Strategies to Improve Your AGREE Metric Score: A Practical Guide for Sustainable Analytical Methods

This guide provides researchers, scientists, and drug development professionals with a comprehensive framework for understanding, applying, and optimizing the Analytical GREEnness (AGREE) metric.

Strategies to Improve Your AGREE Metric Score: A Practical Guide for Sustainable Analytical Methods

Abstract

This guide provides researchers, scientists, and drug development professionals with a comprehensive framework for understanding, applying, and optimizing the Analytical GREEnness (AGREE) metric. It covers the foundational principles of AGREE, offers methodological guidance for its application, presents actionable troubleshooting strategies for score improvement, and outlines validation and comparative assessment techniques. By integrating these strategies, professionals can systematically enhance the environmental sustainability of their analytical procedures, align with green chemistry goals, and meet the growing demand for greener practices in biomedical and pharmaceutical research.

Understanding AGREE: The Foundation of Green Analytical Chemistry Assessment

Frequently Asked Questions (FAQs)

Q1: What is the AGREE metric and what makes it different from other green assessment tools? AGREE (Analytical GREEnness) is a comprehensive metric designed to evaluate the environmental impact of analytical methods. Its key differentiator is that it is explicitly based on the 12 principles of Green Analytical Chemistry (GAC) [1] [2]. Unlike earlier tools that used binary or limited assessments, AGREE provides a numerical score between 0 and 1 and a circular pictogram for visual interpretation, offering a more nuanced and holistic evaluation of an analytical method's greenness across its entire workflow [2].

Q2: What are the 12 principles of Green Analytical Chemistry that form AGREE's foundation? The 12 principles of GAC provide the conceptual backbone for AGREE's assessment criteria [1]. They are summarized by the mnemonic SIGNIFICANCE [3] [1]:

- S - Direct analytical techniques should be applied to avoid sample treatment.

- I - Minimal sample size and minimal number of samples are goals.

- G - In situ measurements should be performed.

- N - Integration of analytical processes and operations saves energy and reduces reagents.

- I - Automated and miniaturized methods should be selected.

- F - Derivatization should be avoided.

- I - Generation of large waste volumes should be avoided; proper waste management should be in place.

- C - Multi-analyte or multi-parameter methods are preferred versus methods using one analyte at a time.

- A - Reagent usage should be minimized, and safer reagents employed.

- N - The energy demand of the method should be minimized.

- C - Reagents from renewable sources should be preferred.

- E - All operators' safety should be increased, and the risk of accidents minimized.

Q3: Where can I find a calculator to perform an AGREE assessment? AGREE is supported by a user-friendly, open-source software calculator [4] [2]. This tool simplifies the assessment process by guiding users through the input parameters and automatically generating the final pictogram and score, ensuring consistency and ease of use.

Q4: My AGREE score is low due to sample preparation. How can I improve it? The sample preparation stage is often a significant source of environmental impact. To improve your score, consider using the AGREEprep metric, a dedicated tool for evaluating sample preparation [4] [2]. AGREEprep is based on 10 principles of green sample preparation and can help you identify specific areas for improvement, such as:

- Transitioning to micro-extraction or miniaturized techniques.

- Implementing on-line or automated sample preparation to reduce solvent use and waste.

- Exploring solvent-less or alternative green extraction techniques.

Q5: How does AGREE fit into the broader concept of White Analytical Chemistry (WAC)? AGREE is a vital component of the White Analytical Chemistry (WAC) framework, where it represents the "green" dimension [5] [2]. WAC advocates for a balanced method assessment across three pillars:

- Red (Quality): Analytical performance and reliability.

- Green (Environment): Environmental impact, assessed by tools like AGREE.

- Blue (Practicality): Practicality, cost, and feasibility of the method. An ideal method should perform well in all three areas, and AGREE is the premier tool for quantifying the green aspect [2].

Troubleshooting Common AGREE Assessment Issues

Problem: The analytical method receives an AGREE score below 0.5, indicating poor greenness.

Solution: Systematically address the principles with the highest penalty. The table below outlines common root causes and targeted mitigation strategies.

Table 1: Troubleshooting a Low AGREE Score

| Root Cause | Diagnostic Check | Corrective Action |

|---|---|---|

| High Hazard Reagent Use | Review safety data sheets (SDS) for all chemicals. | Substitute toxic solvents (e.g., acetonitrile, methanol) with safer alternatives (e.g., water, ethanol, acetone) where chromatographically feasible [6]. |

| Excessive Waste Generation | Calculate total waste volume per analysis. | Miniaturize the method (e.g., use UPLC instead of HPLC, micro-extraction), and investigate solvent recycling programs [2]. |

| High Energy Consumption | Note instrument type and runtime. | Shorten method runtime, use lower-temperature techniques, and turn off instruments when not in use [6]. |

| Inefficient Sample Prep | Audit the number and scale of sample preparation steps. | Automate processes, integrate steps, eliminate unnecessary derivatization, and reduce sample/solvent volumes [1] [4]. |

Inconsistent Scoring

Problem: Different users obtain different AGREE scores for the same method.

Solution: This is often due to subjectivity in interpreting criteria and assigning weights [5]. To ensure consistency:

- Define Objective Metrics: Establish internal guidelines for common criteria. For example, define what constitutes a "high," "medium," or "low" amount of waste based on volume ranges.

- Use Default Weights Judiciously: The AGREE calculator allows for adjusting the weight of each of the 12 principles [5] [4]. For comparative purposes, always use the default weights unless a specific, justified reason exists to change them. Document any weight modifications.

- Cross-Verification: Have a second team member review the assessment inputs to ensure alignment with predefined guidelines.

AGREEprep Assessment Challenges

Problem: Difficulty in quantifying the amount of waste or energy consumption specifically for the sample preparation step [4].

Solution:

- For Waste: Meticulously account for all solvents, reagents, and consumables used only in the sample prep stage. If exact data is unavailable, perform the prep procedure and measure the waste generated.

- For Energy: Sum the energy consumption of all equipment used (e.g., heaters, shakers, centrifuges) for their specific operating times. Use manufacturer specifications for power ratings.

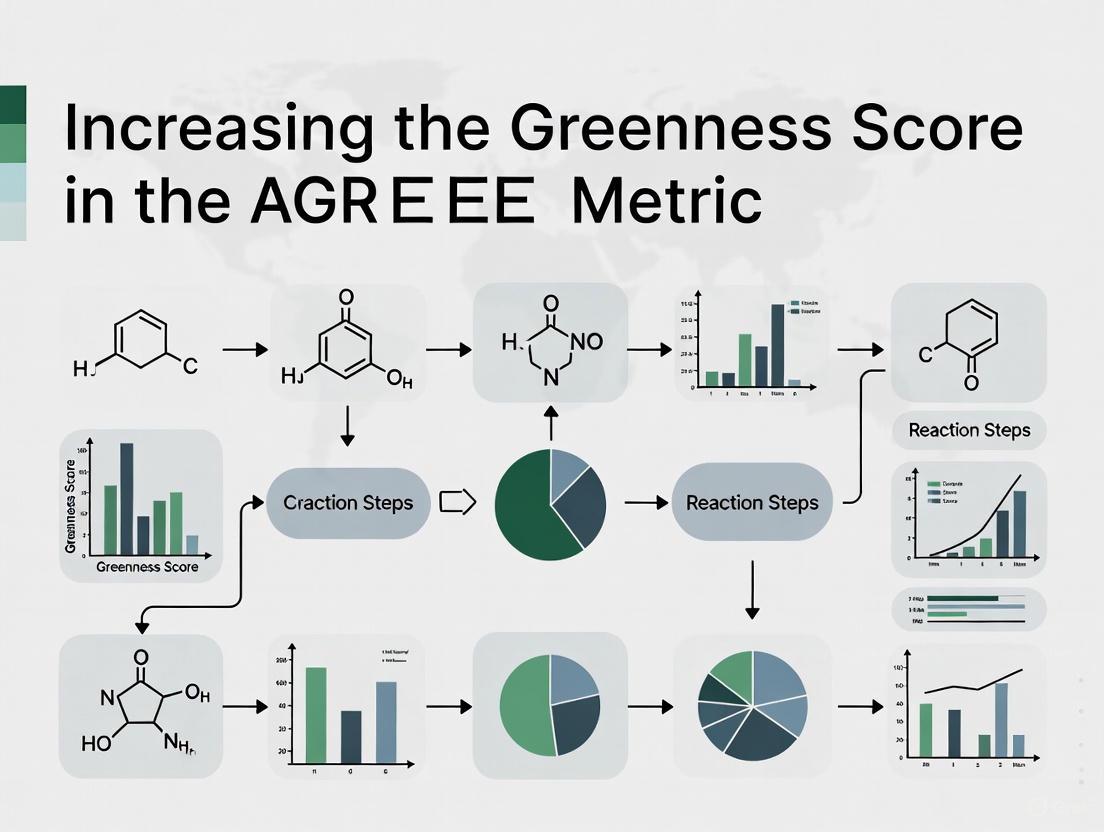

The following workflow diagram illustrates the strategic process for improving your analytical method's greenness using the AGREE metric, from initial assessment to implementation and verification.

Key Reagent Solutions for Greener Methods

Selecting the right reagents and instruments is fundamental to increasing your AGREE score. The following table lists essential items and their role in developing greener analytical methods.

Table 2: Research Reagent Solutions for Improving AGREE Metrics

| Item / Solution | Function in Greener Analysis | Key Benefit |

|---|---|---|

| Safer Solvents (e.g., Water, Ethanol, Acetone) | Replacement for hazardous solvents like acetonitrile and halogenated hydrocarbons in chromatography [6]. | Reduces environmental toxicity and operator risk, directly addressing GAC principles. |

| UPLC/HPLC System | Enables method transfer from HPLC with shorter runtimes and lower solvent flow rates [2]. | Signantly reduces solvent consumption (waste) and energy use per analysis. |

| Micro-extraction Devices (e.g., SPME, MEPS) | Miniaturized sample preparation techniques that require minimal or no solvent [4]. | Dramatically reduces reagent consumption and waste generation. |

| Automated Sample Prep | Integrates and automates steps like dilution, derivation, and extraction [1]. | Improves reproducibility, reduces manual error, and typically uses smaller volumes of reagents. |

| Renewable Sorbents | Use of bio-based materials for sample cleanup and extraction phases [1]. | Lowers the environmental footprint of consumable production and disposal. |

Experimental Protocol: Conducting a Standard AGREE Assessment

This protocol provides a step-by-step methodology for evaluating the greenness of an analytical method using the AGREE metric.

1. Objective: To quantitatively and qualitatively assess the environmental greenness of an analytical method based on the 12 principles of GAC.

2. Materials and Software:

- Description of the analytical method to be assessed (including sample preparation, instrumentation, reagents, and waste data).

- Safety Data Sheets (SDS) for all chemicals used.

- Technical specifications for instruments (e.g., power consumption).

- Access to the open-source AGREE calculator software [2].

3. Procedure: 1. Data Collection: Gather all relevant data for the analytical method. Critical parameters include: * Reagents & Solvents: Type, quantity per analysis, and hazard classifications (from SDS). * Energy: Instrument power consumption (kW) and total runtime per sample. * Waste: Total volume and classification of waste generated per analysis. * Sample Preparation: Number of steps, degree of automation, miniaturization, and use of derivatization. * Operator Safety: Measures taken to reduce exposure to hazardous materials. 2. Software Input: Enter the collected data into the AGREE calculator. The software will prompt for information corresponding to each of the 12 GAC principles. 3. Weight Assignment (Optional): The tool allows for adjusting the importance (weight) of each principle. For standardized comparison, it is recommended to use the default weights unless a specific research context requires a change [5]. 4. Calculation & Visualization: Run the calculation. The software will generate: * A numerical score between 0 (not green) and 1 (ideal green). * A circular pictogram divided into 12 sections, each representing one GAC principle. The sections are colored from red (poor) to green (excellent), providing an immediate visual summary of the method's strengths and weaknesses [2].

4. Interpretation of Results:

- Overall Score: A score >0.75 is generally considered excellent, while a score <0.5 indicates significant room for improvement.

- Pictogram Analysis: Identify the principles with the reddest (least green) sections. These are the primary targets for method optimization. For example, a red section for "Waste" points to a need for miniaturization or solvent recycling, while a red section for "Reagent Toxicity" indicates a need for solvent substitution.

The Analytical GREEness (AGREE) metric is a comprehensive, flexible, and user-friendly assessment tool that evaluates the environmental impact of analytical methods. It calculates a score based on the 12 principles of Green Analytical Chemistry (GAC), which are memorized using the mnemonic SIGNIFICANCE [7]. This framework ensures that all aspects of an analytical procedure—from sample collection to waste disposal—are evaluated for their environmental and safety impacts. The output is an intuitive, clock-like pictogram that provides both an overall score (from 0 to 1) and a visual representation of the method's performance across each of the 12 principles [7]. Understanding this structure is the first step toward systematically improving your method's greenness score.

The SIGNIFICANCE Mnemonic: Principles and Scoring

The 12 principles embedded in the SIGNIFICANCE mnemonic serve as the criteria for the AGREE assessment. The table below decodes each principle, its core requirement, and the typical data required for its evaluation.

Table 1: Decoding the SIGNIFICANCE Mnemonic for AGREE Scoring

| Letter | Principle Number | Principle Description | Key Focus for Data Input |

|---|---|---|---|

| S | 1 | Select direct analytical techniques | Type of analysis (e.g., direct, on-line, off-line); number of sample preparation steps [7]. |

| I | 2 | Integrate analytical processes & operations | Sample size and number of samples; degree of miniaturization [7]. |

| G | 3 | Generate as little waste as possible & perform recycling | Waste volume generated per analysis [7]. |

| N | 4 | Never use large volumes of solvents or reagents; choose safety | Type and volume of solvents/reagents; their safety and hazard profiles [7]. |

| I | 5 | Increase safety for the operator | Operator exposure to hazardous chemicals; use of personal protective equipment (PPE) [7]. |

| F | 6 | Favor methodologies that use minimal energy | Energy consumption of instruments (e.g., kW per sample) [7]. |

| I | 7 | Implement automation and miniaturization of methods | Level of automation; use of miniaturized equipment (e.g., micro-extraction) [7]. |

| C | 8 | Carry out multi-analyte or multi-parameter analyses | Number of analytes determined simultaneously; analytical throughput [7] [8]. |

| A | 9 | Avoid derivatization | Whether a derivatization step is required (which adds reagents and time) [7]. |

| N | 10 | Note that the use of renewable sources is preferred | Source of reagents and materials (e.g., bio-based vs. petroleum-based) [7]. |

| C | 11 | Choose methodologies with a low cost per analysis | Cost of analysis is considered, though not always the primary focus. |

| E | 12 | Eliminate or replace toxic reagents | Toxicity of all chemicals used (solvents, reagents, standards) [7]. |

The relationship between these principles and the final AGREE pictogram is systematic. The AGREE software transforms the input data for each principle into a score on a scale from 0 (not green) to 1 (perfectly green). The final score in the center of the pictogram is a composite of these 12 individual scores. Crucially, the tool allows users to assign a weight to each principle, acknowledging that certain criteria may be more important for a specific application than others [7] [8]. The diagram below illustrates this scoring logic and how individual principle scores are synthesized.

Troubleshooting Guide: Common AGREE Score Issues and Solutions

Researchers often encounter specific challenges when calculating their AGREE score. The following table addresses frequent issues and provides targeted solutions to help improve your score.

Table 2: Frequently Asked Questions (FAQs) for Troubleshooting AGREE Scores

| Question / Issue | Root Cause | Solution / Action |

|---|---|---|

| My score is low due to high waste generation. | Inefficient method design; large solvent volumes in extraction or chromatography [6]. | Miniaturize the method. Switch to micro-extraction techniques (e.g., SPME, MEPS) or use UHPLC with smaller column diameters and lower flow rates to drastically reduce waste volume [7]. |

| How can I improve a poor score in Principle 11 (toxicity)? | Use of hazardous solvents (e.g., chloroform, acetonitrile, n-hexane) [8]. | Replace toxic solvents with safer alternatives. Use solvent selection guides (e.g., ACS GCI's guide). For LC-MS, consider ethanol-water or methanol-water mixtures instead of acetonitrile where possible [6]. |

| The energy consumption (Principle 6) is dragging my score down. | Use of energy-intensive instrumentation over long run times (e.g., traditional GC, HPLC) [7]. | Optimize instrument methods for shorter run times. Use faster heating/cooling cycles. Consider switching to at-line or portable detection systems that consume less energy [7]. |

| Principle 1 (direct analysis) is low, but my sample needs preparation. | Complex samples (e.g., biological, environmental) often require extraction and cleanup, which is penalized [7]. | While direct analysis is ideal, focus on integrating and automating the preparation (Principle 7). Use on-line SPE or in-loop extraction to move from "off-line" to "on-line" analysis, which scores higher [7]. |

| My overall score is acceptable, but I want to optimize it further. | Lack of a strategic approach; not leveraging the weighting feature. | Use the weighting function strategically. If waste and toxicity are your key concerns, assign higher weights (e.g., 4 or 5) to Principles 3, 4, 11, and 12. This highlights your method's superiority in the most critical areas [8]. |

Essential Research Reagent Solutions for a Greener Profile

Selecting the right reagents and materials is a direct and effective way to positively influence your AGREE score, particularly for principles related to toxicity, waste, and the use of renewable sources.

Table 3: Research Reagent Solutions for Improving AGREE Metrics

| Reagent / Material Category | Traditional (Less Green) | Greener Alternative | Principle(s) Impacted |

|---|---|---|---|

| Extraction Solvents | Chloroform, dichloromethane, n-hexane | Ethyl acetate, cyclopentyl methyl ether (CPME), bio-based solvents (e.g., limonene), or deep eutectic solvents (DES) [9]. | P4, P5, P11, P12 |

| Chromatography Mobile Phases | Acetonitrile, methanol with additives | Ethanol-water mixtures, subcritical water chromatography (SWC), or methanol from renewable sources [6] [10]. | P4, P10, P11 |

| Sorbents for Sample Preparation | Synthetic polymers, C18 silica | Bio-sorbents (e.g., chitosan, starch), molecularly imprinted polymers (MIPs), or reusable magnetic nanoparticles [9]. | P10, P12 |

| Derivatization Agents | Highly toxic and unstable reagents (e.g., DNBS, OPA) | Seek direct analysis methods (LC-MS, ICP-MS) to eliminate the derivatization step entirely [7]. | P9, P11, P12 |

| Calibration Standards | Standards prepared in toxic organic solvents | Prepare standards in the initial mobile phase or in water, if solubility allows [6]. | P4, P11 |

Experimental Protocol: A Step-by-Step Guide to AGREE Assessment

To ensure a consistent and accurate evaluation of your analytical method's greenness, follow this detailed experimental protocol. The workflow for this assessment process is summarized in the following diagram.

Step 1: Define Method Scope and Gather Data Clearly outline all steps of your analytical procedure, from sampling to data analysis. Then, systematically collect the quantitative and qualitative data required for each of the 12 SIGNIFICANCE principles as outlined in Table 1 [7]. Key metrics to have on hand include:

- Volumes: Sample size, solvent volumes for extraction and chromatography.

- Quantities: Masses of reagents, sorbents, and other materials.

- Hazard Data: Safety Data Sheets (SDS) for all chemicals to determine toxicity, flammability, and other hazards.

- Energy Data: Power requirements (in kW) of instruments and the total run time per sample.

- Operational Details: Number of samples, number of analytes, degree of automation, and whether derivatization is used.

Step 2: Download and Install the AGREE Software

The AGREE calculator is freely available as open-source software. Download it from the official repository at https://mostwiedzy.pl/AGREE to ensure you are using the correct tool [7].

Step 3: Input Data into the AGREE Software Launch the software and enter the data you gathered in Step 1 into the corresponding fields for each of the 12 principles. The software will typically provide tooltips or guidance for each input. Be as accurate as possible.

Step 4: Assign Weights to the Principles This is a critical step for a meaningful assessment. The default weight for all principles is often 2. However, you should adjust these weights (on a scale of 1 to 5, where 5 is most important) based on your analytical goals and priorities [8]. For example, in a pharmaceutical lab, operator safety (P5) and toxicity (P11) might be weighted higher. In a high-throughput environment, analysis throughput (P8) might be a priority.

Step 5: Calculate the Score and Generate the Pictogram Execute the calculation. The software will generate the characteristic circular pictogram. The overall score (0-1) will be displayed in the center, and the performance for each principle will be shown in the surrounding segments using a color scale (green-yellow-red).

Step 6: Interpret the Results and Identify Improvements Analyze the pictogram. Dark green segments indicate areas where your method is already green. Yellow or red segments highlight aspects that need improvement. Use this diagnostic information to guide your method redevelopment efforts, referring to the troubleshooting guide (Table 2) and reagent solutions (Table 3) for actionable strategies.

This guide helps you accurately interpret the Analytical GREEnness (AGREE) metric pictogram, a key tool for evaluating the environmental friendliness of analytical methods in drug development and scientific research.

The AGREE pictogram provides a visual summary of an analytical method's performance against the 12 principles of Green Analytical Chemistry (GAC). This calculator-based approach transforms complex criteria into an easily interpretable score [7].

The output is a clock-like graph, where the overall score (from 0 to 1) and a color representation appear in the center. Each of the 12 surrounding segments corresponds to one GAC principle, displaying performance through color and segment width [7].

Decoding Scores, Colors, and Segments

The central number and color give an immediate impression of the method's overall greenness:

| Score Range | Color | Interpretation |

|---|---|---|

| 0.8 - 1.0 | Dark Green | Excellent greenness |

| 0.6 - 0.8 | Medium Green | Acceptable greenness |

| 0.4 - 0.6 | Yellow/Yellow-Green | Moderate greenness |

| 0.2 - 0.4 | Orange | Poor greenness |

| 0.0 - 0.2 | Red | Unsatisfactory greenness |

Segment Colors and Widths

Each segment provides specific performance information:

- Segment Color: Indicates performance for that specific principle

- Green → Good performance

- Yellow → Moderate performance

- Red → Poor performance [7]

- Segment Width: Represents the weight assigned to that criterion by the user, reflecting its relative importance in the assessment. Wider segments indicate higher weighted criteria [7].

The 12 Principles of GAC

The AGREE metric evaluates methods against these 12 SIGNIFICANCE principles:

| Principle | Description | High Score Indicator |

|---|---|---|

| 1 | Direct analysis to avoid sample treatment | Remote sensing, non-invasive analysis [7] |

| 2 | Minimal sample size and number of samples | Minimal sample consumption and rapid strategies [7] |

| 3 | In-situ measurements | Measurements taken at the sample location |

| 4 | Integration of analytical operations & device portability | Automated, miniaturized portable equipment |

| 5 | Automated & miniaturized methods | Reduced manual steps and small device footprint |

| 6 | Derivatization avoidance | Direct analysis without chemical modification |

| 7 | Energy reduction & safety | Low energy demand and safe operations |

| 8 | Waste minimization & management | Low waste generation and proper disposal |

| 9 | Multi-analyte or multi-parameter methods | High-throughput simultaneous analysis |

| 10 | Reagent-free or renewable resource use | Alternatives to toxic reagents |

| 11 | Toxicity reduction | Non-toxic chemicals and biodegradable substances |

| 12 | Operator safety | Measures preventing analyst exposure to hazards |

Detailed Scoring for Select Principles

Principle 1: Direct Analytical Techniques

| Sample Pretreatment Activity | Score |

|---|---|

| Remote sensing without sample damage | 1.00 |

| Remote sensing with little physical damage | 0.95 |

| Non-invasive analysis | 0.90 |

| In-field sampling and direct analysis | 0.85 |

| In-field sampling and on-line analysis | 0.78 |

| On-line analysis | 0.70 |

| At-line analysis | 0.60 |

| Off-line analysis | 0.48 |

| External pretreatment (reduced steps) | 0.30 |

| External pretreatment (many steps) | 0.00 |

Principle 2: Minimal Sample Size

This principle uses a complex equation that considers both the mass/volume of sample and the number of samples required. Higher scores are achieved through miniaturized systems and statistical sampling strategies that don't jeopardize sample representativeness [7].

Troubleshooting Common Issues

Problem: The central score is yellow (0.4-0.6) or red (0.0-0.4), indicating poor greenness.

Solutions:

- Identify red or yellow segments in your pictogram - these are your improvement priorities

- For Principle 1 (red/yellow): Explore direct analysis techniques to eliminate sample preparation

- For Principle 8 (red/yellow): Implement waste reduction strategies and proper waste management

- For Principle 11 (red/yellow): Substitute toxic reagents with safer alternatives

Specific Principle Deficiencies

Problem: One or two principles show red segments despite an acceptable overall score.

Solutions:

- Check if the low-scoring principles have been weighted heavily (wider segments)

- Focus improvement efforts specifically on the red-scored principles

- Consult the detailed scoring criteria for those specific principles to identify targeted improvements

Incomplete Data for Assessment

Problem: Missing information makes certain principles difficult to assess accurately.

Solutions:

- Follow Good Evaluation Practice (GEP) rules: use quantitative indicators based on empirical data where possible [11]

- For energy consumption (Principle 7): Use a wattmeter to measure actual electricity usage

- For waste generation (Principle 8): Precisely measure mass/volume of all waste streams

- Document all methodology details to enable accurate assessment

Key Reagents and Materials for Green Chemistry

| Item | Function in Green Chemistry |

|---|---|

| Wattmeter | Measures exact energy consumption of instruments for Principle 7 scoring |

| Miniaturized equipment | Reduces sample and reagent consumption (Principles 2, 5) |

| Portable analytical devices | Enables in-situ measurements (Principles 3, 4) |

| Automated systems | Reduces manual operations and human error (Principle 5) |

| Safer solvent alternatives | Replaces toxic reagents (Principles 10, 11) |

| Waste tracking system | Monitors and quantifies waste generation (Principle 8) |

Frequently Asked Questions

How can I improve my method's AGREE score?

Focus on principles with red or yellow scores in your pictogram. Common improvement areas include reducing sample preparation steps (Principle 1), minimizing waste (Principle 8), replacing toxic reagents (Principle 11), and reducing energy consumption (Principle 7).

Why are some segments wider than others in my pictogram?

Segment width reflects the weight you assigned to each criterion. Wider segments indicate principles you deemed more important for your specific assessment. This allows customization based on analytical goals and priorities.

Is a high AGREE score mandatory for publishing my method?

No, AGREE assessment is not always mandatory but is increasingly recommended. While analytical validation remains essential, greenness assessment provides valuable environmental context, particularly for methods claiming environmental benefits or comparing alternatives [11].

What's the difference between AGREE and other greenness metrics?

AGREE is more comprehensive than earlier metrics like NEMI, evaluating all 12 GAC principles rather than just a few criteria. It provides both quantitative scoring and visual interpretation, with flexibility to weight criteria based on importance [7].

The Analytical GREEnness (AGREE) metric is a comprehensive tool designed to evaluate the environmental impact of analytical methods. Unlike simpler scoring systems, a core feature of AGREE is its incorporation of user-defined weights, allowing researchers to tailor the greenness assessment to their specific priorities and constraints [7].

The AGREE calculator evaluates an analytical procedure against the 12 principles of green analytical chemistry (GACC). Each principle is scored and then combined into a final overall score between 0 and 1, where a score closer to 1 indicates a greener method [7]. The user-assigned weights, which determine the relative importance of each of the 12 principles, are critical in this calculation. This flexibility recognizes that the definition of "greenness" can vary; for one lab, minimizing waste might be paramount, while for another, reducing energy consumption or the use of hazardous solvents could be the primary driver [7]. By adjusting these weights, you directly control how these different aspects of greenness influence the final score, making the AGREE metric a dynamic and customizable tool for driving sustainable practices in research.

Troubleshooting Guide: AGREE Score Calculations

My AGREE score seems incorrect. How can I verify my inputs?

Problem Identification You have calculated an AGREE score, but the result seems unexpectedly high or low, potentially due to an error in how the criteria were scored or weighted.

Troubleshooting Steps [12]

- Re-check Principle Scores: Confirm that you have correctly scored each of the 12 GACC principles. AGREE transforms qualitative descriptions of your method into a unified 0–1 scale for each principle. Ensure your inputs for parameters like sample size, waste amount, and energy consumption are accurate [7].

- Verify Weight Assignments: The most common source of unexpected results is incorrect weight assignment. In the AGREE pictogram, the width of each segment reflects the weight you assigned to that principle [7]. Double-check that you have applied the intended weights (e.g., 1 for low importance, 2 for medium, 3 for high) and that they correctly reflect your priorities.

- Review the Calculation: The final AGREE score is the product of the assessment results for each principle [7]. Use the official, open-source AGREE software to automate this process and reduce human calculation error [7].

- Compare with Default Weights: Run the calculation again with all weights set to the default value (e.g., 1). If the score changes significantly, it confirms that your custom weights are the primary factor influencing the result.

Visual Aid The diagram below illustrates the workflow for troubleshooting an unexpected AGREE score.

Problem Identification You want to optimize your analytical method's AGREE score but are unsure how to strategically assign weights to the 12 principles to reflect improvement efforts best.

Troubleshooting Steps

- Conduct a Baseline Assessment: First, calculate your AGREE score with all weights set equally. This provides a baseline and highlights which principles are naturally scoring low and dragging your overall result down [7].

- Identify Modifiable Principles: Analyze the low-scoring principles from your baseline. Determine which ones can be realistically improved through methodological changes. For example, reducing sample size (Principle 2) or switching to a less hazardous solvent (Principle 6) might be feasible [7].

- Assign Higher Weights to Modifiable Principles: Strategically increase the weights for the principles you have identified as both low-scoring and modifiable. This tells the scoring algorithm that improvements in these critical areas should have a greater positive impact on your final score [7].

- De-emphasize Fixed Constraints: If certain principles have low scores due to unchangeable instrumental or procedural constraints, you can assign them a lower weight. This minimizes their negative impact on the overall score, allowing your improvements in other areas to shine [6].

Visual Aid The following flowchart guides the strategic assignment of weights to optimize an AGREE score.

Frequently Asked Questions (FAQs)

Q1: What is the difference between the AGREE score and the pictogram? The AGREE score is a single number between 0 and 1 in the center of the pictogram, providing a quick, quantitative measure of overall greenness [7]. The pictogram is the circular graph surrounding the score. It offers qualitative insights by showing the performance for each of the 12 principles (via color) and the relative importance you assigned to each principle (via the segment width) [7]. The pictogram helps you understand why you got a certain score.

Q2: Can I directly compare AGREE scores from two studies if they used different weights? No, comparing scores from assessments that used different weight assignments is not valid. Since the user-defined weights directly influence the final score, a higher score might simply reflect a different set of priorities rather than a genuinely greener method [7]. For a fair comparison, you must ensure both methods are evaluated using the same set of weights.

Q3: I've improved my method. Should I change the weights when I re-calculate the score? It depends on your goal. If you want to see the absolute improvement of your method changes, keep the weights the same as your original assessment. This isolates the effect of the methodological improvements. If your organizational priorities have shifted (e.g., a new focus on energy reduction), then updating the weights to reflect these new strategic goals is appropriate for future assessments [7] [6].

Q4: Where can I find the official AGREE calculator? The open-source AGREE software is freely available for download at https://mostwiedzy.pl/AGREE [7]. Using the official software ensures accurate calculations and generates the standardized pictogram output.

Experimental Protocol for Method Greenness Assessment

This protocol provides a step-by-step methodology for evaluating the greenness of an analytical method using the AGREE metric, with a focus on the strategic use of weights.

1. Define Assessment Goal and Scope: Clearly state the objective of the greenness assessment (e.g., internal benchmarking, comparison of two methods, publication). Define the analytical method being evaluated, including all steps from sample collection to data analysis [6].

2. Gather Method Data: Collect all necessary quantitative and qualitative data for the method. Key parameters to document include:

- Sample size and number of samples [7].

- Type, volume, and toxicity of all solvents and reagents used [6].

- Mass of waste generated [7].

- Energy consumption of equipment (e.g., kWh per run) [6].

- Number of procedural steps and degree of automation [7].

3. Establish Weighting Scheme: Convene a team of relevant stakeholders (e.g., lead scientists, lab managers, safety officers) to assign weights to the 12 GACC principles. This can be done through a collaborative discussion or workshop to align on organizational priorities and avoid individual biases [13] [14]. Document the rationale for the assigned weights.

4. Input Data into AGREE Tool: Enter the collected method data and the assigned weights into the official AGREE calculator software [7].

5. Generate and Interpret Results: The software will output the overall AGREE score and the pictogram. Analyze the pictogram to identify segments with poor performance (red or yellow) and correlate them with the corresponding principles.

6. Develop an Improvement Plan: Based on the results, prioritize modifications to the analytical method that target low-scoring, highly-weighted principles. For example, if waste generation (aligned with GACC principles) is a red segment with a high weight, focus on miniaturization or solvent recycling strategies [6].

7. Re-assess and Iterate: After implementing method improvements, repeat the AGREE assessment using the original weighting scheme to quantitatively measure the progress in greenness.

The Scientist's Toolkit: Key Reagents and Concepts for Green Method Development

Table: Essential Concepts and Strategies for Greener Analytical Chemistry

| Concept / Strategy | Function / Role in Increasing Greenness |

|---|---|

| Miniaturization | Reducing the scale of analyses (e.g., using micro-extraction techniques, smaller columns in HPLC) to directly minimize sample size, reagent consumption, and waste generation, positively impacting several AGREE principles [7]. |

| Alternative Solvents | Replacing hazardous solvents (e.g., acetonitrile) with safer, bio-based, or less toxic alternatives (e.g, ethanol) to improve safety profiles and reduce environmental impact [6]. |

| Method Automation | Implementing automated sample preparation and analysis to enhance throughput, improve reproducibility, and reduce manual handling of hazardous materials, while often also optimizing resource use [6]. |

| Energy-Efficient Instrumentation | Utilizing modern analytical equipment designed for lower energy consumption (e.g., UHPLC vs. HPLC) or implementing sleep-mode protocols to directly address the energy-related principles in AGREE [6]. |

| Waste Management Plan | Implementing procedures for sorting, recycling, or treating chemical waste generated from analytical processes, which is a critical factor in the overall greenness assessment [7]. |

Table: AGREE Principle Scoring Examples for a Hypothetical Chromatographic Method

| GACC Principle | Example Assessment Criteria | Low Greenness Score (e.g., 0.2) | High Greenness Score (e.g., 0.9) | User Weight (Example: High Importance) |

|---|---|---|---|---|

| Principle 1: Direct Analysis | Number of sample prep steps | Multi-step offline preparation | Direct, in-line analysis | 2 |

| Principle 2: Sample Size | Volume/Mass required | > 1 mL or 1 g | < 0.1 mL or 0.1 g | 3 |

| Principle 6: Toxicity | Hazard profile of reagents | Use of highly toxic solvents | Use of water or ethanol-based solvents | 3 |

| Principle 9: Waste Generation | Mass of waste per analysis | > 10 g | < 1 g | 2 |

| Principle 12: Operator Safety | Exposure to hazards | High risk, requires extensive PPE | Minimal risk, standard lab attire | 3 |

Final Score Calculation Note: The overall AGREE score is not a simple weighted average but the product of the transformed scores for each principle [7]. This means a very low score in any principle (especially a highly weighted one) can significantly drag down the final result, emphasizing the need for a balanced approach to green method design.

Selecting the right metric is crucial for accurately evaluating the environmental impact of analytical methods in pharmaceutical development. This guide compares four prominent greenness assessment tools—AGREE, NEMI, GAPI, and Analytical Eco-Scale—to help researchers navigate their unique features and applications. The following sections provide a detailed comparison, troubleshooting advice, and practical strategies for improving your method's greenness profile, directly supporting the broader goal of enhancing AGREE metric scores in analytical research.

Understanding the Greenness Assessment Tools

1.1 National Environmental Methods Index (NEMI) NEMI is a simple, pictogram-based tool where a circle is divided into four quadrants. Each quadrant is colored green if a criterion is met or left white if not. The criteria are: the method does not use persistent, bioaccumulative, and toxic (PBT) reagents; it does not use hazardous reagents listed on the TRI (Toxic Release Inventory); the amount of waste generated is less than 50 g; and the pH is not corrosive (2 < pH < 12) [7] [15]. Its primary advantage is simplicity, but this also limits its descriptive power [16].

1.2 Analytical Eco-Scale This tool is a semi-quantitative scoring system. It starts with a base score of 100 points and subtracts penalty points for the use of hazardous reagents, the amount of waste generated, energy consumption, and other health and safety hazards [7] [15]. The final score is interpreted as: >75 representing an excellent green analysis, >50 representing acceptable green analysis, and <50 representing inadequate green analysis [17].

1.3 Green Analytical Procedure Index (GAPI) GAPI uses a multi-criteria pictogram with five pentagrams, each representing a different stage of the analytical process (e.g., sampling, sample preparation, instrumentation). Each segment is colored green, yellow, or red based on the environmental impact of that specific step [16] [15]. It provides a more detailed assessment than NEMI but is also more complex to create [16].

1.4 Analytical GREEnness (AGREE) Metric Approach AGREE is a comprehensive calculator that evaluates methods against all 12 principles of Green Analytical Chemistry (GAC). It uses a user-friendly, open-source software to generate a clock-like pictogram [7]. The tool assigns a score between 0-1 for each principle, and a final overall score from 0-1 is displayed in the center, with a color scale from red to dark green. A key advantage is its ability to assign different weights to each criterion based on user-defined priorities, offering a nuanced and flexible assessment [7] [16].

Table 1: Summary of Greenness Assessment Tool Characteristics

| Tool Name | Type of Output | Scoring Range | Key Advantages | Reported Limitations |

|---|---|---|---|---|

| NEMI | Pictogram (4 quadrants) | Binary (Green/White) | Simple, quick visual assessment [16] | Lacks granularity; poor discriminative power [16] |

| Analytical Eco-Scale | Numerical Score | 0-100 (100 = Ideal) | Semi-quantitative; easy to interpret [16] | Penalty points can be subjective [15] |

| GAPI | Detailed Pictogram | Traffic Light (Red/Yellow/Green) | Comprehensive; covers entire method lifecycle [15] | Complex to create without software [16] |

| AGREE | Circular Pictogram & Numerical Score | 0-1 (1 = Ideal) | Comprehensive; based on 12 GAC principles; flexible weighting [7] | Requires dedicated software for calculation |

Comparative Analysis and Troubleshooting

Direct Comparison of Tool Outputs

Independent studies have applied these tools to evaluate analytical methods, revealing important differences in their discriminatory power.

Table 2: Comparative Greenness Scores from Practical Case Studies

| Case Study | Analytical Method | NEMI | Analytical Eco-Scale | GAPI | AGREE |

|---|---|---|---|---|---|

| Melatonin Analysis [18] | HPLC-PDA | Not Specified | Not Specified | Not Specified | 0.77 (Overall Score) |

| Melatonin Analysis [18] | HPLC-FLD | Not Specified | Not Specified | Not Specified | 0.80 (Overall Score) |

| Melatonin Analysis [18] | HPLC-ELSD | Not Specified | Not Specified | Not Specified | 0.75 (Overall Score) |

| Cannabinoids in Oils [17] | HPLC-UV/MS (8 methods) | Not Specified | 50-80 (7 methods: Acceptable; 1 method: Excellent) | Not Specified | Not Specified |

| Hyoscine N-butyl bromide [16] | 16 Chromatographic Methods | 14 methods had identical pictograms [16] | Scores varied, providing a ranking [16] | Pictograms showed distinct differences [16] | Scores varied (e.g., 0.27 vs. 0.49), highlighting weakest points [16] |

Frequently Asked Questions (FAQs)

Q1: My method received a low AGREE score. How can I improve it? Start by examining the AGREE pictogram's outer segments, which are colored red or yellow. These indicate the GAC principles where your method performs poorly. Common improvements include: replacing toxic solvents with safer alternatives (e.g., ethanol or water), miniaturizing the method to reduce waste and sample size, automating procedures to increase throughput and safety, and integrating sample preparation and analysis to eliminate off-line steps [18] [7].

Q2: Why should I use multiple tools to assess my method's greenness? Each tool has a different focus. Using only one can give an incomplete picture. For example, a method might score well on the simple NEMI scale but poorly on the more comprehensive AGREE metric. Employing multiple tools (e.g., AGREE, Analytical Eco-Scale, and GAPI) provides a more robust and holistic evaluation, ensuring you don't overlook significant environmental impacts [16] [15].

Q3: What is the most significant advantage of AGREE over other tools? AGREE's two greatest advantages are its comprehensiveness, as it is the only tool that directly incorporates all 12 principles of GAC, and its flexibility, allowing users to assign different weights to each principle based on their specific analytical goals and priorities [7] [16].

Q4: I find GAPI complex. Is there a simpler alternative that is still descriptive? Yes, the AGREE tool is an excellent alternative. While both GAPI and AGREE provide detailed, multi-criteria assessments, AGREE automates the calculation and score visualization through its software, making it simpler and faster to implement while providing an easily interpretable result [16].

Troubleshooting Common Assessment Issues

Problem: Inconsistent greenness scores between different tools.

- Cause: This is expected, as each tool uses different criteria and algorithms. NEMI is binary and simple, while AGREE and GAPI are multi-parametric and more sensitive.

- Solution: Do not view this as an error. Instead, analyze the discrepancies. For instance, a good NEMI score but a poor AGREE score suggests your method meets basic criteria but fails on more nuanced GAC principles. Use the outcome of multiple tools to guide comprehensive method optimization [16].

Problem: Difficulty in calculating the energy consumption for the AGREE metric.

- Cause: Exact energy consumption of instrumentation is often not provided in analytical method literature.

- Solution: Make reasonable estimations based on the equipment used. For example, a standard HPLC system consumes more energy than a capillary electrophoresis system. AGREE allows for scoring based on these general energy demands. Refer to the AGREE tutorial and software for guidance on standardized scoring for this principle [7].

Problem: The AGREE software gives a low score for a method I believe is green.

- Cause: The default settings in AGREE assign equal weight to all 12 principles. Your method might excel in the areas you prioritize but perform poorly in others the tool deems important.

- Solution: Use the weighting function in the AGREE software. If your method requires a specific, less-green reagent for sensitivity reasons, you can lower the weight of that principle, providing a more tailored and realistic greenness assessment for your specific context [7].

Experimental Protocols for Green Method Development

Protocol: Transition to a Greener HPLC Mobile Phase

This protocol is based on a study that developed green HPLC methods for Melatonin using ethanol-water mobile phases [18].

- Initial Method Assessment: Begin with your existing HPLC method (e.g., using an acetonitrile-water or methanol-water mobile phase). Assess its starting greenness using AGREE to establish a baseline.

- Solvent Substitution: Replace the organic solvent (ACN or MeOH) with a greener alternative, such as ethanol (EtOH) or isopropanol [18].

- Method Re-optimization: Re-optimize the chromatographic conditions (gradient, flow rate, column temperature) with the new ethanol-water mobile phase to achieve baseline separation of your analytes. This may require testing different ratios of ethanol and water.

- Validation: Validate the new method according to ICH guidelines to ensure it meets required parameters for sensitivity, linearity, precision, and accuracy.

- Final Greenness Assessment: Recalculate the AGREE score for the new method. The replacement of a toxic solvent with ethanol should significantly improve the score in the relevant categories [18].

Protocol: AGREEprep for Sample Preparation

AGREEprep is a dedicated metric for evaluating the greenness of sample preparation steps, which are often the least green part of an analytical process [4].

- Define the Sample Preparation Workflow: List every step of your sample preparation, including the type and volume of solvents, materials (e.g., sorbents for SPE), energy consumption, and waste generation.

- Input Data into Software: Use the dedicated, open-source AGREEprep software. Input the collected data for the ten assessment criteria, which correspond to the ten principles of green sample preparation.

- Interpret the Pictogram: The software will generate a pictogram similar to AGREE. Analyze the results to identify the aspects of your sample prep with the highest environmental impact (red and yellow segments).

- Optimize and Reassess: Modify your sample preparation to address the weak points—for example, by reducing solvent volumes, switching to a less toxic solvent, or implementing miniaturized techniques like micro-extraction. Re-run the AGREEprep assessment to quantify your improvement [4].

Visualization of the AGREE Assessment Framework

The diagram below illustrates the logical workflow and criteria behind the AGREE metric, showing how the 12 principles contribute to the final score.

AGREE Metric Calculation Workflow: This diagram shows how data for each of the 12 Green Analytical Chemistry (GAC) principles are input into the AGREE software, which processes them to generate the final circular pictogram and overall score [7].

The Scientist's Toolkit: Key Reagents for Greener Chromatography

Table 3: Research Reagent Solutions for Improving Method Greenness

| Reagent / Material | Traditional Less-Green Alternative | Function in Analysis | Greenness Benefit |

|---|---|---|---|

| Ethanol | Acetonitrile, Methanol | HPLC mobile phase solvent [18] | Lower toxicity, biodegradable, renewable source [18]. |

| Water | Buffers with toxic additives | HPLC mobile phase solvent | Non-toxic, non-hazardous, readily available. |

| C18 Column | Specialized columns requiring harsh solvents | Stationary phase for separation | Enables use of green mobile phases like ethanol-water [18]. |

| Micro-Scale SPE Cartridges | Conventional SPE cartridges | Sample preparation / clean-up | Reduces solvent consumption and waste generation per sample. |

Practical Application: Implementing AGREE in Your Analytical Workflow

Step-by-Step Guide to Using the AGREE Open-Source Software

Frequently Asked Questions (FAQs)

Q1: What is the AGREE metric, and why is it important for my research? AGREE (Analytical GREEnness) is a comprehensive metric tool designed to evaluate the environmental impact of analytical methods. It provides a visual and numerical score based on the 12 principles of Green Analytical Chemistry (GAC), offering a quick and interpretable assessment of a method's sustainability [19] [20]. For researchers and drug development professionals, using AGREE is crucial for minimizing the environmental footprint of laboratory work, aligning with global sustainability goals, and meeting increasing regulatory and peer-review expectations for green method reporting [6] [19].

Q2: Where can I access the AGREE open-source software? The AGREE calculator is available online. The tool was developed and made accessible to help analysts easily evaluate their methods [20].

Q3: My AGREE score is low. What are the most effective ways to improve it? A low overall score indicates significant environmental impact. The most effective strategy is to focus on the criteria with the lowest individual scores, as these are your method's biggest sustainability weaknesses. Common areas for improvement include:

- Reducing solvent and energy consumption [6].

- Substituting hazardous solvents with safer, greener alternatives [6].

- Minimizing waste generation and enabling waste recycling [5].

- Automating the procedure or implementing real-time analysis to reduce resource use [20].

Q4: Can I use AGREE for techniques other than chromatography? Yes. While some metric tools are specific to chromatography, AGREE is a general tool applicable to a wide range of analytical techniques [20]. It was designed to provide a consistent framework for assessing greenness across different methodological approaches [5].

Q5: How does AGREE differ from other greenness assessment tools like GAPI or NEMI? AGREE offers a more comprehensive and nuanced evaluation than earlier tools. Unlike NEMI, which uses a simple pass/fail system for four criteria, or the semi-quantitative Eco-Scale, AGREE provides a weighted score based on 12 criteria corresponding to the GAC principles. It also generates an intuitive circular pictogram, offering a clearer visual overview of the method's performance across all principles compared to GAPI [19] [20].

Q6: What are the common sources of error or subjectivity when using the AGREE calculator? Subjectivity can arise from the interpretation of certain input parameters that are not directly measurable. The overall score can also be influenced by the default weights assigned to each of the 12 principles. While the tool allows weight adjustment, most users rely on the defaults, which assume all principles are of equal importance. Ensuring accurate, consistent, and justified inputs for each criterion is key to obtaining a reliable and reproducible score [5].

Troubleshooting Common AGREE Issues

Issue 1: Difficulty Interpreting the AGREE Pictogram and Score

| Symptom | Likely Cause | Solution |

|---|---|---|

| The overall score is low, but it's unclear which areas to improve. | The circular pictogram has several red or yellow sections, but the specific weaknesses are not prioritized. | Hover over or examine each of the 12 sections of the pictogram. Each section corresponds to one GAC principle. Identify the sections with the lowest scores (closest to red) and focus your method optimization efforts on those specific principles first [5]. |

| Uncertainty about what a specific section of the pictogram represents. | Lack of familiarity with the 12 principles of Green Analytical Chemistry. | Consult the original AGREE publication or supporting documentation to understand the exact meaning of each principle (e.g., principle 1: direct analysis, principle 2: waste minimization, etc.) [20]. |

Issue 2: Challenges in Selecting Input Parameters for the AGREE Calculator

| Symptom | Likely Cause | Solution |

|---|---|---|

| Not knowing the exact energy consumption of an instrument for a single analysis. | Instruments are often not monitored for per-method energy use. | Calculate energy use by multiplying the instrument's power rating (in kW) by the method's runtime (in hours). If the power rating is unknown, use a standard default value for the instrument type or consult the manufacturer's specifications [6]. |

| Difficulty in assessing the "greenness" of a solvent or chemical. | Lack of a standardized, multi-faceted metric for solvent safety, toxicity, and environmental impact. | Use established solvent selection guides, such as the CHEM21 guide, or refer to the safety, health, and environment (EHS) scores and life cycle assessment (LCA) data that tools like the Analytical Method Greenness Score (AMGS) utilize [6]. |

| Uncertainty about how to account for sample preparation steps. | AGREE evaluates the entire method, but sample preparation can be complex. | Use AGREEprep, a sister metric tool specifically designed for a more detailed assessment of the sample preparation stage. This allows for a more accurate and granular greenness evaluation of the entire workflow [20]. |

Issue 3: Strategies for Improving a Low AGREE Score

| Symptom | Likely Cause | Solution |

|---|---|---|

| High solvent energy and EHS penalty (e.g., from using acetonitrile in HPLC). | Use of hazardous, energy-intensive, or toxic solvents. | Switch to greener solvents. For example, replace acetonitrile with alternatives like ethanol or methanol. The ACS Solvent Selection Guide can help identify suitable alternatives with better environmental profiles [6]. |

| High penalty from waste generation. | Large volumes of solvent waste per analysis, with no recycling. | Miniaturize the method. Scale down to micro- or nano- flow rates in LC to drastically reduce solvent consumption and waste. Implement waste recycling protocols for non-hazardous solvents where possible [6] [20]. |

| Low score on automation and direct analysis principles. | Manual, multi-step sample preparation and offline analysis. | Automate sample preparation to improve efficiency and reduce solvent use. Explore direct analysis techniques (e.g., spectroscopic probes) that require little to no sample preparation, thereby addressing multiple GAC principles at once [20]. |

Experimental Protocol for AGREE Score Assessment and Improvement

This protocol provides a step-by-step methodology to evaluate an analytical method using the AGREE metric and implement changes to increase its greenness score.

1. Method Scoping and Baseline Assessment

- Objective: Establish the current greenness profile of your existing analytical method.

- Procedure:

- Compile all method parameters: instrument type, runtime, solvent types and volumes for mobile phases and sample preparation, sample size, and waste volumes.

- Access the online AGREE calculator.

- Input all gathered parameters into the corresponding fields of the calculator. Be as accurate as possible; estimate using the troubleshooting guide above if precise data is unavailable.

- Record the overall AGREE score (from 0 to 1) and download or screenshot the resulting pictogram. This is your baseline assessment.

2. Data Analysis and "Green Bottleneck" Identification

- Objective: Analyze the AGREE output to identify the specific principles with the lowest scores, which represent the largest opportunities for improvement.

- Procedure:

- Systematically examine each of the 12 sections of the AGREE pictogram.

- Create a table to list the three principles with the lowest individual scores.

| Principle Number | Score | Related Method Parameter | Improvement Strategy |

|---|---|---|---|

| e.g., Principle 6 (Energy Consumption) | 0.3 | HPLC system, 30-minute runtime | Switch to UHPLC to reduce runtime to 10 minutes. |

| e.g., Principle 2 (Waste Generation) | 0.4 | 2 mL/min flow rate, 60 mL waste per run | Reduce flow rate to 1 mL/min or implement a waste recycling system. |

| Principle 4 (Operator Safety) | 0.5 | Use of toxic solvent (e.g., chloroform) | Substitute with a less hazardous solvent (e.g., ethyl acetate). |

3. Method Optimization and Redevelopment

- Objective: Implement practical changes to the analytical method to address the identified "green bottlenecks."

- Procedure:

- Based on the table above, prioritize and test the proposed improvement strategies. A holistic approach often yields the best results. For example, switching from HPLC to UHPLC not only reduces runtime (saving energy) but also typically uses lower flow rates (saving solvent and reducing waste) [6].

- A key strategy is method substitution or simplification. Explore if a different, greener analytical technique can achieve the same analytical goal. For instance, Near-Infrared (NIR) spectroscopy often requires minimal sample preparation and no solvents, significantly improving the greenness profile [20].

- After each modification, re-run the AGREE calculator to quantify the improvement in the score and pictogram.

4. Validation and Verification

- Objective: Ensure that the optimized "greener" method maintains the required analytical performance (accuracy, precision, sensitivity).

- Procedure:

- Perform a full method validation according to ICH or other relevant guidelines on the optimized method.

- Compare the validation results (e.g., precision, accuracy, LOD, LOQ) with those of the original method to confirm that analytical quality has not been compromised. The core tenet of Green Analytical Chemistry is that sustainability should not come at the expense of patient safety or data quality [6].

The Scientist's Toolkit: Research Reagent & Material Solutions

The following table details key materials and strategies for developing greener analytical methods, directly impacting AGREE scores.

| Item/Strategy | Function in Green Method Development | Example & Impact on AGREE Score |

|---|---|---|

| Greener Solvents | To replace hazardous, toxic, or energy-intensive solvents in mobile phases and sample preparation. | Substituting acetonitrile with ethanol or methanol in HPLC reduces penalties for operator safety and toxicity, improving scores in Principles 4 and 8 [6]. |

| Method Miniaturization | To drastically reduce the consumption of solvents, samples, and other reagents. | Using UHPLC with 2.1 mm columns at 0.2 mL/min instead of HPLC with 4.6 mm columns at 1.5 mL/min can reduce solvent consumption and waste by over 85%, positively impacting Principles 2, 6, and 12 [6]. |

| Automated Sample Preparation | To improve efficiency, reduce manual labor, minimize human error, and lower solvent/reagent use. | An automated solid-phase extraction (SPE) system uses precise, small volumes of solvent, enhancing scores for waste (Principle 2), energy (Principle 6), and potentially operator safety (Principle 4) [20]. |

| Direct Analysis Techniques | To enable analysis with minimal or no sample preparation steps, eliminating associated solvents and waste. | Using a direct-injection mass spectrometry technique or a spectroscopic probe avoids all sample preparation solvents, dramatically increasing scores for Principles 1 (direct analysis) and 2 (waste minimization) [20]. |

| Solvent Recycling Systems | To collect, purify, and reuse solvents from analytical runs, reducing waste and consumption. | Implementing an acetonitrile recycling system for HPLC waste reduces the net amount of hazardous waste generated, directly improving the score for Principle 2 [6]. |

AGREE Evaluation and Optimization Workflow

The diagram below illustrates the logical workflow for assessing and improving your analytical method's greenness score using the AGREE metric.

Frequently Asked Questions

What is the AGREE metric and what does it assess?

The AGREE (Analytical GREEnness) metric is a comprehensive assessment tool that evaluates the environmental impact and safety of analytical procedures based on the 12 principles of Green Analytical Chemistry (GAC). It provides a score from 0-1, with higher scores indicating greener methods, and presents results in an intuitive clock-like pictogram that shows performance across all criteria [7].

Why is proper data collection crucial for an accurate AGREE assessment?

Proper data collection ensures your greenness assessment is reproducible, meaningful, and comparable. Incomplete or inaccurate data leads to misleading scores that don't reflect your method's true environmental impact. Standardized data collection also allows for meaningful comparisons between different analytical methods and helps identify specific areas for improvement [9].

What are the most common data gaps in AGREE assessments?

Researchers most frequently lack precise data on waste generation, energy consumption of equipment, and toxicity profiles of all reagents used. Sample preparation steps often lack detailed documentation of solvent volumes and number of procedural steps. Many also struggle with quantifying the "greenness" of their final determination technique [4] [9].

Troubleshooting Guides

Problem: Inconsistent AGREE Scores Between Similar Methods

Symptoms: Two analytically similar procedures yield significantly different AGREE scores without clear justification.

Solution:

- Verify all input data uses consistent units (particularly for waste, energy, and sample size)

- Ensure identical weighting factors are applied to all assessment criteria

- Confirm toxicity assessments use the same data sources for all reagents

- Cross-validate with a second metric tool (like Analytical Eco-Scale) to identify discrepancies [9]

Symptoms: Final assessment shows predominantly red/orange segments in the pictogram.

Solution:

- For waste reduction: Implement micro-extraction techniques or method miniaturization

- For energy reduction: Switch to ambient temperature procedures or automated systems that power down when idle

- For toxicity issues: Replace hazardous solvents with safer alternatives (e.g., water, ethanol, or bio-based solvents)

- For sample treatment: Combine preparation steps or eliminate unnecessary derivatization [7] [9]

Problem: Specific Low Scores in Sample Preparation (AGREEprep)

Symptoms: Poor performance in Principles 1 (direct analysis), 2 (minimal sample size), and 5 (miniaturization) in the AGREEprep assessment.

Solution:

- Document exact sample volumes and number of preparation steps

- Calculate total waste generated including all solvents and materials

- Switch to in-field or on-line analysis where possible to avoid sample transport

- Reduce sample size through miniaturized extraction techniques

- Automate preparation steps to improve reproducibility and reduce reagent consumption [4]

Essential Data Collection Tables for AGREE Assessment

Sample and Reagent Documentation

Table 1: Data requirements for sample and reagent documentation

| Data Category | Specific Information Needed | Measurement Units | Source Documentation |

|---|---|---|---|

| Sample Size | Mass or volume used per analysis | g or mL | Method protocol |

| Number of Samples | Total samples analyzed in batch | Count | Study design |

| Reagents & Solvents | Exact names, quantities, concentrations | mL, mg, mmol | Laboratory notebook |

| Solvent Origins | Renewable vs. petroleum-based | Categorical (Yes/No) | Safety Data Sheets |

| Toxicity Data | GHS hazard classifications, LD50 values | Categorical, mg/kg | Safety Data Sheets |

Waste and Energy Documentation

Table 2: Data requirements for waste and energy assessment

| Data Category | Specific Information Needed | Measurement Units | Calculation Method |

|---|---|---|---|

| Total Waste | Sum of all waste streams per analysis | g or mL | Sum of all inputs minus analytes |

| Energy Consumption | Power requirements of all equipment | kWh per analysis | (Power rating × time)/samples per batch |

| Sample Preparation | Number of discrete steps | Count | Method protocol |

| Analysis Type | Remote, in-field, on-line, at-line, off-line | Categorical | Method description |

| Throughput | Samples analyzed per hour | Samples/hour | Total samples/total analysis time |

AGREE Assessment Workflow

AGREE Assessment Workflow

Research Reagent Solutions for Greener Methods

Table 3: Alternative reagents and materials for improving greenness scores

| Material Category | Traditional Materials | Greener Alternatives | Environmental Benefit |

|---|---|---|---|

| Extraction Solvents | Chloroform, hexane, dichloromethane | Ethyl acetate, cyclopentyl methyl ether, bio-based solvents | Reduced toxicity, biodegradability |

| Solvents for Chromatography | Acetonitrile, methanol | Ethanol, water with modifiers | Reduced hazardous waste |

| Sorbents | Synthetic polymers | Natural materials (silica, chitosan) | Renewable sources |

| Derivatization Agents | Highly toxic catalysts | Biocatalysts, milder conditions | Reduced hazard potential |

| Energy Sources | Conventional heating | Microwave, ultrasound, ambient temperature | Reduced energy consumption |

Key Experimental Protocols for Data Collection

Protocol 1: Accurate Waste Calculation

Purpose: Precisely determine total waste generated per analytical procedure.

Methodology:

- List all materials, solvents, and consumables used in a single analysis

- Convert all inputs to mass or volume units

- Subtract the mass of extracted analytes (typically negligible)

- Include all waste streams: liquid, solid, and gaseous if applicable

- Express results as grams or milliliters per single analysis [4]

Protocol 2: Energy Consumption Profiling

Purpose: Measure total energy requirements of analytical equipment.

Methodology:

- Record power ratings (kW) of all instruments used

- Document exact operating times for each instrument (hours)

- Include ancillary equipment (heaters, pumps, chillers)

- Calculate: (Power × Time) / Number of samples per batch

- Express as kWh per sample [7]

Protocol 3: Toxicity Assessment of Reagents

Purpose: Systematically evaluate environmental and safety impacts of all chemicals used.

Methodology:

- Obtain Safety Data Sheets for all reagents

- Document GHS hazard classifications for each substance

- Record acute toxicity data (LD50) when available

- Note persistence and bioaccumulation potential

- Classify as high, medium, or low concern [9]

The Analytical GREEnness (AGREE) metric is a comprehensive tool designed to evaluate the environmental impact of analytical procedures based on the 12 principles of Green Analytical Chemistry (GAC) [7]. Unlike simpler metrics, a key feature of AGREE is its flexibility, allowing users to assign different weights to each of the 12 principles during an assessment [7]. This means you can tailor the evaluation to reflect your specific environmental priorities or the unique constraints of your analytical method. Setting strategic weights is not just a step in the process—it is a critical action to ensure the greenness score provides a meaningful and relevant assessment that aligns with your organization's sustainability goals.

Frequently Asked Questions (FAQs)

1. What are weights in the AGREE calculator? Weights in the AGREE calculator are importance factors you assign to each of the 12 green analytical chemistry principles. You can increase the weight for a principle that is a high priority for your lab (e.g., waste generation) and decrease it for a less critical one. The calculator uses these weights to calculate a final, prioritized greenness score [7].

2. Why should I change the default weights? The default setting treats all principles as equally important. However, in practice, some factors are more critical than others depending on your context. For example, a lab focusing on operator safety might assign a higher weight to principles concerning toxic reagents, while a lab aiming to reduce its carbon footprint might prioritize energy consumption. Adjusting weights ensures the score reflects your strategic goals [7].

3. How do I assign weights strategically? Strategic weight assignment should be a team decision based on your organization's green chemistry policies, specific regulatory concerns, the type of analysis being performed, and the potential for improvement in certain areas. The AGREE software allows you to easily adjust weights, and the output pictogram visually reflects your choices [7].

4. The final score changed after I adjusted the weights. Is this normal? Yes, this is expected. The overall score is a composite result based on the performance of the method in each principle and the importance (weight) you have assigned to each one. A change in weights will change the final score to better reflect your new priorities [7].

5. Can I save different weight profiles for different types of methods? Yes, for a rigorous approach, it is good practice to create and document standardized weight profiles tailored to different categories of analytical methods (e.g., chromatography vs. spectroscopy) or different project phases. This ensures consistent and comparable evaluations across your portfolio.

Troubleshooting Guides

Issue 1: My AGREE score is low, but I'm not sure which principles to prioritize for improvement.

Diagnosis: The AGREE pictogram shows red or yellow segments, but you lack a strategy for improvement.

Solution: Use the following table to diagnose low scores and identify targeted actions. The principles listed are common high-impact areas for chromatographic methods in pharmaceutical development [6].

Table: Troubleshooting Low Scores in Key AGREE Principles

| GAC Principle | Common Causes of Low Score | Corrective Actions |

|---|---|---|

| #1: Direct Analysis | Off-line sample preparation; multiple treatment steps [7]. | Switch to on-line or at-line analysis; automate and combine steps [6]. |

| #2: Sample Size | Using large sample volumes unnecessarily [7]. | Scale down to micro-extraction techniques; use instrumentation with lower volume requirements [6]. |

| #5: Derivatization | Using reagents that are toxic or generate hazardous waste [7]. | Develop a direct analysis method to avoid derivatization; seek safer alternative reagents [6]. |

| #8: Multianalyte Determination | Methods that measure only one analyte per run [7]. | Develop methods to determine multiple analytes simultaneously to reduce runs and solvent use [6]. |

| #9: Energy Consumption | Using energy-inefficient instruments (e.g., old HPLC systems) [6]. | Replace with modern, energy-efficient equipment; switch to techniques like UPLC that have shorter run times [6]. |

Issue 2: The final AGREE score seems counterintuitive after I changed the weights.

Diagnosis: The relationship between individual principle scores, their weights, and the final score is not fully understood.

Solution: The final score is not a simple average. It is a calculation that considers your assigned weights. To better understand the outcome, follow this logical workflow.

Issue 3: I need to justify my weight choices to my team or management.

Diagnosis: The strategic reasoning behind custom weights needs to be documented and communicated.

Solution: Create a brief justification document. Use the following table to structure your reasoning, linking your weight choices to overarching business or research goals.

Table: Framework for Documenting Strategic Weight Choices

| Strategic Goal | High-Priority AGREE Principles | Example Weight Assignment | Business/Research Justification |

|---|---|---|---|

| Operator Safety | 3 (Use of safe reagents), 12 (Operator safety) [7]. | Increase weights for P3 and P12 to 2.0. | To minimize health risks for laboratory personnel and reduce costs associated with handling hazardous materials. |

| Reducing Environmental Footprint | 4 (Minimize waste), 9 (Reduce energy consumption) [7] [6]. | Increase weights for P4 and P9 to 1.5 or 2.0. | To align with corporate sustainability targets and lower the ecological impact of analytical activities. |

| Method Speed & High Throughput | 8 (Multianalyte determination), 10 (Simplify sample prep) [7]. | Increase weights for P8 and P10. | To accelerate drug development timelines and increase laboratory testing capacity. |

Table: Essential Components for an AGREE Evaluation

| Tool or Resource | Function in AGREE Assessment |

|---|---|

| AGREE Free Software | The open-source calculator that transforms input data and weights into a final score and pictogram [7]. |

| The 12 SIGNIFICANCE Principles | The foundational criteria for the assessment; a checklist for evaluating your method's greenness [7]. |

| Solvent Selection Guide | A critical reference for scoring principles related to reagent toxicity, safety, and waste (e.g., P3, P4) [6]. |

| Method Validation Protocol | Ensures that any changes made to improve greenness do not compromise the method's analytical validity [6]. |

| Energy Consumption Data | Information on instrument power use, required for accurately scoring Principle 9 (Energy Consumption) [6]. |

Experimental Protocol: A Step-by-Step Guide to a Strategic AGREE Assessment

Objective: To consistently evaluate the greenness of an analytical method using the AGREE metric, incorporating strategic weight assignments for a relevant and actionable result.

Materials:

- AGREE software (download from https://mostwiedzy.pl/AGREE) [7].

- Detailed procedure of the analytical method to be assessed.

- Data on solvents, reagents, sample amounts, waste, energy use, and instrument type.

Procedure:

- Gather Inputs: Collect all quantitative and qualitative data for your method, mapping each aspect to one of the 12 SIGNIFICANCE principles [7].

- Set Your Strategy: Before inputting data, convene with stakeholders to decide on strategic priorities. Use the Framework for Documenting Strategic Weight Choices (see above) to guide the discussion and record decisions.

- Input Base Data: Enter the objective data about your method into the AGREE calculator for all 12 principles.

- Assign Weights: In the software, adjust the importance slider for each principle according to your pre-defined strategy.

- Calculate and Interpret: Generate the AGREE pictogram. The final score (0-1) in the center provides a quantitative measure. The colored rings provide a qualitative visual of your method's performance across all principles, with the width of each segment indicating the weight you assigned [7].

- Iterate and Improve: Use the output to identify poorly performing principles (red and yellow segments) and consult the Troubleshooting Guide to brainstorm and test modifications to your method. Re-run the assessment to quantify your greenness improvement.