NEMI Assessment for Chromatography: A Practical Guide to Evaluating Method Greenness

This article provides a comprehensive guide to the National Environmental Methods Index (NEMI) for researchers, scientists, and drug development professionals using chromatographic techniques.

NEMI Assessment for Chromatography: A Practical Guide to Evaluating Method Greenness

Abstract

This article provides a comprehensive guide to the National Environmental Methods Index (NEMI) for researchers, scientists, and drug development professionals using chromatographic techniques. It covers the foundational principles of NEMI assessment, detailed methodological application to HPLC and HPTLC procedures, troubleshooting common implementation challenges, and comparative validation with other green chemistry metrics. By integrating NEMI within broader frameworks like White Analytical Chemistry and Quality by Design, this resource enables laboratories to quantitatively evaluate and improve the environmental sustainability of their analytical methods while maintaining analytical performance and regulatory compliance.

Understanding NEMI: Principles and Framework for Green Chromatography

Historical Development and Core Principles

The National Environmental Methods Index (NEMI) is one of the oldest and most established greenness assessment tools in analytical chemistry. It was developed in 2002 by the Methods and Data Comparability Board (MDCB) [1]. Its creation addressed a critical need: to provide a searchable database and a simple, visual system for evaluating the environmental impact of analytical procedures [2] [1].

NEMI emerged alongside the broader green chemistry movement, which gained formal structure with the publication of the 12 principles of green chemistry by Paul Anastas and others [3]. While these principles provided a framework for synthetic chemistry, analytical chemistry needed its own tailored metrics. NEMI filled this gap by offering a way for scientists to quickly assess and compare the environmental footprint of their methods, particularly those in chromatography laboratories which traditionally consumed large volumes of potentially hazardous solvents [3].

The core principle of NEMI is a simple, visual pictogram that allows for an at-a-glance assessment of a method's environmental impact. This pictogram is a circle divided into four quadrants, each representing a different criterion for environmental friendliness [2] [1]. A quadrant is colored green only if the method meets the specific criterion associated with it.

Table 1: The Four Criteria of the NEMI Pictogram

| Quadrant | Criterion | Requirement for Green Color |

|---|---|---|

| PBT | Persistent, Bio-accumulative, and Toxic | Chemicals used are not on the PBT list [1]. |

| Hazardous | Hazardous Waste | None of the reagents are listed on the D, F, P, or U hazardous wastes lists [1]. |

| Corrosive | Corrosive | The pH of the sample and reagents is between 2 and 12 [1]. |

| Waste | Waste Quantity | The total waste generated is 50 g or less per analysis [1]. |

Application in Chromatography: A Practical Workflow

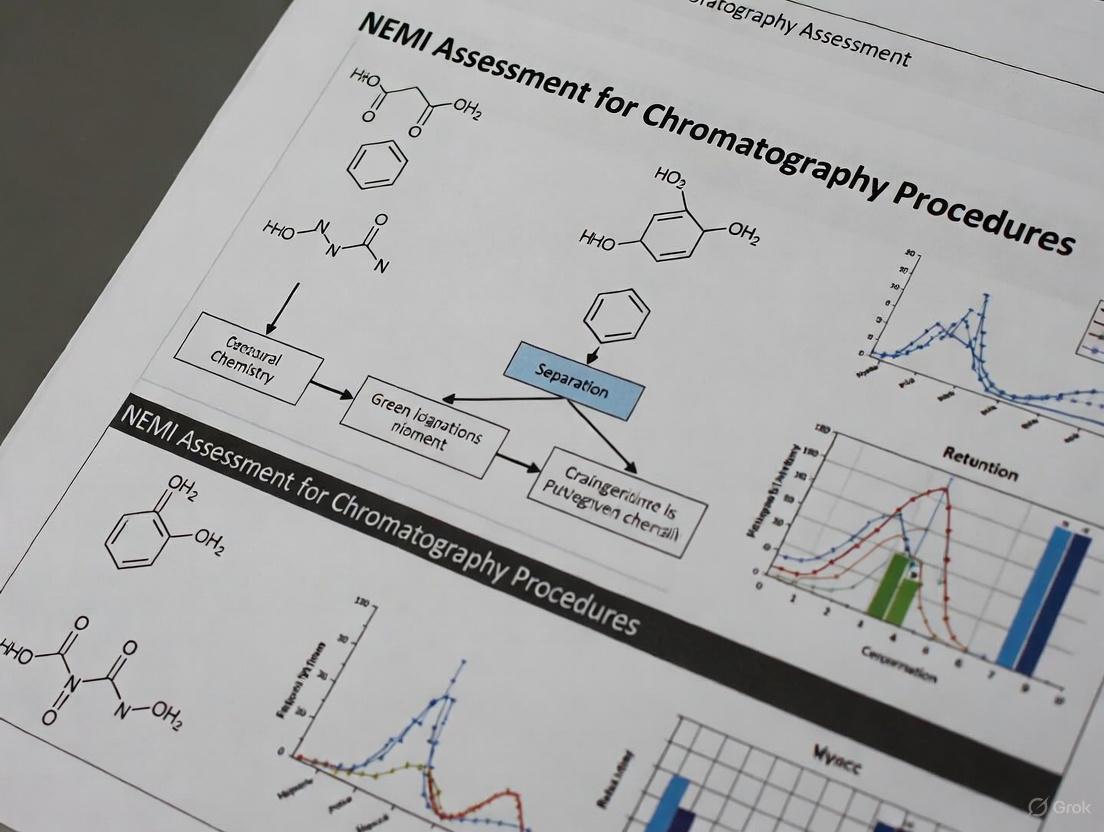

The following diagram illustrates the logical process of applying the NEMI criteria to evaluate an analytical method, leading to the final pictogram.

NEMI Assessment Logical Workflow

Detailed Protocol for NEMI Assessment of a Chromatographic Procedure

Objective: To evaluate the greenness of a chromatographic method using the National Environmental Methods Index (NEMI).

Materials:

- Method Documentation: Complete standard operating procedure (SOP) for the chromatographic method.

- Chemical Inventory Lists: Access to official PBT and hazardous waste lists (e.g., from the US EPA).

- pH Meter: For verification if not specified in the method.

- Waste Calculation Tools: Data on solvent volumes and consumables.

Procedure:

Compile Method Parameters:

- List all chemicals, solvents, and reagents used in the analysis, including sample preparation and mobile phase composition.

- Record the exact pH of all final solutions as per the method.

- Calculate the total waste generated per single analysis run. This includes all solvents, sample preparation materials, and consumables.

Evaluate PBT Criterion (Quadrant 1):

- Cross-reference every chemical used against the official PBT (Persistent, Bio-accumulative, and Toxic) chemical list.

- Decision: If none of the chemicals are on the PBT list, this quadrant is colored green.

Evaluate Hazardous Criterion (Quadrant 2):

- Cross-reference every chemical against the "D", "F", "P", and "U" hazardous waste lists.

- Decision: If none of the reagents are present on these lists, this quadrant is colored green.

Evaluate Corrosive Criterion (Quadrant 3):

- Verify the pH of the final sample solution or analytical stream. If not explicitly stated, measure using a calibrated pH meter.

- Decision: If the pH is between 2 and 12 (inclusive), this quadrant is colored green.

Evaluate Waste Criterion (Quadrant 4):

- Sum the mass (in grams) of all waste produced in a single analytical run.

- Decision: If the total waste is ≤ 50 g, this quadrant is colored green.

Construct the NEMI Pictogram:

- Draw a circle and divide it into four equal quadrants.

- For each criterion above that is met, fill the corresponding quadrant with green.

- Leave any unmet criterion as a white/blank quadrant.

Interpretation: A method with all four quadrants green is considered the most environmentally friendly according to NEMI's criteria. The presence of one or more blank quadrants immediately highlights specific areas where the method has a higher environmental impact [2] [1].

Comparative Analysis with Other Green Assessment Tools

NEMI is often used alongside other greenness assessment tools to provide a more comprehensive profile. The following table summarizes how NEMI compares to other commonly used metrics.

Table 2: Comparison of NEMI with Other Green Assessment Tools

| Tool Name | Type of Output | Scope of Assessment | Key Advantage | Key Limitation |

|---|---|---|---|---|

| NEMI | Qualitative (Green/Blank quadrants) | Reagent hazard, corrosiveness, waste amount [1]. | Simple, fast, and provides an immediate visual summary [2] [1]. | Provides only general, qualitative information. Does not cover the entire analytical process (e.g., sample collection) [2] [4]. |

| Analytical Eco-Scale | Semi-quantitative (Score out of 100) | Reagents, energy, waste [2]. | Provides a total score, allowing for easier ranking of methods. An "excellent green analysis" score is >75 [2] [4]. | Penalty points are assigned by the user, which can introduce subjectivity [1]. |

| GAPI | Qualitative (Color-coded pentagon) | Comprehensive, covering all steps from sample collection to final determination [5] [4]. | More comprehensive than NEMI; evaluates the entire analytical procedure [2] [4]. | The pictogram is more complex to create and interpret than NEMI [4]. |

| AGREE | Quantitative (Score 0-1) + Visual | Comprehensive, based on all 12 principles of GAC [2] [1]. | Provides a quantitative score in the center of the pictogram, is digital, and easy to use [2]. | A more recent tool; may require specialized software for full implementation [1]. |

Essential Research Reagent Solutions

The following table details key reagents and materials frequently encountered in chromatography, along with their relevance to NEMI assessment.

Table 3: Key Reagents and Materials in Chromatographic Analysis

| Item | Function in Chromatography | Relevance to NEMI Assessment |

|---|---|---|

| Acetonitrile | Common organic modifier in Reversed-Phase HPLC mobile phases [3]. | Often a significant contributor to the "Hazardous" and "Waste" criteria due to its toxicity and the large volumes typically used [3]. |

| Methanol | Alternative organic modifier in mobile phases. | Generally considered less toxic than acetonitrile but still contributes to hazardous waste and overall waste volume [3]. |

| Chlorinated Solvents (e.g., Methylene Chloride) | Used in certain extractions and normal-phase chromatography [3]. | Highly likely to be listed as hazardous, often failing the "Hazardous" criterion. Their use is a major red flag in NEMI [3]. |

| Strong Acids/Bases (e.g., TFA, NaOH) | Used for pH adjustment in mobile phases or sample digestion. | Can push the pH outside the 2-12 range, causing the method to fail the "Corrosive" criterion [1]. |

| Solid Phase Extraction (SPE) Cartridges | For sample clean-up and pre-concentration of analytes. | Contribute to the physical waste generated, impacting the "Waste" criterion if the total mass exceeds 50 g per analysis [5]. |

| Micellar Solvents (e.g., SDS) | Used in Micellar Liquid Chromatography (MLC) as a green alternative [5]. | Can help methods pass the "Hazardous" and "PBT" criteria, making MLC a greener technique as assessed by NEMI [5]. |

The National Environmental Methods Index (NEMI) is one of the oldest and most established tools for evaluating the environmental impact of analytical procedures [1] [6]. Developed in 2002 by the Methods and Data Comparability Board, it provides a simple, pictorial system for assessing and comparing the greenness of analytical methods, including chromatography procedures [7] [8]. Its primary function is to offer researchers, scientists, and drug development professionals a mechanism to quickly evaluate whether their analytical methods adhere to fundamental environmental safety criteria [1]. The tool is freely accessible through the NEMI database (www.nemi.gov), which contains one of the largest collections of environmental analytical methods and serves as a valuable resource for method selection and development [6].

NEMI's significance lies in its ability to provide immediate, general information about the environmental impact of an analytical procedure through a simple visual representation [1]. Unlike more complex assessment tools that require detailed calculations and specialized software, NEMI offers a straightforward approach that enables rapid screening of methods for their environmental compliance [7]. This makes it particularly valuable during the initial stages of method development or when comparing multiple established procedures for routine use in pharmaceutical analysis and drug development [9].

The Four Quadrants of NEMI: Core Assessment Criteria

The NEMI assessment is visually represented by a circular pictogram divided into four quadrants, with each quadrant corresponding to a specific environmental criterion [8]. A quadrant is colored green only when the analytical method satisfies the requirement for that criterion. If the criterion is not met, the quadrant remains uncolored (blank) [1] [6]. This simple color-coding system allows researchers to quickly assess a method's environmental profile at a glance. The table below details the four core criteria that form the basis of NEMI's assessment framework.

Table 1: The Four Core Assessment Criteria of the NEMI Pictogram

| Quadrant | Criterion | Requirement for Green Coloring | Data Sources for Verification |

|---|---|---|---|

| 1 | PBT Chemicals | No chemicals used are Persistent, Bioaccumulative, and Toxic (PBT) | EPA's Toxic Release Inventory (TRI) PBT list [8] |

| 2 | Hazardous Chemicals | No solvents or reagents are classified as hazardous (Corrosive, Ignitable, Reactive, or Toxic) | EPA's Resource Conservation and Recovery Act (RCRA) lists (D, F, P, U) [1] [8] |

| 3 | Corrosivity | The pH of the sample solution remains between 2 and 12 throughout the procedure | Method documentation and reagent specifications |

| 4 | Waste Generation | The total amount of waste generated per analysis is less than 50 g | Calculation based on solvent volumes and consumables |

NEMI's Four-Quadrant Assessment Pictogram

Quadrant 1: PBT Chemicals

The first quadrant of the NEMI pictogram addresses the use of Persistent, Bioaccumulative, and Toxic (PBT) chemicals [8]. For this quadrant to be colored green, the analytical method must not utilize any reagents, solvents, or other chemicals that are listed on the Environmental Protection Agency's (EPA) Toxic Release Inventory (TRI) as PBT substances [1]. PBT chemicals are of particular environmental concern because they resist natural degradation, accumulate in living organisms, and exhibit toxicity even at low concentrations [1]. The presence of such chemicals in analytical methods poses long-term risks to ecosystems and human health, as they can persist in the environment and enter the food chain. When developing or evaluating chromatography methods, researchers must consult the TRI PBT list to verify that all mobile phase components, extraction solvents, and derivatization reagents are free from PBT-listed substances.

Quadrant 2: Hazardous Chemicals

The second quadrant evaluates the use of hazardous chemicals according to the EPA's Resource Conservation and Recovery Act (RCRA) [8]. This quadrant is colored green only if none of the chemicals used in the analytical procedure are classified as hazardous wastes under the RCRA categories D, F, P, or U [1]. These categories encompass a wide range of hazardous characteristics, including ignitability, corrosivity, reactivity, and toxicity [8]. Common organic solvents used in chromatography, such as acetonitrile, methanol, and chlorinated solvents, often fall into these hazardous categories [7]. To achieve a green rating for this quadrant, method developers should prioritize substituting hazardous solvents with safer alternatives, such as ethanol or water-based mobile phases, where analytically feasible [10].

Quadrant 3: Corrosivity (pH)

The third quadrant focuses on corrosivity, specifically the pH of solutions used throughout the analytical procedure [8]. This quadrant is colored green when the pH of all solutions remains between 2 and 12 during the entire analytical process [1]. Solutions with pH values outside this range (highly acidic or highly basic) are considered corrosive and pose special handling, disposal, and environmental concerns [7]. In chromatography applications, this criterion is particularly relevant during sample preparation steps, which may involve acid or base hydrolysis, pH adjustment for extraction efficiency, or sample clean-up procedures [11]. Method developers should aim to minimize the use of extreme pH conditions and consider neutral alternatives whenever possible to meet this criterion.

Quadrant 4: Waste Generation

The fourth and final quadrant addresses waste generation, a critical concern in analytical laboratories seeking to minimize their environmental footprint [8]. This quadrant is colored green when the total amount of waste produced per analysis is less than 50 grams [1]. Waste includes all solvents, reagents, consumables, and other materials that are disposed of after the analysis is complete [7]. For chromatography methods, this typically encompasses mobile phase waste, sample preparation solvents, and used columns or cartridges [10]. Strategies to reduce waste include miniaturizing methods, scaling down sample volumes, implementing solvent recycling systems, and extending column lifetime through proper maintenance [11] [10].

Experimental Protocol: Conducting a NEMI Assessment

Materials and Data Requirements

Table 2: Essential Research Reagents and Resources for NEMI Assessment

| Item | Function in NEMI Assessment | Examples/Specifications |

|---|---|---|

| Chemical Inventory | Document all reagents, solvents, and standards used | List all mobile phase components, extraction solvents, derivatization reagents, etc. |

| Safety Data Sheets (SDS) | Verify hazard classifications and physicochemical properties | Obtain latest SDS for all chemicals from manufacturers |

| EPA PBT List | Check for Persistent, Bioaccumulative, Toxic chemicals | Access via EPA's Toxic Release Inventory (TRI) |

| RCRA Hazardous Waste Lists | Identify regulated hazardous chemicals | Review RCRA D, F, P, and U lists (available online) |

| pH Measurement Tools | Verify solution pH meets corrosivity criterion | pH meter, indicators, or method documentation |

| Waste Tracking System | Quantify total waste generated per analysis | Record solvent volumes, consumables, and disposables |

Step-by-Step Assessment Procedure

Compile Complete Chemical Inventory: Create a comprehensive list of all chemicals used throughout the analytical procedure, including sampling, sample preparation, separation, and detection stages. Document the exact names, concentrations, and quantities of each chemical used per analysis [1] [8].

Evaluate PBT Status (Quadrant 1): Cross-reference each chemical from the inventory against the EPA's Toxic Release Inventory PBT list. If any chemical appears on this list, the first quadrant cannot be colored green. Document the PBT status of each substance for your assessment records [8].

Assess Hazard Classification (Quadrant 2): Review Safety Data Sheets for all chemicals and compare against the RCRA hazardous waste lists (D, F, P, U). Pay particular attention to sections addressing hazardous waste classification. If any chemical is classified as hazardous waste under these categories, the second quadrant remains uncolored [1] [8].

Verify pH Range (Quadrant 3): Identify all steps in the procedure where solution pH is relevant. This includes sample preparation, extraction, mobile phase preparation, and any pH adjustment steps. Measure or review documented pH values for these solutions. If all solutions maintain pH between 2 and 12 throughout the procedure, the third quadrant can be colored green [1].

Calculate Waste Generation (Quadrant 4): Quantify the total mass of waste generated per analysis. Include all solvents, reagents, sample materials, consumables, and any other disposables. Convert liquid volumes to mass using appropriate density values (approximately 1 g/mL for aqueous solutions). If the total waste is less than 50 g per analysis, the fourth quadrant qualifies for green coloring [8].

Construct Final NEMI Pictogram: Create the four-quadrant circle and color each quadrant based on the assessment results. Only those quadrants whose criteria are fully met should be colored green. The completed pictogram provides an immediate visual representation of the method's environmental performance [6].

NEMI in Practice: Application to Chromatography Methods

In pharmaceutical analysis, NEMI has been widely applied to assess the greenness of various chromatographic methods. For instance, a comparative study of liquid chromatographic methods for analyzing hydroxychloroquine in biological samples revealed a limitation of NEMI: all 18 evaluated methods received identical NEMI pictograms, suggesting it may lack the discriminative power for detailed comparisons between similar methods [7]. Similarly, an assessment of seven chromatographic methods for neurotransmitter analysis found that while NEMI provided a quick overview, it failed to differentiate effectively between methods, as all shared the same shortcomings in the PBT and hazardous chemical quadrants [6].

These applications highlight both the utility and limitations of NEMI in real-world scenarios. Its strength lies in providing a basic environmental screening tool that promotes awareness of key sustainability criteria among researchers [12]. However, its qualitative nature and limited scope mean it is often used alongside more comprehensive assessment tools like the Analytical Eco-Scale, GAPI, and AGREE for a more complete environmental profile [7] [1] [6].

Complementary Assessment Tools and Future Directions

While NEMI serves as an excellent introductory tool for greenness assessment, researchers should be aware of its limitations, including its qualitative nature and limited scope [1] [6]. For more comprehensive evaluations, several advanced metric tools have been developed:

- Analytical Eco-Scale (AES): A semi-quantitative tool that assigns penalty points for hazardous reagents, energy consumption, and waste generation, providing a numerical score where higher values indicate greener methods [7] [8].

- Green Analytical Procedure Index (GAPI): A more comprehensive visual tool that evaluates the entire analytical procedure across multiple stages, using a color-coded system to indicate environmental impact [7] [6].

- Analytical GREEnness (AGREE) Metric: A recently developed tool that incorporates all 12 principles of Green Analytical Chemistry, providing both a numerical score and a visual output for easier interpretation and comparison [10] [1].

The field of green analytical chemistry continues to evolve, with emerging concepts like White Analytical Chemistry (WAC) seeking to balance environmental, practical, and analytical criteria [13] [8]. For chromatography researchers, employing a combination of assessment tools—using NEMI for initial screening and more sophisticated metrics for comprehensive evaluation—represents the most robust approach to developing truly sustainable analytical methods.

NEMI's Role in the Green Analytical Chemistry (GAC) Landscape

Green Analytical Chemistry (GAC) has emerged as a critical subdiscipline focused on minimizing the environmental impact of analytical procedures while maintaining analytical performance. The field has evolved significantly since its inception in 2000, driven by growing environmental awareness and the need for sustainable laboratory practices [14]. Within this framework, the National Environmental Methods Index (NEMI) represents a foundational milestone as one of the first systematic tools developed to assess the environmental impact of analytical methods [15]. Established as a user-friendly pictogram, NEMI provides researchers with a straightforward mechanism to evaluate whether a method complies with four basic environmental criteria related to toxicity, waste, and safety [14]. Its simplicity and accessibility made it particularly valuable for initial greenness assessments in chromatographic method development, offering a starting point for what would become an increasingly sophisticated landscape of green metrics.

The introduction of NEMI marked a significant shift in how analytical chemists approach method development, encouraging early consideration of environmental factors alongside traditional performance parameters such as accuracy, precision, and sensitivity [5]. For chromatography professionals, NEMI provided a standardized approach to document and compare the environmental attributes of methods, fostering greater awareness of solvent toxicity, waste generation, and hazardous chemical usage [14]. While more comprehensive tools have since emerged, NEMI's establishment of core assessment criteria continues to influence the evolution of green chemistry metrics, making it an essential historical and practical component of the GAC landscape.

Core Principles and Assessment Methodology of NEMI

Fundamental Design and Structure

The NEMI assessment tool employs a simple, visual pictogram consisting of four quadrants, each representing a specific environmental criterion. A method is considered "green" for a particular criterion if it meets the established benchmark, indicated by a filled-in green quadrant in the pictogram. Conversely, if the method fails to meet the criterion, the quadrant remains blank, providing an immediate visual representation of the method's environmental performance [14]. This binary (yes/no) assessment approach makes NEMI particularly accessible for initial screening and comparative evaluations of analytical methods.

Detailed Assessment Criteria

Table 1: NEMI Assessment Criteria and Benchmark Values

| Criterion | Requirement for Green Status (Filled Quadrant) | Data Source |

|---|---|---|

| PBT (Persistent, Bioaccumulative, Toxic) | None of the reagents used are persistent, bioaccumulative, and toxic. | EPA's Toxic Substances Control Act (TSCA) list |

| Hazardous | None of the reagents appear on the TRI (Toxic Release Inventory) list as hazardous. | EPA's Toxic Release Inventory (TRI) list |

| Corrosive | pH remains between 2 and 12 during the entire analytical process. | Method documentation and reagent specifications |

| Waste | Total waste generated is ≤50 g per single analysis. | Calculation from method parameters |

The four quadrants of the NEMI pictogram evaluate the following aspects of an analytical method [14] [15]:

PBT (Persistent, Bioaccumulative, and Toxic): This quadrant is filled green only if none of the chemicals used in the method are classified as PBT substances according to the U.S. Environmental Protection Agency's Toxic Substances Control Act (TSCA) list. This criterion addresses long-term environmental impact.

Hazardous: This quadrant remains blank if any reagents are listed on the EPA's Toxic Release Inventory (TRI) as hazardous substances. It focuses on immediate toxicity and potential for harm.

Corrosive: This quadrant is filled green only if the pH throughout the analytical procedure remains between 2 and 12, ensuring that strongly acidic or basic conditions that could pose handling risks or environmental concerns are avoided.

Waste: This quadrant is filled green if the total waste generated per analytical sample is 50 grams or less. This criterion encourages method miniaturization and waste reduction.

The binary nature of this assessment provides clear, unambiguous feedback but lacks granularity in distinguishing between methods that share the same pictogram profile but may have different levels of environmental impact [14].

Experimental Protocol for Conducting a NEMI Assessment

Protocol 1: Standard NEMI Assessment for Chromatographic Methods

Purpose: To systematically evaluate the greenness profile of a chromatographic method (e.g., HPLC, UPLC) using the National Environmental Methods Index (NEMI) criteria.

Materials and Reagents:

- Detailed method procedure for the chromatographic analysis

- Safety Data Sheets (SDS) for all solvents, reagents, and chemicals used

- Method parameters (sample volume, mobile phase composition and volume, flow rate, run time)

- Access to EPA's TSCA and TRI lists (available online)

Procedure:

Method Documentation and Inventory:

- Compile a complete list of all chemicals, solvents, and reagents used in the analytical procedure, including those for sample preparation, mobile phase preparation, and calibration standards.

- Record precise volumes/masses of each chemical used per sample analysis.

PBT Criterion Assessment:

- Cross-reference each chemical from the inventory against the EPA's TSCA PBT list.

- If any chemical is listed as a PBT substance, the PBT quadrant remains blank.

- If no chemicals are PBT-listed, the PBT quadrant is filled green.

Hazardous Criterion Assessment:

- Cross-reference each chemical against the EPA's Toxic Release Inventory (TRI) list of hazardous chemicals.

- Using SDS, also check for other hazard classifications (e.g., GHS hazard statements).

- If any chemical is listed on the TRI or is classified as hazardous, the Hazardous quadrant remains blank.

- If no chemicals are hazardous-listed, the Hazardous quadrant is filled green.

Corrosive Criterion Assessment:

- Identify all procedural steps where pH is a factor (e.g., mobile phase pH, extraction step pH).

- Measure or review the documented pH values for these steps.

- If the pH for all steps remains between 2 and 12 (inclusive), the Corrosive quadrant is filled green.

- If the pH in any step is <2 or >12, the Corrosive quadrant remains blank.

Waste Criterion Assessment:

- Calculate the total waste mass generated per single sample analysis.

Total Waste (g) = Sum of masses of all solvents and reagents used per sample + any solid waste- For liquids, assume density of ~1 g/mL for approximate calculation unless exact densities are known.

- If the calculated waste is ≤50 g, the Waste quadrant is filled green.

- If the calculated waste is >50 g, the Waste quadrant remains blank.

Pictogram Generation and Reporting:

- Draw or generate the four-quadrant NEMI pictogram.

- Fill each quadrant based on the outcomes from steps 2-5.

- Report the final pictogram alongside the method summary.

Workflow Visualization

The following diagram illustrates the logical decision process for a NEMI assessment:

NEMI Assessment Decision Workflow: This diagram outlines the logical sequence and decision points for evaluating a chromatographic method against NEMI's four criteria, showing the conditions under which each pictogram quadrant is filled.

NEMI in Practice: Application to Chromatography

Case Study: Comparative Assessment of HPLC Methods

In a practical application, NEMI was used to evaluate three chromatographic methods developed for quantifying sulfadiazine and trimethoprim in bovine meat and chicken muscles [5]:

- Method I: Conventional RP-HPLC using a water:ethanol (90:10 v/v) mobile phase.

- Method II: Micellar Liquid Chromatography (MLC) using 0.1 M SDS, 12% isopropanol in 0.1 N citric acid.

- Method III: UPLC-MS/MS using ammonium acetate:acetonitrile (80:20 v/v).

The NEMI assessment revealed that Methods II (MLC) and III (UPLC-MS/MS) demonstrated superior greenness profiles compared to the conventional HPLC approach [5]. The MLC method benefited from using less hazardous surfactants and alcohols while generating minimal waste, and the UPLC-MS/MS method achieved significant reductions in solvent consumption and analysis time through miniaturization and increased efficiency.

Essential Research Reagent Solutions

Table 2: Key Reagents and Their Functions in Green Chromatography

| Reagent/Solution | Function in Chromatography | Green Considerations |

|---|---|---|

| Ethanol | Polar protic solvent for mobile phases and extraction | Renewable, biodegradable, less toxic alternative to acetonitrile or methanol [5]. |

| Water | Primary solvent for reversed-phase mobile phases | Non-toxic, non-hazardous, ideal green solvent [5] [16]. |

| Supercritical CO₂ | Extraction solvent and mobile phase (in SFC) | Non-flammable, non-toxic, easily removed; requires specialized equipment [16]. |

| Ionic Liquids | Extraction solvents, stationary phase modifiers | Low volatility reduces air pollution; toxicity varies [16]. |

| Surfactants (e.g., SDS) | Mobile phase component in Micellar Liquid Chromatography (MLC) | Reduces need for organic solvents; biodegradable options preferred [5]. |

| Bio-based Solvents | Replacements for petroleum-derived solvents | Derived from renewable resources; overall greenness depends on lifecycle impact [16]. |

Comparative Analysis with Other GAC Tools

Evolution Beyond NEMI

While NEMI pioneered greenness assessment, its limitations spurred the development of more sophisticated tools. The Analytical Eco-Scale introduced a semi-quantitative approach by assigning penalty points to non-green attributes, with a perfect method scoring 100 [14]. The Green Analytical Procedure Index (GAPI) expanded assessment scope with a color-coded pictogram covering the entire analytical process from sample collection to final determination [14] [10]. The most recent advancement, AGREE (Analytical GREEnness), integrates all 12 principles of GAC into a comprehensive evaluation that provides both a unified pictogram and a numerical score between 0 and 1 [14] [10].

Tool Comparison and Strategic Application

Table 3: Comparison of NEMI with Other Greenness Assessment Tools

| Assessment Tool | Assessment Approach | Key Advantages | Key Limitations |

|---|---|---|---|

| NEMI | Binary (Yes/No) for 4 criteria | Simple, intuitive, rapid evaluation | Lacks granularity; doesn't cover energy use or sample prep [14] [15] |

| Analytical Eco-Scale | Penalty points subtracted from ideal score (100) | Semi-quantitative, allows method ranking | Relies on expert judgment for penalties; no visual output [14] |

| GAPI | Color-coded pictogram for multiple process steps | Comprehensive workflow coverage | No single overall score; some subjectivity in color assignment [14] [10] |

| AGREE | Numerical score (0-1) based on 12 GAC principles | Holistic, user-friendly software, combines score and graphic | Potential subjectivity in weighting criteria [14] [10] |

NEMI remains most valuable as an introductory educational tool and for initial screening of methods. For more comprehensive assessments, particularly in research publications or regulatory submissions, modern tools like AGREE and GAPI offer more nuanced evaluations [14] [10]. The field continues to evolve with the development of specialized metrics such as AGREEprep for sample preparation and the Carbon Footprint Reduction Index (CaFRI) focused specifically on climate impacts [14].

The National Environmental Methods Index (NEMI) occupies a fundamental position in the history and practice of Green Analytical Chemistry. Its straightforward, visual approach successfully introduced environmental considerations into analytical method development, particularly in chromatography. While its binary assessment structure and limited scope are superseded by more sophisticated contemporary tools, NEMI's core principles continue to influence modern green metrics. For today's researcher, NEMI provides an accessible entry point for greenness assessment, while the evolving ecosystem of GAC tools offers increasingly comprehensive frameworks for developing truly sustainable chromatographic methods that minimize environmental impact without compromising analytical performance.

The National Environmental Methods Index (NEMI) is a foundational tool in Green Analytical Chemistry (GAC), designed to provide a quick, visual assessment of an analytical method's environmental impact [6]. Developed by the Methods and Data Comparability Board (MDCB), it emerged as one of the first standardized approaches to evaluating the ecological footprint of laboratory procedures, particularly in chromatography [1] [8]. In the pharmaceutical industry, where analytical methods are routinely employed for quality control and therapeutic drug monitoring, understanding and applying the NEMI pictogram is crucial for transitioning toward more sustainable laboratory practices without compromising analytical performance [17].

The NEMI tool functions as a visual communication device, translating complex data about chemical usage, waste generation, and environmental hazards into an easily interpretable pictogram. This allows researchers, scientists, and drug development professionals to rapidly compare the greenness of multiple analytical methods [6] [7]. Its simplicity and accessibility have established NEMI as a starting point for environmental assessment within a broader strategy that often incorporates more comprehensive metrics.

Decoding the NEMI Pictogram: Structure and Criteria

The NEMI pictogram is a simple circle divided into four equal quadrants [17]. Each quadrant represents a specific environmental criterion, as detailed in Table 1. A quadrant is colored green only if the analytical method meets the associated environmental standard; otherwise, it remains blank (white) [1] [8]. This binary, pass-fail system is the core of NEMI's straightforward visual language.

Table 1: The Four Criteria of the NEMI Pictogram

| Quadrant | Criterion | Description | Requirement for Green Color |

|---|---|---|---|

| PBT | Persistent, Bio-accumulative, and Toxic | Assesses whether any chemicals used are on the EPA's PBT list [8]. | No chemicals used are PBT substances [1]. |

| Hazardous | Hazardous Waste | Evaluates if reagents are classified as hazardous waste [2]. | No solvents/reagents are on the RCRA D, F, P, or U hazardous waste lists [1]. |

| Corrosive | Corrosive | Determines the corrosiveness of the chemical environment [17]. | The pH of the sample or solvents is between 2 and 12 [1]. |

| Waste | Waste Quantity | Measures the total waste generated per analytical run [7]. | The waste amount is ≤ 50 g per sample analysis [1]. |

The following diagram illustrates the decision-making process for determining the final NEMI pictogram, from assessing each individual criterion to the final visual output.

Diagram: NEMI Pictogram Decision Workflow. This flowchart outlines the logical process for determining the color of each quadrant in the NEMI pictogram based on the four environmental criteria.

Experimental Protocol for NEMI Assessment

Implementing a NEMI assessment requires a systematic approach to evaluate an analytical method against the four established criteria. This protocol provides a step-by-step guide for researchers to consistently apply the NEMI tool to chromatographic methods.

Data Collection and Calculation

- Step 1: Compile a Chemical Inventory. List all solvents, reagents, and chemicals used in the analytical procedure, including those for sample preparation, mobile phase composition, and calibration [7].

- Step 2: Determine Total Waste Mass. Calculate the total mass of waste generated per analytical run. This includes all solvents, reagents, and consumables. The calculation is: Total Waste (g) = Σ (Volume of each solvent (mL) × Density (g/mL)) + mass of solid waste (g). A method is considered compliant if the total is ≤ 50 g [1] [8].

- Step 3: Measure or Calculate pH. Determine the pH of the final sample solution or the most extreme pH condition used in the procedure (e.g., pH of extraction solvents or mobile phase). A pH meter is typically used for this measurement. The method is compliant if the value is between 2 and 12, inclusive [1].

Reference Checking and Pictogram Creation

- Step 4: Screen for PBT Substances. Cross-reference all chemicals from Step 1 against the EPA's Toxic Release Inventory (TRI) PBT list. If any chemical is on the list, the PBT quadrant remains blank [8].

- Step 5: Screen for Hazardous Waste. Cross-reference all chemicals against the EPA's Resource Conservation and Recovery Act (RCRA) lists (D, F, P, and U). If any chemical appears on these lists, the Hazardous quadrant remains blank [1] [8].

- Step 6: Construct the NEMI Pictogram. Draw a circle and divide it into four equal quadrants. Label each quadrant (PBT, Hazardous, Corrosive, Waste). Based on the results from Steps 2-5, color the compliant quadrants green and leave non-compliant quadrants blank [2] [17].

NEMI in Practice: A Chromatographic Case Study

A published study evaluating chromatographic methods for the analysis of Empagliflozin provides a clear illustration of NEMI's application and limitations [17]. In this study, 26 different chromatographic methods were assessed using the NEMI tool.

The outcome was revealing: the majority of methods received an identical NEMI pictogram, with only the Corrosive and Waste quadrants colored green, while the PBT and Hazardous quadrants were consistently blank [17]. This result highlights a key finding in modern GAC: while contemporary methods often control waste and pH effectively, they frequently rely on solvents or reagents that are classified as hazardous or PBT, such as acetonitrile or methanol in the mobile phase [2] [7].

This case study demonstrates that while NEMI successfully identifies a common environmental challenge in HPLC methods, its binary and simplistic nature makes it difficult to differentiate between methods that are otherwise quite different in their consumption of reagents, energy use, or sample preparation workflow [17]. Consequently, a method that uses 100 mL of acetonitrile and one that uses 10 mL may receive the same NEMI score, as both would likely fail the hazardous criterion and generate similar waste mass above the 50 g threshold.

Successfully implementing a NEMI assessment requires access to specific informational resources and reagents. Table 2 below lists key reagents and their functional role in the context of green chromatography, along with crucial database links.

Table 2: Essential Research Reagents and Resources for NEMI Assessment

| Reagent/Resource | Function/Role in Analysis | Relevance to NEMI Assessment |

|---|---|---|

| Acetonitrile & Methanol | Common organic modifiers in reversed-phase HPLC mobile phases [7]. | Often cause the "Hazardous" quadrant to be blank due to classification. |

| Phosphate Buffers | Used to control pH of the mobile phase for separation of ionizable analytes [7]. | Critical for the "Corrosive" quadrant; pH must be between 2-12. |

| Water (HPLC Grade) | The greenest solvent, used as the weak mobile phase in reversed-phase HPLC [14]. | Positively contributes to greenness; non-hazardous and non-PBT. |

| EPA PBT List | Official list of Persistent, Bio-accumulative, and Toxic chemicals [8]. | Essential reference for checking the "PBT" quadrant criterion. |

| RCRA Hazardous Waste Lists (D, F, P, U) | Lists defining hazardous wastes under the Resource Conservation and Recovery Act [1]. | Essential reference for checking the "Hazardous" quadrant criterion. |

| NEMI Online Database | Publicly accessible database (www.nemi.gov) for environmental methods [6] [17]. | Primary portal for accessing official criteria and related method information. |

Comparative Analysis with Other Green Metrics

While NEMI provides an excellent introductory framework, it is most powerful when used as part of a suite of assessment tools. The field of GAC has evolved to include several metrics that offer more granular or comprehensive evaluations.

- Analytical Eco-Scale Assessment (ESA): This is a semi-quantitative tool that assigns an overall score out of 100. It starts with a perfect score of 100 and deducts penalty points for hazardous reagents, high energy consumption, and large waste generation [2] [6]. A score above 75 is considered excellent green. Unlike NEMI, it accounts for the amount and degree of hazard, providing better differentiation between methods [17].

- Green Analytical Procedure Index (GAPI): This tool uses a multi-colored pictogram (green, yellow, red) to evaluate the environmental impact of each step in the entire analytical procedure, from sample collection to final determination [2] [6]. It is more comprehensive than NEMI as it covers aspects like sample collection, preservation, and transportation, which NEMI omits [7].

- Analytical Greenness (AGREE) Metric: AGREE is a modern, software-based tool that evaluates methods against all 12 principles of GAC. It provides a digital score between 0 and 1 in the center of a circular pictogram, offering a balanced and user-friendly assessment [14]. It is considered one of the most advanced metrics currently available [14].

Table 3: Comparison of NEMI with Other Green Assessment Tools

| Feature | NEMI | Analytical Eco-Scale | GAPI | AGREE |

|---|---|---|---|---|

| Type of Output | Visual (4-quadrant pictogram) | Numerical score (0-100) | Visual (5-section pictogram) | Visual & Numerical (score 0-1) |

| Basis of Assessment | 4 criteria (PBT, Hazardous, Corrosive, Waste) | Penalty points for hazards, energy, waste | Multiple criteria across all analytical steps | 12 Principles of GAC |

| Ease of Use | Very easy, fast | Moderate, requires calculation | Complex, requires detailed method knowledge | Easy (uses free software) |

| Key Advantage | Quick visual comparison | Quantitative, allows ranking | Comprehensive, covers entire method | Holistic, aligns with GAC principles |

| Key Limitation | Qualitative, limited scope, low differentiating power [17] | Relies on expert judgment for penalties [14] | No overall score, can be subjective [14] | Does not fully cover pre-analytical steps [14] |

The NEMI pictogram remains a valuable entry-point tool for rapidly gauging the environmental profile of chromatographic methods. Its strength lies in its simplicity and ability to communicate core hazards at a glance. As demonstrated, its interpretation is straightforward once the four criteria are understood. However, the scientific community recognizes that its binary and limited scope is a significant drawback for thorough environmental benchmarking [2] [17].

For researchers and drug development professionals, the strategic path forward involves using NEMI as a first-pass filter rather than a standalone verdict. A robust greenness assessment protocol should triangulate results by complementing NEMI with more quantitative tools like the Analytical Eco-Scale and comprehensive frameworks like GAPI or AGREE [17] [7]. This multi-tool approach provides both the quick insight offered by NEMI and the nuanced, actionable data needed to genuinely reduce the ecological footprint of pharmaceutical analysis, thereby supporting the industry's vital journey toward greater sustainability.

Advantages and Limitations of the NEMI Framework

The National Environmental Methods Index (NEMI) is a foundational tool in the field of Green Analytical Chemistry (GAC), first developed in 2002 by the Methods and Data Comparability Board [1] [8]. It was created as one of the earliest systematic approaches to help scientists evaluate the environmental impact of analytical methods, including chromatographic procedures [14] [6]. NEMI functions as both a searchable database and a qualitative assessment tool, providing researchers with a mechanism to evaluate and select analytical methods based on their environmental footprint [1]. The primary purpose of NEMI is to offer a quick, visual representation of a method's greenness, allowing scientists to make more environmentally conscious decisions in method selection and development for drug analysis and other applications [6] [8].

The NEMI Assessment Framework

Core Principles and Pictogram Design

The NEMI framework employs a simple, visually intuitive pictogram system that enables rapid assessment of an analytical method's environmental performance [1]. The pictogram consists of a circle divided into four quadrants, each representing a specific environmental criterion. A quadrant is colored green only if the method meets the established benchmark for that criterion; if not, the quadrant remains uncolored [1] [8]. This binary (yes/no) approach allows for immediate visual interpretation of a method's environmental strengths and weaknesses without requiring complex calculations or specialized expertise [1].

The Four Assessment Criteria

Table 1: The Four Key Assessment Criteria in the NEMI Framework

| Criterion | Requirement for Green Coloring | Purpose | Regulatory Basis |

|---|---|---|---|

| PBT Substances | No chemicals used are on the Persistent, Bioaccumulative, and Toxic (PBT) list | Prevents use of environmentally persistent chemicals | EPA's Toxic Release Inventory (TRI) [8] |

| Hazardous Chemicals | No solvents or reagents are classified as hazardous waste | Reduces handling and disposal hazards | EPA's Resource Conservation and Recovery Act (RCRA) categories (D, F, P, U lists) [1] [8] |

| Corrosiveness | Sample pH remains between 2 and 12 throughout the procedure | Minimizes corrosion potential and environmental damage | - |

| Waste Generation | Total waste produced is ≤50 g per analysis | Encourages waste minimization and pollution prevention | - |

The four criteria work together to provide a comprehensive overview of the most significant environmental impacts associated with analytical methods, with particular relevance to chromatography procedures where solvent use and waste generation are substantial concerns [1] [18].

Experimental Protocol for Conducting NEMI Assessment

Sample NEMI Assessment of a Chromatographic Method

Protocol: Applying the NEMI Framework to a Chromatography Procedure

Objective: To systematically evaluate the greenness of a chromatographic method for pharmaceutical analysis using the NEMI framework.

Materials Required:

- Complete method documentation including reagents, volumes, and procedures

- Safety Data Sheets (SDS) for all chemicals

- pH measurement equipment

- Waste tracking system

Step-by-Step Procedure:

Chemical Inventory Assessment

- Create a comprehensive list of all chemicals, solvents, and reagents used in the analytical procedure

- Cross-reference each chemical against the EPA's PBT list (available at www.nemi.gov)

- Documentation: Record any PBT substances found. If none are present, the first quadrant qualifies for green coloring [1] [8]

Hazardous Waste Evaluation

pH Assessment

- Measure pH at each stage of the analytical procedure where aqueous solutions are used

- Determine if pH remains between 2 and 12 throughout the method

- Documentation: Record all pH measurements. If consistently between 2-12, the third quadrant qualifies for green coloring [1]

Waste Quantification

- Calculate total waste generated per analytical run, including:

- Sample preparation waste

- Mobile phase waste

- Cleaning solutions

- Consumables

- Ensure measurement includes all materials that require disposal

- Documentation: Sum total waste. If ≤50 g per analysis, the fourth quadrant qualifies for green coloring [1] [8]

- Calculate total waste generated per analytical run, including:

Pictogram Completion

- Color only those quadrants where all criteria are fully met

- Leave non-compliant quadrants blank (uncolored)

- Include the completed NEMI pictogram in method documentation

Validation:

- Repeat assessment for method variations or modifications

- Compare NEMI profiles of alternative methods to select the greenest option

- Use assessment during method development to improve environmental performance

Workflow Visualization

Diagram 1: NEMI Assessment Workflow. This flowchart illustrates the systematic process for evaluating an analytical method using the NEMI framework, from initial chemical inventory to final pictogram generation.

Advantages of the NEMI Framework

Practical Benefits for Chromatography Research

The NEMI framework offers several significant advantages that have contributed to its enduring relevance in analytical chemistry, particularly in chromatographic method development:

Simplicity and Accessibility: The straightforward pictogram approach requires minimal training to implement and interpret, making green chemistry principles accessible to researchers at all levels [1] [6]. The binary assessment system (green/uncolored) eliminates ambiguity and simplifies decision-making during method selection.

Rapid Visual Assessment: The color-coded pictogram enables immediate understanding of a method's environmental profile at a glance, facilitating quick comparisons between multiple methods [1]. This visual efficiency is particularly valuable in industrial settings where time constraints are significant.

Freely Accessible Database: NEMI provides a publicly available database (www.nemi.gov) containing over 800 analytical methods with their environmental profiles, offering a valuable resource for method selection and benchmarking [19] [6].

Early Integration Capability: The framework can be applied during initial method development stages, allowing researchers to identify and address environmental concerns before method validation [18]. This proactive approach is more efficient than retrospective assessment.

Educational and Regulatory Value

Educational Tool: NEMI serves as an effective introduction to green chemistry concepts for students and early-career researchers, building foundational awareness of environmental considerations in analytical science [1] [18].

Standardized Benchmarking: By establishing consistent criteria across different methodologies, NEMI enables objective comparison of diverse analytical approaches, supporting evidence-based selection of environmentally preferable methods [6].

Limitations and Constraints

Technical Limitations

Despite its utility, the NEMI framework possesses several limitations that restrict its comprehensiveness for modern green chemistry evaluation:

Qualitative Binary Assessment: The simple yes/no approach lacks granularity and cannot differentiate between degrees of greenness [14] [1]. Methods with minor violations receive the same assessment as those with major environmental concerns.

Limited Scope: NEMI evaluates only four environmental parameters, omitting other critical factors such as energy consumption, operator safety, reagent toxicity, and renewability of materials [14] [8]. This narrow focus provides an incomplete picture of a method's overall environmental impact.

No Lifecycle Considerations: The framework does not account for upstream environmental costs associated with reagent production, equipment manufacturing, or downstream waste treatment processes [14].

Inadequate for Modern Techniques: NEMI's criteria do not fully address the environmental aspects of emerging technologies such as microextraction techniques, capillary chromatography, or on-line sample preparation [19].

Practical Implementation Challenges

Table 2: Comparative Analysis of Green Assessment Tools

| Assessment Tool | Scoring System | Scope | Visual Output | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| NEMI | Qualitative (Binary) | 4 criteria | 4-quadrant circle | Simple, rapid visual assessment | Limited scope, no quantitative scoring [14] [1] |

| Analytical Eco-Scale | Semi-quantitative (0-100 points) | Reagents, energy, waste, hazards | Numerical score | Detailed penalty point system, enables fine differentiation | No visual component, requires expert judgment [14] [1] |

| GAPI | Semi-quantitative | Entire analytical process | 5-section pentagram | Comprehensive workflow assessment | Complex pictogram, subjective color assignment [14] [6] |

| AGREE | Quantitative (0-1 scale) | 12 GAC principles | Circular diagram with score | Comprehensive, combines score with visual output | Does not sufficiently address pre-analytical processes [14] |

Oversimplification Risk: The binary nature may lead researchers to overlook incremental improvements that don't change the pictogram but still reduce environmental impact [14]. Methods showing partial improvement in environmental performance may not receive appropriate recognition.

Lack of Guidance: NEMI identifies environmental concerns but provides no specific direction for method improvement or optimization, limiting its utility in method development [1].

Subjectivity in Waste Calculation: The ≤50g waste criterion can be interpreted differently across laboratories, potentially compromising comparability between assessments [1].

Complementary Assessment Tools and Research Reagents

Advanced Green Assessment Metrics

To address NEMI's limitations, researchers should employ complementary assessment tools that provide more comprehensive environmental evaluation:

Analytical Eco-Scale: A semi-quantitative tool that assigns penalty points for non-green practices, resulting in a numerical score where 100 represents an ideal green analysis [1] [6]. This approach enables more nuanced differentiation between methods.

Green Analytical Procedure Index (GAPI): Extends assessment to the entire analytical process from sample collection to final detection using a multi-section color-coded pictogram [14] [19]. Particularly valuable for evaluating complex analytical workflows.

AGREE and AGREEprep: Comprehensive metrics based on the 12 principles of GAC that provide both quantitative scores (0-1) and visual outputs [14] [19]. AGREEprep specifically focuses on sample preparation, often the most environmentally impactful stage.

White Analytical Chemistry (WAC): An emerging approach that balances environmental sustainability with analytical performance and practical utility, addressing the multi-dimensional nature of method optimization [8].

Research Reagent Solutions for Greener Chromatography

Table 3: Essential Reagents for Green Chromatography Methods

| Reagent Category | Green Alternatives | Function | Environmental Benefit |

|---|---|---|---|

| Extraction Solvents | Ethanol, ethyl acetate, cyclopentyl methyl ether | Sample preparation, extraction | Reduced toxicity and environmental persistence compared to chlorinated solvents [19] |

| Mobile Phase Modifiers | Methanol, ethanol, acetone | HPLC mobile phase components | Lower toxicity and better biodegradability vs. acetonitrile [18] |

| Green Solvents | Ionic liquids, deep eutectic solvents, bio-derived solvents | Extraction, reaction media | Reduced volatility, lower toxicity, renewable sourcing [19] |

| Sorbents | Biobased sorbents, molecularly imprinted polymers | Sample cleanup, extraction | Enhanced selectivity, reduced solvent consumption [19] |

The NEMI framework represents a pioneering effort to introduce environmental considerations into analytical method evaluation, particularly for chromatography procedures in pharmaceutical research. Its straightforward pictogram approach provides an accessible entry point for green chemistry implementation, enabling rapid assessment and comparison of methods based on four key environmental criteria [1] [6]. However, its qualitative nature and limited scope constrain its utility for comprehensive environmental assessment [14] [8].

For contemporary chromatography research, NEMI serves most effectively as a preliminary screening tool rather than a comprehensive assessment system. Researchers should employ it in conjunction with more advanced metrics such as AGREE, GAPI, or Analytical Eco-Scale to obtain a multidimensional understanding of their method's environmental impact [14] [19] [6]. The future of green assessment in chromatography lies in integrated approaches that balance environmental considerations with analytical performance, practical feasibility, and economic constraints—a concept embodied by the emerging White Analytical Chemistry framework [8].

The ongoing evolution of green assessment tools reflects analytical chemistry's growing commitment to sustainability, with NEMI establishing the foundational principles upon which more sophisticated evaluation systems continue to build [14]. As the field advances, the integration of lifecycle assessment, carbon footprint calculations, and more nuanced environmental impact metrics will further enhance our ability to develop truly sustainable chromatographic methods for pharmaceutical analysis and drug development.

Implementing NEMI Assessment in Chromatographic Workflows

Step-by-Step Guide to NEMI Evaluation for HPLC Methods

The National Environmental Methods Index (NEMI) is a foundational and user-friendly tool designed for the rapid assessment of the environmental impact of analytical methods, including High-Performance Liquid Chromatography (HPLC) procedures [2] [14]. Its development was motivated by the need to provide analytical chemists with a simple, visual means to evaluate the greenness of their methods, aligning with the broader principles of Green Analytical Chemistry (GAC) [5] [14]. The core strength of NEMI lies in its straightforward pictogram, which offers an at-a-glance summary of a method's environmental performance based on four key criteria [2] [20].

This guide provides a detailed, step-by-step protocol for applying the NEMI assessment to HPLC methods, enabling researchers, scientists, and drug development professionals to systematically evaluate and improve the environmental sustainability of their chromatographic procedures within the context of modern green chemistry principles.

Principles of the NEMI Assessment

The NEMI assessment tool operates on a binary, pass/fail system for four environmental criteria, visualized as a pictogram divided into four quadrants [2] [14]. A quadrant is colored green only if the method satisfies all the requirements associated with that criterion. If any requirement is not met, the quadrant remains blank (white). The four criteria evaluated are:

- PBT: The method does not use reagents containing Persistent, Bio-accumulative, and Toxic substances.

- Hazardous: The method does not use reagents that the United States Environmental Protection Agency (EPA) classifies as hazardous.

- Corrosive: The method does not use reagents with a pH ≤ 2 or ≥ 12.

- Waste: The method generates ≤ 50 g of waste per sample analysis [2].

A method is considered to have a better environmental profile if more quadrants are filled in green. However, it is crucial to note that while NEMI is valued for its simplicity and speed, this same simplicity is its primary limitation, as it does not distinguish degrees of greenness or account for the entire analytical workflow, such as sample preparation and energy consumption [2] [14].

Step-by-Step Evaluation Protocol

Step 1: Data Compilation for the Target HPLC Method

The first step involves gathering all necessary data on the reagents and materials used in the HPLC method. A detailed methodology is essential for an accurate assessment.

- Action: Compile a complete inventory of all chemicals, solvents, and reagents used in the method, including their quantities per analysis. This includes the mobile phase components, standards, sample preparation solvents, and any cleaning solutions.

- Essential Information:

- Names and Chemical Abstracts Service (CAS) numbers of all substances.

- Exact volumes or masses used for a single sample analysis.

- The pH of the final solutions or mobile phases.

Step 2: Criterion 1 - PBT (Persistent, Bio-accumulative, and Toxic) Assessment

This step evaluates whether the method uses any PBT substances.

- Action: For each chemical in your inventory, consult official lists from regulatory bodies like the US EPA to determine if it is classified as persistent, bio-accumulative, and toxic.

- Evaluation Rule: If ANY chemical used in the method is listed as a PBT substance, this quadrant fails and remains white. If NONE of the chemicals are PBTs, this quadrant passes and is colored green [2].

- Example: A method using the solvent n-hexane would fail this criterion, as it is classified as hazardous [5].

Step 3: Criterion 2 - Hazardous Substance Assessment

This step identifies the use of any hazardous reagents.

- Action: Cross-reference all chemicals with the US EPA's list of hazardous wastes (e.g., F-list, K-list, P-list, U-list).

- Evaluation Rule: If ANY chemical is EPA-listed as hazardous, this quadrant fails. If NONE are listed, the quadrant passes and is colored green [2].

Step 4: Criterion 3 - Corrosivity Assessment

This step assesses whether the method employs highly acidic or basic conditions.

- Action: Measure or calculate the pH of all solutions used throughout the analytical process. Identify the most extreme pH value (lowest or highest).

- Evaluation Rule: If ANY solution has a pH ≤ 2 or ≥ 12, the quadrant fails. If ALL solutions have a pH between 2 and 12, the quadrant passes and is colored green [2].

- Example: An HPLC mobile phase buffered at pH 5.5, like water:ethanol (90:10 v/v, pH=5.5), would pass this criterion [5].

Step 5: Criterion 4 - Waste Generation Assessment

This step quantifies the total waste produced per sample.

- Action: Sum the masses (in grams) of all solvents, reagents, and consumables used for a single sample analysis. For liquids, assume a density of 1 g/mL for aqueous solutions or consult safety data sheets for organic solvents.

- Evaluation Rule: If the total waste generated is > 50 g, the quadrant fails. If the total waste is ≤ 50 g, the quadrant passes and is colored green [2].

- Example: A method using 20 mL of a solvent with a density of 0.79 g/mL would contribute 15.8 g of waste from that solvent alone.

Step 6: Pictogram Generation and Interpretation

The final step is to synthesize the results from Steps 2-5 into the final NEMI pictogram.

- Action: Draw a circle and divide it into four equal quadrants. Label each quadrant with one criterion: PBT, Hazardous, Corrosive, and Waste.

- Coloring: For each criterion that passed (i.e., met the green condition), fill the corresponding quadrant with the color green. Leave any failed quadrant white.

- Interpretation: A fully green pictogram indicates the method meets all four environmental criteria. The presence of white quadrants quickly highlights specific areas where the method has a higher environmental impact and could be improved.

The following workflow diagram summarizes the step-by-step NEMI evaluation process:

Case Study: NEMI Evaluation of HPLC Methods for Antibiotic Analysis

To illustrate the practical application of this protocol, consider a published study that evaluated three chromatographic methods for quantifying sulfadiazine and trimethoprim in meat samples [5].

- Method I: Conventional RP-HPLC using a mobile phase of water:ethanol (90:10 v/v, pH=5.5).

- Method II: Micellar Liquid Chromatography (MLC) using 0.1 M SDS, 12% isopropanol in 0.1 N citric acid (pH=5.5).

- Method III: UPLC-MS/MS using ammonium acetate:acetonitrile (80:20 v/v, pH=5.5).

The evaluation of these methods using the NEMI protocol yielded the following results:

Table 1: NEMI Evaluation Results for Case Study Methods [5]

| Method | PBT | Hazardous | Corrosive | Waste | Overall Greenness Profile |

|---|---|---|---|---|---|

| Method I (Conventional HPLC) | Pass (Green) | Pass (Green) | Pass (Green) | Fail (White) | Moderate |

| Method II (MLC) | Pass (Green) | Pass (Green) | Pass (Green) | Pass (Green) | Greener |

| Method III (UPLC-MS/MS) | Pass (Green) | Pass (Green) | Pass (Green) | Pass (Green) | Greener |

Interpretation: The study concluded that Methods II (MLC) and III (UPLC-MS/MS) were the greenest, as their NEMI pictograms were fully green [5]. Method I likely failed the waste criterion due to higher solvent consumption typical of conventional HPLC, demonstrating how NEMI can guide analysts towards more sustainable techniques like MLC or UPLC, which use less solvent and generate less waste.

Comparison of NEMI with Other Greenness Assessment Tools

While NEMI is an excellent starting point for greenness assessment, it is one of many available tools. A comprehensive thesis on chromatography greenness assessment should recognize that more recent tools offer deeper insights.

Table 2: Comparison of NEMI with Other Green Assessment Tools [2] [14] [20]

| Tool Name | Type of Output | Scope of Assessment | Key Advantages | Key Limitations |

|---|---|---|---|---|

| NEMI | Pictogram (4 quadrants) | Reagent toxicity & waste | Very simple, fast, visual | Binary output; limited scope; ignores energy & toxicity [2] |

| Analytical Eco-Scale | Numerical score (0-100) | Reagents, energy, waste | Quantitative; allows method comparison [2] | Relies on expert judgment for penalties [14] |

| GAPI | Pictogram (5 pentagrams, multi-color) | Full method from sampling to detection | Comprehensive; visualizes bottlenecks [2] [14] | No single final score; some subjectivity [14] |

| AGREE | Pictogram (12 segments) & numerical score (0-1) | Full method based on 12 GAC principles | Comprehensive, user-friendly, provides a final score [2] [14] | Does not fully account for pre-analytical processes [14] |

As noted in a study on Remdesivir methods, "NEMI is the easiest and fastest greenness evaluation tool; however, the information it provides is particularly of limited scope and sometimes inaccurate" [2]. For a robust environmental impact assessment, using NEMI in conjunction with more comprehensive tools like AGREE or GAPI is highly recommended.

The Scientist's Toolkit: Essential Reagents and Materials

When designing or modifying an HPLC method for improved greenness and NEMI profile, the choice of reagents is critical. The following table lists key solutions and their functions in the context of green chemistry.

Table 3: Research Reagent Solutions for Greener HPLC Methods

| Reagent / Material | Function in HPLC | Green Chemistry Considerations |

|---|---|---|

| Ethanol | Organic solvent in mobile phase | Biobased, less hazardous alternative to acetonitrile [5] |

| Micellar Solutions (e.g., SDS) | Mobile phase in Micellar Liquid Chromatography (MLC) | Low toxicity, biodegradable, reduces organic solvent use [5] |

| Water (at various pH) | Aqueous component of mobile phase | Non-toxic, non-hazardous, ideal green solvent |

| Ammonium Acetate Buffer | Buffer for mobile phase | Low toxicity, suitable for LC-MS applications [5] |

| Methanol | Organic solvent in mobile phase | Preferable to acetonitrile from a green perspective, but still hazardous [21] |

| UPLC Columns (e.g., 50 x 2.1 mm, 1.7 µm) | Stationary phase for separation | Smaller particle sizes enable faster runs and lower solvent consumption [5] |

Advanced Concepts and Future Perspectives

The field of green analytical chemistry is rapidly evolving beyond the foundational principles captured by NEMI. The concept of White Analytical Chemistry (WAC) has emerged as a holistic framework that integrates environmental impact (the green component) with analytical performance quality (the red component) and practical & economic feasibility (the blue component) [22] [23] [24]. A truly "white" method represents an ideal balance between these three dimensions.

Furthermore, new assessment tools continue to be developed. AGREEprep focuses specifically on the environmental impact of sample preparation steps [25]. The Carbon Footprint Reduction Index (CaFRI) estimates carbon emissions associated with analytical procedures, and the Analytical Green Star Analysis (AGSA) provides an intuitive star-shaped diagram for multi-criteria assessment [14]. Staying informed of these advancements ensures that research in chromatography remains at the forefront of both scientific and environmental best practices.

Within the framework of green analytical chemistry (GAC), the environmental profiling of analytical methods is crucial for sustainable pharmaceutical development [14]. This case study applies the National Environmental Methods Index (NEMI) to assess a published high-performance liquid chromatography (HPLC) method for the simultaneous determination of alectinib and its impurity, 5-trifluoroacetate [24]. Alectinib, a second-generation anaplastic lymphoma kinase inhibitor, is a critical therapeutic for non-small cell lung cancer (NSCLC), making quality control of its formulation essential [24] [26]. The NEMI tool provides a simple, pictogram-based assessment, serving as a foundational greenness metric for evaluating the environmental impact of chromatographic procedures [1].

Background and Context

Alectinib as a Therapeutic Agent

Alectinib (marketed as Alecensa) is an oral ATP-competitive ALK tyrosine kinase inhibitor approved for the treatment of ALK-positive metastatic NSCLC [24] [26]. Its potency is approximately five times greater than the first-generation inhibitor crizotinib, and it is effective against various ALK mutations that confer resistance to crizotinib [24]. The safety and efficacy of drugs like alectinib are partially dependent on controlling impurities in the active pharmaceutical ingredient and final dosage form [24].

Green Analytical Chemistry and the Role of NEMI

Green Analytical Chemistry aims to minimize the environmental impact of analytical activities by reducing waste, energy consumption, and the use of hazardous reagents [27] [14]. The National Environmental Methods Index (NEMI) is one of the oldest and simplest metrics for this purpose [1]. Its pictogram is a circle divided into four quadrants, each representing a different environmental criterion. A quadrant is colored green only if the method meets that specific criterion [1].

NEMI Assessment Workflow

Chromatographic Method

The assessed HPLC method was developed for the simultaneous analysis of alectinib and its impurity in Alecensa capsules (150 mg alectinib/capsule) [24].

- Stationary Phase: Ascentis Express 90 Å C8 column (10 cm × 4.6 mm, 2.7 µm) [24].

- Mobile Phase: Gradient system with Acetonitrile and Ammonium Acetate buffer [24].

- Detection: Photodiode Array (PDA) detector at 269 nm [24].

- Optimization: The method was optimized using a Box-Behnken experimental design, with optimal conditions selected via a desirability function [24].

Validation Procedure

The method was validated according to the International Council for Harmonisation (ICH) Q2(R2) guidelines, demonstrating satisfactory analytical performance [24].

- Linearity, LOD, and LOQ:

- Alectinib: LOD 0.1 µg/mL, LOQ 0.3 µg/mL.

- 5-trifluoroacetate impurity: LOD 0.3 µg/mL, LOQ 0.5 µg/mL [24].

- Recovery Study: Performed using the commercial capsule formulation, yielding high recovery percentages, confirming the method's precision and accuracy [24].

- Measurement Uncertainty: A bottom-up approach was used to estimate uncertainty, identifying and quantifying sources affecting the chromatographic responses [24].

NEMI Assessment and Data Presentation

Application of NEMI Criteria

The NEMI assessment of the HPLC method for alectinib is based on its compliance with four key criteria [1]:

Table 1: NEMI Assessment Criteria and Method Compliance

| Criterion | Requirement for Green Profile | Method Compliance |

|---|---|---|

| PBT Chemicals | No persistent, bioaccumulative, and toxic (PBT) chemicals used. | Not Compliant (Likely due to reagents/solvents) |

| Hazardous Waste | No solvents from "D", "F", "P", or "U" hazardous waste lists. | Not Compliant (Likely due to acetonitrile) |

| Corrosivity (pH) | Sample pH between 2 and 12. | Compliant (Ammonium acetate buffer) |

| Waste Amount | Total waste generated is ≤ 50 g per sample. | Not Compliant |

NEMI Pictogram and Interpretation

Based on the criteria in Table 1, the NEMI pictogram for this method is:

NEMI Pictogram for Alectinib HPLC Method

The single green quadrant indicates the method is only partially compliant with green chemistry principles. The primary environmental concerns arise from the use of potentially hazardous solvents and the generation of more than 50 g of waste [1].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Research Reagent Solutions for HPLC Analysis of Alectinib

| Item | Function/Description |

|---|---|

| Ascentis Express C8 Column | Core stationary phase for chromatographic separation. The 2.7 µm particle size provides high efficiency [24]. |

| Acetonitrile | Organic modifier in the mobile phase for gradient elution, critical for resolving alectinib and its impurity [24]. |

| Ammonium Acetate | Source for the aqueous buffer component of the mobile phase, helping to control pH and improve peak shape [24]. |

| Alectinib Reference Standard | High-purity material used for calibration, quantification, and method validation [24]. |

| 5-trifluoroacetate Impurity Standard | High-purity impurity standard essential for specificity testing and quantifying the impurity [24]. |

| Alecensa Capsules | The commercial drug product (150 mg alectinib/capsule) used as the real-world sample matrix for the method [24]. |

The NEMI assessment provides a rapid, initial evaluation of the environmental profile of the HPLC method for alectinib analysis. The results indicate that while the method is analytically sound for its intended purpose, there is significant potential for improvement from a green chemistry perspective. Key areas for future work include investigating the replacement of hazardous solvents with safer alternatives and implementing strategies for waste reduction, such as miniaturization or recycling. For a more comprehensive sustainability assessment, the use of advanced metrics like AGREE, GAPI, or the White Analytical Chemistry (WAC) model is recommended, as they offer a more nuanced evaluation encompassing analytical performance and practical applicability alongside environmental impact [24] [14] [1].

The National Environmental Methods Index (NEMI) provides a foundational framework for evaluating the environmental impact of analytical methods. Although newer metrics like AGREE and GAPI have emerged with more comprehensive scoring systems, NEMI's straightforward approach focuses on four key criteria: persistent, bioaccumulative, or toxic (PBT) chemicals; hazardous waste generation; corrosive pH levels; and waste quantity [28]. In the context of High-Performance Thin-Layer Chromatography (HPTLC), applying NEMI principles means selecting solvent systems and developing protocols that minimize environmental impact while maintaining analytical performance.

The comparison between normal-phase (NP) and reversed-phase (RP) HPTLC is particularly relevant for green analytical chemistry. NP-HPTLC typically utilizes a polar stationary phase (e.g., silica gel) with non-polar to moderately polar mobile phases. In contrast, RP-HPTLC employs a non-polar stationary phase (e.g., C18-bonded silica) with aqueous-organic mobile phases [29] [30]. This fundamental difference in separation mechanics directly influences their environmental footprint, method practicality, and alignment with NEMI's criteria for greener analytical procedures.

Theoretical Foundations and Separation Mechanisms

Normal-Phase HPTLC

In normal-phase chromatography, the stationary phase is more polar than the mobile phase. Retention is governed by adsorption kinetics and the affinity of analytes for the polar sites on the stationary phase, typically silica gel (Si–OH groups). The separation of analytes is primarily based on their polarity, with more polar compounds exhibiting stronger retention and higher Rf values [30]. Selectivity can be finely tuned by adjusting the polarity of the mobile phase through the addition of polar modifiers such as ethyl acetate or alcohols.

Reversed-Phase HPTLC