Mastering Continuous Oscillatory Baffled Reactors (COBRs) for Advanced API Synthesis: A Comprehensive Guide for Pharmaceutical Researchers

This article provides a detailed examination of Continuous Oscillatory Baffled Reactors (COBRs) for Active Pharmaceutical Ingredient (API) synthesis.

Mastering Continuous Oscillatory Baffled Reactors (COBRs) for Advanced API Synthesis: A Comprehensive Guide for Pharmaceutical Researchers

Abstract

This article provides a detailed examination of Continuous Oscillatory Baffled Reactors (COBRs) for Active Pharmaceutical Ingredient (API) synthesis. It explores the fundamental principles of COBR technology, establishing its role in enhancing mixing and heat/mass transfer for complex chemical reactions. A methodological guide covers reactor design, operation, and its application in specific API synthesis pathways, such as crystallization, polymerization, and multi-step processes. Practical sections address common operational challenges, troubleshooting strategies, and optimization techniques to maximize yield and purity. The content validates COBR performance by comparing it to traditional batch and other continuous flow reactors, analyzing key metrics like space-time yield, impurity profile control, and process intensification. Aimed at researchers, scientists, and drug development professionals, this guide synthesizes current best practices and future outlooks for implementing COBRs in modern, agile pharmaceutical manufacturing.

COBR Fundamentals: Unlocking Plug Flow and Intensification for Pharmaceutical Manufacturing

Application Notes: Core Principles and Operational Advantages

The Continuous Oscillatory Baffled Reactor (COBR) represents a transformative technology for the intensification of chemical processes, particularly in the synthesis of Active Pharmaceutical Ingredients (APIs). It achieves near-plug flow conditions within a tubular geometry by superimposing an oscillatory flow onto a low net flow, using periodically placed baffles. This creates a flow pattern characterized by uniform, vortical mixing, offering significant advantages over traditional batch and continuous stirred tank reactors (CSTRs).

Fundamental Principles

The performance of a COBR is governed by the interaction between oscillatory flow and baffle geometry. The key dimensionless numbers defining this interaction are:

- Oscillatory Reynolds Number ((Reo)): Characterizes the intensity of oscillatory mixing. (Reo = \frac{2\pi f x0 \rho D}{\mu}), where (f) is frequency (Hz), (x0) is oscillation center-to-peak amplitude (m), (\rho) is density, (D) is tube diameter (m), and (\mu) is dynamic viscosity.

- Strouhal Number ((St)): Describes the ratio of oscillatory displacement to tube diameter. (St = \frac{D}{2\pi x_0}). For effective mixing, (St) is typically ~1.

- Net Flow Reynolds Number ((Ren)): Characterizes the mean flow. (Ren = \frac{\rho u D}{\mu}), where (u) is the superficial net flow velocity.

Optimal operation occurs in the oscillatory flow mixing regime, where (Reo) > 100 and (Ren) < (Re_o), ensuring mixing is dominated by oscillation-generated vortices rather than net flow.

Baffle Design

Baffle geometry is critical for generating reproducible, radially uniform mixing. Common designs include:

- Orifice Baffles: A simple constricted plate. Effective but can have higher shear and dead zones.

- Smooth Periodic Constrictions (SPC): A sinusoidal constriction integrated into the tube wall. Offers lower shear and more uniform energy dissipation.

- Helical Baffles: Introduce a swirling component, enhancing radial mixing and residence time distribution (RTD).

Table 1: Comparison of Key COBR Operational Parameters vs. Traditional Reactors

| Parameter | Batch Stirred Tank | CSTR Cascade (3 units) | Ideal COBR |

|---|---|---|---|

| Typical RTD Spread ((\sigma^2)) | Very High (Batch) | Medium | Low (Near-Plug Flow) |

| Mixing Time Scale | Seconds to Minutes | Minutes | 10-100 ms |

| Heat Transfer Coefficient | Low to Medium | Medium | High (>1000 W/m²K) |

| Scal-up Basis | Geometric, Empirical | Number of Units | Constant (Re_o), (St) |

| Space-Time Yield | Low | Medium | High |

| Shear Stress on Particles | Variable, High | Medium | Controllable, Uniform |

Advantages for API Synthesis

- Enhanced Process Control: Precise control over mixing intensity ((Re_o)) independent of residence time (controlled by net flow). This decoupling is impossible in traditional reactors.

- Improved Product Quality: Near-plug flow RTD minimizes side reactions, byproduct formation, and ensures consistent product quality crucial for API specifications.

- Process Intensification: Excellent heat and mass transfer enables faster reactions, higher concentrations, and safer handling of exothermic reactions.

- Seamless Scal-up: "Numbering-up" of identical, small-diameter tubes maintains performance from lab to production, reducing scale-up risk and timeline.

Experimental Protocol: Determining Residence Time Distribution (RTD) in a Lab-Scale COBR

Objective: To characterize the mixing and flow behavior of a laboratory COBR by measuring its Residence Time Distribution (RTD) and comparing it to ideal reactor models.

2.1 Materials and Equipment (The Scientist's Toolkit) Table 2: Key Research Reagent Solutions & Essential Materials

| Item | Function/Specification | Example Product/Chemical |

|---|---|---|

| Lab-scale COBR System | Core reactor; typically 10-25 mm ID, 0.5-2 m length, with interchangeable baffles (SPC or orifice). | AM Technology CoBR, NiTech Solutions |

| Oscillatory Drive Unit | Generates controlled sinusoidal oscillation of piston/diaphragm. Must precisely control (f) (0.5-10 Hz) and (x_0) (1-15 mm). | Reciprocating piston with linear actuator |

| Peristaltic or Syringe Pump | Provides low, steady net flow of fluid (Q). | Cole-Parmer Masterflex L/S |

| Conductivity Meter & Probe | Detects tracer concentration at reactor outlet. Fast response time (<100 ms) is critical. | Hanna Instruments HI763100 |

| Data Acquisition System | Logs conductivity vs. time at high frequency (>10 Hz). | National Instruments DAQ with LabVIEW |

| Tracer Solution | A pulse of electrolyte (e.g., KCl, NaCl) that does not react with or disturb the flow. | 1M Potassium Chloride (KCl) |

| Carrier Fluid | The continuous phase in which the reactor operates. | Deionized Water |

| Data Analysis Software | For calculating E(t), F(t), mean residence time ((\tau)), and variance ((\sigma^2)). | Python (NumPy, SciPy), MATLAB |

2.2 Methodology

- System Setup & Calibration: Assemble the COBR column with selected baffles (e.g., SPC with 30% constriction). Fill the system with carrier fluid (water). Set the oscillatory drive to target conditions (e.g., (f) = 2 Hz, (x0) = 5 mm, giving (Reo) ≈ 1500). Start the net flow pump at the desired flow rate to set residence time (e.g., Q = 10 ml/min for (\tau) ~ 10 min). Allow system to stabilize for >5(\tau).

- Tracer Pulse Injection: Using a high-precision syringe, rapidly inject (<1 s) a small, known volume (e.g., 0.5 ml) of concentrated KCl tracer solution directly into the flow at the reactor inlet.

- Data Acquisition: Simultaneously with injection, begin recording the output from the conductivity probe placed at the reactor outlet. Record at 20 Hz for the duration of the experiment (typically >3(\tau)).

- Data Processing:

- Convert conductivity data to tracer concentration, C(t), using a pre-established calibration curve.

- Calculate the normalized RTD function, E(t): (E(t) = \frac{C(t)}{\int{0}^{\infty} C(t)dt}).

- Calculate the mean residence time: (\tau = \frac{\int{0}^{\infty} tE(t)dt}{\int{0}^{\infty} E(t)dt}).

- Calculate the variance: (\sigma^2 = \frac{\int{0}^{\infty} (t-\tau)^2 E(t)dt}{\int{0}^{\infty} E(t)dt}).

- Compare the normalized variance ((\sigma\theta^2 = \sigma^2/\tau^2)) to ideal models: 0 for plug flow, 1 for a single CSTR.

- Parameter Variation: Repeat the experiment for different (Reo) (vary (f) or (x0)) while keeping (\tau) constant, and vice-versa, to demonstrate the decoupling of mixing and residence time.

2.3 Expected Outcomes A well-designed COBR operating at sufficient (Reo) will yield a narrow, symmetrical E(t) curve with (\sigma\theta^2) << 0.1, demonstrating behavior close to ideal plug flow. Increasing (Re_o) will further narrow the RTD, while reducing it will broaden the distribution towards CSTR-like behavior.

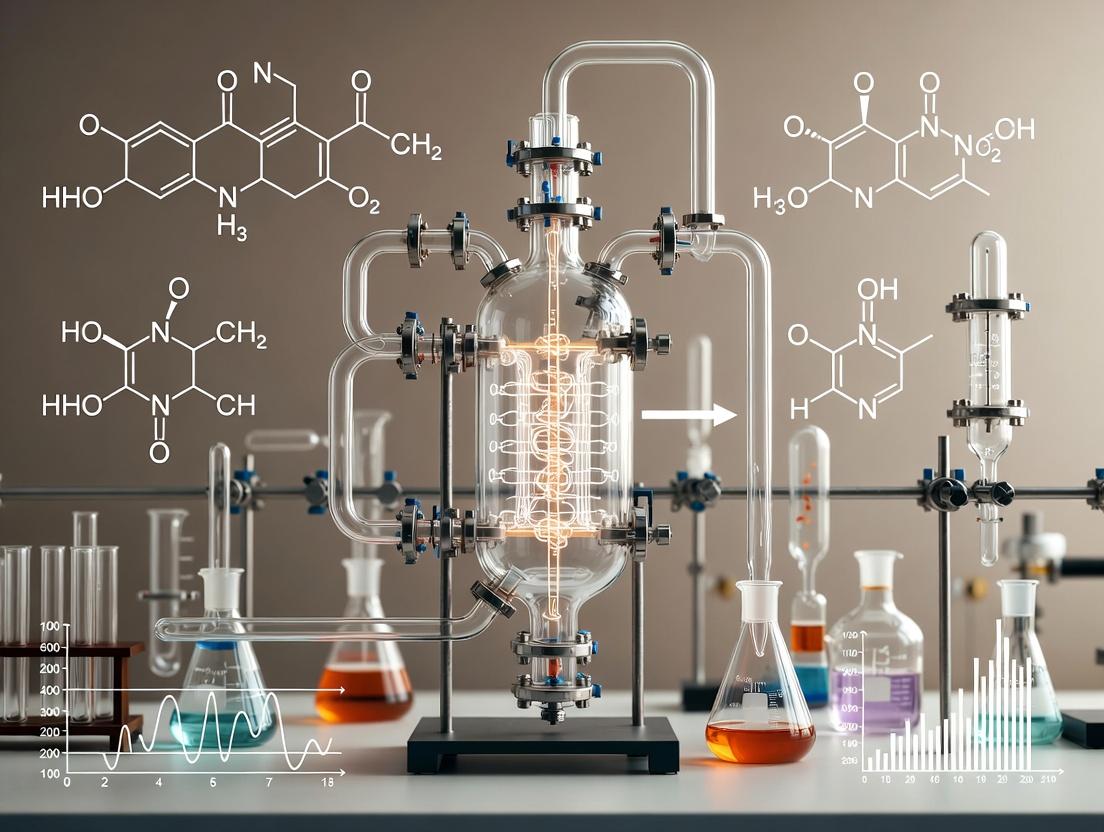

Diagrams

This application note details the implementation of a Continuous Oscillatory Baffled Reactor (COBR) within an API (Active Pharmaceutical Ingredient) synthesis research program. The core thesis posits that superimposing oscillatory flow onto net throughput in a baffled tube generates a flow physics environment uniquely suited for precise, scalable, and intensified chemical synthesis. The controlled, predictable vortices created by oscillation between each baffle achieve plug flow conditions with superior radial mixing and axial dispersion control compared to traditional continuous stirred-tank reactors (CSTRs) or tubular laminar flow reactors. This translates to enhanced heat and mass transfer, reproducible mixing timescales, and the ability to handle challenging multiphase or viscous fluids common in pharmaceutical intermediates.

Quantitative Performance Data: COBR vs. Traditional Reactors

Table 1: Comparative Performance Metrics for API Synthesis Conditions

| Parameter | Continuous Stirred-Tank Reactor (CSTR) | Tubular Laminar Flow Reactor | Continuous Oscillatory Baffled Reactor (COBR) |

|---|---|---|---|

| Mixing Time (ms) | 100-1000 (highly scale-dependent) | 1000-10000 (diffusion-limited) | 10-100 (scale-independent, oscillation-controlled) |

| Heat Transfer Coefficient (W/m²·K) | 200-500 | 50-150 | 400-1000 |

| Axial Dispersion Number (D/uL) | ~1 (High back-mixing) | 0.01-0.1 | 0.01-0.001 (Near-ideal plug flow) |

| Space-Time Yield (kg·m⁻³·h⁻¹)* | Medium | Low | High (2-10x CSTR) |

| Power Density (W/m³) | High (agitator) | Low (pump only) | Medium (pump + oscillator) |

| Handles High Viscosity (>1 Pa·s) | Limited (motor torque) | Poor (high ∆P) | Excellent (positive mixing) |

*Example for a fast exothermic coupling reaction.

Table 2: Impact of Oscillation Parameters on Key Physical Processes

| Oscillation Variable | Primary Effect on Mixing | Primary Effect on Heat Transfer | Typical Range for API Synthesis |

|---|---|---|---|

| Frequency (f, Hz) | Vortex generation rate. Increases radial fluid exchange. | Increases turbulence at wall, reduces boundary layer thickness. | 0.5 - 6 Hz |

| Amplitude (x₀, mm) | Vortex size and intensity. Governs effective shear. | Increases fluid penetration to heat transfer surface. | 1 - 15 mm (peak-to-peak) |

| Centrifugal Reynold`s Number (Reₒ = 2πfx₀ρD/μ) | Dimensionless scaling parameter. Reₒ > 100 for effective vortex mixing. | Correlates with Nusselt number enhancement. | 10 - 10,000 |

| Net Flow Reynold`s Number (Reₙ = ρuD/μ) | Determines baseline axial flow regime. | Contributes to convective transfer. | 10 - 2000 (often laminar) |

Experimental Protocols

Protocol 3.1: Establishing Residence Time Distribution (RTD) in a COBR

Objective: To characterize the axial dispersion and confirm plug flow behavior under specific oscillation conditions. Materials: COBR setup (baffled tube, piston/diaphragm oscillator, pumps), tracer (conductivity or dye), in-line detector (conductivity probe/UV-Vis), data acquisition system. Procedure:

- Set the reactor temperature and net flow rate (Q) to desired residence time (τ = V/Q).

- Set oscillation frequency (f) and amplitude (x₀). Calculate Reₒ.

- Under steady-state flow and oscillation, inject a sharp pulse of tracer at the inlet.

- Record the tracer concentration vs. time profile (C(t)) at the outlet.

- Calculate the normalized E(t) curve: E(t) = C(t) / ∫₀^∞ C(t)dt.

- Determine the mean residence time (t_mean) and variance (σ²) of the E(t) curve.

- Compute the Bodenstein number (Bo = uL/D_ax) or axial dispersion number (D/uL). A high Bo (>100) indicates near-ideal plug flow.

Protocol 3.2: Measuring Heat Transfer Coefficients (U)

Objective: To quantify the enhanced heat transfer performance due to oscillatory mixing. Materials: COBR with jacketed heat transfer section, constant temperature bath/circulator for jacket, precision inlet/outlet temperature sensors (RTDs), flow meters, data logger. Procedure:

- Circulate a heat transfer fluid at constant temperature (T_j) through the reactor jacket.

- Pump the process fluid at a controlled net flow rate and a known inlet temperature (T_in).

- Initiate oscillation at defined f and x₀. Allow the system to reach thermal steady state.

- Record the stable outlet temperature (T_out) of the process fluid.

- Calculate the log mean temperature difference (LMTD).

- Using the known heat transfer area (A) and heat duty (Q = ṁ·Cp·(Tout - Tin)), calculate the overall heat transfer coefficient: U = Q / (A · LMTD).

- Repeat across a range of Reₒ and Reₙ to build performance correlations.

Protocol 3.3: Conducting a Fast Exothermic Reaction

Objective: To demonstrate improved temperature control and yield in a model exothermic API step. Materials: COBR system, feeds for two reactants (A & B), precision syringe pumps, in-line temperature/pH probes, in-line FTIR or UV for conversion monitoring, quenching/collection system. Procedure:

- Calibrate in-line analytical tools for key reagent and product.

- Set reactor temperature via jacket control.

- Start oscillation at pre-optimized f and x₀ for the fluid properties.

- Initiate feeds of reactants A and B at stoichiometric ratio and a total flow rate for desired τ.

- Monitor in-line temperature profile along the reactor length. The profile should be flat, indicating isothermal operation.

- Use in-line analytics to confirm conversion >99% at outlet.

- Compare yield/selectivity and temperature peak against batch or CSTR data.

Visualization of Key Concepts

Title: COBR Physics Leading to API Outcomes

Title: COBR Process Development Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for COBR API Synthesis Studies

| Item | Function & Rationale |

|---|---|

| Model Reaction Kit (e.g., Bourne Reaction) | A fast, competitive-parallel exothermic reaction pair (alkaline hydrolysis of ethyl chloroacetate vs. diazo coupling). Quantifies micromixing efficiency directly. |

| Conductivity Tracer (e.g., KCl Solution) | Inert, easily detectable electrolyte for precise Residence Time Distribution (RTD) analysis to characterize axial dispersion. |

| Viscosity Modifiers (e.g., Polyethylene Glycol (PEG), Glycerol-Water Mixtures) | To systematically study the performance of COBR across a range of fluid viscosities relevant to polymerizing or condensed-phase API streams. |

| Immiscible Liquid-Liquid System (e.g., Toluene-Water with Passivated Reactor) | To study liquid-liquid extraction or multiphase reaction kinetics, leveraging COBR's excellent interphase mass transfer. |

| pH-Sensitive Dye or In-line pH Probe | To monitor reaction progression and mixing homogeneity in acid-base reactions or crystallizations. |

| In-line Spectroscopic Flow Cell (FTIR, UV-Vis) | For real-time monitoring of reactant consumption and product formation, enabling kinetic modeling and endpoint determination. |

| Calibrated Thermal Imaging Camera | To visualize the external temperature profile along the reactor length, providing direct evidence of isothermal operation during exothermic steps. |

| Non-fouling Baffle Material (e.g., PTFE-coated, Glass) | For processes prone to scaling or crystallization, ensuring consistent hydrodynamic performance over extended runs. |

Application Notes

Within the broader research on Continuous Oscillatory Baffled Reactors (COBRs) for Active Pharmaceutical Ingredient (API) synthesis, three interlinked advantages are paramount. COBR technology decouples mixing from net flow rate by employing periodically spaced baffles and an oscillatory motion, creating uniform, controllable vortices. This foundational principle directly enables superior performance in critical development areas.

Enhanced Mass Transfer: The predictable, plug-flow-like regime with high radial mixing dramatically improves mass and heat transfer coefficients compared to traditional batch or tubular reactors. This is critical for fast, exothermic, or multiphase reactions common in API synthesis, leading to higher selectivity, reduced by-products, and safer operation.

Reproducibility: The highly uniform mixing environment ensures each fluid element experiences nearly identical processing history (shear, temperature, residence time). This eliminates the scale-up problem of inhomogeneity inherent in batch processing, leading to highly consistent product quality and impurity profiles from lab to pilot scale.

Scalability: COBRs are scaled up by maintaining geometric and dynamic similarity (oscillatory Reynolds number and Strouhal number). This "number-up" approach, rather than traditional size-up, allows for linear and predictable scaling from laboratory milliliter volumes to production cubic meter capacities with minimal re-optimization.

Experimental Protocols & Data

Protocol 1: Determination of Mass Transfer Coefficient (kLa) in a COBR System

Objective: To quantify the enhanced gas-liquid mass transfer capability in a COBR for a model oxidation reaction.

Materials & Equipment:

- Lab-scale COBR (e.g., 10 mm internal diameter, 1 m length, with baffled inserts).

- Precision syringe pumps for liquid feed.

- Oscillatory piston drive unit.

- Mass flow controller for gas (O₂) feed.

- Dissolved oxygen probe and data logger.

- Sodium sulfite solution (0.5 M) with cobalt chloride catalyst (1 mM).

Methodology:

- System Preparation: Fill the COBR with deoxygenated water. Calibrate the dissolved oxygen probe.

- Steady-State Operation: Start co-current flow of sodium sulfite solution and oxygen gas at fixed net flow rates (e.g., 10 mL/min liquid, 5 mL/min gas).

- Oscillation Variation: Apply oscillations at a fixed frequency (e.g., 2 Hz) and gradually increase the oscillation amplitude from 1 to 10 mm.

- Data Acquisition: Record the steady-state dissolved oxygen concentration at multiple axial positions for each amplitude setting under a constant gas holdup.

- Calculation: The mass transfer coefficient kLa is calculated using the oxygen balance equation: kLa = (QL * ΔC) / (V * (C* - Cavg)), where QL is liquid flow rate, ΔC is oxygen concentration change, V is reactor volume, C* is saturation concentration, and Cavg is the log-mean concentration.

Protocol 2: Residence Time Distribution (RTD) Analysis for Reproducibility Assessment

Objective: To characterize the plug-flow nature and mixing consistency of the COBR.

Materials & Equipment:

- COBR setup as in Protocol 1.

- Tracer substance (e.g., NaCl solution, inert dye).

- Conductivity probe or UV-Vis flow cell at reactor outlet.

- Data acquisition system.

Methodology:

- Baseline Establishment: Establish steady-state flow of the main process solvent through the COBR at the desired net flow and oscillation conditions.

- Tracer Pulse Injection: Inject a sharp, small-volume pulse of tracer into the inlet stream.

- Outlet Monitoring: Continuously measure the tracer concentration at the outlet over time.

- Data Analysis: Plot the normalized concentration (E-curve) versus time. Calculate the variance (σ²) of the distribution. A low variance (σ²/τ² < 0.1, where τ is mean residence time) indicates near-ideal plug flow and high reproducibility potential.

- Repeatability Test: Repeat the experiment at least three times under identical conditions to confirm the consistency of the RTD curve.

Table 1: Comparative Performance Metrics: COBR vs. Stirred Tank Batch Reactor (STR) for a Model API Coupling Reaction

| Parameter | COBR (Lab Scale) | Batch STR (1 L) | Advantage Factor (COBR/STR) |

|---|---|---|---|

| Mass Transfer Coefficient (kLa) (s⁻¹) | 0.15 - 0.35 | 0.02 - 0.08 | ~4-5x |

| Mixing Time (s) | < 2 (radial) | 10 - 60 | >5x faster |

| Residence Time Variance (σ²/τ²) | 0.05 - 0.15 | 0.8 - ∞ (ideal batch = ∞) | Highly predictable flow |

| Scale-up Consistency (Yield at 100x scale) | 98% ± 0.5% | 95% ± 5% | Dramatically improved reproducibility |

| Space-Time Yield (kg m⁻³ h⁻¹) | 25 - 100 | 5 - 20 | ~3-5x higher |

Table 2: Key Scaling Parameters for COBR Technology

| Scaling Parameter | Definition | Scale-up Rule | Target Value for Consistency |

|---|---|---|---|

| Oscillatory Reynolds Number (Reₒ) | (2πfaρD)/μ | Keep Constant | 1000 - 10,000 (turbulent mixing) |

| Strouhal Number (St) | D/(4π*a) | Keep Constant | 0.3 - 3.0 (stable vortex formation) |

| Net Flow Reynolds Number (Reₙ) | (ρuD)/μ | Increases linearly with flow rate | < Reₒ for oscillation dominance |

Visualizations

COBR Advantage Pathway

RTD Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function in COBR API Synthesis Research |

|---|---|

| Lab-scale COBR Assembly | Modular reactor with baffled tubes, oscillatory diaphragm/piston, and temperature control jackets for foundational hydrodynamics and reaction studies. |

| Precision Syringe Pumps | Deliver consistent, pulse-free net flow of reagent solutions, critical for maintaining stable residence times. |

| Mass Flow Controller (MFC) | Precisely meters gaseous reagents (e.g., H₂, O₂) for hydrogenations/oxidations and mass transfer studies. |

| In-line PAT Probes | Fourier-Transform Infrared (FTIR), UV-Vis, or Raman spectroscopy for real-time monitoring of reaction progression and endpoint detection. |

| Static Mixer Baffle Inserts | Geometrically defined (e.g., helical, orifice) baffles that generate controlled vortices; different designs optimize mixing for varying fluid viscosities. |

| Residence Time Distribution (RTD) Tracer | Non-reactive species (e.g., NaCl, fluorescent dye) used to characterize flow mixing and validate plug-flow behavior. |

| Model Reaction Kit | Well-studied reactions (e.g., Suzuki coupling, esterification) with known kinetics, used to benchmark COBR performance against traditional reactors. |

| Multiphase Feed System | Enables stable introduction of solid slurries or immiscible liquids for investigating complex API synthesis steps in continuous flow. |

Within the broader thesis on Continuous Oscillatory Baffled Reactors (COBR) for Active Pharmaceutical Ingredient (API) synthesis, a critical engineering challenge is overcoming the radial mixing limitations inherent in traditional tubular laminar flow reactors. Plug flow is essential for high product yield and purity in multi-step API synthesis. While tubular reactors operating under laminar flow conditions offer simplicity, their parabolic velocity profile leads to broad residence time distributions (RTD) and poor radial mixing, which can cause hot spots, side reactions, and inconsistent product quality. COBR technology decouples mixing from net flow by superimposing oscillatory motion on the net flow through a series of baffles. This creates repeated eddies, enabling superior radial mixing and near-ideal plug flow behavior even at very low net flow rates. This application note provides a comparative analysis and practical protocols for evaluating and implementing COBR systems to overcome the limitations of tubular laminar flow in API research.

Quantitative Data Comparison

Table 1: Performance Comparison of COBR vs. Tubular Laminar Flow Reactors

| Parameter | Tubular Laminar Flow Reactor (Straight Tube) | Continuous Oscillatory Baffled Reactor (COBR) | Implications for API Synthesis |

|---|---|---|---|

| Primary Mixing Mechanism | Molecular diffusion & weak convective currents (Taylor dispersion) | Controlled, oscillatory-generated eddies between baffles. | COBR provides intense, uniform radial mixing independent of net flow. |

| Residence Time Distribution (RTD) Variance (σ²) | High (broad distribution). Model-dependent (e.g., σ²/τ² ~ 0.02-0.1 for laminar). | Very Low (sharp distribution). Can achieve σ²/τ² < 0.01. | Narrow RTD in COBR ensures uniform reaction time, critical for consistent API quality and yield. |

| Reynolds Number (Re) Range (Net Flow) | Re < 2100 (Laminar regime). | Re (net) typically < 10 (Highly laminar). | COBR operates at low net flow, enabling long residence times in compact equipment. |

| Oscillatory Reynolds Number (Reₒ) | Not Applicable (N/A). | Typically 100 - 5000 (tunable). | Reₒ governs mixing intensity. It is the primary control variable for scaling in COBR. |

| Velocity Profile | Parabolic (highly variable radial velocity). | Near-flat ("plug-like") across baffle cavity. | Flat profile minimizes axial dispersion and prevents hot spots in exothermic API reactions. |

| Heat Transfer Coefficient | Low to Moderate (30 - 200 W/m²·K). | High (200 - 1000+ W/m²·K) due to fluid agitation. | Superior heat transfer in COBR enables better control of exothermic or temperature-sensitive reactions. |

| Scale-up Methodology | Complex; diameter increase worsens mixing. | Straightforward via geometric and dynamic similarity (constant Reₒ, Strouhal No.). | Simplifies translation from lab (mL/min) to pilot/production (L/min) scale for API processes. |

Table 2: Typical Operating Parameters for a Lab-Scale COBR in API Synthesis

| Parameter | Symbol | Typical Range | Function & Control |

|---|---|---|---|

| Net Flow Rate | Q | 1 - 100 mL/min | Controls residence time (τ = V/Q). Sets production rate. |

| Oscillation Frequency | f | 1 - 6 Hz | Governs mixing energy input. Increases Reₒ. |

| Oscillation Amplitude (center-to-peak) | x₀ | 2 - 10 mm | Governs mixing scale. Increases Reₒ. |

| Oscillatory Reynolds Number | Reₒ = (2πf x₀ ρ D)/μ | 100 - 2000 | Dimensionless number characterizing mixing intensity. Key scale-up parameter. |

| Strouhal Number | St = D/(4π x₀) | ~0.2 - 2.0 | Ratio of tube to oscillation amplitude. Optimized for efficient eddy propagation. |

| Residence Time | τ | 5 - 120 min | Determined by reactor volume and Q. Easily extended without compromising mixing. |

Experimental Protocols

Protocol 1: Residence Time Distribution (RTD) Analysis for Reactor Characterization

Objective: To quantitatively compare the degree of axial dispersion and plug flow performance between a tubular laminar flow reactor and a COBR.

Materials: See "Scientist's Toolkit" (Section 5).

Method:

- Reactor Setup: Install either the straight tubular reactor (e.g., 1/8" ID, 5m length coil) or the COBR module (e.g., 15mm ID, 10 baffled cells) in the flow rig. Connect to feed pumps and a detector (e.g., UV-Vis, Conductivity).

- Conditioning: Pump the carrier fluid (e.g., deionized water, solvent) through the system at the desired net flow rate (Q) until stable baseline is achieved. For COBR, set oscillation parameters (f, x₀) to target Reₒ.

- Tracer Injection: At time t=0, swiftly inject a small, sharp pulse of tracer (e.g., 0.1% acetone in water for UV at 270nm, or NaCl solution for conductivity) into the feed stream.

- Data Acquisition: Record the detector output (C(t)) at high frequency (e.g., 10 Hz) until the signal returns to baseline.

- Data Processing: Normalize the concentration curve (E-curve). Calculate the mean residence time (τ = ∫ t·E(t) dt) and variance (σ² = ∫ (t-τ)²·E(t) dt).

- Analysis: Compare the normalized variance (σ²/τ²) and shape of the E-curve. A lower σ²/τ² and sharper peak indicate closer approach to ideal plug flow.

Protocol 2: Investigating a Model API Synthesis Reaction (e.g., Imine Formation)

Objective: To demonstrate the impact of radial mixing on the yield and selectivity of a fast, mixing-sensitive reaction.

Materials: See "Scientist's Toolkit." Primary reagents: Benzaldehyde and aniline in ethanol (for imine formation).

Method:

- Solution Preparation: Prepare separate 0.1M solutions of benzaldehyde (Solution A) and aniline (Solution B) in anhydrous ethanol.

- System Equilibration: Prime both feed lines with their respective solutions. Start net flow (Q) and, for COBR, oscillations to establish steady-state flow. Use a tee mixer before the reactor inlet.

- Reaction Execution: Commence pumping A and B at equal flow rates (total flow = Q) into the reactor. Allow >5 residence times to achieve steady state.

- Sampling & Analysis: Collect effluent stream over a known period. Analyze by HPLC-UV.

- HPLC Method: C18 column; Mobile Phase: 60:40 Acetonitrile:Water; Flow: 1 mL/min; Detection: 254 nm.

- Quantify remaining benzaldehyde and aniline, and product imine using calibrated standards.

- Variable Study: Repeat experiment varying:

- Tubular Reactor: Net flow rate (Q) only.

- COBR: Net flow rate (Q) at constant Reₒ, and Reₒ at constant Q.

- Metrics: Calculate conversion (%) and selectivity to imine (%) for each condition. Plot against Damköhler number (Da) or power density.

Mandatory Visualizations

Title: Reactor Selection Logic for API Synthesis

Title: RTD Experimental Workflow Protocol

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Key Materials for COBR vs. Tubular Flow Experiments

| Item | Function/Description | Example(s) & Notes |

|---|---|---|

| Lab-Scale COBR Module | Baffled tube reactor where oscillatory mixing occurs. Typically glass or stainless steel with fixed-orifice baffles. | Vendor: NiTech Solutions, AM Technology. Spec: 10-30mm ID, 5-20 baffled cells, jacketed for temperature control. |

| Oscillation Drive Unit | Generates and controls the sinusoidal piston motion (frequency & amplitude). | Electromechanical or pneumatic actuator. Must provide stable, adjustable oscillation (0.5-10 Hz, 1-20 mm amp). |

| Precision Pumps (x2) | Deliver reagent feeds at precise, pulseless low flow rates for continuous operation. | Type: HPLC-grade syringe pumps or dual-piston diaphragm pumps. Range: 0.1 - 50 mL/min. |

| Pulse-Free Diaphragm Pump | For single-phase net flow circulation in RTD studies. | Provides constant flow without interfering with oscillation. |

| In-Line UV/Vis Spectrophotometer | Real-time concentration monitoring for RTD or reaction progression. | Flow cell (e.g., 10 mm path). Suitable for tracers (acetone, dyes) or reacting species with chromophores. |

| In-Line Conductivity Probe | Alternative for tracer detection in RTD studies using ionic tracers (e.g., KCl). | Provides fast response for sharp pulse detection. |

| Tee Mixer or Static Mixer | Initial merging point for reagent streams before entering the reactor. | Low dead-volume mixer essential for studying fast kinetics. |

| Temperature Control Unit | Circulates heat transfer fluid through reactor jacket for isothermal operation. | Essential for exothermic API reactions to maintain safety and selectivity. |

| Chemical-Compatible Tubing & Fittings | Connects all components. Must be inert to solvents used (e.g., EtOH, ACN, DMF). | Material: PTFE, PFA, or 316L SS. Size: 1/16" or 1/8" OD. |

| Model Reaction Reagents | For demonstrating mixing-sensitive chemistry. | Imine Formation: Benzaldehyde, Aniline, anhydrous Ethanol. Azo-Coupling: Diazonium salt, Naphthol. |

Within the broader thesis on advancing Continuous Oscillatory Baffled Reactor (COBR) technology for Active Pharmaceutical Ingredient (API) synthesis, the optimization of core components is critical. This document details application notes and protocols for the three foundational pillars of COBR design: baffle geometries, oscillation mechanisms, and material compatibility. These elements collectively govern mixing efficiency, heat/mass transfer, residence time distribution (RTD), and ultimately, the yield and purity of pharmaceutical intermediates and final APIs.

Baffle Geometries: Design and Comparative Analysis

Baffles are the central mixing elements in a COBR. Their geometry dictates the creation of eddies and uniform radial mixing while maintaining plug flow.

Common Baffle Geometries and Performance Data

Table 1: Comparative Analysis of Standard Baffle Geometries

| Baffle Geometry | Typical Dimensions (Relative to Tube Diameter, D) | Key Flow Characteristics | Optimal Strouhal Number (St) Range | Mixing Intensity | Notes for API Synthesis |

|---|---|---|---|---|---|

| Orifice Baffle | Hole diameter = 0.2-0.5 D | High shear, abrupt contraction/expansion. | 0.2 - 0.6 | Very High | Excellent for fast reactions, but potential for dead zones behind baffle. High shear may damage sensitive biocatalysts. |

| Integral Baffle (e.g., Single Baffle) | Baffle diameter = 0.7-0.85 D | Smooth, annular flow. Low pressure drop. | 0.3 - 1.0 | Moderate | Promotes uniform laminar shear. Suitable for shear-sensitive particles (e.g., crystallization). |

| Dual Helical Baffle | Baffle pitch = 1.5 D, Diameter ~0.7 D | Induces global swirling motion in addition to radial mixing. | 0.4 - 0.8 | High | Superior radial mixing and reduced axial dispersion. Excellent for multiphase (solid-liquid) reactions. |

| Segmented Helical Baffle | Segments with 180° twist, spaced 0.5 D | Combines orifice-like mixing with helical flow guidance. | 0.3 - 0.7 | Very High | Minimizes dead zones, enhances heat transfer. Ideal for viscous non-Newtonian media in polymer-supported synthesis. |

Protocol: Experimental Characterization of Baffle Performance

Objective: To quantify the mixing performance and Residence Time Distribution (RTD) for a given baffle geometry.

Materials:

- COBR test rig with interchangeable baffle inserts.

- Positive displacement pump for continuous feed.

- Oscillation mechanism (piston/diaphragm).

- Tracer solution (e.g., NaCl solution, inert dye).

- Conductivity probe/UV-Vis flow cell at reactor outlet.

- Data acquisition system.

Procedure:

- Setup: Install the test baffle set into the reactor tube. Ensure seals are tight.

- Calibration: Establish a baseline relationship between tracer concentration and detector signal (conductivity/absorbance).

- Steady Flow: Set a constant net flow rate (Q) to achieve a target residence time (τ).

- Oscillation Initiation: Apply sinusoidal oscillation at a fixed frequency (f) and amplitude (x₀). Calculate oscillatory Reynolds number (Reo = \frac{2\pi f x0 \rho D}{\mu}) and Strouhal number (St = \frac{D}{4\pi x_0}).

- Tracer Injection: At time t=0, inject a sharp pulse of tracer into the feed stream.

- Data Collection: Record the detector output over time (C(t) curve) until it returns to baseline.

- Analysis: Calculate the mean residence time (( \tau{mean} = \frac{\int0^\infty tC(t)dt}{\int0^\infty C(t)dt} )) and variance (( \sigma^2 = \frac{\int0^\infty (t-\tau{mean})^2 C(t)dt}{\int0^\infty C(t)dt} )). The dimensionless variance (( \sigma\theta^2 = \sigma^2 / \tau{mean}^2 )) inversely correlates with plug flow quality.

- Repetition: Repeat steps 3-7 across a matrix of Re_o and St numbers.

COBR Baffle Performance Testing Workflow

Oscillation Mechanisms: Drive Systems and Control

Oscillation provides the energy for mixing independently of net flow. Precise control is vital for reproducible API synthesis.

Mechanism Types and Specifications

Table 2: Comparison of Oscillation Drive Mechanisms

| Mechanism Type | Principle | Maximum Frequency (Hz) / Amplitude (mm) | Control Precision | Advantages | Limitations |

|---|---|---|---|---|---|

| Reciprocating Piston | Electric motor with crankshaft or linear actuator. | ~5 Hz / ±50 mm | Moderate | Robust, high force capability for high viscosity. | Mechanical linkages cause wear. Mid-stroke control can be imprecise. |

| Pneumatic Diaphragm | Alternating air pressure on a diaphragm. | ~10 Hz / ±10 mm | Low to Moderate | Simple, clean (no lubricants in fluid path). | Stiffness of diaphragm limits amplitude. Compression heating of gas. |

| Electromagnetic Shaker | Moving coil in a magnetic field (like a loudspeaker). | >20 Hz / ±5 mm | Very High | Excellent dynamic control, arbitrary waveforms possible. | Limited force/payload, requires specialized amplifier/cooling. |

| Hydraulic Actuator | Servo-valve controlled hydraulic piston. | ~15 Hz / ±25 mm | High | Very high force, good speed and control. | Complex, expensive, risk of hydraulic fluid contamination. |

Protocol: Calibration and Tuning of an Oscillation System

Objective: To verify and calibrate the actual oscillatory displacement and waveform at the reactor.

Materials:

- COBR with oscillation mechanism.

- Non-contact position sensor (e.g., laser displacement sensor, LVDT).

- Oscilloscope or high-speed DAQ.

- Function generator (for electromagnetic systems).

Procedure:

- Sensor Mounting: Fix the displacement sensor pointing at the oscillating shaft or a target attached to it.

- Signal Connection: Connect the sensor output to the oscilloscope/DAQ.

- Waveform Verification: Command a low-frequency sinusoidal oscillation (e.g., 0.5 Hz). Capture the position vs. time signal.

- Amplitude Calibration: Measure the peak-to-peak distance (mm) from the waveform. Compare to the setpoint amplitude. Create a calibration curve if necessary.

- Frequency Verification: Measure the period of the oscillation and calculate the frequency.

- Harmonic Analysis: Increase the frequency towards the operational range. Use FFT analysis on the DAQ to check for distortion from the commanded sine wave (indicative of mechanical slack or resonance).

- Tuning: For PID-controlled systems, use the step response from the sensor to tune the controller for minimal overshoot and fast settling time.

Material Considerations: Compatibility and Fabrication

Material selection ensures chemical resistance, prevents contamination, and allows for scalability.

Key Material Classes and Applications

Table 3: Material Selection Guide for COBR Components

| Material Class | Specific Examples | Key Properties | Typical Use in API Synthesis | Critical Considerations |

|---|---|---|---|---|

| Borosilicate Glass | Duran, Pyrex | Excellent chemical resistance, transparent, smooth surface. | Lab and pilot-scale tubes, sight glasses. | Brittle, low pressure/temperature limits. Not for HF or strong alkalis. |

| Stainless Steel | 316L, 316LVM | High strength, good general corrosion resistance, sterilizable. | Pilot/production baffles, housings, jackets. | Risk of metal ion leaching (Ni, Cr, Mo). Can be passive for many processes. |

| Hastelloy | C-22, C-276 | Exceptional resistance to reducing acids (HCl, H₂SO₄) and chlorides. | Reactor tubes/baffles for highly corrosive chemistries. | Very high cost. Machining requires expertise. |

| PTFE (Teflon) | Virgin PTFE | Nearly universal chemical inertness, low surface energy. | Seals, gaskets, diaphragm for oscillation, lining. | Low mechanical strength, creeps under load. Not for molten alkali metals. |

| PFA / FEP | Perfluoroalkoxy | PTFE-like resistance with better formability/molding. | Transparent flexible tubing for lines, sight sections. | Softer than PTFE, lower temperature rating. |

| Silicon Carbide (SiC) | Sintered SiC | Extreme corrosion/erosion resistance, high thermal conductivity. | Specialized baffles for abrasive slurries or extreme conditions. | Very brittle and expensive. Complex fabrication. |

Protocol: Leachate Testing for Material Compatibility

Objective: To assess the potential for extractable compounds to leach from reactor wetted materials into process solvents.

Materials:

- Material coupons (e.g., 316L, PTFE, sealed glass).

- Relevant solvents/process fluids (e.g., MeOH, DCM, toluene, aqueous acid/base).

- Control solvent (no coupon).

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS) or HPLC-MS.

- Accelerated aging oven.

Procedure:

- Coupon Preparation: Clean coupons per ASTM or USP guidelines. Weigh and dimension each.

- Immersion: Place each coupon in a separate sealed vessel with the chosen solvent. Ensure complete immersion. Prepare a solvent-only control.

- Accelerated Aging: Age samples at an elevated temperature (e.g., 50°C) for 7-14 days to simulate long-term exposure.

- Sample Extraction: Remove solvent from each vessel, taking care not to introduce particulate.

- Analysis:

- For metals: Analyze via ICP-MS for relevant elements (Fe, Cr, Ni, Mo from steel; Si from glass).

- For polymers: Analyze via HPLC-MS for organic additives (plasticizers, antioxidants).

- Reporting: Report leachate concentration in µg/mL or ppb. Normalize by surface area and time if required.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials and Reagents for COBR API Synthesis Research

| Item | Function in COBR Research | Example/Notes |

|---|---|---|

| Calibration Tracers | To experimentally determine Residence Time Distribution (RTD). | NaCl (conductivity), UV-active dyes (Rhodamine B), or a non-reactive analog of the API. |

| Process Analytical Technology (PAT) Probes | For in-line, real-time monitoring of reaction progress. | FTIR (ReactIR), Raman, or UV-Vis flow cells. Enables feedback control. |

| Corrosion Inhibitors / Passivation Solutions | To pre-treat stainless steel surfaces and minimize metal leaching. | Nitric acid solutions for SS passivation. Specific inhibitors for process media. |

| High-Performance Sealing Grease | To lubricate oscillating shafts while maintaining chemical integrity. | PFPE (Perfluoropolyether) based greases (e.g., Fomblin). Inert and non-flammable. |

| Static Mixer Elements | For preliminary fluid mixing before entering the COBR, ensuring consistent feed. | Used in feed lines to homogenize multi-component streams. |

| Non-Newtonian Fluid Models | To study mixing with viscosity changes, relevant for polymer-supported synthesis. | Aqueous solutions of CMC or PAA at varying concentrations. |

| Computational Fluid Dynamics (CFD) Software | To simulate fluid mechanics and predict mixing performance before fabrication. | ANSYS Fluent, COMSOL Multiphysics with oscillatory flow modules. |

Implementing COBRs: Design, Operation, and Real-World API Synthesis Case Studies

Application Notes

This document provides detailed application notes and experimental protocols for the key design parameters of a Continuous Oscillatory Baffled Reactor (COBR) within the context of Active Pharmaceutical Ingredient (API) synthesis research. The systematic optimization of oscillation frequency, amplitude, net flow, and reactor dimensions is critical for achieving precise control over mixing, residence time distribution (RTD), and ultimately, the yield and purity of pharmaceutical intermediates.

Core Design Parameters & Their Interrelationships

The performance of a COBR is governed by the interaction of oscillatory conditions and geometric parameters. The oscillatory Reynolds number (Reo) and the velocity ratio (ψ) are key dimensionless groups that characterize the flow regime.

- Oscillation Frequency (f): The number of oscillatory cycles per second (Hz). Directly influences the mixing intensity and shear rate.

- Amplitude (*x0): The center-to-peak displacement of the oscillating fluid (m). Combined with frequency, it defines the oscillatory velocity.

- Net Flow Velocity (*Unet): The superficial velocity of the process stream through the reactor, governing the mean residence time.

- Reactor Sizing: Primarily defined by tube diameter (D) and baffle geometry (baffle hole diameter dh, baffle spacing, baffle thickness). Dictates the available volume and influences the oscillatory flow dynamics.

The oscillatory Reynolds number Reo = (2πf x0 ρ *D) / μ describes the intensity of oscillatory mixing, while the velocity ratio ψ = (2πf x0) / *Unet describes the relative contribution of oscillatory to net flow. For effective plug-flow characteristics, ψ > 1 is typically targeted.

Table 1: Quantitative Design Parameter Ranges for API Synthesis COBRs

| Parameter | Symbol | Typical Range for Lab-Scale API Synthesis | Influence on Process |

|---|---|---|---|

| Oscillation Frequency | f | 0.5 – 6.0 Hz | ↑ Mixing, ↑ Heat/Mass Transfer, ↑ Shear |

| Oscillation Amplitude | x0 | 1 – 15 mm | ↑ Mixing, ↑ Axial Dispersion at high Reo |

| Net Flow Velocity | Unet | 1 – 10 mm/s | Determines Residence Time, Throughput |

| Tube Diameter | D | 10 – 50 mm | Scales Volume, Influences Reo |

| Baffle Hole Diameter | dh | 0.4 – 0.6 D | Controls Eddy Generation & Pressure Drop |

| Baffle Spacing | lb | 1.5 – 2.0 D | Optimizes Vortex Formation & Interaction |

| Oscillatory Reynolds | Reo | 100 – 10,000 | <100: Laminar; >1000: Turbulent Mixing |

| Velocity Ratio | ψ | 2 – 20 | >1: Dominant Oscillatory Mixing |

Key Experimental Protocols

Protocol 1: Determination of Optimal Oscillatory Conditions (f&x0) for a Given Reaction

Objective: To identify the combination of frequency and amplitude that minimizes RTD and maximizes yield for a model API step. Methodology:

- Setup: Install a calibrated COBR module with a transparent section. Use a non-reactive tracer (e.g., dye or conductive salt solution) matching the process fluid's physical properties.

- Residence Time Distribution (RTD) Study:

- Set a constant net flow (Unet) to achieve a target residence time (e.g., 5 minutes).

- For a fixed amplitude x0, incrementally increase frequency f across the range (e.g., 1, 2, 3, 4 Hz).

- At each condition, inject a pulse of tracer at the reactor inlet and measure the concentration profile at the outlet via UV/Vis or conductivity probe.

- Calculate the normalized variance (σ2θ) of the RTD curve. Lower variance indicates closer approach to ideal plug flow.

- Reaction Yield Study:

- Conduct a model reaction (e.g., a fast, exothermic coupling reaction relevant to API synthesis) under the same matrix of f and x0 conditions.

- Hold residence time constant via Unet adjustment.

- Sample the outlet stream and analyze yield via HPLC/UPLC.

- Analysis: Plot contours of RTD variance and reaction yield against f and x0. The optimum is the region that minimizes variance and maximizes yield, often corresponding to Reo > 1000.

Protocol 2: Scaling Based on Constant Oscillatory Power Density (Pv)

Objective: To maintain consistent mixing intensity when increasing reactor diameter from lab to pilot scale. Methodology:

- Lab-Scale Characterization: For the optimal lab condition, calculate the oscillatory power dissipation per unit volume: Pv = (2 ρ (2πf x0)3 ξ) / (3π C D) where ξ is the fractional baffle free area and C is an orifice discharge coefficient (~0.7).

- Scale-Up Calculation: To design a larger diameter reactor (D2), maintain geometric similarity (constant dh/D, lb/D).

- Solve for Conditions: Rearrange the Pv equation to solve for the required product (f x0) for the large scale that gives the same Pv as the lab scale. Multiple combinations of f and x0 may satisfy this; mechanical constraints guide the final selection.

- Verification: Perform RTD studies on the scaled reactor to confirm similar plug-flow performance.

Visualization of COBR Design Logic

Title: COBR Parameter Influence Pathway for API Synthesis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for COBR API Synthesis Research

| Item | Function in Research | Typical Specification / Example |

|---|---|---|

| Model Reaction Kit | To validate reactor performance under relevant chemistries. | Fast exothermic reaction (e.g., alkaline hydrolysis of ethyl acetate), diazotization, or a photochemical step. |

| Tracer Solutions | For Residence Time Distribution (RTD) analysis to quantify plug-flow behavior. | Potassium chloride (conductivity), dye (e.g., Rhodamine B for UV/Vis), or a non-reactive HPLC marker. |

| Process Analytical Technology (PAT) Probes | For real-time monitoring of reaction progression. | Inline FTIR, UV/Vis spectrophotometer, or conductivity/pH probes. |

| Oscillation-Compatible Diaphragm/Piston Pump | Generates the precise, controllable oscillatory flow. | Chemically resistant wetted materials (PTFE, SS316L), capable of 0-10 Hz, 0-20 mm amplitude. |

| Precision HPLC/UPLC System | For off-line quantitative analysis of API/intermediate yield and purity. | C18 column, PDA/UV detector, capable of gradient elution. |

| Calibrated Flow Meters & Pumps | For accurate delivery of net flow and reagent streams. | Coriolis mass flow meter for liquids, syringe or HPLC pump for low flow rates. |

| Thermostatted Jacket/Circulator | Maintains precise temperature control for kinetic studies. | Range: -10°C to 150°C, with PID control. |

| Baffle & Tube Sets | Modular reactor geometries for parameter screening. | Borosilicate glass or SS316L tubes with interchangeable PTFE or metal baffles of varying dh and spacing. |

Within the broader research on advanced reactor technology for Active Pharmaceutical Ingredient (API) synthesis, the Continuous Oscillatory Baffled Reactor (COBR) presents a transformative methodology. It enhances mixing and heat/mass transfer through oscillatory flow and baffled geometry, enabling precise control over reaction parameters critical for pharmaceutical development. These Application Notes provide a structured protocol for transitioning COBR systems from laboratory-scale research to pilot-scale operation, ensuring reproducibility and safety in API synthesis.

Core Principles & System Components

A COBR achieves plug-flow conditions at low net flow rates by superimposing an oscillatory motion onto the net flow through a tube containing equally spaced baffles. This creates uniform, scalable mixing independent of net throughput.

Table 1: Key COBR System Components and Functions

| Component | Function in API Synthesis | Material Considerations |

|---|---|---|

| Baffled Tube Reactor | Provides the primary reaction volume; baffles generate vortices for mixing. | Glass (lab), 316L Stainless Steel or Hastelloy (pilot/corrosive reagents). |

| Oscillation Mechanism | Piston or diaphragm generating the oscillatory flow. | Requires precise control of amplitude and frequency. |

| Heat Exchanger Jacket | Controls exotherm/endotherm of API reactions for safety & yield. | Compatible with heating/cooling fluids. |

| Feed & Product Vessels | Holds starting materials and product collection. | Size scales with operation; may require inert atmosphere. |

| Process Control System (PCS) | Monitors and controls T, flow rate, oscillation, pressure. | Critical for cGMP compliance in pharmaceutical pilot. |

| Sampling Point | Allows for inline/offline analysis of reaction progress. | Must be representative and safe for hazardous materials. |

Step-by-Step Setup & Operational Protocol

Laboratory-Scale Setup & Commissioning

Objective: Establish stable operation and gather kinetic data for scale-up. Protocol:

- Assembly: Mount the glass baffled tube vertically/horizontally. Connect feed pumps, oscillation unit, and thermal jacket to the PCS.

- Leak Test: Pressure test with inert gas (N₂) at 1.5x operating pressure. Check all fittings with leak detection spray.

- Hydraulic Testing: Fill system with a benign solvent (e.g., water, ethanol). Start oscillation unit. Gradually increase amplitude (x₀: 1-10 mm) and frequency (f: 0.5-5 Hz) to characterize fluid dynamics. Measure and record pressure drop.

- Calibration: Calibrate all sensors (T, pressure) and pumps against certified standards.

- Initial Chemical Test: Perform a test reaction with a non-hazardous model compound to validate mixing performance and residence time distribution (RTD).

Pilot-Scale Setup & Qualification

Objective: Scale the validated lab process safely and efficiently. Protocol:

- Design Transfer: Scale using geometric similarity (constant baffle spacing/diameter ratio) and dynamic similarity (maintaining oscillatory Reynolds number Reₒ = (2πfx₀ρD)/μ and Strouhal number St = D/(4πx₀)).

Table 2: Key Scaling Parameters for COBR

Parameter Definition Scale-Up Goal Oscillatory Reynolds (Reₒ) Inertial vs. viscous forces Keep constant for similar mixing. Velocity Ratio (ψ) Oscillatory velocity / net flow velocity Keep >1 to maintain plug flow. Power Density Power input per unit volume Similar or adjusted for heat transfer. - Installation & Safety: Install in a designated pilot area with bunding, ventilation, and emergency showers. Integrate with plant utilities. Install emergency stop circuits and pressure relief devices.

- Operational Qualification (OQ): Execute predefined tests with water/solvent to prove system operates as designed across all operational ranges (flow, oscillation, T).

- Performance Qualification (PQ): Execute a dummy run with solvent and model reaction to demonstrate consistent product quality (e.g., yield, purity) over an extended period (>24h).

Detailed Experimental Protocol: API Intermediate Synthesis

Reaction: A model nucleophilic substitution to form an API intermediate. Reagents: Substrate A (0.5 M), Nucleophile B (0.75 M), in solvent Tetrahydrofuran (THF).

Procedure:

- Prepare reagent solutions in an inert atmosphere glovebox if moisture-sensitive.

- Pre-heat/cool COBR to setpoint temperature (e.g., 45°C) using jacketed system.

- Start oscillation: set amplitude to 6 mm, frequency to 2 Hz (Reₒ ~ 4500 for typical solvent).

- Initiate feeds of A and B into the reactor at fixed flow rates to achieve target residence time (τ = reactor volume / total flow rate). E.g., for a 500 mL reactor volume, set total flow to 50 mL/min for τ = 10 min.

- Allow system to reach steady-state (≥ 3τ). Monitor PCS for stability.

- Collect product stream samples at regular intervals (every τ) for 5 residence times.

- Analyze samples immediately by HPLC to determine conversion and selectivity.

- Post-run, flush system thoroughly with clean solvent following a pre-defined safe shut-down procedure.

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

| Item | Function in COBR API Synthesis |

|---|---|

| Anhydrous, HPLC-Grade Solvents | Ensure reaction consistency, prevent side reactions, allow for direct analysis. |

| Calibrated Syringe/PLC Pumps | Provide precise, pulse-free delivery of reagents for accurate stoichiometry and residence time. |

| In-line FTIR or UV-Vis Probe | Enables real-time monitoring of reaction progression and endpoint detection. |

| Quench Solution Collection | Rapidly stops reaction at sampling point for accurate offline analysis. |

| Stabilized Reagent Solutions | Pre-mixed, standardized solutions ensure run-to-run reproducibility during long campaigns. |

Safety & Operational Best Practices

- Chemical Hazard Assessment: Conduct for all reagents, intermediates, and products (e.g., NFPA, GHS). Implement appropriate containment.

- Pressure Management: Never exceed the maximum working pressure of the weakest component. Install rupture discs for overpressure protection.

- Thermal Hazard Control: For exotherms, ensure jacket cooling capacity exceeds maximum potential heat release. Use redundant temperature sensors with automated shutdown.

- Oscillation Safety: Install mechanical guards. Ensure emergency stop immediately halts oscillation.

- Waste Handling: Plan for collection and neutralization of the continuous product stream.

Data Collection & Analysis

Table 3: Critical Process Parameters (CPPs) & Their Impact on Critical Quality Attributes (CQAs)

| CPP | Typical Range (Lab/Pilot) | Impact on API CQAs (Yield, Purity) |

|---|---|---|

| Residence Time (τ) | 2 min - 2 hours | Determines conversion; side products may form if too long. |

| Oscillation Amplitude (x₀) | 1 - 15 mm | Influences mixing and heat transfer; affects uniformity. |

| Oscillation Frequency (f) | 0.5 - 6 Hz | Combined with x₀, defines mixing intensity (Reₒ). |

| Temperature (T) | -20°C to 150°C | Impacts reaction rate, selectivity, and stability. |

| Reactant Concentration | Variable | Stoichiometry and kinetics dictate optimal values. |

Diagram Title: COBR Development Workflow from Lab to Pilot

Diagram Title: COBR Process Control and Quality Feedback Loop

Introduction Within the paradigm of continuous manufacturing for Active Pharmaceutical Ingredients (APIs), the Continuous Oscillatory Baffled Reactor (COBR) presents a transformative platform for synthesis and downstream processing. This case study focuses on the application of COBR technology for the controlled crystallization and precise Particle Size Distribution (PSD) management of a model API, Ibuprofen. Consistent PSD is critical for downstream formulation processes, bioavailability, and final drug product performance. The oscillatory flow within a COBR provides uniform mixing and predictable supersaturation generation, enabling superior control over nucleation and crystal growth compared to traditional batch crystallizers.

Application Notes: COBR Crystallization of Ibuprofen

- Objective: To achieve a consistent, narrow PSD of ibuprofen crystals via antisolvent crystallization in a COBR.

- System Advantages: The COBR's plug-flow characteristics, induced by oscillatory motion and baffles, ensure every fluid element experiences identical supersaturation and residence time profiles. This minimizes spatial inhomogeneities, leading to a more uniform crystal population.

- Key Process Parameters (KPPs):

- Oscillation Amplitude (

x₀) and Frequency (f): Control mixing intensity and shear, impacting nucleation kinetics. - Residence Time (

τ): Dictates total time for growth and determines process throughput. - Antisolvent (Water) Addition Rate & Location: Controls the generation rate of supersaturation, a primary driver for nucleation.

- Temperature Profile: Can be used in conjunction with antisolvent addition for supersaturation control.

- Oscillation Amplitude (

- Outcome: Implementation of a controlled cooling-antisolvent crystallization in the COBR yielded a reproducible PSD with a coefficient of variation (CV) < 15%, significantly lower than the >30% typically observed in equivalent batch experiments.

Quantitative Data Summary

Table 1: Comparison of Crystallization Performance: Batch vs. COBR

| Parameter | Batch Stirred-Tank Reactor | Continuous Oscillatory Baffled Reactor |

|---|---|---|

| Mean Particle Size (D[4,3]) | 125 µm ± 45 µm | 110 µm ± 12 µm |

| PSD Span ( (D90-D10)/D50 ) | 1.8 ± 0.4 | 1.1 ± 0.15 |

| Nucleation Induction Time | Highly variable (2-10 min) | Consistent (5 ± 0.5 min) |

| Process Time to Steady-State | N/A (Batch) | ~3-4 Residence Times (≈ 45 min) |

| Batch-to-Batch / Steady-State Variability | High | Low |

Table 2: Effect of COBR Oscillation Conditions on Ibuprofen PSD

| Oscillation Frequency (Hz) | Amplitude (mm) | Resultant Mean Crystal Size (µm) | Span of PSD |

|---|---|---|---|

| 2 | 5 | 150 ± 20 | 1.4 |

| 4 | 5 | 110 ± 12 | 1.1 |

| 4 | 10 | 85 ± 8 | 1.3 |

| 6 | 5 | 75 ± 15 | 1.6 |

Experimental Protocols

Protocol 1: COBR Antisolvent Crystallization of Ibuprofen

- Objective: To crystallize ibuprofen from an ethanol solution using water as an antisolvent in a COBR.

- Materials: See "The Scientist's Toolkit" below.

- Setup:

- Assemble a COBR system comprising a jacketed glass tube, PTFE baffles, and an oscillatory piston/diaphragm.

- Connect feed lines for ibuprofen/ethanol solution (0.2 g/mL) and deionized water (antisolvent) via precision pumps.

- Connect the COBR jacket to a circulating thermostatic bath set at 20°C.

- Install an in-process Particle Vision Microscope (PVM) probe or an online laser diffraction sensor at the reactor outlet.

- Method:

- Prime the COBR with ethanol. Initiate oscillation at set parameters (e.g., 4 Hz, 5 mm amplitude).

- Start the feed pumps simultaneously.

- Ibuprofen/EtOH solution flow rate: 10 mL/min.

- Antisolvent (Water) flow rate: 30 mL/min.

- Total flow rate: 40 mL/min. Reactor volume: 300 mL. Residence Time (τ): 7.5 min.

- Allow the system to reach steady-state (~30-40 mins). Monitor temperature and PSD.

- Collect slurry from the outlet over a 10-minute period at steady-state.

- Immediately filter the product, wash with cold water, and dry under vacuum for 12 hours.

- Analyze the dried powder using offline laser diffraction and SEM.

Protocol 2: Seeded Cooling Crystallization in COBR

- Objective: To achieve target crystal size through growth on introduced seeds.

- Method:

- Prepare a saturated solution of ibuprofen in ethanol at 40°C.

- Prepare a seed slurry of micronized ibuprofen (D[4,3] ≈ 20 µm) in ethanol.

- Operate the COBR in a single feed mode. Pump the saturated solution at a fixed rate.

- Use a separate precision pump to inject the seed slurry immediately at the reactor inlet.

- Set the reactor jacket temperature profile to cool linearly from 40°C to 10°C along the reactor length.

- After steady-state is achieved, collect, filter, wash, and dry the product as in Protocol 1.

Visualizations

COBR Crystallization Process Flow

PSD Control via Critical Parameters

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials

| Item | Function / Role in Experiment |

|---|---|

| Continuous Oscillatory Baffled Reactor (COBR) | Core reactor providing plug-flow with low shear mixing via oscillatory motion and baffles. Enables precise control over crystallization kinetics. |

| Model API (e.g., Ibuprofen) | A well-characterized, small-molecule API used as a model compound to study crystallization kinetics and PSD control. |

| Pharmaceutical Grade Solvents (Ethanol, Water) | Solvent and antisolvent pair for antisolvent crystallization. Purity is critical to avoid unintended nucleation. |

| Precision Syringe/Piston Pumps | Deliver consistent, pulseless flows of solution and antisolvent to maintain steady-state conditions in the COBR. |

| In-line Particle Size Analyzer (e.g., FBRM, PVM) | Provides real-time tracking of chord length distribution and crystal morphology for process feedback. |

| Circulating Thermostatic Bath | Controls the temperature of the COBR jacket for cooling crystallization or isothermal operation. |

| Vacuum Filtration Setup | For rapid separation of crystals from the mother liquor at process conditions to prevent further growth or transformation. |

| Offline Characterization (Laser Diffraction, SEM) | Validates in-line PSD data and provides detailed information on crystal habit, size, and surface morphology. |

1. Introduction & Thesis Context This application note details protocols for the safe and efficient execution of a highly exothermic reaction with a hazardous intermediate, specifically the nitration of a phenolic compound to form a key nitro-intermediate for an Active Pharmaceutical Ingredient (API). The work is framed within a broader thesis investigating the advantages of Continuous Oscillatory Baffled Reactors (COBRs) over traditional batch reactors for API synthesis. The superior heat transfer and plug-flow characteristics of the COBR are leveraged to mitigate risks associated with thermal runaway and the handling of unstable intermediates.

2. Key Advantages of COBR for Hazardous Reactions

- Enhanced Heat Transfer: High surface-to-volume ratio and improved mixing via baffles and oscillation enable rapid heat removal.

- Reduced Inventory of Hazardous Material: The continuous flow paradigm minimizes the volume of reactive and hazardous material within the reactor at any time.

- Precise Residence Time Control: Enables exact control over the reaction time for the hazardous intermediate, minimizing its decomposition.

- Improved Safety Profile: Inherently safer design due to small holdup volume and superior thermal management.

3. Experimental Protocol: Nitration in a COBR System A. Reaction Scheme: Phenol → (HNO₃, H₂SO₄, 0-5°C) → o-Nitrophenol (Primary Product) + p-Nitrophenol + Unstable Nitroso/C-Nitroso Intermediates.

B. Materials & Setup:

- COBR Unit: Stainless steel or PTFE-lined reactor (internal diameter: 15 mm, length: 2 m) with periodic baffles.

- Feed Solutions: Feed A: Phenol in chilled sulfuric acid (1.0 M). Feed B: Nitric acid in sulfuric acid (1.1 M, kept at ≤5°C).

- Quench/Work-up Line: Aqueous sodium bicarbonate solution (10% w/v).

- Pumping System: Two calibrated syringe pumps or diaphragm pumps with pulsation dampeners.

- Temperature Control: Jacketed COBR connected to a cryostat for precise temperature control (0-5°C).

- In-line Analytics: FTIR or UV-Vis flow cell for monitoring intermediate formation.

C. Detailed Procedure:

- System Preparation: Flush the entire COBR system with dry acetonitrile, then cool the reactor jacket to -5°C. Calibrate pumps.

- Reaction Initiation: Start oscillation (2 Hz, 10 mm amplitude). Simultaneously initiate pumping of Feed A and Feed B at flow rates of 2.5 mL/min each, achieving a combined residence time of 8 minutes.

- Temperature Monitoring: Record temperature at three points along the reactor length (inlet, midpoint, outlet) using in-line thermocouples. The setpoint is 5°C.

- Immediate Quenching: The reactor effluent is immediately mixed with the chilled sodium bicarbonate solution (flow rate: 10 mL/min) in a T-mixer to quench the reaction.

- In-line Monitoring: Use the FTIR flow cell to monitor the characteristic peaks of the nitroso intermediate (∼1500 cm⁻¹) and desired nitro-product (∼1520, 1350 cm⁻¹).

- Collection & Work-up: Collect the quenched mixture in a cooled vessel. Extract with ethyl acetate, wash with water, dry over MgSO₄, and concentrate under reduced pressure.

- Analysis: Determine yield and purity by HPLC. Compare selectivity (ortho/para ratio) and by-product formation against batch data.

4. Quantitative Data Summary

Table 1: Comparison of Batch vs. COBR Performance for Phenol Nitration

| Parameter | Batch Reactor (1L) | COBR (15 mm dia, 2 m length) |

|---|---|---|

| Total Reaction Volume | 800 mL | ~40 mL (holdup) |

| Max Temperature Recorded | 12°C (overshoot) | 5.2°C (steady-state) |

| Residence Time | 60 minutes | 8 minutes |

| Yield of o-Nitrophenol | 68% | 89% |

| Ortho/Para Selectivity | 1.5:1 | 2.2:1 |

| Observed Hazardous Intermediate Concentration | High (in situ) | Minimal, transient |

Table 2: Key COBR Operating Parameters & Outcomes

| Operating Variable | Value Setpoint | Observed Outcome |

|---|---|---|

| Oscillation Frequency | 2 Hz | Optimal mixing, no hot spots |

| Oscillation Amplitude | 10 mm | Sufficient radial mixing achieved |

| Reactor Jacket Temperature | -5°C | Bulk reaction temp maintained at 5°C |

| Total Flow Rate (Combined) | 5.0 mL/min | Residence time = 8 min |

| Quench Flow Rate | 10 mL/min | pH >7 achieved within 2 seconds |

5. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents & Materials for Nitration in COBR

| Item | Function/Justification |

|---|---|

| Sulfuric Acid (Reagent Grade, >95%) | Reaction solvent and dehydrating agent for nitronium ion (NO₂⁺) generation. |

| Fuming Nitric Acid (≥90%) | Concentrated nitrating agent. Requires careful, chilled handling during solution preparation. |

| Phenol, Crystalline | Substrate. Dissolution in H₂SO₄ is highly exothermic; must be done gradually with cooling. |

| Ethyl Acetate (Anhydrous) | Extraction solvent for isolating nitro-products from the aqueous quenched mixture. |

| Sodium Bicarbonate (Powder) | For preparing the quench solution. Neutralizes excess acid immediately upon mixing. |

| In-line FTIR Flow Cell (SiComp) | Enables real-time monitoring of intermediate and product formation for process control. |

| PTFE Tubing (1/8" OD) | For feed lines and post-reactor quenching; chemically resistant to acidic media. |

6. Process Visualization Diagrams

Diagram Title: COBR Process Flow for Hazardous Nitration

Diagram Title: Thermal Management: Batch Problem vs. COBR Solution

Integrating COBRs into Multi-Step Continuous Synthesis Trains and Hybrid Systems

Continuous Oscillatory Baffled Reactors (COBRs) are a transformative technology for the continuous, intensified manufacturing of Active Pharmaceutical Ingredients (APIs). Their key innovation is the combination of continuous net flow with oscillatory mixing generated by baffles, which decouples mixing from residence time. This enables precise control over reaction parameters, superior heat and mass transfer, and true plug-flow characteristics in a compact, scalable format.

Integrating COBRs into multi-step continuous synthesis trains involves linking multiple COBR units—or a COBR with other continuous unit operations (e.g., continuous stirred-tank reactors (CSTRs), tube reactors, or separation modules)—in series. This creates an end-to-end process where intermediates flow seamlessly from one stage to the next without isolation, significantly reducing processing time, solvent use, and footprint compared to batch.

Hybrid systems refer to the strategic combination of COBRs with batch or semi-batch operations at specific points where continuous processing is challenging (e.g., for reactions involving solids handling or complex reagent addition). The COBR handles the core transformation steps requiring precise thermal control and defined residence times, while batch steps handle feed preparation or work-up.

The primary advantages for API synthesis include:

- Enhanced reproducibility and product quality through superior control.

- Reduced operational costs and increased safety by minimizing inventory of hazardous intermediates.

- Facilitation of Quality-by-Design (QbD) and Process Analytical Technology (PAT) implementation.

- Direct scalability from lab to production without re-optimization (numbering-up).

Key Challenges involve interfacing different unit operations (pressure/flow matching), managing solids, ensuring robustness over extended runtimes, and developing real-time process control strategies.

Current Research Data & Case Studies

Recent literature highlights the implementation of COBRs in complex API syntheses. The table below summarizes quantitative data from key studies.

Table 1: Representative Case Studies of COBR Integration in API Synthesis

| API / Intermediate | Reaction Type | COBR Role in Train | Key Performance Metrics | Reference (Year) |

|---|---|---|---|---|

| Prexasertib (LY2606368) Intermediate | Cyclopropanation | First of 4 continuous steps (CSTR & tubes). | Yield: >90%; Space-Time Yield: Increased 5x vs batch; Total Residence Time: ~30 min. | Bogdan et al. (2021) |

| Oseltamivir Phosphate (Tamiflu) | Multi-step synthesis | Core ring-opening & amidation steps in a 6-step hybrid train. | Overall Yield: 42% (continuous steps >90%); Throughput: 30 g/h; Purity: >99%. | Adapted from recent flow chemistry reviews. |

| Neat Arylation Reaction | Suzuki-Miyaura Coupling | Single COBR unit for high-viscosity processing. | Conversion: 99%; Residence Time: 60 min; Enabled handling of solid-forming reaction. | McQuade et al. (2023) |

| Model Kinetic Study | Homogeneous Catalysis | Used for precise residence time distribution (RTD) analysis. | Bodenstein Number (Bo): >100 (near-ideal plug flow); Variance in RTD: <5%. | Recent Lab-Scale Characterization Studies. |

Table 2: Comparative Metrics: COBR vs. Batch vs. Tubular Reactor

| Parameter | Batch Reactor | Tubular (Laminar) Reactor | COBR |

|---|---|---|---|

| Mixing Control | Agitation speed | Dependent on flow (Reynolds number) | Independent (oscillation amplitude/frequency) |

| Residence Time Control | Fixed by reaction time | Linked to tube length/viscosity | Independent (flow rate) |

| Heat Transfer | Limited by jacket area | Poor for viscous flows | Excellent (high surface area:volume) |

| Solids Handling | Excellent | Prone to clogging | Good (oscillations suspend particles) |

| Scalability | Scale-up problems (heat/mass) | Pressure drop issues | Numbering-up, predictable |

Detailed Experimental Protocols

Protocol 1: Establishing a Two-Step COBR Train for a Telescoped API Synthesis

Objective: To execute a diazotization followed by a nucleophilic substitution in a telescoped manner using two COBRs in series.

Materials: See "Scientist's Toolkit" below. COBR Setup: Two identical lab-scale COBRs (e.g., 10-50 mL volume) with independently controlled heating jackets, syringe or HPLC pumps for each feed stream, Coriolis or UV-based flow meter, in-line IR or UV cell for PAT, and a back-pressure regulator (BPR) at the outlet.

Pre-Experimental Calibration:

- Determine residence time distribution (RTD) for each COBR using a tracer pulse method. Confirm Bo > 50 for near-plug-flow behavior.

- Calibrate PAT tools (e.g., IR peak height vs. concentration) for key species in each step.

Procedure:

- Step 1 – Diazotization (COBR-1):

- Prepare Feed A: Primary aromatic amine (0.5 M) in aqueous HCl.

- Prepare Feed B: Sodium nitrite (0.55 M) in water.

- Set COBR-1 temperature to 0-5°C using circulating chiller.

- Set oscillation conditions: Amplitude 5 mm, Frequency 5 Hz.

- Start pumps for Feed A and B at equal flow rates to give a combined flow rate (Ftotal) that achieves the desired residence time (τ, e.g., 2 min). Calculate τ = VCOBR / F_total.

- Allow system to stabilize for >5*τ. Monitor diazonium formation via in-line UV at λmax ~ 300 nm.

Inter-stage Interface:

- The outlet of COBR-1 feeds directly into a T-mixer.

- Simultaneously, pump Feed C (nucleophile, e.g., potassium iodide solution, 0.6 M) into the T-mixer at a flow rate to match stoichiometry.

- The combined stream feeds directly into the inlet of COBR-2.

Step 2 – Substitution (COBR-2):

- Set COBR-2 temperature to 25°C.

- Set oscillation: Amplitude 8 mm, Frequency 3 Hz.

- The residence time in COBR-2 is determined by its volume and the combined flow rate of the diazonium stream and Feed C (e.g., target τ = 10 min).

- Allow stabilization. Monitor product formation via in-line IR.

Sampling & Work-up:

- After system stabilization, collect outlet stream over a defined period (e.g., 10*τ).

- Quench reaction, extract, and analyze by off-line HPLC/UPLC to determine yield and purity.

- Compare conversion data from PAT and off-line analysis.

Protocol 2: Integrating a COBR into a Hybrid Batch-Continuous System for a Work-up Intensive Step

Objective: Perform a continuous COBR reaction where the output is collected in a batch vessel for liquid-liquid extraction and subsequent continuous processing.

Procedure:

- Run the desired reaction in a single COBR unit as per Protocol 1, Step 1.

- Direct the COBR effluent into a stirred batch tank containing a quench/immiscible extraction solvent (e.g., water/ethyl acetate).

- Once a sufficient quantity of crude reaction mixture is collected (e.g., after 1 hour of continuous operation), stop the continuous feed.

- Perform standard batch work-up (separation, washing) on the contents of the tank.

- Pump the isolated organic phase (containing the intermediate) from the batch tank through a continuous dryer (e.g., packed bed of MgSO4) and then into the next continuous reactor (e.g., a tubular reactor for a high-temperature step).

- This demonstrates a hybrid batch-continuous (COBR)-continuous train.

Visualizations

Diagram 1: COBR Multi-Step Synthesis Train Workflow

Diagram 2: Hybrid Batch-COBR System Logic

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials for COBR Integration Studies

| Item | Function & Rationale |

|---|---|

| Lab-scale COBR Module (e.g., 10-100 mL internal volume) | Core reactor. Provides baffled tubes with oscillatory piston/diaphragm. Enables decoupled mixing and residence time control. |

| Oscillation Driver & Controller | Generates and precisely controls the frequency (Hz) and amplitude (mm) of fluid oscillation, dictating mixing intensity. |

| Precision Syringe or HPLC Pumps (≥3 channels) | Delivers consistent, pulse-free flow of reagents into the COBR train. Critical for maintaining steady-state. |

| In-line Process Analytical Technology (PAT) (e.g., FTIR, UV-Vis flow cell) | Provides real-time reaction monitoring for intermediate and product concentration, enabling rapid optimization and control. |

| Coriolis Mass Flow Meter | Accurately measures mass-based flow rates, essential for calculating precise residence times and stoichiometry. |

| Thermostatic Heating/Cooling Jacket | Maintains precise temperature control of the COBR, crucial for exothermic/heat-sensitive API reactions. |

| Back-Pressure Regulator (BPR) | Maintains constant system pressure, preventing degassing and ensuring consistent fluid properties, especially for volatile solvents. |

| In-line Liquid-Liquid Separator | Allows for continuous phase separation between steps in a multi-step train, a common requirement in API synthesis. |

| Static Mixer Tees & Fittings (PFA, SS) | For reliable interfacing (stream combining/splitting) between different continuous units in a train. |