Microwave Synthesis of Metal Nanoparticles: A Sustainable Methodology for Advanced Biomedical Applications

This article provides a comprehensive analysis of microwave-assisted synthesis (MAS) as a sustainable and efficient methodology for producing metal nanoparticles.

Microwave Synthesis of Metal Nanoparticles: A Sustainable Methodology for Advanced Biomedical Applications

Abstract

This article provides a comprehensive analysis of microwave-assisted synthesis (MAS) as a sustainable and efficient methodology for producing metal nanoparticles. Tailored for researchers, scientists, and drug development professionals, it explores the fundamental principles of microwave heating that enable rapid, uniform nucleation and reduced energy consumption. The scope covers foundational concepts, detailed protocols for synthesizing noble and non-noble metal nanoparticles, and strategies for troubleshooting and optimizing key parameters like size and shape. A critical validation of MAS against conventional methods is presented, using green chemistry metrics and performance data to highlight its advantages in creating nanoparticles for cutting-edge applications in drug delivery, biosensing, and antimicrobial therapies.

Microwave Synthesis Fundamentals: Principles, Mechanisms, and Green Chemistry Advantages

Core Concepts of Microwave-Assisted Synthesis

Microwave-Assisted Synthesis (MAS) is a sustainable chemical processing method that utilizes microwave irradiation to intensify various chemical processes, particularly in nanomaterial fabrication [1] [2]. This technique employs electromagnetic energy within the 0.3–300 GHz spectrum, with 2.45 GHz being the standard frequency in laboratory settings [2] [3]. Unlike conventional heating methods that rely on surface-to-core thermal transfer through conduction and convection, MAS delivers energy directly and volumetrically to reactants, creating internal heat generation through molecular-level interactions [1] [3].

The primary mechanism of microwave heating involves dielectric heating, where polar molecules or ions in the reaction mixture absorb microwave radiation and align with the oscillating electric field [1] [3]. This alignment causes rapid molecular rotation and subsequent heat generation throughout the entire reaction volume, enabling simultaneous molecular agitation via dipole oscillation and charged particle migration [1]. This internal energy deposition theoretically achieves homogeneous temperature profiles and accelerated reaction kinetics, though practical implementation can be affected by vessel configuration, reaction scale, and material dielectric characteristics [1].

Table 1: Key Advantages of Microwave-Assisted Synthesis Over Conventional Methods

| Parameter | Microwave-Assisted Synthesis | Conventional Synthesis |

|---|---|---|

| Heating Mechanism | Volumetric/internal heating | Conductive/surface-to-core heating |

| Heating Rate | Very rapid (150–250°C in <1 minute) | Slow (30+ minutes for similar temperatures) |

| Energy Transfer | Direct electromagnetic energy transfer | Sequential energy migration |

| Reaction Times | Minutes | Hours to days |

| Temperature Profiles | Potentially uniform throughout volume | Thermal gradients inevitable |

| Energy Consumption | Significant reduction | Higher energy requirements |

| Selectivity | Often improved | Typically standard |

Additional heating mechanisms include Ohmic loss from free charge currents in conductive materials like metals and semiconductors, and magnetic loss from vortex currents excited by magnetic fields [2]. For metal nanoparticles supported on solid carriers, microwave absorption is also influenced by the carrier materials, with carbon and transition metal oxides heating effectively, while aluminum, magnesium, and silicon oxides show limited heating capacity [2].

Historical Context and Development

The foundation of microwave-assisted chemistry was established in 1986 through two independent pioneering studies. Gedye and colleagues in Canada, alongside Giguere, Majetich, and colleagues in the United States, demonstrated that organic reactions performed in domestic microwave ovens could be dramatically accelerated, often with higher yields and cleaner profiles compared to conventional heating methods [3]. These seminal reports marked the birth of Microwave-Assisted Organic Synthesis (MAOS), though early adoption was limited due to safety concerns, poor reproducibility, and lack of specialized equipment [3].

A significant breakthrough occurred in the mid-1990s with the introduction of dedicated microwave reactors that provided precise control over temperature, pressure, and power [3]. This technological advancement enabled systematic studies of microwave effects and expanded the scope of transformations that could be reliably performed under microwave irradiation. By the early 2000s, MAOS had matured into a widely accepted methodology, with comprehensive reviews and mechanistic discussions consolidating its theoretical foundations and practical advantages [3].

The initial focus on organic synthesis gradually expanded to include nanomaterials, with the first publications on metal nanoparticle synthesis using microwave heating appearing in the 1990s [2]. Continued development throughout the 2000s-2020s established MAS as a versatile approach for fabricating various nanomaterials, including metal nanoparticles, metal oxides, carbon-based quantum dots, and nanocomposites with tailored properties for numerous applications [1].

Experimental Protocols: Representative Examples

Protocol 1: Microwave-Assisted Green Synthesis of Silver Nanoparticles (AgNPs) Using Plant Extracts

This protocol adapts the methodology reported for synthesizing AgNPs using Trigonella hamosa L. leaf extract [4].

Materials and Equipment:

- Microwave reactor with temperature and pressure control

- Silver nitrate (AgNO₃) solution (1-10 mM)

- Aqueous leaf extract of Trigonella hamosa L. (or alternative plant species)

- Distilled deionized water

- Centrifuge and characterization equipment (UV-Vis, TEM, XRD)

Procedure:

- Extract Preparation: Prepare aqueous leaf extract by boiling 10 g of clean, dried leaves in 100 mL distilled water for 15 minutes. Filter through Whatman No. 1 filter paper.

- Reaction Mixture: Mix 10 mL of plant extract with 90 mL of 1 mM AgNO₃ solution in a dedicated microwave reaction vessel.

- Microwave Irradiation: Subject the mixture to microwave irradiation at 2.45 GHz using the following parameters:

- Power: 300-800 W

- Temperature: 60-90°C

- Time: 1-10 minutes

- Pressure: Maintain atmospheric pressure

- Product Recovery: Centrifuge the resulting solution at 12,000 rpm for 20 minutes. Wash the pellet with distilled water and repeat centrifugation.

- Characterization: Resuspend nanoparticles in distilled water and characterize using UV-Vis spectroscopy (SPR peak at ~430 nm), TEM (size distribution), and XRD (crystallinity).

Key Parameters for Optimization:

- Plant extract concentration affects reduction rate and nanoparticle size

- Microwave power and irradiation time control nucleation and growth

- Higher power and shorter times typically yield smaller nanoparticles

Protocol 2: Microwave Solvothermal Synthesis (MSS) of Doped Metal Oxide Nanocrystals

This protocol outlines the synthesis of aluminum-doped ZnO (AZO) nanocrystals in non-polar media for IR emissivity modulation devices [5].

Materials and Equipment:

- Microwave solvothermal synthesis system

- Metal precursors (zinc and aluminum salts)

- Hydrocarbon solvent (non-polar medium)

- Reducing/stabilizing agents

- Inert atmosphere capability

Procedure:

- Precursor Preparation: Dissolve appropriate zinc and aluminum precursors in hydrocarbon solvent at desired molar ratios (typically 1-5% doping).

- Reaction Setup: Transfer solution to microwave-compatible vessel under inert atmosphere.

- Microwave Processing: Apply microwave irradiation with controlled ramp to target temperature (typically 150-300°C).

- Crystallization Control: Maintain temperature for 5-60 minutes to control nanocrystal growth.

- Product Isolation: Cool rapidly and precipitate nanocrystals using appropriate antisolvent.

- Purification: Wash multiple times with solvent and characterize.

Table 2: Essential Research Reagent Solutions for MAS

| Reagent Category | Specific Examples | Function in MAS | Key Considerations |

|---|---|---|---|

| Metal Precursors | AgNO₃, HAuCl₄, Zn acetate, Ta₂O₅ | Source of metallic elements for nanoparticle formation | Concentration affects nucleation rate and final particle size |

| Solvents | Water, ethylene glycol, hydrocarbon solvents | Reaction medium with specific dielectric properties | Polar solvents (high dielectric constant) absorb MW energy efficiently |

| Reducing Agents | Plant extracts, trisodium citrate, ascorbic acid | Convert metal ions to elemental nanoparticles | Biological reducing agents offer greener alternatives |

| Stabilizing/Capping Agents | CTAB, alkanethiols, bovine serum albumin | Control particle growth and prevent aggregation | Affect surface chemistry and biological compatibility |

| Dopants | Aluminum salts for ZnO doping | Modify electronic and optical properties | Concentration critical for tuning material properties |

| Structure-Directing Agents | Molten salts, templates | Control morphology and crystal structure | Enable formation of rods, wires, or other anisotropic shapes |

In the context of microwave-assisted synthesis (MAS) of metal nanoparticles, a critical methodology in modern nanotechnology and drug development, understanding the core heating mechanisms is paramount for achieving precise control over reaction kinetics and product characteristics. Microwave heating distinguishes itself from conventional thermal methods through its ability to generate heat internally within the reaction mixture, via mechanisms such as dipole polarization, ionic conduction, and specific interfacial effects [6] [1]. These mechanisms enable rapid, uniform heating, often reducing reaction times from hours to minutes while improving product yield and uniformity, which is particularly valuable for synthesizing metal nanoparticles for biomedical applications [7] [8]. This document provides a detailed theoretical and practical framework for leveraging these mechanisms in experimental protocols for metal nanoparticle synthesis.

Theoretical Foundations of Microwave Heating

Dipole Polarization

Dipolar polarization is a primary heating mechanism in microwave-assisted synthesis. It involves the physical rotation of polar molecules that possess a permanent electrical dipole moment [9] [10]. When exposed to an oscillating electromagnetic field, these molecules, such as water, alcohols, and dimethylformamide (DMF), continuously attempt to align themselves with the rapidly changing electric field. This molecular rotation occurs at a frequency of 2.45 billion times per second in a standard microwave system operating at 2.45 GHz [6]. The resulting molecular friction, as rotating molecules collide and interact with neighboring molecules, converts kinetic energy into thermal energy, thereby heating the material volumetrically [9] [10]. This mechanism is most effective for materials with a high dielectric loss factor [9].

Ionic Conduction

The ionic conduction mechanism contributes to heating through the movement of dissolved ions (e.g., Na⁺, Cl⁻, H⁺) present in the reaction medium [6]. Under the influence of the microwave's electric field, these charged particles accelerate and move translationally through the solvent, constantly reversing direction as the field oscillates [6]. The resulting collisions between these moving ions and surrounding solvent molecules generate heat. The efficiency of this heating mechanism is influenced by the ion's charge, size, and conductivity. Notably, this mechanism can lead to localized superheating at catalytic centers, significantly enhancing reaction rates in certain catalytic cycles [11]. In conductive liquids, a related mechanism known as "ion-drag" can also cause significant heating, even at lower frequencies [9].

Interfacial Heating and Kapitza Resistance

At the nanoscale, particularly at the interface between a solid material (e.g., a growing nanoparticle or a reactor wall) and a liquid medium, a thermal barrier known as interfacial thermal resistance or Kapitza resistance exists [12]. This resistance arises from the scattering of thermal energy carriers (e.g., phonons or electrons) due to a mismatch in the vibrational properties of the two materials, leading to a temperature discontinuity at the interface [12]. Recent molecular dynamics simulations have shown that an external electric field, such as that generated in microwave heating, can significantly reduce this Kapitza resistance—by up to 78.4% in copper-water systems with dissolved ions [13]. This enhancement is attributed to improved phonon coupling at the interface, which facilitates more efficient heat transfer from the solution to the nascent nanoparticles, potentially influencing nucleation and growth rates [13].

Table 1: Comparative Analysis of Microwave Heating Mechanisms

| Feature | Dipolar Polarization | Ionic Conduction |

|---|---|---|

| Primary Actor | Polar molecules (e.g., H₂O, EtOH) [6] | Dissolved ions (e.g., Na⁺, Cl⁻) [6] |

| Molecular Motion | Molecular rotation [9] [6] | Translational ion movement [6] |

| Key Parameter | Dielectric loss factor of solvent [9] | Ionic strength and conductivity of solution [6] |

| Impact on Catalysis | General bulk heating [1] | Selective heating of ionic catalysts; localized superheating [11] |

Experimental Protocols for Metal Nanoparticle Synthesis

Protocol: Microwave-Assisted Synthesis of Gold Nanoparticle Composites

This protocol outlines the synthesis of a gold nanoparticle-integrated carbon sphere and graphene oxide composite (AuNPs@Cs-TA@GO), demonstrating the synergistic action of dipole polarization and ionic conduction [8].

Application Note: This multifunctional composite is suitable for colorimetric ascorbic acid detection and exhibits strong antibacterial activity against pathogens like S. aureus and V. parahaemolyticus [8].

Materials and Reagents

Table 2: Research Reagent Solutions for AuNPs@Cs-TA@GO Synthesis

| Reagent/Material | Function/Note | Source Example |

|---|---|---|

| Tetrachloroauric(III) acid trihydrate (HAuCl₄·3H₂O) | Gold precursor; source of Au³⁺ ions [8] | Merck, Acros Organic |

| Tannic Acid (C₇₆H₅₂O₄₆) | Acts as both carbon sphere precursor and reducing agent [8] | Merck, Acros Organic |

| Graphene Oxide (GO) Sheets | Support material; provides high surface area and functional groups for nanoparticle stabilization [8] | Synthesized in-lab via Hummer's method |

| Deionized Water | Solvent; polar molecule for dipole rotation heating [8] | N/A |

Procedure

- Solution Preparation: In a dedicated microwave reaction vessel, prepare a homogeneous solution by dissolving tannic acid (e.g., 50 mg) in deionized water (e.g., 20 mL) [8].

- Precursor Addition: Under constant stirring, add an aqueous solution of HAuCl₄ (e.g., 5 mL of 10 mM) to the tannic acid solution. The mixture will begin to change color.

- Microwave Irradiation: Securely cap the vessel and place it in the microwave synthesizer. Program the instrument with the following parameters:

- Temperature: 90°C

- Hold Time: 10 minutes

- Ramp Time: 2-3 minutes

- Stirring: Continuous, high speed [8].

- Composite Formation: The rapid heating via dipole rotation of water and ionic conduction from Au³⁺/Cl⁻ ions will quickly reduce gold ions and form carbon spheres embedded with gold nanoparticles (AuNPs@Cs-TA) [8].

- Integration with GO: After the reaction cycle and cooling, mix the resulting AuNPs@Cs-TA dispersion with a pre-synthesized aqueous suspension of graphene oxide (GO).

- Purification: Isolate the final AuNPs@Cs-TA@GO composite by centrifugation (e.g., 12,000 rpm for 15 minutes), followed by repeated washing with water and ethanol, then dry under vacuum [8].

Characterization and Analysis

- Particle Size & Morphology: Analyze via High-Resolution Transmission Electron Microscopy (HR-TEM). Expected outcome: spherical AuNPs with a uniform size distribution between 6–17 nm anchored on carbon spheres and GO sheets [8].

- Crystallinity: Confirm using X-ray Diffraction (XRD).

- Stability: Measure the zeta potential. The composite typically exhibits high colloidal stability with a zeta potential of around -64.7 mV [8].

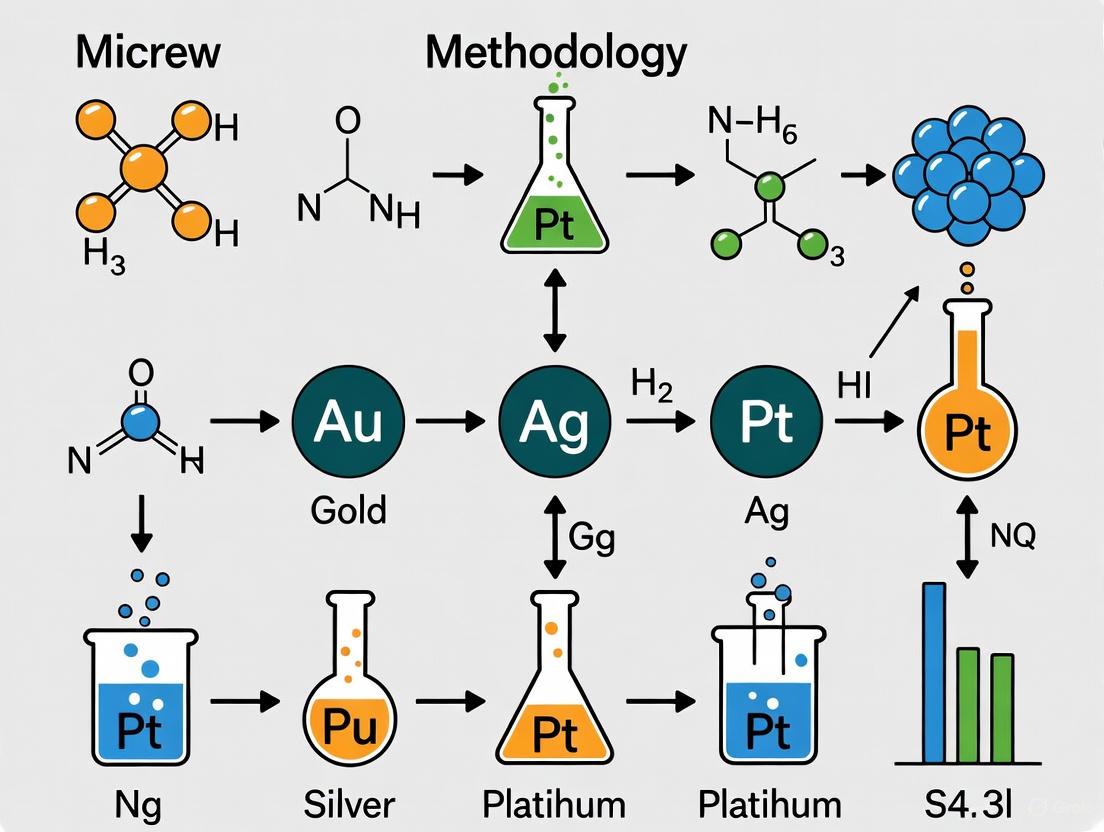

Diagram 1: Synthesis of AuNPs@Cs-TA@GO composite.

Protocol: Enhancing Interfacial Heat Transfer in Nanoscale Systems

This protocol, based on molecular dynamics simulation data, provides a framework for experimentally leveraging electric fields to modulate interfacial effects during synthesis [13].

Application Note: Controlling Kapitza resistance is crucial for optimizing heat dissipation in nano-engineered devices and can influence nanomaterial synthesis where temperature-sensitive kinetics are at play [12] [13].

Key Parameters for Electric Field Application

Table 3: Parameters for Electric Field-Induced Interfacial Heat Transfer Enhancement

| Parameter | Optimal Range / Effect | Experimental Consideration |

|---|---|---|

| Electric Field Intensity | 0 - 10 V/nm; Maximum reduction of Kapitza resistance (up to 78.4%) observed at higher intensities [13]. | Calibrate field strength to system components. |

| Ion Concentration | 0 - 5 mol/L; Dominant effect at low field strengths (<4 V/nm) with up to 31.0% reduction in Rₖ [13]. | Use salts like NaCl to adjust ionic strength. |

| Field Direction | Perpendicular and parallel fields both effective; parallel may enhance evaporation, perpendicular affects surface tension [13]. | Field orientation relative to the solid-liquid interface matters. |

Methodology Outline

- System Setup: Configure a reaction cell with metal electrodes (e.g., copper) to apply a controlled electric field across the reaction mixture containing ionic species [13].

- Field Application: During the microwave or conventional heating process, apply a DC electric field within the 0–10 V/nm range. Monitor the system temperature closely.

- Analysis of Effect: The primary effect is a reduced temperature gradient at the solid-liquid interface, which can be inferred from more uniform reaction outcomes or directly measured with specialized thermal probes.

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for Microwave Synthesis

| Reagent / Material | Primary Function in Microwave Synthesis | Specific Role / Property |

|---|---|---|

| Polar Solvents (e.g., Water, Ethanol) | Primary medium for dipole rotation [6] [1]. | High dielectric loss enables efficient microwave absorption and bulk heating. |

| Ionic Precursors (e.g., HAuCl₄, AgNO₃) | Source of metal ions for nanoparticle formation; enables ionic conduction [6] [8]. | Charged ions oscillate in the electric field, generating heat and facilitating reduction. |

| Stabilizing Agents (e.g., Tannic Acid, Polymers) | Control nanoparticle growth and prevent aggregation [7] [8]. | Capping agents dictate final nanoparticle size, shape, and colloidal stability. |

| Support Materials (e.g., Graphene Oxide, Mesoporous Polymers) | Provide a high-surface-area scaffold for nanoparticle immobilization [8] [14]. | Enhances dispersion, stability, and functional properties of the nanocomposite. |

Diagram 2: Logical flow from microwave energy to synthesis outcomes.

Microwave-assisted synthesis (MAS) represents a transformative approach in the fabrication of metal nanoparticles, operating on fundamentally different principles than conventional thermal heating. This method utilizes electromagnetic energy within the 0.3–300 GHz spectrum to generate heat directly within the reaction mixture itself, a process known as rapid volumetric heating [1] [15]. Unlike conventional methods that rely on slow, conductive surface-to-core heat transfer—which often creates thermal gradients and extended processing durations—MAS enables instantaneous and uniform internal heating [1]. The core of this technology lies in two primary mechanisms: dipolar polarization, where molecular dipoles (like water or solvents) align with the oscillating electromagnetic field, generating molecular friction and heat; and ionic conduction, where dissolved charged particles oscillate, causing collisions that generate thermal energy [15]. For researchers in drug development and materials science, this direct coupling of energy translates into unparalleled control over reaction kinetics and nanoparticle properties, facilitating the production of nanomaterials with precise sizes, morphologies, and surface characteristics essential for advanced biomedical applications [2].

Fundamental Principles and Comparative Advantages

The Volumetric Heating Mechanism

The distinctive "in-core" heating profile of microwave irradiation inverts the traditional thermal gradients found in conventionally heated systems [15]. In a standard oil bath, heat must first transfer from the source to the vessel surface and then to the reaction contents, often leading to local overheating and the decomposition of sensitive materials [15]. In contrast, microwaves pass through the reaction vessel and energy is deposited directly into the molecules of the solvent, reagents, and precursors. This direct interaction at a molecular level is the origin of the dramatic reductions in reaction time. The efficiency of this heating for a given substance is determined by its dielectric loss tangent (tan δ), which quantifies its ability to convert microwave energy into heat [15]. Solvents with high tan δ values, such as ethylene glycol (tan δ = 1.350) or ethanol (tan δ = 0.941), are heated with exceptional efficiency, while low tan δ solvents like hexane (tan δ = 0.020) are nearly microwave-transparent [15]. This principle allows for selective heating of specific reaction components, opening pathways for novel reaction conditions not achievable with conventional methods.

Quantitative Comparison of Synthesis Performance

The following table synthesizes quantitative data from recent studies, highlighting the profound impact of microwave-assisted techniques on the synthesis of metal nanoparticles compared to conventional methods.

Table 1: Performance Comparison of Microwave vs. Conventional Synthesis for Metal Nanoparticles

| Nanoparticle / System | Conventional Method Time/Temp | Microwave Method Time/Temp | Key Outcome/Improvement | Citation |

|---|---|---|---|---|

| General Organic Reaction | 8 hours at 80°C | 2 minutes at 160°C | Reaction time reduced by a factor of 240. | [15] |

| Ag Nanoclusters on SBA-15 | Hours (Conventional Batch) | Minutes with simultaneous ice cooling | Exceptional long-term (1-year) catalytic stability; high yield/selectivity. | [16] |

| Fe(OH)₃ with Surfactant | Not specified | Rapid irradiation | Surfactant capping effect suppressed particle/bubble growth for finer sizes. | [17] |

| AgNPs (Trigonella hamosa) | Not specified (Conventional) | Microwave-assisted | Smaller average crystal size (14 nm vs. 16 nm), enhancing photocatalytic activity. | [18] |

| General Metal NPs (Ag, Au, Pt, Pd) | 30+ minutes to reach 150–250°C | <1 minute to reach 150–250°C | Faster temperature ramping, uniform nucleation, monodisperse particles. | [2] |

The data unequivocally demonstrates that MAS offers dramatic reductions in reaction times—from hours to minutes or even seconds [15] [2]. This acceleration is primarily governed by the Arrhenius law, where each 10°C increase in temperature approximately doubles the reaction rate [15]. Microwave systems uniquely enable reactions to be safely performed in sealed vessels at temperatures far above the solvent's standard boiling point, thereby unlocking these exponential kinetic accelerations. Beyond mere speed, this rapid and uniform heating profile promotes homogeneous nucleation and suppresses aggregation and Ostwald ripening, leading to nanoparticles with narrower size distributions, unique morphologies, and enhanced catalytic and functional properties [16] [2] [18].

Energy Efficiency and Sustainability

The energy efficiency of MAS stems from its targeted delivery of energy. Since heat is generated directly within the reaction mixture rather than having to heat a vessel and its surroundings, the process waste is minimized [1]. This aligns with the principles of green chemistry and supports several UN Sustainable Development Goals (SDGs), including SDG 7 (Affordable and Clean Energy) and SDG 12 (Responsible Consumption and Production) [1]. The significant reduction in processing time directly translates to lower energy consumption per batch of synthesized nanoparticles. Furthermore, the ability to achieve higher yields and selectivity reduces the need for subsequent purification steps, which are often energy- and solvent-intensive [1] [19]. When combined with green solvents or solvent-free conditions, and bio-based reducing agents (like plant extracts), microwave-assisted synthesis becomes a cornerstone for sustainable nanomaterial fabrication [1] [18].

Experimental Protocols

Protocol 1: Microwave-Assisted Synthesis of Supported Silver Nanoclusters for Catalysis

This protocol, adapted from a 2023 study, details the synthesis of highly stable, ultrasmall Ag nanoclusters supported on an ordered mesoporous silica (SBA-15) using a specialized simultaneous ice-cooling and microwave heating technique [16].

Research Goal: To produce long-term stable, catalytically active silver nanoclusters with minimal aggregation. Principle: The reactor design exploits selective microwave heating to induce rapid localized nucleation, while the simultaneous ice cooling provides nearly instantaneous quenching. This combination effectively prevents cluster aggregation and Ostwald ripening [16].

Materials:

- Metal Precursor: Silver salt (e.g., AgNO₃).

- Support Material: Ordered mesoporous silica SBA-15.

- Solvent: Deionized water or other appropriate polar solvent.

- Equipment: Dedicated microwave reactor capable of controlling temperature and pressure, equipped with a vessel cooling accessory (ice-cooling jacket).

Procedure:

- Impregnation: Disperse the SBA-15 support in an aqueous solution of the silver precursor. Ensure homogeneous wetting of the support.

- Loading: Transfer the mixture to a dedicated microwave reactor vessel designed to allow for simultaneous cooling.

- Microwave Treatment: Seal the vessel and place it in the microwave reactor. Activate the external ice-cooling system to begin cooling. Subject the mixture to microwave irradiation using a moderate power setting to rapidly achieve a target temperature (e.g., 120-150°C). Maintain this temperature for a short duration (typically 1-10 minutes).

- Quenching: The reaction is rapidly quenched in situ by the continuous ice cooling.

- Work-up: After irradiation, cool the vessel to room temperature. Recover the solid material by filtration or centrifugation, wash thoroughly with water and ethanol, and dry under vacuum. Characterization: The resulting Ag/SBA-15 nanoclusters should be characterized by TEM for size distribution, XRD for crystallinity, and nitrogen physisorption for textural properties. Catalytic activity can be tested in reactions such as the reduction of 4-nitrophenol or alkyne cyclization [16].

Protocol 2: Surfactant-Enhanced Microwave Synthesis of Iron Oxide Nanoparticles

This protocol outlines the use of surfactants to control particle and bubble size during microwave-assisted nanoparticle synthesis, addressing common issues like superheating and aggregation [17].

Research Goal: To synthesize monodisperse nanoparticles while suppressing superheating and particle growth. Principle: Surfactants adsorb at the solid-liquid interface, creating a "capping effect" that suppresses particle growth. Additionally, they help stabilize smaller bubbles formed during microwave irradiation, leading to a more stable process with finer particle sizes [17].

Materials:

- Metal Precursor: Ferric chloride (FeCl₃).

- Solvent: Distilled water.

- Surfactant: Triton X-series (e.g., X-45, X-100, X-405) or similar non-ionic surfactant.

- Equipment: Dedicated microwave reactor with in-situ monitoring capabilities (e.g., dynamic light scattering for particle size).

Procedure:

- Solution Preparation: Dissolve ferric chloride in distilled water to form a clear solution.

- Surfactant Addition: Add a specified concentration of surfactant (e.g., 0.1 - 1.0 wt%) to the solution and stir to ensure homogeneity.

- Microwave Irradiation: Transfer the solution to a microwave reactor vessel. Heat the solution under controlled microwave irradiation using a predefined power and temperature program. Shorter, high-power pulses may be used to promote nucleation.

- Monitoring: Use in-situ dynamic light scattering (DLS) to monitor bubble and particle size profiles during and after irradiation, if available.

- Recovery: After irradiation and cooling, the resulting colloidal suspension of Fe(OH)₃ nanoparticles can be used directly or recovered by centrifugation. Characterization: Analyze the final particle size distribution via DLS or TEM. Compare the effectiveness of different surfactants and their chain lengths, with shorter-chain surfactants (e.g., Triton X-45) typically providing better performance in preventing particle and bubble growth [17].

Protocol 3: Green Synthesis of Silver Nanoparticles Using Plant Extract

This protocol describes a sustainable, microwave-enhanced method for synthesizing silver nanoparticles (AgNPs) using plant extract as both reducing and stabilizing agent, suitable for photocatalytic applications [18].

Research Goal: To rapidly produce biocompatible AgNPs with small size and high photocatalytic activity. Principle: Phytochemicals in plant extracts (e.g., alkaloids, flavonoids, terpenoids) reduce metal ions to their zero-valent state. Microwave irradiation drastically accelerates this reduction and nucleation process, leading to smaller, more uniform particles compared to conventional heating [18].

Materials:

- Metal Precursor: Silver nitrate (AgNO₃) solution.

- Reducing/Stabilizing Agent: Aqueous extract of Trigonella hamosa leaves (or other suitable plant).

- Equipment: Domestic microwave oven or dedicated microwave reactor.

Procedure:

- Extract Preparation: Prepare an aqueous extract by boiling dried and powdered Trigonella hamosa leaves in deionized water, followed by filtration.

- Reaction Mixture: Mix the aqueous plant extract with a predetermined volume of AgNO₃ solution (e.g., 1 mM) in a fixed ratio (e.g., 1:9 v/v) in a glass beaker or microwave vessel.

- Microwave Irradiation: Place the mixture in a microwave oven and irradiate at medium power (e.g., 600W) for short intervals (e.g., 30-60 seconds). Monitor the color change (to brownish-yellow) indicating AgNP formation.

- Purification: Recover the nanoparticles by high-speed centrifugation, followed by re-dispersion in deionized water or ethanol to remove any unreacted components. Characterization: Confirm AgNP formation by UV-Vis spectroscopy (Surface Plasmon Resonance peak at ~430 nm). Use TEM and XRD to determine particle size, morphology, and crystallinity. Evaluate photocatalytic activity by monitoring the degradation of methylene blue or paracetamol under sunlight or visible light [18].

Visualization of Workflows and Mechanisms

Microwave Heating Mechanisms and Process Workflow

Advanced Process Enhancement Strategies

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagent Solutions for Microwave-Assisted Nanoparticle Synthesis

| Reagent / Material | Function / Role | Specific Examples & Notes |

|---|---|---|

| High tan δ Solvents | Efficiently absorb microwave energy, enabling rapid heating. | Ethylene glycol (tan δ=1.350), DMSO (tan δ=0.825), Ethanol (tan δ=0.941). Water (tan δ=0.123) is medium-absorbing [15]. |

| Metal Salt Precursors | Source of metal ions for nanoparticle formation. | AgNO₃, HAuCl₄, H₂PtCl₆, PdCl₂, FeCl₃. Choice affects reduction kinetics and final particle composition [16] [17] [18]. |

| Surfactants / Capping Agents | Control particle growth, prevent aggregation, and stabilize colloids. | Triton X-series (e.g., X-45, X-100); shorter chains often more effective. Polymers like PVP are also common [17]. |

| Green Reducing Agents | Eco-friendly alternative to chemical reductants; often also act as capping agents. | Plant extracts (e.g., Trigonella hamosa); contain flavonoids, alkaloids that reduce metal ions [18]. |

| Support Materials | Provide a high-surface-area matrix for depositing and stabilizing nanoparticles. | Ordered mesoporous silica (SBA-15), carbon materials, metal oxides (e.g., Al₂O₃, TiO₂) [16]. |

| Passive Heating Elements | Aid heating in low tan δ reaction mixtures by absorbing microwaves. | Silicon carbide (SiC), carbon black. Added to the reaction vessel to initiate heating [15] [20]. |

The synthesis of metal nanoparticles represents a frontier of materials science with significant implications for catalysis, drug development, and energy applications. However, conventional synthesis methods often involve substantial solvent consumption, energy-intensive processes, and generation of hazardous waste, creating environmental and economic challenges. Green chemistry principles provide a framework for addressing these challenges by promoting pollution prevention, atom economy, and safer chemical design [21]. Within this framework, microwave-assisted synthesis (MAS) has emerged as a powerful tool that aligns with green chemistry objectives by enabling rapid, energy-efficient nanoparticle fabrication with reduced environmental footprint [1]. This application note examines the role of green chemistry in minimizing solvent use and hazardous waste, with specific protocols for microwave synthesis of metal nanoparticles tailored for researchers, scientists, and drug development professionals.

Green Chemistry Principles in Nanoparticle Synthesis

The 12 Principles of Green Chemistry, established by Anastas and Warner, provide a systematic approach to designing chemical products and processes that reduce or eliminate hazardous substance use and generation [22]. Several principles are particularly relevant to microwave synthesis of metal nanoparticles:

Prevention

The foundational principle of green chemistry emphasizes waste prevention rather than treatment or cleanup [21]. In nanoparticle synthesis, this translates to designing processes that minimize byproduct formation through precise reaction control enabled by microwave irradiation.

Atom Economy

Synthetic methods should maximize incorporation of all materials into the final product [22]. Microwave-assisted reactions often demonstrate improved atom economy through enhanced selectivity and reduced byproduct formation compared to conventional heating methods.

Less Hazardous Chemical Syntheses

Wherever practicable, synthetic methods should use and generate substances with little or no toxicity to human health and the environment [22]. MAS facilitates this through:

- Reduced requirement for hazardous reagents

- Shorter reaction times minimizing decomposition

- Enhanced selectivity reducing toxic byproducts

Safer Solvents and Auxiliaries

The use of auxiliary substances should be made unnecessary wherever possible and, when used, innocuous [21]. Microwave synthesis enables:

- Reduced solvent volumes through concentrated reactions

- Use of greener solvent alternatives

- Potential for solvent-free reactions in some cases

Design for Energy Efficiency

Energy requirements should be recognized for their environmental and economic impacts and should be minimized [21]. Microwave irradiation provides direct energy transfer to reactants rather than heating reaction vessels, significantly reducing energy consumption.

Use of Renewable Feedstocks

Starting materials should be renewable rather than depletable [21]. Microwave synthesis can utilize plant-derived extracts as reducing and capping agents for nanoparticle formation.

Table 1: Alignment of Microwave Synthesis with Green Chemistry Principles

| Green Chemistry Principle | Conventional Synthesis Challenges | Microwave Synthesis Advantages |

|---|---|---|

| Prevention of Waste | Significant byproduct generation | Reduced reaction times minimize decomposition |

| Atom Economy | Poor incorporation of starting materials | Enhanced selectivity and yield |

| Less Hazardous Syntheses | Often requires toxic reagents | Enables use of greener reducing agents |

| Safer Solvents | Large volumes of hazardous solvents | Reduced solvent volumes; water often applicable |

| Energy Efficiency | Prolonged heating requirements | Rapid, targeted heating reduces energy use |

| Renewable Feedstocks | Petroleum-derived precursors | Compatible with bio-based precursors |

Quantitative Assessment of Green Chemistry Benefits

The environmental advantages of microwave-assisted synthesis can be quantified using established green chemistry metrics. These metrics provide objective measures for comparing synthesis methods and identifying opportunities for improvement.

Table 2: Green Metrics Comparison for Metal Nanoparticle Synthesis

| Metric | Conventional Thermal Synthesis | Microwave-Assisted Synthesis | Calculation Method |

|---|---|---|---|

| Process Mass Intensity (PMI) | 100-150 kg/kg NP | 20-50 kg/kg NP | Total mass in process/Mass of product |

| Reaction Time | 2-24 hours | 1-30 minutes | Time to complete reaction |

| Temperature | 70-300°C | 50-200°C | Maximum process temperature |

| Energy Consumption | 500-2000 kJ/mol | 50-200 kJ/mol | Total energy input per mole product |

| Solvent Volume | 100-500 mL/g NP | 10-100 mL/g NP | Total solvent per gram nanoparticles |

| Atom Economy | 40-80% | 60-95% | (MW product/MW reactants) × 100 |

The data in Table 2 demonstrates significant advantages for microwave-assisted approaches across multiple environmental parameters. The reduction in process mass intensity is particularly noteworthy, indicating decreased material consumption throughout the synthesis process [1]. Similarly, the dramatic decrease in energy requirements – often by an order of magnitude – highlights the energy efficiency of microwave irradiation compared to conventional thermal methods [2].

Experimental Protocols for Microwave-Assisted Nanoparticle Synthesis

Protocol 1: Microwave-Assisted Synthesis of Silver Nanoparticles Using Green Reductants

Principle Demonstrated: Less Hazardous Chemical Syntheses, Use of Renewable Feedstocks

Materials:

- Metal precursor: Silver nitrate (AgNO₃), 1 mM aqueous solution

- Reducing agent: Plant extract (e.g., aloe vera, citrus) or biocompatible reductant (e.g., sodium citrate)

- Capping agent: Starch or chitosan (0.1-0.5% w/v)

- Solvent: Deionized water

Equipment:

- Microwave synthesis system with temperature control (e.g., Anton Paar Monowave 300)

- Quartz or microwave-safe reaction vessels

- Ultraviolet-visible spectrophotometer

- Transmission electron microscope

Procedure:

- Prepare 50 mL of 1 mM AgNO₃ solution in deionized water

- Add plant extract (1-5 mL) or sodium citrate (1% w/v) as reducing agent

- Add capping agent (0.2% w/v) to control nanoparticle growth

- Transfer solution to microwave reaction vessel, seal appropriately

- Program microwave system: 100°C, 5-10 minutes, 300-600 W power

- After reaction completion, cool rapidly to room temperature

- Characterize nanoparticles by UV-Vis spectroscopy (λmax ~400-420 nm for Ag NPs)

- Analyze size distribution and morphology by TEM

Green Chemistry Benefits:

- Aqueous solvent system eliminates organic solvent waste

- Biocompatible reducing and capping agents replace toxic chemicals

- Rapid synthesis reduces energy consumption by ~80% compared to conventional methods

- Process mass intensity typically <30 kg/kg nanoparticles [1]

Protocol 2: Microwave-Assisted Synthesis of Magnetic Iron Oxide Nanoparticles

Principle Demonstrated: Safer Solvents, Energy Efficiency

Materials:

- Iron precursor: Solid iron oleate (0.15 g) or iron chloride (FeCl₃·6H₂O)

- Solvent: Dibenzyl ether or benzyl alcohol (8-10 mL)

- Surfactant: Oleic acid (0.76 g)

- Washing solvent: Ethanol or acetone

Equipment:

- Microwave synthesis system with magnetic stirring and fiber-optic temperature monitoring

- Centrifuge

- Schlenk line for inert atmosphere operations (if required)

Procedure:

- Combine solid iron oleate (0.15 g), oleic acid (0.76 g), and dibenzyl ether (8.32 mL) in microwave vessel

- Flush with nitrogen or argon to create inert atmosphere if required

- Program microwave: Ramp to 250°C at 3.75°C/min, maintain for 1 hour with stirring at 600 rpm

- After reaction, cool to room temperature

- Precipitate nanoparticles by adding ethanol or acetone (2:1 v/v)

- Recover nanoparticles by centrifugation (7500 rcf, 10 minutes)

- Redisperse in toluene or hexane for storage

- Characterize by XRD, TEM, and FTIR

Green Chemistry Benefits:

- Solid iron oleate precursor enhances reproducibility and reduces liquid waste

- ~90% reduction in reaction time compared to thermal decomposition (1 hour vs 10+ hours)

- Significant reduction in solvent consumption through optimized concentrations

- Improved size uniformity reduces purification requirements [23]

Protocol 3: Solvent-Reduced Synthesis of Gold Nanoparticles

Principle Demonstrated: Safer Solvents and Auxiliaries, Prevention

Materials:

- Metal precursor: Chloroauric acid (HAuCl₄), 1 mM aqueous solution

- Reducing agent: Trisodium citrate (1% w/v) or ascorbic acid

- Stabilizing agent: Polyvinylpyrrolidone (PVP, MW 40,000)

- Solvent: Deionized water

Procedure:

- Prepare concentrated HAuCl₄ solution (5 mM) in minimum water volume

- Add PVP (0.5% w/v) as stabilizer

- Add trisodium citrate solution (1% w/v, 1:10 v/v ratio to gold solution)

- Transfer to microwave vessel with stirring capability

- Program microwave: 90°C, 2-5 minutes, 200-400 W power

- Monitor color change (pale yellow to ruby red) indicating nanoparticle formation

- Cool and characterize by dynamic light scattering and UV-Vis spectroscopy

Green Chemistry Benefits:

- 70-80% reduction in solvent volume compared to conventional Turkevich method

- Water-based system eliminates organic solvent hazard

- Minimal reagent consumption through optimized concentrations

- Rapid synthesis prevents energy waste [2]

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents for Green Microwave Synthesis of Metal Nanoparticles

| Reagent Category | Specific Examples | Function | Green Characteristics |

|---|---|---|---|

| Metal Precursors | Silver nitrate, chloroauric acid, solid iron oleate | Source of metal ions for nanoparticle formation | Solid precursors enhance stability, reduce waste |

| Green Reducing Agents | Sodium citrate, plant extracts, ascorbic acid | Convert metal ions to zero-valent nanoparticles | Biodegradable, low toxicity, renewable sources |

| Capping/Stabilizing Agents | Chitosan, PVP, starch, cellulose derivatives | Control nanoparticle growth and prevent aggregation | Biocompatible, renewable, minimal environmental impact |

| Solvents | Water, ethanol, 2-methyltetrahydrofuran | Reaction medium for nanoparticle synthesis | Renewable, low toxicity, biodegradable |

| Catalysts | Heterogeneous catalysts on silica supports | Accelerate specific reactions without consumption | Reusable, minimal leaching, reduced metal waste |

| Metal Scavengers | Functionalized silica gels (e.g., SiliaMetS) | Remove metal impurities from solutions | Reusable, reduce metal waste in effluent |

The reagents highlighted in Table 3 demonstrate the shift toward safer, more sustainable chemistry practices. Functionalized silica products, for example, offer low toxicity, versatility across reaction types, and minimal energy requirements for implementation [24]. Similarly, bio-based capping agents represent a renewable alternative to synthetic polymers.

Visualization of Microwave Synthesis Workflow and Green Chemistry Principles

Diagram 1: MAS Workflow and Green Benefits

The workflow illustrates the integrated approach of microwave-assisted synthesis in achieving green chemistry objectives. The direct microwave energy transfer to reactants enables rapid nucleation and controlled growth while simultaneously delivering significant environmental benefits through reduced solvent consumption, minimized waste generation, and enhanced energy efficiency [2] [1].

Diagram 2: Green Principles to MAS Implementation

This diagram illustrates the logical relationship between fundamental green chemistry principles and their practical implementation through microwave-assisted synthesis strategies, leading to measurable sustainability outcomes. The framework demonstrates how abstract principles translate to concrete laboratory practices with quantifiable environmental benefits [21] [22] [1].

Microwave-assisted synthesis represents a significant advancement in green chemistry approaches to metal nanoparticle fabrication. Through reduced solvent consumption, minimized hazardous waste generation, and enhanced energy efficiency, MAS aligns with multiple principles of green chemistry while maintaining high product quality and reproducibility. The protocols and data presented in this application note provide researchers with practical methodologies for implementing these sustainable approaches in laboratory and potential industrial settings. As microwave technology continues to evolve and green chemistry metrics become more sophisticated, the integration of these approaches promises to further reduce the environmental footprint of nanomaterial production while maintaining the precision and control required for advanced applications in drug development, catalysis, and materials science.

Microwave Equipment and Reactor Design for Nanomaterial Fabrication

Microwave-assisted synthesis has emerged as a revolutionary approach for nanomaterial fabrication, offering significant advantages over conventional heating methods through rapid, uniform heating mechanisms that substantially reduce energy usage, processing time, and hazardous waste generation [1]. The fundamental principle distinguishing microwave-assisted synthesis involves electromagnetic energy delivery within the 0.3–300 GHz spectrum, creating internal heat generation through dipole rotation and ionic conduction rather than relying on surface-to-core thermal transfer characteristics of traditional methodologies [1]. This unique heating mechanism enables precise control over reaction conditions, specifically temperature, pressure, and reaction kinetics, with a degree of precision unattainable with conventional heating systems [1].

The growing global interest in microwave-assisted synthesis for sustainable nanomaterial fabrication stems from its ability to enhance reaction rates by orders of magnitude while producing nanomaterials with superior properties, including narrow particle size distribution, high crystallinity, and exceptional purity [25]. Microwave technology promotes simultaneous molecular agitation via dipole oscillation and charged particle migration throughout the entire reaction volume, though practical implementation reveals significant challenges in achieving perfectly homogeneous temperature profiles [1]. As research continues to advance, microwave reactor designs have evolved from simple domestic oven modifications to sophisticated laboratory instruments specifically engineered to meet the rigorous demands of synthetic chemistry and nanomaterial production [26].

Microwave Reactor Configurations and Design Principles

Multi-mode vs. Single-mode Microwave Cavities

Microwave reactors for laboratory applications primarily utilize two distinct cavity designs: multi-mode and single-mode systems. Multi-mode microwave applicators, derived from domestic oven designs, feature larger cavity geometries that allow processing of multiple samples simultaneously [26]. These systems contain multiple energy pockets dispersed throughout the cavity volume with different levels of energy intensity, often referred to as hot and cold spots [26]. To compensate for this inherent field inhomogeneity, multi-mode systems continuously rotate samples throughout the energy field to smooth or average the field exposure across all samples during the energy cycle [26]. While industrial multi-mode instruments generate high total power (typically 1000–1200 W), their power density remains quite low (0.025–0.040 W/mL) due to the large cavity volume, making them less suitable for small individual samples characteristic of drug discovery or nanomaterial research [26].

Single-mode instruments produce one homogenous, intense pocket of energy that is highly reproducible, with higher power density (approximately 0.90 W/mL) despite lower total power output (300–400 W) [26]. The development of circular waveguide designs capable of self-tuning represents a significant advancement in single-mode technology, featuring multiple entry points for microwave energy to enter the cavity [26]. This design compensates for variations in sample coupling characteristics, physical size, and geometrical placement, effectively rendering the cavity immune to tuning issues while providing flexibility in sample volume (1 mL to 125 mL) [26].

Table 1: Comparison of Multi-mode and Single-mode Microwave Reactors

| Parameter | Multi-mode Reactors | Single-mode Reactors |

|---|---|---|

| Cavity Geometry | Large volume | Small, focused volume |

| Energy Distribution | Multiple energy pockets (hot/cold spots) | Single homogeneous energy pocket |

| Power Output | 1000–1200 W | 300–400 W |

| Power Density | 0.025–0.040 W/mL | ~0.90 W/mL |

| Sample Processing | Multiple samples simultaneously | Typically single sample |

| Field Homogeneity | Low (requires sample rotation) | High |

| Typical Applications | Large-scale reactions, parallel processing | Small-scale research, method development |

Advanced Reactor Designs

Recent innovations in microwave reactor design have addressed scalability challenges that traditionally limited industrial application of microwave-assisted nanomaterial synthesis. A novel coaxial probe-type microwave reactor design utilizes a Transverse Electric and Magnetic Field (TEM) wave configuration where both electric and magnetic fields are orthogonal to the direction of propagation [25]. This design eliminates concept of cut-off frequency, allowing easier scale-down and scale-up operations compared to traditional waveguide systems [25]. Numerical simulations coupling Maxwell's wave equations with traditional reactor models demonstrate that this configuration provides better electromagnetic uniformity compared to readily available cavity-type microwave reactors [25].

The coaxial microwave probe consists of two portions: the section outside the reactor constructed by an inner conductor and an outer conductor with polytetrafluoroethylene (PTFE) between them, and the portion embedded in the reactor containing only the inner conductor coated by PTFE [25]. Simulation results indicate that temperature distribution follows wavy fluctuation patterns consistent with microwave distribution, with both electric and magnetic field strength attenuating along the radial direction [25]. For large-scale production, implementing agitation is recommended to eliminate hot spots, and multi-probe arrays can be utilized to maintain uniform heating in reactors with increased capacities [25].

Experimental Protocols for Nanomaterial Synthesis

Continuous-Flow Synthesis of Silver Nanoparticles

Principle: This protocol describes the continuous-flow synthesis of silver nanoparticles (AgNPs) using a single-mode microwave reactor and polyol process, enabling high-yield production of small, spherical particles with narrow size distribution [27].

Materials:

- Silver acetate (AgOAc, +99%) or silver nitrate (AgNO3, +99.9%)

- Polyvinylpyrrolidone (PVP, K-25 or K-30 type, Mw 24-40 kDa)

- Ethylene glycol (EG, 99.9%)

- Alternative polyols: 1,2-propanediol or 1,4-butanediol (if needed)

Equipment:

- Single-mode microwave system (2.45 GHz, 2 kW power capacity)

- PTFE tubular reactor (8 mm internal diameter, 42 mm irradiated length)

- Fine metering pump

- Thermo-couple for temperature monitoring at outlet

- Cooling system for product collection

Procedure:

- Solution Preparation: Dissolve PVP in ethylene glycol at 80°C with stirring to achieve molar ratio Ag:PVP (monomeric unit) of 1:7. Cool to room temperature.

- Precursor Addition: Add silver acetate (10-50 mM) to the PVP-EG solution. For AgOAc concentrations >10 mM, briefly sonicate to ensure homogeneity, then maintain continuous magnetic stirring at room temperature before delivery into reactor.

- Reactor Setup: Set microwave power to achieve desired outlet temperature (90–170°C ±1°C, depending on silver precursor).

- Continuous Flow Operation: Pump reaction solution at controlled flow rates (0.318–2.5 dm³/h) to achieve residence times of 3–24 seconds in the irradiation zone.

- Product Collection: Rapidly cool the suspension exiting the reactor and collect for analysis.

Characterization:

- Silver ion content: Differential pulse voltammetry (DPV)

- Particle size: Dynamic light scattering (DLS)

- Morphology: High-resolution transmission electron microscopy (HRTEM)

- Crystalline structure: X-ray diffractometry (XRD)

- Optical properties: UV-Vis absorption spectroscopy

Key Parameters:

- Silver acetate demonstrated superior reactivity compared to silver nitrate for producing smaller particles (10–20 nm)

- Restricted solubility of silver acetate in ethylene glycol enables effective separation of nucleation and growth stages

- Higher heating rates (>40°C/s) achievable with microwave irradiation are essential for high-yield production

Rapid Synthesis of Carbon Dots

Principle: Single-step microwave-assisted synthesis of water-stable, non-toxic carbon dots using glucose as carbon source and polyethyleneimine (PEI) as passivating agent [28].

Materials:

- D-(+)-Glucose, anhydrous (99%)

- Polyethyleneimine branched (M.W. 25,000)

- Deionized water

Equipment:

- Microwave irradiation reactor (MARS 6, CEM Corporation or equivalent)

- Sonicator

Procedure:

- Solution Preparation: Dissolve 0.3 g glucose and 350 μL PEI in 15 mL deionized water.

- Mixing: Sonicate for 15 minutes until homogeneous, colorless mixture is obtained.

- Microwave Reaction: Transfer solution to microwave reactor and irradiate at:

- Temperature: 100°C, 120°C, or 140°C

- Time: 3 minutes

- Product Identification: Successful synthesis indicated by dark brown solution.

Characterization:

- Morphology: Transmission electron microscopy (TEM)

- Surface chemistry: Fourier transform infrared spectroscopy (FT-IR)

- Optical properties: Photoluminescence and UV-visible spectroscopy

- Band gap estimation: Tauc plot

Key Parameters:

- Synthesis completed in remarkably short time (3 minutes)

- Temperature range 100–140°C found optimal

- PEI functionalization provides surface amine groups enhancing aqueous stability and fluorescence

- Products demonstrate no toxicity in brine shrimp assays, making them suitable for biomedical applications

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Microwave-Assisted Nanomaterial Synthesis

| Reagent/Material | Function | Application Examples | Considerations |

|---|---|---|---|

| Silver Acetate | Metal precursor | Silver nanoparticle synthesis | Superior to silver nitrate for producing smaller particles (10-20 nm); restricted solubility in EG beneficial for separating nucleation and growth [27] |

| Polyvinylpyrrolidone (PVP) | Stabilizing agent | Metal nanoparticle synthesis | Prevents aggregation; molar ratio to metal precursor critical for controlling particle size [27] |

| Ethylene Glycol | Solvent and reducing agent | Polyol process for metal nanoparticles | High boiling point suitable for elevated temperature reactions; acts as both solvent and reducing agent [27] |

| D-Glucose | Carbon source | Carbon dot synthesis | Economical and non-toxic precursor; decomposes to form carbon nuclei under microwave irradiation [28] |

| Polyethyleneimine (PEI) | Passivating agent | Carbon dot functionalization | Provides amine groups for surface functionalization; enhances water stability and fluorescence [28] |

| PTFE (Polytetrafluoroethylene) | Reactor material | Coaxial probe reactors | Microwave-transparent; chemically inert; suitable for reactor construction [25] |

Reactor Performance and Scaling Considerations

Temperature and Field Distribution

In coaxial probe-type microwave reactors, temperature distribution displays wavy fluctuation patterns consistent with microwave distribution, with both electric and magnetic field strength attenuating along the radial direction [25]. Numerical simulations reveal that proper power application with frequency of 2.45 GHz and specific probe configurations (e.g., ϕ2* = 0.08333) provide better performance for efficient microwave heating [25]. Dielectric properties of reaction solutions, specifically dielectric constant and dielectric loss factor, require careful adjustment to avoid overheating even when average temperature requirements are met [25].

Scale-up Strategies

The most significant limitation of microwave-assisted techniques for industrial-scale production is the constrained penetration depth of microwaves, typically limited to a few centimeters [27]. This limitation renders scale-up of batch reactors challenging but suitable for continuous-flow synthesis designs to achieve high yields [27]. For large-scale production, multi-probe arrays can maintain uniform heating in reactors with increased capacities [25]. Agitation is particularly recommended for large-scale operations to eliminate hot spots and ensure homogeneous reaction conditions [25].

Table 3: Scale-up Parameters for Coaxial Probe-type Microwave Reactors

| Parameter | Laboratory Scale | Pilot Scale | Industrial Scale |

|---|---|---|---|

| Reactor Capacity | 0.1–1 L | 1–10 L | 10–100 L |

| Power Configuration | Single probe | Multi-probe array | Multiple multi-probe arrays |

| Heating Uniformity | High (natural) | Moderate (requires optimization) | Requires active agitation |

| Flow Type | Batch or continuous | Continuous | Continuous |

| Key Challenge | Method development | Maintaining uniformity | Energy efficiency, cost optimization |

Schematic Representations

Microwave Reactor Configurations

Continuous-Flow Nanoparticle Synthesis Workflow

Microwave reactor design has evolved significantly from simple domestic oven modifications to sophisticated systems specifically engineered for nanomaterial fabrication. The choice between multi-mode and single-mode cavities depends on specific application requirements, with single-mode systems offering superior field homogeneity for research-scale applications, while multi-mode systems accommodate larger volumes and parallel processing [26]. The development of coaxial probe-type reactors with TEM wave propagation addresses scalability challenges through designs without cut-off frequency limitations [25].

Continuous-flow microwave reactors represent particularly promising platforms for industrial-scale nanomaterial production, overcoming penetration depth limitations while maintaining precise control over particle size and distribution [27]. When integrated with appropriate precursor systems and stabilizing agents, these advanced reactor designs enable rapid, reproducible synthesis of various nanomaterials, including metal nanoparticles and carbon dots, with applications spanning catalysis, biomedicine, electronics, and environmental remediation [1] [28]. As microwave technology continues to advance, further innovations in reactor design are expected to enhance scalability, energy efficiency, and process control for nanomaterial fabrication.

Synthesis Protocols and Biomedical Applications: From Lab to Clinic

Microwave-assisted synthesis has emerged as a powerful methodology for the production of noble metal nanoparticles (NPs), offering significant advantages over conventional heating methods. This technique enables precise control over particle size, size distribution, morphology, and crystallinity through rapid and uniform heating mechanisms [2]. The application of microwave irradiation facilitates the preparation of monometallic, bimetallic, and more complicated metal nanoparticle structures with tailored properties for specialized applications in catalysis, biomedicine, and sensing [2] [29].

The fundamental principle underlying microwave synthesis involves the transfer of electromagnetic energy (typically at 2.45 GHz) directly to the reaction mixture through dielectric polarization mechanisms [2]. This results in instantaneous internal heating throughout the reaction volume, unlike conventional heating which relies on slower conductive and convective heat transfer. The selective heating of reaction components provides superior control over temperature, pressure, and reaction kinetics, leading to more efficient nucleation and crystallization processes [1]. For noble metals specifically, microwave irradiation promotes the formation of nanoparticles with narrow size distributions and unique morphological characteristics that are often unattainable through traditional synthetic routes.

Fundamental Microwave Heating Mechanisms

The efficiency of microwave-assisted nanoparticle synthesis stems from three primary heating mechanisms that operate simultaneously in reaction mixtures. Dielectric polarization occurs when polar molecules (e.g., water, alcohols, and other oxygen-containing compounds) continuously align with the rapidly oscillating electric field, generating molecular friction and heat [2]. Conduction mechanism involves the excitation of free charges in materials with substantial conductivity (metals and semiconductors), resulting in heating through Ohmic loss [2]. The interfacial polarization (Maxwell-Wagner effect) emerges at the interface between phases with different dielectric properties, causing charge accumulation and enhanced energy absorption [2].

The effectiveness of these mechanisms depends critically on the dielectric properties of the reaction components. Materials are categorized as high, medium, or low microwave absorbers based on their dissipation factors. For nanoparticle synthesis, the presence of polar molecules and ionic species typically ensures efficient coupling with microwave energy, enabling rapid heating rates that can exceed 100°C per minute [30]. This rapid heating promotes instantaneous nucleation events followed by controlled growth phases, yielding uniform nanoparticles with narrow size distributions.

Experimental Protocols

General Microwave Synthesis Setup

Equipment and Materials:

- Microwave synthesis system with temperature and pressure monitoring

- Certified pressure vessels (for sealed reactions) or round-bottom flasks (for open reactions)

- Reflux condensers (for atmospheric reactions)

- Polar solvents (water, ethylene glycol, dimethylformamide)

- Metal precursors (salts of Ag, Au, Pt, Pd)

- Reducing agents (sodium citrate, sodium borohydride, ascorbic acid)

- Stabilizing agents/capping agents (polymers, surfactants)

Standard Operating Procedure:

- Reaction Vessel Selection: Choose between sealed vessels for high-temperature/pressure conditions or open vessels with reflux for atmospheric operations [30].

- Reagent Preparation: Dissolve metal precursor in an appropriate solvent with concentration typically ranging from 0.1-10 mM.

- Additive Incorporation: Introduce reducing and stabilizing agents in predetermined molar ratios relative to the metal precursor.

- Parameter Programming: Set microwave parameters including temperature, irradiation time, and power level based on the specific nanoparticle target.

- Reaction Execution: Initiate microwave irradiation with real-time monitoring of temperature and pressure.

- Product Recovery: Cool the reaction mixture rapidly and purify nanoparticles through centrifugation/redispersion cycles.

Table 1: Microwave System Configuration Guidelines

| Parameter | Sealed Vessel | Open Vessel (Reflux) | Solvent-Free |

|---|---|---|---|

| Typical Scale | 1-10 mL | 10-100 mL | 1-50 g |

| Temperature Range | Up to 300°C | Up to solvent boiling point + 20°C | 150-250°C |

| Power Setting | Start at 50 W, adjust as needed | 250-300 W for reflux | 25-50 W |

| Heating Time | 5-10 minutes | 10-60 minutes | 5-15 minutes |

| Key Advantages | Higher temperatures, inert atmosphere, faster kinetics | Scalability, compatibility with standard glassware | Minimal waste, simplified purification |

Silver Nanoparticle Synthesis

Protocol for Antibacterial Ag NPs (Adapted from [2] [16])

Materials:

- Silver nitrate (AgNO₃) as precursor

- Sodium citrate or sodium borohydride as reducing agent

- Polyvinylpyrrolidone (PVP) as capping agent

- Deionized water or ethylene glycol as solvent

Experimental Procedure:

- Prepare a 1 mM solution of AgNO₃ in deionized water.

- Add PVP (0.3% w/v) and sodium citrate (3 mM) to the solution with stirring.

- Transfer 15 mL of the mixture to a microwave vessel.

- Program the microwave system: 150°C for 10 minutes with ramp time of 2 minutes using 300 W power.

- After irradiation, cool the vessel rapidly to room temperature.

- Purify the yellow-colored Ag NP suspension by centrifugation at 12,000 rpm for 15 minutes.

- Redisperse the pellet in deionized water for characterization.

Advanced Technique: Simultaneous Ice-Cooling and Microwave Heating For ultrasmall Ag clusters with exceptional stability [16]:

- Implement a reactor system that combines microwave heating with external ice-cooling.

- Use aqueous AgNO₃ solution (0.5 mM) with mesoporous silica support (SBA-15).

- Apply pulsed microwave irradiation (30 seconds on, 60 seconds off) for 5 cycles.

- Maintain internal temperature below 50°C despite microwave heating.

- Recover supported Ag clusters by filtration and drying at 60°C.

Table 2: Silver Nanoparticle Synthesis Parameters and Outcomes

| Parameter | Spherical Ag NPs | Ultrasmall Ag Clusters | Antimicrobial Ag NPs |

|---|---|---|---|

| Precursor | AgNO₃ (1 mM) | AgNO₃ (0.5 mM) | AgNO₃ (2 mM) |

| Reducing Agent | Sodium citrate (3 mM) | NaBH₄ (1 mM) | Morus alba leaf extract |

| Stabilizing Agent | PVP (0.3%) | SBA-15 support | Starch (0.5%) |

| Solvent | Deionized water | Water/ethanol (1:1) | Deionized water |

| Microwave Conditions | 150°C, 10 min, 300W | Pulsed, 50°C max, 5 cycles | 100°C, 15 min, 250W |

| Particle Size | 15-25 nm | 1-2 nm | 10-30 nm |

| Application | Catalysis, sensing | Catalytic cyclization | Antibacterial coatings |

Gold Nanoparticle Synthesis

Protocol for Drug Delivery Au NPs (Adapted from [29] [31])

Materials:

- Chloroauric acid (HAuCl₄) as precursor

- Trisodium citrate as reducing and stabilizing agent

- Functionalization ligands (PEG-thiol, targeting peptides)

Experimental Procedure:

- Prepare a 0.5 mM HAuCl₄ solution in deionized water.

- Add trisodium citrate (1.5 mM) to the solution.

- For functionalized Au NPs, include PEG-thiol (0.1 mM) or other surface ligands.

- Transfer 20 mL to a microwave vessel and heat at 120°C for 8 minutes with 250 W power.

- Observe color change from pale yellow to deep red indicating nanoparticle formation.

- Cool rapidly and characterize the UV-Vis spectrum for surface plasmon resonance (typically 515-530 nm).

Functionalization for Biomedical Applications:

- Synthesize Au NPs as described above.

- Add thiolated PEG (MW 2000-5000) to the cooled NP solution at 1:1000 molar ratio (Au:PEG).

- React for 12 hours with gentle stirring.

- Purify by centrifugal filtration and resuspend in phosphate buffer.

- Conjugate with targeting molecules (e.g., folic acid for cancer targeting) using EDC/NHS chemistry [29].

Platinum and Palladium Nanoparticle Synthesis

Protocol for Catalytic Pt/Pd NPs (Adapted from [2] [31])

Materials:

- Chloroplatinic acid (H₂PtCl₆) or palladium chloride (PdCl₂) as precursors

- Ethylene glycol as solvent and reducing agent

- PVP or citrate as stabilizing agents

Experimental Procedure:

- Prepare a 1 mM solution of H₂PtCl₆ or PdCl₂ in ethylene glycol.

- Add PVP (0.5% w/v) as stabilizer.

- Transfer 15 mL to a microwave vessel.

- Program microwave: 180°C for 15 minutes with ramp time of 3 minutes at 400 W power.

- Cool naturally to room temperature.

- Precipitate nanoparticles with acetone and centrifuge at 10,000 rpm for 10 minutes.

- Redisperse in ethanol or water for further use.

Bimetallic System:

- Use molar ratios of 1:1 for two metal precursors (e.g., HAuCl₄ and H₂PtCl₆).

- Adjust reducing agent concentration accordingly.

- Employ stepwise reduction if large reduction potential differences exist between metals.

Table 3: Platinum and Palladium Nanoparticle Synthesis Parameters

| Parameter | Platinum NPs | Palladium NPs | Au-Pd Bimetallic |

|---|---|---|---|

| Precursor | H₂PtCl₆ (1 mM) | PdCl₂ (1 mM) | HAuCl₄ + PdCl₂ (1:1) |

| Solvent/Reducer | Ethylene glycol | Ethylene glycol | Water/ethylene glycol mix |

| Stabilizing Agent | PVP (0.5%) | Sodium citrate (2 mM) | PVP (0.3%) |

| Microwave Conditions | 180°C, 15 min, 400W | 160°C, 12 min, 350W | 170°C, 10 min, 350W |

| Particle Size | 2-5 nm | 3-7 nm | 5-10 nm (core-shell) |

| Key Application | Fuel cells, catalysis | Cross-coupling reactions | Enhanced catalysis |

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for Microwave Nanoparticle Synthesis

| Reagent Category | Specific Examples | Function | Concentration Range |

|---|---|---|---|

| Metal Precursors | AgNO₃, HAuCl₄, H₂PtCl₆, PdCl₂ | Source of metal ions for reduction | 0.1-10 mM in final solution |

| Reducing Agents | Sodium citrate, NaBH₄, ascorbic acid, ethylene glycol | Convert metal ions to zero-valent atoms | 1-100 mM (depending on strength) |

| Stabilizing Agents | PVP, citrate, PEG, CTAB, polymers | Control growth and prevent aggregation | 0.1-1% w/v for polymers |

| Solvents | Water, ethylene glycol, DMF, ethanol | Reaction medium and sometimes reducer | Neat or mixtures |

| Surfactants | Triton X-series, SDS, polysorbates | Modify morphology and dispersion | 0.01-0.1 M |

| Functionalization Ligands | Thiolated PEG, oligonucleotides, antibodies | Impart specific surface functionality | Varies by application |

Process Optimization Strategies

Advanced Microwave Techniques

Two-Stage Irradiation [17]:

- Apply high-power irradiation (800-1000 W) for 30-60 seconds to promote rapid nucleation.

- Immediately switch to low-power irradiation (50-100 W) for 10-20 minutes to control growth.

- Results in narrower size distributions and prevents Oswald ripening.

Surfactant-Enhanced Synthesis [17]:

- Incorporate short-chain surfactants (Triton X-45, concentration 0.01-0.1 M).

- Surfactant adsorption at solid-liquid interfaces suppresses particle growth via capping effect.

- Enables control over final particle size and prevents aggregation.

Anti-Solvent Addition [17]:

- Add high-boiling-point anti-solvent (5-20% v/v) to primary solvent.

- Reduces superheating risk by modifying dielectric properties.

- Lowers probability of solute ions meeting, suppressing particle growth.

Troubleshooting Common Issues

Problem: Polydisperse Size Distribution

- Solution: Implement faster heating ramps, use stronger reducing agents, or employ two-stage irradiation protocols [17].

Problem: Particle Aggregation

- Solution: Increase stabilizer concentration, introduce electrostatic or steric stabilization, or use shorter surfactants [17].

Problem: Irregular Morphologies

- Solution: Optimize heating rate, use shape-directing capping agents, or employ lower power with longer irradiation times [2].

Problem: Superheating and Solvent Degradation

- Solution: Add high-boiling-point co-solvents, implement pulsed irradiation, or use simultaneous cooling techniques [16].

Workflow Visualization

Characterization and Quality Control

Essential Characterization Techniques:

- UV-Visible Spectroscopy: Confirmation of nanoparticle formation through surface plasmon resonance detection (Ag: ~400 nm, Au: ~520 nm).

- Dynamic Light Scattering: Size distribution analysis and stability assessment.

- Transmission Electron Microscopy: Morphological evaluation, size measurement, and crystallinity analysis.

- X-ray Diffraction: Crystallographic phase identification and structural characterization.

- Zeta Potential Measurements: Surface charge analysis and stability prediction.

Quality Control Parameters:

- Size Distribution: Polydispersity index <0.2 indicates monodisperse population.

- Stability: No aggregation or precipitation for >30 days at 4°C.

- Concentration: Metal content determination through ICP-MS or atomic absorption.

- Surface Functionality: Verification through FTIR or NMR spectroscopy.

Microwave-assisted synthesis represents a robust and efficient methodology for producing noble metal nanoparticles with precise control over their physicochemical properties. The protocols outlined herein for silver, gold, platinum, and palladium nanoparticles provide researchers with standardized approaches that can be further optimized for specific applications. The integration of advanced microwave techniques such as two-stage irradiation, surfactant enhancement, and simultaneous cooling enables the production of nanoparticles with tailored characteristics for biomedical, catalytic, and electronic applications. As microwave technology continues to evolve, these synthesis protocols will undoubtedly become increasingly sophisticated, offering enhanced control over nanoparticle architecture and functionality.

The integration of plant extracts into microwave-assisted synthesis represents a significant advancement in the sustainable production of metal nanoparticles (MNPs). This approach aligns with green chemistry principles by utilizing biologically active compounds from plants as both reducing agents, to convert metal ions to their elemental state, and capping agents, to stabilize the formed nanoparticles and control their growth [32]. When combined with microwave irradiation, which provides rapid, uniform heating, this method enables the efficient and eco-friendly synthesis of MNPs with precise control over their size, morphology, and properties [1]. These enhancements are critical for applications in catalysis, biomedicine, and environmental remediation, making this integrated protocol a valuable tool for researchers and developers seeking to minimize environmental impact while maximizing nanoparticle performance [33] [18].

The following tables summarize optimized synthesis parameters and the characteristics of resulting metal nanoparticles from recent studies.

Table 1: Optimization Parameters for Microwave-Assisted Green Synthesis of Metal Nanoparticles

| Nanoparticle Type | Plant Material | Optimal Microwave Conditions | Key Phytochemicals Involved | Primary Nanoparticle Characteristics |

|---|---|---|---|---|

| Silver (Ag) NPs [33] | Pineapple Leaves | Concentration: 5-25 mM AgNO₃, Volume: 2-8 mL, Time: 2-24 h | Not Specified | Size: 40-150 nmShape: Spherical, HexagonalApplication: Antimicrobial |

| Silver (Ag) NPs [18] | Trigonella hamosa L. Leaves | Microwave-assisted method | Alkaloids, Terpenoids, Flavonoids [18] | Size: ~14 nmShape: Nearly SphericalApplication: Photocatalysis |

| Selenium (Se) NPs [34] | Cocoa Bean Shell | Time: 15.6 min, Power: 788.6 W, Na₂SeO₃: 0.14 g | Polyphenols, Polysaccharides, Proteins | Size: 1-3 nmShape: SphericalApplication: Antioxidant |

| Magnetite (Fe₃O₄) NPs [35] | Sea Buckthorn Berries | Power: 900 W, Time: 5 min, Solvothermal: 150°C for 24 h | Polyphenols, Flavonoids, Ascorbic Acid | Size: 15.6 nm (core)Shape: CrystallineApplication: Anticancer |

Table 2: Biological and Catalytic Performance of Synthesized Nanoparticles

| Nanoparticle | Application Test | Performance Metrics | Key Findings |

|---|---|---|---|

| Ag from Pineapple Leaves [33] | Antimicrobial Activity | Minimum Inhibitory Concentration (MIC) | MIC of 60 μg/mL against E. coli, B. subtilis, and S. aureus |

| Ag from Trigonella hamosa [18] | Photocatalysis | Degradation Efficiency (%) | Methylene Blue: 96.2% (sunlight), 94.9% (visible lamp)Paracetamol: 94.5% (sunlight), 92% (visible lamp) |