (DCM) | 15.00 | Solvent | Recovered & incinerated |

| Water (quench) | 10.00 | Quenching Agent | Wastewater stream |

| Sodium Bicarbonate (5% aq.) | 5.00 | Wash | Wastewater stream (solid content negligible) |

| Brine | 5.00 | Wash | Wastewater stream |

| Sodium Sulfate | 1.00 | Drying Agent | Solid waste (wet) |

| Heptane (anti-solvent) | 10.00 | Anti-solvent | Sent for recovery |

| Heptane (wash) | 2.00 | Wash | Sent for recovery |

| Ethyl Acetate (recryst.) | 20.00 | Crystallization Solvent | Sent for recovery |

| Ethyl Acetate (wash) | 2.00 | Wash | Sent for recovery |

| Total Input Mass | 72.41 | ||

| Sildenafil API (Product) | 1.05 | Isolated, dry mass |

Total Waste Mass = Total Input Mass - Product Mass = 72.41 kg - 1.05 kg = 71.36 kg

Process E Factor = 71.36 kg / 1.05 kg ≈ 68.0

Table 2: E Factor Breakdown by Waste Category

| Waste Category | Total Mass (kg) | Contribution to E Factor | Examples |

|---|---|---|---|

| Solvents | 49.00 | 46.7 | DCM, Heptane, Ethyl Acetate |

| Aqueous Waste | 20.00 | 19.0 | Quench water, washes |

| Reagents/Byproducts | 1.67 | 1.6 | Urea from EDC, excess acid |

| Auxiliaries | 1.00 | 1.0 | Drying agent (Na₂SO₄) |

| Total | 71.36 | 68.0 |

4. Interpretation and Industry Context

An E Factor of 68 is characteristic of pharmaceutical API synthesis, aligning with the industry's typical range. The breakdown reveals solvents as the dominant waste stream (~69% of total waste mass), highlighting the prime target for green chemistry improvements: solvent selection, reduction, and recycling. Comparing this to E Factors in other sectors underscores the unique environmental challenge in pharmaceuticals.

Table 3: E Factor Comparison Across Chemical Industries

| Industry Segment | Typical E Factor Range | Key Drivers |

|---|---|---|

| Oil Refining | ~0.1 | Highly integrated, catalytic processes. |

| Bulk Chemicals | <1 to 5 | Large-scale, optimized continuous processes. |

| Fine Chemicals | 5 to 50 | Multi-step batch processes, higher purities. |

| Pharmaceuticals | 25 to >100 | Complex multi-step synthesis, stringent purity, regulatory constraints. |

5. Pathways for E Factor Optimization

Diagram 1: Strategic Pathways to Reduce API Synthesis E Factor (100 chars)

Diagram 2: E Factor Calculation Workflow for API Synthesis (99 chars)

6. The Scientist's Toolkit: Key Reagents & Materials for API Synthesis & E Factor Analysis

Table 4: Essential Research Reagent Solutions and Materials

| Item | Function in API Synthesis/Green Metrics | Relevance to E Factor |

|---|---|---|

| Coupling Agents (e.g., EDC, HATU) | Facilitate amide bond formation, a ubiquitous reaction in API synthesis. | Stoichiometric use generates equimolar waste. Catalytic alternatives are a key research target. |

| Green Solvent Selection Guide | A tool (e.g., ACS GCI or Pfizer guide) to choose solvents based on safety, health, and environmental criteria. | Directly targets the largest waste stream. Switching to biodegradable or recyclable solvents reduces environmental impact. |

| Process Mass Intensity (PMI) Calculator | Software/spreadsheet to track all material inputs per unit of product. | PMI = E Factor + 1. Automated calculation aids in rapid comparison of route efficiency. |

| Heterogeneous Catalysts | Reusable catalysts (e.g., immobilized enzymes, metal on support) for key transformations. | Enable recovery and reuse, eliminating waste from homogeneous catalysts/reagents. |

| In-line Analytical Tools (PAT) | Process Analytical Technology (e.g., FTIR, FBRM) for real-time reaction monitoring. | Enables precise endpoint determination, reducing excess reagent use and byproducts, improving yield. |

| Life Cycle Assessment (LCA) Software | Comprehensive environmental impact analysis beyond simple mass metrics. | Puts E Factor into broader context (energy, water, toxicity) for sustainable process design. |

Integrating E Factor with Green Chemistry Principles (Atom Economy, Solvent Selection)

The Environmental Factor (E Factor), defined as the mass ratio of waste to desired product, has become a critical metric for quantifying the sustainability of chemical processes across industries. This whitepaper provides a technical guide for integrating E Factor analysis with the foundational green chemistry principles of atom economy and systematic solvent selection. The discussion is framed within the thesis that E Factor values reveal a stark sustainability gradient—from relatively low-impact bulk chemical and oil refining operations to the extraordinarily waste-intensive pharmaceutical and fine chemical sectors. For researchers and drug development professionals, mastering this integration is key to designing next-generation sustainable synthetic pathways.

The E Factor Gradient: From Refining to Pharmaceuticals

E Factor values vary dramatically across the chemical industry, underscoring the unique sustainability challenges in pharmaceutical research, where complex syntheses and purification-heavy workflows dominate.

Table 1: Industry-Specific E Factor Ranges and Primary Waste Sources

| Industry Segment | Typical E Factor Range (kg waste/kg product) | Primary Waste Components |

|---|---|---|

| Oil Refining | <0.1 | Catalyst fines, spent acids, tars. |

| Bulk Chemicals | <1-5 | Inorganic salts, aqueous streams, by-products. |

| Fine Chemicals | 5-50 | Solvents, spent reagents, packaging. |

| Pharmaceuticals | 25-100+ | Solvents, chromatography media, reaction by-products. |

Core Integration Framework

Atom Economy as the First-Principle Determinant of E Factor

Atom Economy (AE), calculated as (MW of desired product / Σ MW of all reactants) x 100%, defines the theoretical minimum E Factor. A low AE guarantees a high inherent waste burden, primarily from stoichiometric reagents. The experimental E Factor is the sum of this theoretical chemical waste and all process mass intensity contributions (solvents, work-up, purification).

Protocol: Calculating the Atom Economy-Limited Theoretical E Factor

- Define the Reaction Stoichiometry: Map the balanced equation for the longest linear sequence in the synthesis.

- Calculate Molecular Weights: Determine the MW for all stoichiometric reactants and the target product.

- Compute Atom Economy: AE (%) = (MWproduct / Σ MWreactants) x 100.

- Derive Theoretical Minimum E Factor: EFactortheoretical = (1/AE - 1) in mass units. This represents the chemical waste generated per unit mass of product, assuming 100% yield and no process waste.

- Contrast with Experimental E Factor: Measure total mass of all input materials (reactants, solvents, reagents) and subtract the mass of the isolated product. EFactorexperimental = (Total mass in - mass product) / mass product. The difference between experimental and theoretical E Factor quantifies the process waste overhead.

Systematic Solvent Selection: The Major Lever for E Factor Reduction

In pharmaceutical research, solvents often constitute 80-90% of the total mass intensity of a process. Strategic solvent selection is therefore the most impactful action for reducing the experimental E Factor.

Protocol: Implementing a Solvent Selection Guide for E Factor Reduction

- Inventory & Mass Accounting: For each step (reaction, work-up, purification), record the type and mass of every solvent used.

- Apply SHESS (Safety, Health, Environment, Solvent Selection) or CHEM21 Guide: Classify solvents as Preferred, Problematic, or Hazardous. Mandate substitution of problematic (e.g., DCM, DMF, NMP, THF) and hazardous (e.g., benzene, CCl4) solvents with preferred alternatives (e.g., water, ethanol, 2-MeTHF, Cyrene).

- Optimize for Minimal Mass Intensity:

- Concentration: Maximize reaction concentration to minimize solvent mass per unit product.

- Volume Efficiency: Design work-ups that use minimal volumes of wash solvents.

- Recycle/Reuse: Implement in-process solvent recovery, especially for high-volume distillation or extraction solvents.

- Calculate Solvent Contribution to E Factor: EFactorsolvents = (Total mass of solvents used) / (mass of product). Track this metric independently to gauge improvement.

Advanced Experimental Workflow for Integrated Design

The following diagram and protocol outline a circular development process for continuous E Factor improvement.

Diagram Title: Integrated E Factor & Green Chemistry Design Workflow

Protocol: Holistic Process Development with E Factor Tracking

- Route Identification: Based on the target molecule, propose 2-3 synthetic routes. For each, calculate the overall step economy and theoretical cumulative atom economy.

- Theoretical Waste Assessment: Perform the Atom Economy-Limited E Factor calculation (Protocol 3.1) for each route to identify the one with the lowest inherent waste burden.

- Solvent Selection & Process Design: For the chosen route, design each step using the Solvent Selection Guide protocol (3.2). Document all solvent choices and justifications.

- Experimental Execution & Mass Tracking: Conduct the synthesis. CRITICAL STEP: Accurately weigh and record the mass of every input material (reactants, solvents, catalysts, work-up materials, chromatography media) and the mass of the final, dried product.

- E Factor Calculation & Breakdown:

- Calculate the total experimental E Factor.

- Break it down into sub-categories:

E_Factor_stoichiometric(from reaction by-products),E_Factor_solvents,E_Factor_purification(e.g., silica gel, filter aids).

- Iterative Optimization: Use the breakdown to identify the largest waste stream. Redesign that aspect (e.g., switch solvent, employ catalytic over stoichiometric reagents, switch to a crystallization over chromatography) and repeat the cycle.

The Scientist's Toolkit: Key Reagent Solutions

Table 2: Essential Research Materials for Green Chemistry & E Factor Optimization

| Item / Reagent Solution | Function in E Factor Reduction | Example/Note |

|---|---|---|

| Cyrene (Dihydrolevoglucosenone) | Biobased, dipolar aprotic solvent replacement for DMF, NMP, DMAc. | Reduces process hazard profile and lifecycle waste. |

| 2-Methyltetrahydrofuran (2-MeTHF) | Renewable, safer replacement for THF and chlorinated solvents in extractions/grignards. | Forms a separate phase from water, aiding work-up. |

| Silica-Free Purification Media | Reduces solid waste from chromatography. | ISOLUTE HM-N, functionalized polymers, catch-and-release agents. |

| Heterogeneous Catalysts (e.g., Pd/C, immobilized enzymes) | Enable facile recovery/reuse, replacing stoichiometric or homogeneous metal reagents. | Drastically reduces heavy metal waste (E Factor contributor). |

| Switchable Solvents (e.g., CO₂-triggered) | Allow for easy solvent recovery and recycling within a process. | Minimizes net solvent consumption. |

| In-Line Analytical (PAT) | Provides real-time reaction monitoring to minimize over-processing and quench errors. | Reduces failed experiments and unnecessary material use. |

Quantitative Analysis: Case Study Data

A recent study comparing a traditional and a redesigned green synthesis of a common pharmaceutical intermediate illustrates the power of integration.

Table 3: Comparative E Factor Analysis for Sertraline Intermediate Synthesis

| Process Parameter | Traditional Process | Green Redesign (Pfizer) | % Reduction |

|---|---|---|---|

| Overall Atom Economy | 28% | 77% | -- |

| Number of Solvents | 4 (incl. CH₂Cl₂, Hexane) | 1 (Ethanol) | 75% |

| Total Solvent Volume (L/kg API) | ~60,000 | ~6,000 | 90% |

| Purification | Multiple chromatographies | Crystallization | ~100% |

| Theoretical E Factor (from AE) | 2.6 | 0.3 | 88% |

| Reported Experimental E Factor | >40 | ~8 | >80% |

Integrating E Factor metrics with the first principles of atom economy and systematic solvent selection provides a rigorous, data-driven framework for sustainable process design. For pharmaceutical researchers, this integration is not merely an academic exercise but an essential strategy to address the sector's extreme waste profile. By adopting the protocols, workflows, and toolkit items outlined in this guide, scientists can make quantified strides in reducing environmental impact while maintaining efficiency and innovation in drug development.

Tools and Software for Automated E Factor and Life Cycle Inventory (LCI) Estimation

This whitepaper provides an in-depth technical guide on computational tools for automating the calculation of the Environmental Factor (E Factor) and Life Cycle Inventory (LCI) data. The thesis context posits that E Factor values follow a predictable hierarchy across industrial sectors, increasing by orders of magnitude from oil refining (<0.1) to bulk chemicals (1-5) to pharmaceuticals (5-1000+). This gradient underscores the critical need for precise, automated assessment tools, especially in research and drug development, to enable greener process design from the laboratory scale.

Core Tools and Software: A Comparative Analysis

The following table summarizes key software platforms, their primary functions, automation capabilities, and suitability across the thesis-defined sectors.

Table 1: Comparison of Automated E Factor and LCI Estimation Tools

| Software/Tool | Primary Function | Automation & Data Sources | Sector Applicability (Thesis Context) | Key Advantage |

|---|---|---|---|---|

| Ecosolvent | Solvent E Factor & LCI | Automated E Factor calculation from reaction masses; links to EHS databases. | Pharmaceuticals (lab/process) | Specialized for solvent selection in medicinal chemistry. |

| CAPE/OPEN to LCA | Process flow to LCI | Automates LCI generation from process simulation software (Aspen, CHEMCAD). | Bulk Chemicals, Oil Refining | Bridges process engineering with LCA. |

| Sphera LCA (GaBi) | Full LCA | Extensive automated background databases; scriptable scenarios. | All (Oil to Pharma) | Comprehensive, industry-standard database. |

| openLCA | Full LCA | Open-source; can automate via scripting; integrates various LCI databases. | All (esp. research) | Free, flexible, modular platform. |

| Brightway2 | LCA Calculation | Python-based; fully scriptable for automated, high-throughput LCI modeling. | Pharmaceuticals (research) | Programmatic control ideal for research workflows. |

| Chem21 LCA Toolkit | Simplified LCI for Pharma | Pre-screened inventory data for common pharmaceutical reagents. | Pharmaceuticals | Curated, relevant data for synthesis. |

| SimaPro | Full LCA | Automated database links; parameterized unit process modeling. | All (Oil to Pharma) | Robust, widely accepted methodology library. |

Experimental Protocols for Tool Application

Protocol 3.1: High-Throughput E Factor Screening for Route Scouting (Pharmaceuticals)

- Objective: Automatically calculate and compare the E Factor of multiple synthetic routes to a target molecule.

- Materials: Reaction data (SMILES, masses, yields), Ecosolvent or Brightway2 software, Chem21 LCI database.

- Methodology:

- Data Input: For each route, define all reaction steps in a machine-readable format (e.g., CSV), specifying input masses (reagents, solvents), product masses, and yields.

- Tool Setup: In Brightway2, create a project and import the Chem21 database. Write a Python script to iterate over each route dataset.

- Automated Calculation: The script, for each step, searches for LCI data of chemicals, sums the total waste (input mass - product mass), and computes the step E Factor (mass waste / mass product).

- Aggregation: The script aggregates waste across all steps to calculate the total process E Factor for each route.

- Output: Results are tabulated and visualized for comparative analysis.

Protocol 3.2: From Process Simulation to Cradle-to-Gate LCI (Bulk Chemicals)

- Objective: Generate a cradle-to-gate LCI directly from a steady-state process simulation model.

- Materials: Process simulation file (e.g., Aspen Plus), CAPE/OPEN interface, Sphera GaBi LCA software.

- Methodology:

- Simulation Finalization: Ensure the process model is converged, with all mass and energy streams fully characterized.

- Interface Activation: Use the CAPE/OPEN interface in the simulator to export a complete list of unit operations and their connecting streams with all relevant properties (mass flow, composition, temperature, pressure).

- LCI Database Mapping: In the LCA software (e.g., GaBi), the imported flows are automatically mapped to corresponding background LCI datasets (e.g., for electricity grid mix, steam production, raw material extraction).

- System Boundary Definition: Define the cradle-to-gate boundary (e.g., from crude oil extraction to purified bulk chemical).

- Automated Inventory Compilation: The software automatically generates the full LCI, summing all mapped elementary flows (resource use, emissions).

Visualization of Automated Workflows

Diagram 1: High-throughput E factor calculation workflow.

Diagram 2: From process simulation to LCI.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents/Materials for Sustainable Chemistry Assessment

| Item | Function in E Factor/LCI Context |

|---|---|

| LCI Databases (e.g., Chem21, Ecoinvent) | Provide pre-calculated environmental inventory data for raw materials, energy, and waste treatment, essential for automated background system modeling. |

| Process Mass Intensity (PMI) Calculator | A standardized spreadsheet or script to calculate PMI (closely related to E Factor) from experimental masses, forming the primary data input for automation. |

| Solvent Selection Guides (e.g., CHEM21, GSK) | Rank solvents based on safety, health, and environmental (EHS) criteria, informing greener choices that directly lower E Factor and improve LCI. |

| Automation Scripts (Python/R) | Custom scripts to link reaction data, LCI databases, and calculation engines, enabling high-throughput assessment of multiple routes or conditions. |

| Reaction Inventory Template | A structured data capture form (digital or physical) ensuring all input/output masses, solvents, and energy use are recorded for subsequent tool input. |

Within the broader landscape of industrial chemical synthesis, from oil refining to bulk chemicals and specialty pharmaceuticals, the measurement of environmental efficiency is paramount. The pharmaceutical industry, characterized by complex, multi-step syntheses, has adopted two principal metrics: the E Factor and Process Mass Intensity (PMI). This whitepaper provides an in-depth technical analysis of these complementary metrics, detailing their calculation, application, and significance in driving sustainable drug development.

The historical development of efficiency metrics reveals a continuum across chemical industries. Oil refining and bulk chemical production operate with exceptionally low E Factors (often <0.1), reflecting highly optimized, large-scale processes with minimal waste. In stark contrast, pharmaceutical manufacturing, particularly in research and development and early-phase active pharmaceutical ingredient (API) production, historically exhibited E Factors ranging from 25 to over 100. This disparity highlights the unique challenges in Pharma: molecular complexity, stringent purity requirements, rapid process development timelines, and the use of protecting groups. Both PMI and E Factor serve to quantify this waste, providing benchmarks for the industry’s Green Chemistry initiatives.

Definitions and Calculations

E Factor, introduced by Roger Sheldon, is defined as the mass ratio of waste to desired product.

E Factor = (Total waste mass in kg) / (Mass of product in kg)

Process Mass Intensity (PMI), championed by the American Chemical Society Green Chemistry Institute Pharmaceutical Roundtable (ACS GCI PR), is defined as the total mass of materials used to produce a specified mass of product.

PMI = (Total mass of inputs in kg) / (Mass of product in kg)

The key relationship is: PMI = E Factor + 1. The "+1" accounts for the product itself, which is included in the total input mass for PMI but not counted as waste in the E Factor.

Table 1: Comparative Metric Calculation

| Metric | Formula | Components | Typical Pharma Range (API) |

|---|---|---|---|

| E Factor | Waste / Product | All process waste (solvents, reagents, auxiliaries, water) | 25 - 100+ (Research); <10-25 (Process Chemistry) |

| Process Mass Intensity (PMI) | Total Inputs / Product | All raw materials + solvents + water + reagents | 26 - 101+ (Research); <11-26 (Process Chemistry) |

| Relationship | PMI = E Factor + 1 | The product mass is the differentiating term. | N/A |

Methodologies for Data Collection and Calculation

Accurate calculation requires rigorous mass tracking across the synthetic sequence.

Protocol 3.1: Experimental Material Inventory for PMI/E Factor Determination

- Define System Boundary: Typically "cradle-to-gate" for the specific chemical step or entire API synthesis. Include all reaction, workup, and purification steps.

- Weigh All Inputs: Precisely record masses of all starting materials, reagents, catalysts, solvents (for reaction and extraction), and water used in workup.

- Weigh All Outputs: Isolate and weigh the final purified product. Quantify and weigh all identifiable waste streams: aqueous layers, organic mother liquors, solid filter cakes, spent chromatography media, etc.

- Account for Stoichiometry: For non-catalytic reagents, use the theoretical molar amount to calculate the mass contribution to waste.

- Calculate Waste Mass:

Waste = Total Input Mass - Mass of Isolated Product. - Compute Metrics: Apply the formulas in Section 2. The calculation is best performed per synthetic step and then aggregated for the entire sequence.

Table 2: The Scientist's Toolkit for PMI/E Factor Analysis

| Research Reagent / Solution | Function in Context of Green Metrics |

|---|---|

| Electronic Laboratory Notebook (ELN) | Critical for accurate, auditable digital recording of all material masses and process conditions. |

| Process Mass Spectrometry (MS) | Enables real-time tracking of reaction conversion and byproduct formation, informing waste minimization. |

| Analytical Balance (High Precision) | Foundational for obtaining accurate input and product mass data. |

| Life Cycle Assessment (LCA) Software | Extends gate-to-gate PMI to a full environmental footprint (e.g., using Ecoinvent databases). |

| Green Solvent Selection Guides (ACS GCI PR) | Provides data to substitute hazardous, high-PMI solvents (e.g., dichloromethane, DMF) with safer alternatives. |

Complementary Roles in Process Development

PMI and E Factor serve distinct yet complementary roles. PMI is a mass productivity metric directly tied to material costs and resource utilization; it is the preferred metric for process chemists optimizing for overall efficiency. E Factor is an environmental impact metric that starkly highlights the waste generation problem; it is powerful for benchmarking and communicating sustainability goals.

Experimental Protocol 4.1: Comparative Analysis of Route Scouting

- Objective: To evaluate two proposed synthetic routes for an intermediate using PMI and E Factor.

- Method:

- Execute each route (Route A: linear 5-step synthesis; Route B: convergent 3-step synthesis) at laboratory scale (1-10g target).

- Follow Protocol 3.1 for each step and the entire sequence.

- Calculate cumulative PMI and E Factor for each route.

- Perform a contribution analysis to identify steps with the highest mass intensity (often isolation/purification).

- Expected Outcome: Route B, though using a more expensive reagent, may demonstrate a lower overall PMI and E Factor due to fewer steps and higher atom economy, guiding route selection.

Title: Complementary Roles of PMI and E Factor in Process Optimization

Industry Benchmarks and Trends

Recent data from the ACS GCI PR and industry publications show a downward trend in median PMI, reflecting concerted green chemistry efforts.

Table 3: PMI/E Factor Benchmarks Across Industries & Pharma Stages

| Industry / Stage | Typical PMI Range | Typical E Factor Range | Primary Drivers |

|---|---|---|---|

| Oil Refining | ~1.01 - 1.05 | 0.01 - 0.05 | Scale, continuous processing, high atom economy. |

| Bulk Chemicals | 1.1 - 5 | 0.1 - 4 | Optimization for cost, often continuous processes. |

| Pharma (Preclinical R&D) | 50 - 300+ | 49 - 299+ | Speed, molecular complexity, chromatography. |

| Pharma (Process Chemistry) | 10 - 50 | 9 - 49 | Route scouting, solvent selection, green chemistry. |

| Pharma (Commercial API) | <10 - 25 | <9 - 24 | Intensification, recycling, catalysis, cost pressure. |

Advanced Considerations and Limitations

Both metrics are gate-to-gate and measure mass, not environmental impact. A low E Factor/PMI does not necessarily equate to low toxicity or energy usage. Complementary tools are required:

- Life Cycle Assessment (LCA): Accounts for upstream resource extraction and energy use.

- Solvent Environmental Assessment (SEA): Evaluates solvent-related environmental, health, and safety (EHS) impacts.

- CHEM21 Metric Toolkit: A multi-criteria decision-making framework incorporating life cycle thinking.

Title: PMI and E Factor Within a Broader Sustainability Toolkit

PMI and E Factor are foundational, complementary metrics for quantifying the mass efficiency of pharmaceutical processes against the backdrop of far more efficient bulk chemical industries. PMI serves as a direct measure of resource consumption critical for cost and supply chain management, while E Factor powerfully communicates the waste reduction imperative. Their systematic application from early R&D through commercial manufacturing, guided by detailed experimental protocols and integrated with broader impact assessment tools, is essential for the pharmaceutical industry to advance its sustainability and efficiency goals.

The E Factor, defined as the mass ratio of waste to desired product, is a pivotal metric for assessing the environmental impact of chemical processes. Its significance spans industries, from the relatively low E Factors of oil refining (≈0.1) and bulk chemicals (1–5) to the exceedingly high values in pharmaceuticals (25–>100). This whitepaper provides an in-depth technical guide on designing synthetic routes with minimal E Factor, focusing on the dual pillars of convergent synthesis and advanced catalysis. The overarching thesis is that deliberate strategic planning at the route design stage, informed by green chemistry principles, is the most effective lever for waste reduction in research and development, particularly for complex molecules like active pharmaceutical ingredients (APIs).

Core Principles of Low E-Factor Design

Convergent vs. Linear Synthesis

A linear (sequential) synthesis compounds the waste at each step, as the overall yield is multiplicative. A convergent synthesis, where intermediate fragments are built separately and then combined, dramatically improves atom economy and reduces total waste.

Table 1: Quantitative Comparison of Linear vs. Convergent Synthesis for a Hypothetical API

| Synthesis Strategy | Number of Steps | Average Yield per Step | Overall Yield | Estimated E Factor |

|---|---|---|---|---|

| Linear Route | 12 | 85% | 14.2% | ~87 |

| Convergent Route (3+3+3) | 9 (3 fragments of 3 steps) | 85% | 38.7% | ~32 |

| Convergent Route with Catalysis | 9 (with 3 catalytic steps) | 92% (catalytic) / 85% (others) | 53.4% | ~18 |

Catalysis as a Waste-Reduction Engine

Catalytic processes (homogeneous, heterogeneous, biocatalysis) reduce waste by avoiding the use of stoichiometric reagents, enabling fewer steps, and operating under milder conditions.

Table 2: E Factor Impact of Replacing Stoichiometric with Catalytic Methods

| Transformation | Traditional Stoichiometric Reagent | Catalytic Alternative | Typical E Factor Reduction |

|---|---|---|---|

| Oxidation | KMnO₄, CrO₃ | O₂ with Heterogeneous Pt/Pd Catalyst | 5 – 10 units |

| Reduction | NaBH₄ / LiAlH₄ (wasteful workup) | H₂ with Pd/C or Transfer Hydrogenation | 3 – 8 units |

| Cross-Coupling | Stille (R₄Sn), Negishi (R₂Zn) | Suzuki-Miyaura (R-B(OH)₂) | 2 – 5 units (reduced metal waste) |

| Amide Formation | CDI, DCC (generates stoichiometric urea) | Enzymatic (Lipase) | 8 – 15 units |

Experimental Protocols for Key Low E-Factor Strategies

Protocol 1: Telescoped Multi-Step Synthesis Without Intermediate Isolation

Objective: To reduce waste from workup and purification by carrying a crude intermediate directly into the next reaction. Methodology:

- Conduct the first reaction (e.g., a nitro reduction to aniline) in a suitable solvent (e.g., EtOAc/MeOH).

- Upon reaction completion (monitored by TLC/LCMS), do not perform a standard aqueous workup. Instead, directly add the reagents for the subsequent step (e.g., acyl chloride and base for amide formation).

- If necessary, remove the initial solvent in vacuo and replace with the optimal solvent for the second transformation.

- After the final step, perform a single, comprehensive workup and purification (e.g., chromatography or crystallization). Key Consideration: Compatibility of solvents, reagents, and by-products across steps is essential. High-yielding, clean reactions are prerequisites.

Protocol 2: Heterogeneous Catalytic Hydrogenation for Nitro Reduction

Objective: Replace stoichiometric metal reductions (Fe, Zn, Sn in acid) with a catalytic, high-atom-economy process. Methodology:

- Charge a hydrogenation vessel with the nitroarene substrate (1.0 mmol) and 10% Pd/C (5 mol% Pd).

- Add a green solvent (e.g., 2-MeTHF or EtOH, 10 mL).

- Purge the vessel with N₂, then apply a H₂ atmosphere (1–4 bar, balloon or parr apparatus).

- Stir at room temperature for 2–16 hours, monitoring by TLC.

- Upon completion, filter the reaction mixture through a Celite pad to remove the heterogeneous catalyst. The catalyst can potentially be recovered and regenerated.

- Concentrate the filtrate in vacuo to obtain the aniline product, often in high purity without further purification.

Protocol 3: Enzymatic Kinetic Resolution Using Immobilized Lipase

Objective: Perform enantioselective acylations without chiral auxiliaries or metal-based catalysts. Methodology:

- Prepare a mixture of racemic alcohol (2.0 mmol), vinyl acetate (2.4 mmol, as acyl donor), and molecular sieves (3Å) in dry MTBE (10 mL).

- Add immobilized Candida antarctica Lipase B (Novozym 435, 200 mg).

- Stir the mixture at 30°C, monitoring enantiomeric excess (ee) by chiral HPLC or GC.

- Stop the reaction at ≈50% conversion (typically 2–24h) when ee of the remaining (R)-alcohol is >99%.

- Filter to remove the immobilized enzyme (reusable).

- Separate the (R)-alcohol from the (S)-acetate product via flash chromatography or direct hydrolysis.

Visualization of Strategic Concepts

Title: Linear Synthesis Yield Attenuation

Title: Convergent Synthesis Pathway

Title: Low E-Factor Route Design Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Low E-Factor Research

| Item / Reagent Solution | Function in Low E-Factor Synthesis | Example/Supplier |

|---|---|---|

| Immobilized Catalysts (e.g., Pd/C, PS-TBD, SiliaCat) | Enables facile filtration recovery and reuse, reducing metal/ligand waste. | Sigma-Aldrich, Strem, SiliCycle |

| Biocatalysts (Immobilized Lipases, KREDs, Transaminases) | Provide high enantioselectivity under mild conditions, avoiding heavy metals. | Codexis, Novozymes, Almac |

| Green Solvent Kits | Pre-curated selection of sustainable solvents (Cyrene, 2-MeTHF, CPME) for replacement of hazardous solvents. | Sigma-Aldrich (ACS Green Chemistry), Merck |

| Flow Chemistry Systems (Microreactors) | Enable precise reaction control, safer handling of hazardous intermediates, and easier telescoping. | Vapourtec, Chemtrix, Syrris |

| Polystyrene-Supported Reagents (e.g., PS-NCO, PS-DIEA) | Allow use of excess reagent with simple filtration workup, reducing aqueous waste streams. | TCI America, Argonaut (Biotage) |

| Molecular Sieves (3Å, 4Å) | In-situ water scavenging for equilibrium-driven reactions (e.g., esterifications), avoiding bulky dehydrating agents. | Standard supplier |

| In-situ Reaction Monitoring (ReactIR, FTIR, PAT tools) | Provides real-time data to minimize over-reaction, optimize reaction times, and reduce failed experiments. | Mettler Toledo, Anton Paar |

Designing low E-Factor routes is not merely a regulatory compliance exercise but a fundamental redesign of synthetic logic. The strategic integration of convergent architectures and catalytic key steps forms the cornerstone of sustainable synthesis for pharmaceuticals and fine chemicals. By adopting the experimental protocols and tools outlined, researchers can systematically de-risk the environmental profile of their processes from the earliest stages of development, aligning with the broader industrial trajectory from high-waste linear models to efficient, circular chemistry.

Reducing the Pharmaceutical E Factor: Troubleshooting High-Waste Processes

The E Factor, defined as the mass ratio of waste to desired product, is a pivotal metric for quantifying the environmental impact of chemical processes. Its values span orders of magnitude across industries: from <0.1 in modern oil refining, to 1-5 for bulk chemicals, 5-50 for fine chemicals, and 25-100+ for pharmaceutical manufacturing. This whitepaper addresses the latter extreme, providing a diagnostic framework for researchers and process chemists to identify and remediate high E Factor hotspots, with a focus on solvents, stoichiometry, and purification—the three most significant contributors to waste in API (Active Pharmaceutical Ingredient) development and production.

Solvent Waste: The Primary Contributor

Solvents constitute approximately 50-80% of the total mass waste in pharmaceutical processes. High E Factors often stem from solvent-intensive reactions and, predominantly, purification steps.

Table 1: E Factor Impact of Common Pharmaceutical Solvents

| Solvent | Typical Use Mass (kg/kg API) | PMI* (Ideal) | Typical Recovery Rate (%) | Waste Factor | E Factor Contribution (Range) |

|---|---|---|---|---|---|

| Tetrahydrofuran (THF) | 10-30 | 1.1 | 60-80 | 2.0 - 6.0 | 20 - 180 |

| Dichloromethane (DCM) | 15-40 | 1.2 | 70-85 | 2.1 - 6.9 | 31 - 276 |

| N,N-Dimethylformamide (DMF) | 8-20 | 1.05 | 50-70 | 2.4 - 8.6 | 19 - 172 |

| Diethyl Ether | 20-50 | 1.07 | 40-60 | 4.0 - 12.5 | 80 - 625 |

| Water | 20-100 | 1.00 | 90-98 | 1.0 - 2.2 | 20 - 220 |

| 2-Methyltetrahydrofuran (2-MeTHF) | 10-30 | 1.1 | 75-90 | 1.4 - 4.0 | 14 - 120 |

*Process Mass Intensity (PMI) = total mass in / mass of product (minimum theoretical value).

Experimental Protocol: Solvent Recovery Efficiency Analysis

- Objective: Quantify recoverable vs. waste solvent in a crystallization process.

- Methodology:

- Charge solvent (S) and product (P) into a crystallization vessel. Record masses (mSinitial, mP).

- Perform crystallization, filtration, and cake washing (with solvent W).

- Collect all filtrates (mother liquor + washes). Distill under reduced pressure.

- Accurately measure the mass of recovered solvent (mSrecovered).

- Calculate: Recovery Efficiency (%) = (mSrecovered / (mSinitial + mW)) * 100.

- The waste mass is the deficit. Analyze distillate purity by GC-MS.

Stoichiometry and Auxiliary Reagents

Excess reagents and the use of stoichiometric (rather than catalytic) auxiliaries are the second major hotspot.

Table 2: E Factor Impact of Common Reagent Strategies

| Reagent Class | Example | Typical Stoichiometry (equiv.) | Byproduct Mass (g/mol reagent) | Catalytic Alternative | E Factor Reduction Potential |

|---|---|---|---|---|---|

| Coupling Agents | HOBt, EDCI | 1.2 - 1.5 | ~200 (urea) | Enzymatic catalysis | 50-70% |

| Reducing Agents | NaBH₄, BH₃·THF | 1.5 - 2.0 | Boron salts | Catalytic hydrogenation | 60-80% |

| Oxidants | Jones reagent, m-CPBA | 2.0 - 5.0 | Cr or Chloride salts | O₂ or H₂O₂ catalysis | 70-90% |

| Bases/Sources | Pyridine, KOᵗBu | 2.0 - 3.0 | Salts | Solid-supported bases | 30-50% |

| Protecting Groups | Boc₂O, TMSCl | 1.5 - 2.0 | Siloxanes / CO₂ | Protecting-group-free synthesis | 40-60% |

Experimental Protocol: Atom Economy vs. Real-World E Factor

- Objective: Contrast theoretical atom economy with actual E Factor from a model amide coupling.

- Methodology:

- Perform a model reaction (e.g., Acetic Acid + Benzylamine) using EDCI/HOBt (1.5 equiv. each).

- Calculate theoretical Atom Economy = (MW product / Σ(MW reactants)) * 100.

- After work-up (aqueous washes to remove ureas) and isolation, measure exact mass of isolated product.

- Measure total mass of all waste streams (aqueous layers, solid filter cakes, chromatography residues).

- Calculate Actual E Factor = (Total waste mass) / (Mass of isolated product).

- The discrepancy highlights the "stoichiometry penalty."

Purification: Chromatography as a Critical Hotspot

Flash column chromatography is a major, often dominant, contributor to laboratory-scale E Factors due to high solvent and silica gel consumption.

Table 3: E Factor of Common Purification Methods

| Purification Method | Typical Solvent (L/kg API) | Solid Sorbent (kg/kg API) | Solvent Recovery Possible? | Approx. E Factor Range |

|---|---|---|---|---|

| Flash Chromatography | 100 - 1000 | 20 - 100 | Limited | 50 - 500 |

| Recrystallization | 10 - 100 | 0 | High | 5 - 50 |

| Distillation | 0 - 10 | 0 | Very High | <1 - 5 |

| Centrifugal Partition Chromatography | 50 - 200 | 0 | High | 20 - 100 |

Experimental Protocol: Chromatography Waste Audit

- Objective: Quantify the mass flow of a standard chromatographic purification.

- Methodology:

- Weigh crude material (mcrude) and silica gel (msilica) before packing column.

- Record total volume and type of eluent used (Veluent). Collect all fractions.

- After combining product fractions and solvent removal, weigh pure product (mproduct).

- Recover solvent from product fractions via distillation (msolventrecovered).

- Waste Calculation: E Factor = [(Veluent * ρsolvent) + msilica - msolventrecovered] / mproduct.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| 2-MeTHF or CPME | Biobased, greener ether solvents with better water separation, facilitating recovery and reducing aquatic toxicity. |