Life Cycle Assessment of API Synthesis: A Comparative Guide for Sustainable Pharmaceutical Development

This article provides a comprehensive framework for conducting comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes.

Life Cycle Assessment of API Synthesis: A Comparative Guide for Sustainable Pharmaceutical Development

Abstract

This article provides a comprehensive framework for conducting comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes. Targeted at researchers and drug development professionals, it explores foundational LCA principles, methodological applications to chemical processes, strategies for troubleshooting and optimizing assessments, and rigorous validation and comparative analysis techniques. The guide synthesizes current best practices to enable informed decision-making for reducing the environmental footprint of pharmaceutical manufacturing, aligning with green chemistry and corporate sustainability goals.

What is LCA for APIs? Core Principles and System Boundaries Explained

Defining Life Cycle Assessment (LCA) in the Pharmaceutical Context

Life Cycle Assessment (LCA) is a systematic, data-driven methodology used to evaluate the environmental impacts associated with all stages of a product's life, from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling. In the pharmaceutical context, LCA is applied to quantify the environmental footprint of drug production, focusing on Active Pharmaceutical Ingredient (API) synthesis, formulation, packaging, distribution, and waste management. This is critically framed within research comparing the environmental performance of different API synthetic routes, where LCA serves as the primary tool for objective comparison.

Comparative LCA of API Synthetic Routes: A Guide

This guide compares the environmental performance of two hypothetical synthetic routes for a model API, "PharmaX," based on typical gate-to-gate LCA studies (cradle-to-gate data often derived from literature and process simulation).

Table 1: Inventory Analysis for the Synthesis of 1 kg of PharmaX API

| Inventory Item | Route A (Traditional Linear Synthesis) | Route B (Green Chemistry-Inspired Synthesis) | Unit |

|---|---|---|---|

| Inputs | |||

| Starting Material M1 | 8.5 | 5.2 | kg |

| Solvent (Dichloromethane) | 120 | 0 | kg |

| Solvent (Isopropanol) | 15 | 25 | kg |

| Water (Process) | 800 | 400 | L |

| Palladium Catalyst | 0.05 | 0.01 | kg |

| Energy (Steam) | 450 | 250 | MJ |

| Outputs | |||

| PharmaX API | 1.0 | 1.0 | kg |

| Hazardous Waste (Incinerated) | 95 | 18 | kg |

| Wastewater (Organic Load) | High | Moderate | - |

| VOCs to Air | 12 | 3 | kg |

Table 2: Impact Assessment Comparison (Per 1 kg API)

| Impact Category | Route A | Route B | Reduction | Unit |

|---|---|---|---|---|

| Global Warming Potential (GWP100) | 850 | 320 | 62% | kg CO₂ eq |

| Fine Particulate Matter Formation | 1.8 | 0.6 | 67% | kg PM2.5 eq |

| Terrestrial Acidification | 12.5 | 4.1 | 67% | mol H+ eq |

| Process Mass Intensity (PMI) | 1,024 | 481 | 53% | kg total input/kg API |

| E-Factor | 1,023 | 480 | 53% | kg waste/kg API |

Experimental Protocols for LCA Data Generation

1. Protocol for Life Cycle Inventory (LCI) Compilation:

- Goal & Scope: Define the functional unit (e.g., 1 kg of 99.5% pure PharmaX). Set system boundaries as gate-to-gate (from raw material entry at plant to packaged API).

- Data Collection: For each synthetic step, measure or obtain from batch records: masses of all input chemicals (reactants, solvents, catalysts), utilities (steam, electricity, chilled water), and outputs (product, by-products, waste streams sent for treatment).

- Allocation: For multi-product processes, allocate environmental burdens based on mass or economic value of outputs.

- Database Integration: Combine primary process data with background data from commercial LCA databases (e.g., Ecoinvent, GaBi) for upstream production of chemicals and energy, and downstream waste treatment.

2. Protocol for Calculating Green Metrics (PMI & E-Factor):

- Process Mass Intensity (PMI): Sum the total mass (kg) of all materials input into the process to produce a specified mass of API.

PMI = (Total mass of inputs) / (Mass of API). - Environmental Factor (E-Factor): Sum the total mass (kg) of all waste generated.

E-Factor = (Total mass of waste) / (Mass of API). Waste is defined as everything produced except the desired product.

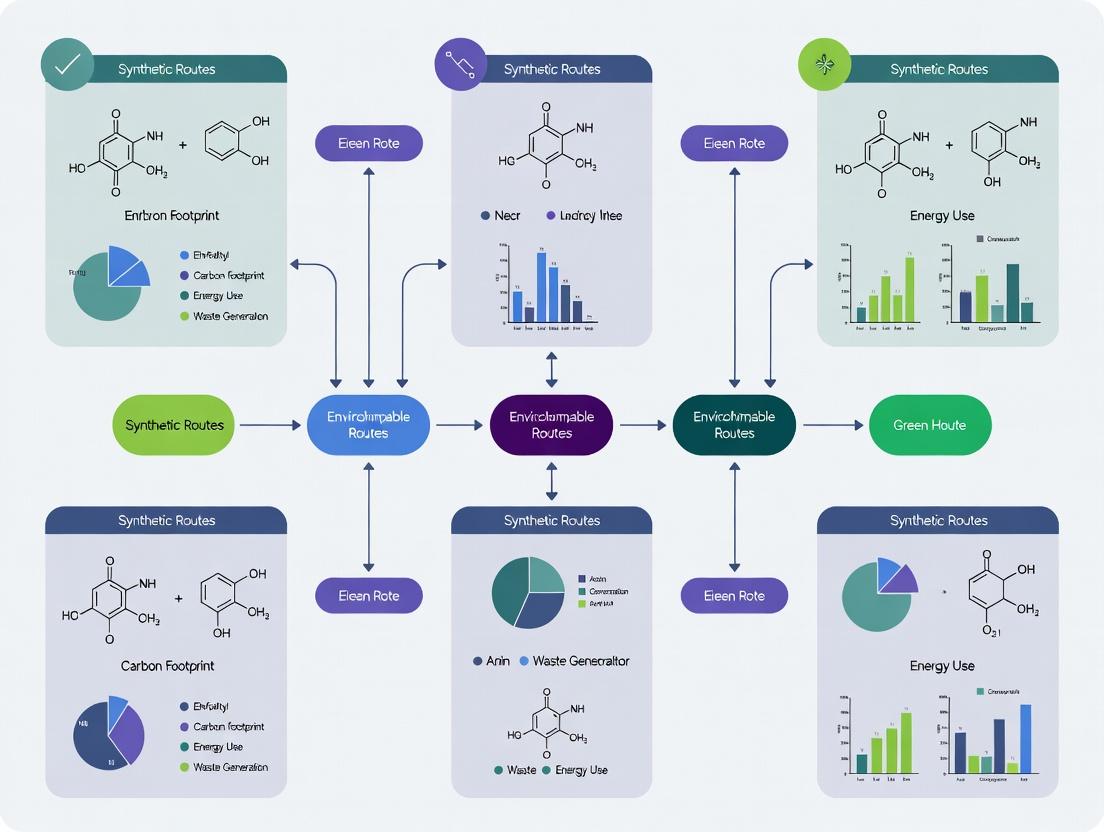

Visualizing the LCA Workflow in API Route Comparison

LCA Methodology for API Route Comparison

Hotspot Analysis: Linear vs. Convergent Synthesis

The Scientist's Toolkit: Essential Research Reagents & Solutions for LCA Studies

Table 3: Key Tools for Comparative LCA in Pharmaceutical Research

| Item/Software | Function in API Route LCA |

|---|---|

| Process Modeling Software (e.g., Aspen Plus) | Simulates mass and energy balances for novel synthetic routes before pilot-scale experiments, generating critical LCI data. |

| LCA Database (e.g., Ecoinvent) | Provides life cycle inventory data for upstream production of common chemicals, solvents, and energy grids. |

| LCA Software (e.g., SimaPro, openLCA) | The core platform for modeling the product system, performing LCIA calculations, and generating comparative results. |

| Green Chemistry Solvent Guides (ACS, CHEM21) | Informs solvent selection to replace hazardous, high-impact solvents (e.g., DCM) with safer alternatives in route design. |

| Catalyst Databases (e.g., CatDB) | Aids in selecting efficient, low-loading catalysts to reduce PMI and energy use in key synthetic steps. |

| Laboratory Reaction Calorimeter | Measures heat flow of reactions experimentally, providing data to model energy requirements at scale. |

The imperative to develop sustainable manufacturing processes for Active Pharmaceutical Ingredients (APIs) is being shaped by three converging forces: stringent Regulatory Pressure (e.g., EMA, FDA guidance on solvent control, ICH Q3C, Q11), the principles of Green Chemistry (atom economy, waste reduction, safer solvents), and corporate ESG Goals (Environmental, Social, and Governance). This Comparative Life Cycle Assessment (LCA) research evaluates synthetic routes, moving beyond traditional yield/cost metrics to quantify environmental and safety impacts, directly informing greener process selection.

Comparative Guide: Routes to Sitagliptin API

This guide compares the traditional transition-metal-catalyzed enamine hydrogenation route with the novel biocatalytic transamination route.

Table 1: Performance Comparison of Sitagliptin Synthetic Routes

| Metric | Traditional Metal-Catalyzed Route (MCR) | Novel Biocatalytic Route (BCR) | Data Source / Experimental Reference |

|---|---|---|---|

| Overall Yield | ~85% | >95% | Savile et al., Science, 2010 |

| Atom Economy | ~70% | ~99% | Calculated from stoichiometry |

| E-Factor (kg waste/kg API) | ~25 | ~5.5 | Calculated from process mass intensity |

| Key Solvent | Tetrahydrofuran (THF) | 2-Propanol (IPA) | ICH Q3C: THF (Class 2), IPA (Class 3) |

| Catalyst | Rhodium/Josiphos | Engineered Transaminase (ATA) | Cost & heavy metal residue concern vs. biodegradable enzyme |

| Process Conditions | High-pressure H₂ (250 psi), 50°C | Ambient pressure, 45°C | Safety hazard vs. benign operation |

| LCA Impact (GWP) | ~120 kg CO₂-eq/kg API | ~55 kg CO₂-eq/kg API | SimaPro modeling, ReCiPe 2016 method |

Detailed Experimental Protocols

1. Protocol for Biocatalytic Transamination (BCR Route):

- Reaction Setup: In a stirred bioreactor, combine pro-sitagliptin ketone (1.0 M) and isopropylamine (2.0 M) as amine donor in 2-propanol:water (9:1 v/v, pH 8.0 phosphate buffer).

- Catalyst Loading: Add engineered transaminase (ATA-117) at 5% w/w relative to ketone substrate.

- Conditions: Maintain at 45°C with gentle agitation (200 rpm) under ambient pressure for 24 hours.

- Monitoring: Reaction progress is monitored by HPLC (C18 column, UV detection at 210 nm).

- Work-up: Upon >99% conversion, the reaction mixture is filtered to remove the enzyme. The filtrate is concentrated, and the product is crystallized from tert-butyl methyl ether (TBME).

2. Protocol for Metal-Catalyzed Hydrogenation (MCR Route):

- Reaction Setup: Charge a high-pressure autoclave with the enamine substrate (1.0 M) in anhydrous THF under nitrogen.

- Catalyst Activation: Add Rh(COD)₂OTf and (S)-Josiphos ligand (S/C = 1000).

- Conditions: Purge with H₂, pressurize to 250 psi, and heat to 50°C with vigorous stirring for 16 hours.

- Monitoring: Reaction progress monitored by in-situ FTIR or by sampling for GC-MS.

- Work-up: Cool, vent hydrogen, and filter through a Celite pad to remove catalyst residues. Concentrate and purify via chromatography.

Visualizations

Diagram 1: LCA System Boundary for API Route Comparison

Diagram 2: Decision Workflow for Greener Route Selection

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function in Comparative LCA Research | Key Consideration |

|---|---|---|

| Process Mass Intensity (PMI) Calculator | Quantifies total mass input per mass of API, the basis for E-Factor. | Essential for standardizing waste comparison between routes. |

| LCA Software (e.g., SimaPro, GaBi) | Models environmental impacts (GWP, water use, toxicity) across the life cycle. | Requires reliable inventory data (e.g., solvent production emissions). |

| Engineered Transaminase (ATA-117) | Biocatalyst for asymmetric amine synthesis; enables greener route. | Stability under process conditions and substrate specificity are critical. |

| Rhodium/Josiphos Catalyst | High-activity chiral catalyst for enantioselective hydrogenation. | Cost, metal leaching, and regulatory limits in final API. |

| ICH Q3C Solvent Class Guide | Classifies solvents by toxicity and environmental hazard (Class 1-3). | Direct link to Regulatory Pressure; dictates solvent substitution goals. |

| Green Chemistry MOTD Calculator | Calculates mass, environmental, and safety metrics for reactions. | Integrates multiple green chemistry principles into a single score. |

Establishing the Goal and Scope for API Route Comparison

In the context of Comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes, establishing a precise goal and scope is the critical first phase. This framework ensures that subsequent comparisons of performance, environmental impact, and efficiency are meaningful, reproducible, and relevant to stakeholders in drug development.

Defining the Goal of the Comparison

The primary goal is to objectively evaluate and compare alternative synthetic routes for a target API based on a multi-faceted set of criteria. This analysis supports the broader thesis of determining the most sustainable and efficient synthesis from a holistic perspective.

- Intended Application: To inform route selection in late-stage process development and commercial manufacturing.

- Reason for Study: To quantify trade-offs between green chemistry metrics, economic viability, and technical performance to guide sustainable drug development.

- Target Audience: Process chemists, chemical engineers, environmental sustainability officers, and regulatory affairs professionals within pharmaceutical R&D.

Delineating the Scope of the Comparison

The scope defines the boundaries of the study, specifying what is included and excluded.

System Boundaries

The assessment typically follows a "cradle-to-gate" approach for LCA, while technical comparisons may focus on the synthesis tree.

- Included: Raw material extraction (resource mining), synthesis of all starting materials, reagents, and solvents, all chemical transformation steps, purification stages, waste treatment (on-site and off-site), energy generation and consumption, and equipment use.

- Excluded: Packaging of the final API, transportation of personnel, capital equipment manufacturing, and administration. The clinical use and end-of-life disposal of the drug product are outside the boundary.

Functional Unit

The basis for all quantitative comparisons. For API synthesis, the functional unit is: "The production of 1 kilogram of [Target API] with a specified purity (e.g., ≥99.0% by HPLC)." All input and output data (mass, energy, environmental impacts) are normalized to this unit.

Key Comparison Parameters & Data Requirements

Performance is compared across the following dimensions, with data gathered from laboratory experiments, pilot-scale data, and rigorous literature analysis.

Table 1: Core Quantitative Parameters for API Route Comparison

| Parameter Category | Specific Metric | Unit of Measure | Data Source |

|---|---|---|---|

| Environmental (LCA) | Global Warming Potential (GWP) | kg CO₂-eq / kg API | Simulation (e.g., GaBi, SimaPro) |

| Cumulative Energy Demand (CED) | MJ / kg API | Life Cycle Inventory Database | |

| E-Factor (Total Waste) | kg waste / kg API | Mass balance from experimental data | |

| Process Efficiency | Overall Yield | % (molar) | Experimental batch records |

| Number of Linear Steps | Count | Synthetic route analysis | |

| Total Processing Time | Hours / kg API | Development reports | |

| Green Chemistry | Process Mass Intensity (PMI) | kg total input / kg API | Calculated from material inventories |

| Solvent Intensity | kg solvent / kg API | Solvent recovery & waste logs | |

| Safety/Hazard Profile | NFPA or GHS scores | Reagent/material safety data sheets | |

| Economic | Estimated Cost of Goods (COGs) | $ / kg API | Vendor quotes, internal costing models |

| Catalyst/Ligand Loading | mol% or wt% | Experimental protocol |

Experimental Protocols for Key Metrics

To ensure comparability, standardized experimental or calculation protocols must be defined.

Protocol A: Determination of Process Mass Intensity (PMI)

- Scale: Run the synthesis at a minimum of 10-gram final product scale for each route.

- Material Accounting: Precisely weigh all input materials (starting materials, reagents, solvents, catalysts) for each step.

- Workup & Purification: Account for all solvents and materials used in workup, quenching, extraction, and chromatography/crystallization.

- Calculation: PMI = (Total mass of all materials used) / (Mass of isolated API). Report as a dimensionless ratio (kg/kg).

Protocol B: Life Cycle Inventory (LCI) Compilation for GWP

- Inventory Compilation: Create a comprehensive list of all material and energy inputs from the defined system boundary.

- Database Mapping: Map each input (e.g., 1 kg acetonitrile, 10 kWh electricity) to corresponding upstream environmental flows using a reputable LCI database (e.g., Ecoinvent, USDA).

- Impact Calculation: Use characterization factors (e.g., from IPCC 2021) within LCA software to convert inventory data into GWP (kg CO₂-eq).

- Allocation: Apply mass or economic allocation if processes yield multiple products.

Visualization of Comparative Workflow

Diagram 1: Workflow for Comparative API Route Assessment

The Scientist's Toolkit: Essential Research Reagents & Solutions

Table 2: Key Research Reagents for Route Development & Analysis

| Item | Function in Comparison | Example (Illustrative) |

|---|---|---|

| High-Resolution Mass Spectrometry (HRMS) System | Unambiguous confirmation of API and intermediate structures, ensuring functional unit purity criteria are met. | Bruker timsTOF, Thermo Fisher Orbitrap |

| Process Analytical Technology (PAT) | Real-time monitoring of reaction progression and impurity formation, enabling precise yield and efficiency calculations. | ReactIR (FTIR), EasyMax/Optimax calorimeter |

| Chiral Stationary Phase HPLC Columns | Accurate determination of enantiomeric excess (ee) for chiral APIs, a critical quality attribute. | Daicel Chiralpak (e.g., IA, IC, AD-H) |

| Sustainable Solvent Screening Kits | Systematic evaluation of alternative, greener solvents to improve solvent intensity and E-Factor metrics. | CHEM21 Solvent Selection Guide, Sanofi Solvent Toolbox |

| Heterogeneous Catalyst Libraries | Screening for efficient, recoverable catalysts to reduce metal usage, cost, and heavy metal waste streams. | Aldrich CatCubes (Pd, Ni, Cu on support) |

| Life Cycle Inventory (LCI) Database | Providing the underlying emission and resource data for calculating environmental impact metrics (GWP, CED). | Ecoinvent, USDA LCA Digital Commons |

| LCA Software Suite | Modeling the synthetic route system, calculating impact metrics, and performing sensitivity analysis. | Sphera GaBi, SimaPro, openLCA |

Defining Functional Unit and System Boundaries (Cradle-to-Gate)

Within the context of a thesis on Comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes, establishing a precise functional unit and defensible system boundaries is the critical foundation for any meaningful comparative study. This guide compares prevalent methodological approaches for LCA in pharmaceutical development, focusing on cradle-to-gate analyses common for API route scouting.

Comparative Frameworks for Functional Unit Definition

The functional unit (FU) quantifies the performance of the system, enabling equitable comparison of alternative synthetic routes.

Table 1: Common Functional Unit Definitions in API Synthesis LCA

| Functional Unit Type | Description & Rationale | Key Application Context | Potential Limitations |

|---|---|---|---|

| Mass-based (e.g., 1 kg API) | Standardizes comparison per unit mass of final product. Simple and common for early route screening. | Preliminary route scouting where primary data is limited; comparison of bulk chemical processes. | Ignores potency, purity, and pharmacological efficacy. A less potent API may require more mass per dose. |

| Potency-adjusted (e.g., 1 mole of API) | Based on the molar quantity, relating more directly to the molecular synthesis effort. | Comparing routes for the same chemical entity; focuses on molecular efficiency. | Does not account for bioavailability or formulation needs. |

| Therapeutic Dose-based (e.g., API for 1000 treatment courses) | Links environmental impact directly to delivered therapeutic outcome. Most representative of function. | Later-stage development, comparing different salts or polymorphs affecting dosage. | Requires complex modelling of formulation, bioavailability, and clinical data often unavailable early on. |

Supporting Data: A 2023 review of 50 pharmaceutical LCA studies (J. Clean. Prod.) found that 62% used a mass-based FU (1 kg API), 28% used a molar-based FU, and only 10% attempted a dose-adjusted FU. This highlights the prevalence of simpler FUs in early development, where the dose may be undefined.

Comparative Analysis of System Boundary Definitions (Cradle-to-Gate)

Defining where the analysis starts and ends is paramount for consistent comparison. The "cradle-to-gate" boundary ends at the API before formulation.

Table 2: Comparative Scopes of Cradle-to-Gate System Boundaries

| System Boundary Scope | Included Processes | Excluded Processes | Best Use Case |

|---|---|---|---|

| Core Chemical Synthesis | Reaction steps, solvent use, in-process purification, catalyst use. | Raw material production, energy generation, capital equipment, waste treatment, packaging, transportation. | Initial high-level screening of synthetic step count and inherent green chemistry metrics. |

| Extended Chemical Process | Core synthesis + production of key starting materials (KSMs), solvent recovery, on-site waste handling. | Production of basic chemicals (e.g., petrochemicals), extensive transportation, facility infrastructure. | Detailed route comparison within a defined supply chain, common in most API LCAs. |

| Comprehensive Cradle-to-Gate | Extended process + production of all chemical inputs from raw resources (ore, crude oil), transportation, energy mix, capital equipment. | Drug formulation, distribution, patient use, end-of-life (disposal). | Full environmental footprint for regulatory or sustainability reporting. Data-intensive. |

Experimental Protocol for Boundary Definition:

- Process Mapping: Create a detailed flow diagram for each synthetic route, identifying all input materials, outputs, and unit operations.

- Cut-off Criteria Application: Apply a mass- or energy-based cut-off (e.g., exclude flows <1% of total mass input). Document all exclusions.

- Data Inventory: Collect primary data (mass, energy) for all included flows from lab/pilot plant records. For excluded upstream processes, use secondary data from databases like Ecoinvent or GaBi.

- Allocation Procedures: In cases of multi-output processes (e.g., co-products), apply allocation rules (mass, economic, energy). ISO 14044 recommends system expansion where possible.

Visualizing System Boundaries and LCA Workflow

Diagram 1: Cradle-to-Gate System Boundary for API Synthesis

Diagram 2: LCA Workflow for Comparing API Synthetic Routes

The Scientist's Toolkit: Research Reagent Solutions for LCA Data Generation

Accurate inventory data requires precise measurement in the lab.

Table 3: Essential Research Tools for Generating LCA Inventory Data

| Reagent / Tool | Function in LCA Context | Key Consideration |

|---|---|---|

| Process Mass Spectrometry (MS) | Real-time monitoring of reaction gases (e.g., CO2, CH4) for direct greenhouse gas emission factors. | Enables direct measurement rather than estimation from stoichiometry. |

| Solvent Recovery Systems (e.g., Rotovap, Short Path) | Measures recoverable vs. waste solvent mass, critical for inventory accuracy. | Recovery efficiency (%) is a key parameter for the inventory. |

| High-Performance Liquid Chromatography (HPLC) | Quantifies reaction yield and purity, informing the mass of required inputs per FU. | Directly supports the calculation for mass- or molar-based FUs. |

| Differential Scanning Calorimetry (DSC) | Measures energy inputs for phase changes (e.g., melting) in process modeling. | Provides data for energy balances in unit operations. |

| Life Cycle Inventory (LCI) Databases (e.g., Ecoinvent) | Provides secondary data for upstream materials (e.g., solvent production) not produced on-site. | Choice of database and regional model (e.g., US vs. EU grid mix) affects results. |

| LCA Software (e.g., SimaPro, openLCA) | Manages complex inventory data, performs impact calculations, and facilitates scenario comparison. | Essential for handling multi-route comparisons systematically. |

Life Cycle Assessment (LCA) of Active Pharmaceutical Ingredient (API) synthesis requires accurate and transparent inventory data. This guide compares the primary data sources available to researchers, evaluating their scope, reliability, and applicability for comparative LCA studies of synthetic routes. The choice of data source directly impacts the validity and defensibility of environmental impact conclusions.

Table 1: Comparison of Primary Inventory Data Sources for API Synthesis LCA

| Data Source | Description & Provider | Key Strengths | Key Limitations | Typical Use Case |

|---|---|---|---|---|

| Primary Process Data | Direct measurement from lab/pilot/plant operations. Generated by the research team. | Highest accuracy, process-specific, includes solvent recovery & utilities. | Resource-intensive, limited to developed processes, confidential. | Detailed comparison of in-house synthetic Routes A vs. B. |

| Ecoinvent Database | Commercial LCA database (Ecoinvent v3.9+). Industry-average and process-specific data. | Comprehensive, well-documented, includes background systems (energy, waste treatment). | May lack specific novel reagents, represents regional averages, cost barrier. | Modeling standard chemical inputs & energy for cradle-to-gate assessment. |

| EPA USETox & ChemSTEER | Public models from U.S. EPA for chemical release and exposure. | Freely accessible, standardized methodology for emission estimation. | Focus on emissions, not full inventory; requires significant input parameter estimation. | Estimating fugitive emissions for life cycle impact assessment (LCIA) toxicity. |

| Pharmaceuticals API LCA Database | Emerging dedicated databases (e.g., academic projects, proprietary compilations). | Sector-specific, may include proprietary industry data aggregates. | Limited public availability, often incomplete transparency on sources. | Screening assessment when primary data is unavailable for key intermediates. |

| Literature & Patents | Published life cycle inventory (LCI) data in journals or patent applications. | Context-specific examples, may detail novel green chemistry routes. | Inconsistent boundaries and methodologies, often missing key inventory flows. | Preliminary scoping and identifying data gaps for novel synthesis pathways. |

| Supplier EPDs | Environmental Product Declarations from chemical suppliers. | Product-specific, third-party verified (ISO 14025), includes supply chain data. | Limited to commercially available materials, variable depth of data. | Inventory for key purchased raw materials (e.g., chiral catalysts, specialty reagents). |

Experimental Protocol for Generating Primary Inventory Data

This protocol outlines the methodology for collecting gate-to-gate inventory data for an API synthesis step, essential for robust comparative LCA.

1. Objective: To quantify all material and energy inputs and emissions for a defined API synthesis reaction step (e.g., a coupling or hydrogenation reaction).

2. System Boundary: The reaction step from input of reactants to output of crude product ready for isolation/purification. Includes reaction, work-up, and solvent swaps. Excludes final crystallization, drying, and packaging.

3. Materials & Setup:

- Reaction vessel equipped with mass flow meters for cooling water/inert gas.

- Precision balances for weighing all inputs.

- Calibrated electricity meter on major equipment (reactor, chiller, vacuum pump).

- Emission capture setup (e.g., cold trap, gas bag) for volatile organic compound (VOC) sampling.

- Solvent recycling apparatus to measure recoverable mass.

4. Procedure: 1. Tare Weights: Record empty mass of all input containers (solvent drums, reagent bottles). 2. Charge Inputs: Perform the reaction according to the synthetic protocol. Record final masses of input containers. 3. Utility Monitoring: Continuously log electricity consumption (kWh) of the reactor system and auxiliary equipment. Record volume of process water (L) and chilled water (L) used, noting inlet/outlet temperatures for energy calculation if needed. 4. Emission Sampling: Use the capture setup to collect non-condensable gases and volatilized solvents over the reaction and work-up period. Analyze via GC-MS or FTIR to quantify species. 5. Output Quantification: Weigh the final crude product. Weigh all waste streams separately: aqueous phase, organic waste, solid filter cakes. Sample and characterize waste compositions. 6. Solvent Recovery: Distill and weigh the amount of solvent recovered for reuse within the system boundary.

5. Data Calculation: * Input mass = Initial container mass - Final container mass. * Net raw material input = Gross input - recovered/recycled material (internal recovery). * Emission mass = Concentration (from analysis) × total gas volume. * All data normalized per kg of crude product output.

Inventory Data Integration Workflow for API LCA

The Scientist's Toolkit: Essential Research Reagents & Materials for LCI Data Generation

Table 2: Key Reagent Solutions for Inventory Data Generation Experiments

| Item | Function in Inventory Data Generation |

|---|---|

| Deuterated Solvents (e.g., DMSO-d6, CDCl3) | Used as NMR solvents for quantitative reaction monitoring and yield determination without interfering signals, crucial for accurate output mass allocation. |

| Internal Standards (e.g., Anthracene, 1,3,5-Trimethoxybenzene) | Added in known quantities to reaction samples for GC-MS or HPLC analysis to quantify unreacted starting materials, intermediates, and byproducts in waste streams. |

| Calibration Gas Mixtures (e.g., 100 ppm VOC in N2) | Essential for calibrating FTIR or GC analyzers used to characterize and quantify gaseous emissions from reaction vents. |

| Sorbent Tubes (Tenax/Carbon) | Used in thermal desorption systems to capture and concentrate volatile organic compounds (VOCs) from air streams for subsequent GC-MS analysis. |

| Titration Kits (e.g., for water content, acid number) | For characterizing waste stream composition (e.g., water in organic waste, acidity of aqueous waste) to inform waste treatment process modeling. |

| Precision Calorimeter | Measures heat flow of a reaction to calculate heating/cooling energy requirements and model utility demands at scale. |

| Traceable Certified Reference Materials (CRMs) | Ensures accuracy of analytical balances and meters used for all mass and volume measurements, the foundation of reliable inventory data. |

This guide, framed within the thesis on Comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes, provides an objective comparison of three critical environmental impact metrics. The evaluation is based on experimental data from published comparative LCA studies for specific API syntheses, illustrating how route selection dictates sustainability performance.

Comparative Impact Data for API Synthetic Routes

The following table summarizes quantitative data from comparative LCA studies for representative APIs. Data is presented per kilogram of final API produced.

Table 1: Comparative Environmental Impact of Alternative API Synthetic Routes

| API (Case Study) | Synthetic Route | Carbon Footprint (kg CO₂ eq/kg API) | Process Mass Intensity (PMI) / E-Factor* | Water Use (L/kg API) | Key Differentiating Factor |

|---|---|---|---|---|---|

| Sitagliptin (Merck) | Original Rh-catalyzed enamine hydrogenation | ~220 | ~126 | ~15,200 | Solvent use, high-pressure H₂, metal catalyst |

| Redesigned Enzymatic Transamination | ~110 | ~52 | ~6,500 | Biocatalyst, ambient conditions, step reduction | |

| Atorvastatin | Traditional Chemical Synthesis | ~180 | ~78 | ~12,500 | Multiple protection/deprotection steps, chiral resolution |

| Chemoenzymatic Synthesis (Codexis) | ~95 | ~47 | ~7,800 | Biocatalytic chiral step, improved atom economy | |

| Paracetamol | Traditional Nitration Route (from phenol) | ~8 | ~4 | ~1,200 | Fossil-based feedstock, nitration waste |

| Green Route (from hydroquinone) | ~5 | ~2 | ~600 | Fewer steps, cleaner by-products |

Note: E-Factor = (Total mass of inputs - mass of API) / mass of API. Process Mass Intensity (PMI) is mass of inputs/mass of API, hence PMI = E-Factor + 1. Values in table are PMI.

Experimental Protocols for Comparative LCA in API Synthesis

The data in Table 1 is generated through standardized comparative LCA methodologies. Below is the core experimental and analytical protocol.

Protocol 1: Comparative Life Cycle Inventory (LCI) Compilation for Route Comparison

- Goal & Scope Definition: Define functional unit (e.g., 1 kg of >99% pure API). Set system boundaries from "cradle-to-gate" (raw material extraction to finished API at plant gate). Include all chemical inputs, solvents, catalysts, energy, and waste treatment.

- Inventory Analysis (Primary Data Collection):

- For each synthetic route, obtain from R&D/pilot plant: precise material balance (bill of materials), solvent volumes (and recovery rates), energy consumption (heating, cooling, stirring, purification), and yields for each step.

- For upstream materials (e.g., solvent production), use secondary data from commercial LCA databases (e.g., Ecoinvent, GaBi).

- Impact Assessment (Calculation):

- Carbon Footprint: Apply relevant characterization factors (e.g., from IPCC) to all greenhouse gas emissions (CO₂, CH₄, N₂O) from energy use and chemical reactions across the inventory.

- E-Factor/PMI: Calculate directly from the material balance: PMI = (Total mass of all input materials) / (Mass of final API).

- Water Use: Sum all process water, cooling water, and water embedded in raw materials. Differentiate between water consumption (lost) and withdrawal.

- Interpretation: Compare results for each route, identify environmental hotspots (e.g., step using high PMI solvent, energy-intensive distillation), and perform sensitivity analyses.

Protocol 2: Gate-to-Gate Process Mass Intensity (PMI) Experimental Determination

- Lab/ Pilot-Scale Synthesis: Perform each alternative synthetic route under optimized conditions.

- Mass Tracking: Accurately weigh all input materials (reagents, solvents, catalysts, filters) for the entire sequence.

- Yield and Purity Determination: Isolate and dry the final API. Measure mass and confirm purity (HPLC, NMR).

- Calculation: PMI = Total mass of inputs (kg) / Mass of pure API product (kg). E-Factor = PMI - 1.

Visualizing Comparative LCA Workflow and Impact Drivers

Diagram Title: Comparative LCA Workflow for API Routes

Diagram Title: Key Drivers of API Environmental Impact

The Scientist's Toolkit: Essential Reagents & Solutions for Green Metrics Analysis

Table 2: Key Research Reagent Solutions for LCA & Green Chemistry Metrics

| Item | Function in Comparative Analysis |

|---|---|

| Process Mass Intensity (PMI) Calculator | Software or spreadsheet template to aggregate mass inputs from each step and compute PMI/E-Factor. Essential for quantitative route comparison. |

| Life Cycle Inventory (LCI) Database Access (e.g., Ecoinvent, Sphera) | Provides secondary data on the environmental burdens of upstream chemicals, solvents, and energy grids. Critical for carbon and water footprinting. |

| Solvent Selection Guides (e.g., ACS GCI, CHEM21) | Charts rating solvents by health, safety, and environmental (HSE) criteria. Used to identify and substitute high-PMI or toxic solvents (e.g., replace DCM with EtOAc). |

| Biocatalyst Libraries (e.g., engineered transaminases, ketoreductases) | Enable replacement of metal-catalyzed or stoichiometric steps, often reducing step count, energy intensity, and metal waste. |

| High-Throughput Experimentation (HTE) Platforms | Allow rapid screening of reaction conditions (catalyst, solvent, temp) to maximize yield and minimize waste early in route scouting. |

| Advanced Analytical Standards (HPLC, GC, NMR) | Ensure accurate yield and purity determination, which is fundamental for correct PMI and LCA calculations. |

How to Perform an API LCA: Step-by-Step Methodology and Tools

Comparative Guide: LCI Data Collection Methodologies for API Synthesis

A critical first step in the Comparative Life Cycle Assessment (LCA) of Active Pharmaceutical Ingredient (API) synthetic routes is the construction of a robust Life Cycle Inventory (LCI). This guide compares prevalent experimental and computational methodologies for primary data acquisition in pharmaceutical process chemistry, a core challenge for researchers.

Comparison of Primary LCI Data Collection Approaches

The table below compares three principal methodologies for generating primary LCI data at the laboratory scale, which serve as the basis for scaling estimates.

Table 1: Comparison of Laboratory-Scale LCI Data Generation Methods

| Method | Key Principle | Data Granularity | Typical Time Investment | Scalability Uncertainty | Best For |

|---|---|---|---|---|---|

| Traditional Material Accounting | Direct measurement of all input masses and output products/waste from a published synthetic procedure. | High (discrete steps) | Medium (1-2 days per route) | High (requires process modeling) | Established routes with detailed experimental procedures. |

| In-situ Reaction Calorimetry & Analytics | Real-time monitoring of heat flow, material consumption (e.g., via FTIR, Raman), and gas evolution (e.g., CO₂). | Very High (continuous) | High (setup + run time) | Medium-Low (provides kinetic & thermal data) | Optimizing reaction conditions, assessing exothermic risks, and precise solvent/ reagent tracking. |

| High-Throughput Experimentation (HTE) Platforms | Automated parallel synthesis in microtiter plates with integrated analytics for rapid screening. | Medium (for multiple variants) | Low per data point (high efficiency) | Medium (requires correlation to bench scale) | Rapid comparison of alternative catalysts, solvents, or reagents across a design space. |

Experimental Protocols for Key LCI Methods

Protocol 1: Traditional Material Accounting for a Stepwise Synthesis

- Procedure Selection: Choose a peer-reviewed synthetic procedure for the target API intermediate.

- Bench-Scale Execution: Perform the reaction at a sensible laboratory scale (e.g., 1-10 mmol) precisely following the reported conditions.

- Input Weighing: Accurately weigh all reactants, catalysts, solvents, and drying agents before addition.

- Output Quantification: After work-up and purification, weigh all isolated products, by-products, and recovered materials. Collect all waste streams (aqueous, organic, solid) separately.

- Solvent Accounting: Estimate solvent losses from evaporation and transfers. Measure the mass of recovered solvent post-distillation, if applicable.

- Data Recording: Record all masses, volumes, and energy consumption (e.g., stirring, heating, cooling, vacuum distillation time).

Protocol 2: In-situ Reaction Monitoring for LCI via Reaction Calorimetry

- Calorimeter Setup: Calibrate a reaction calorimeter (e.g., RC1e, ChemiSens) according to manufacturer specifications. Prepare reagents and temperature control fluid.

- Baseline Establishment: Load the solvent and starting materials into the reactor. Achieve thermal equilibrium at the target reaction temperature.

- Reagent Addition & Monitoring: Initiate the reaction by adding a key reagent (e.g., catalyst, base) via a syringe pump or calorimeter dosing system. The software records heat flow (dq/dt), cumulative heat (Q), and temperature in real-time.

- Parallel Analytics: Couple the reactor outlet to an FTIR or Raman probe to monitor concentration changes of key species, providing direct data on conversion and by-product formation.

- Gas Evolution Tracking: Connect a gas flowmeter or mass spectrometer to quantify the release of gases (e.g., CO₂ from decarboxylation, H₂ from reductions).

- Data Integration: Combine thermal, compositional, and gas evolution data to create a time-resolved inventory of mass and energy flows.

Workflow for LCI in Comparative API Route Assessment

Title: Workflow for Generating API Synthesis LCI Data

The Scientist's Toolkit: Essential Reagents & Solutions for LCI Studies

Table 2: Key Research Reagent Solutions for Experimental LCI

| Item | Function in LCI Studies | Example / Rationale |

|---|---|---|

| Deuterated Solvents (e.g., DMSO-d₆, CDCl₃) | Enables reaction monitoring via in-situ NMR for precise conversion/yield data without workup. | Tracking reagent consumption in real-time for accurate mass balance. |

| Internal Standards for GC/MS/HPLC | Quantifies reactants and products in complex reaction mixtures for mass balance closure. | Adding a known quantity of a non-interfering compound to calculate concentrations. |

| Calorimeter Calibration Solutions | Validates the heat flow and temperature measurements of reaction calorimetry systems. | Electrical calibration (Joule effect) or chemical calibration (e.g., hydrolysis of acetic anhydride). |

| Catalyst Screening Kits (HTE) | Allows rapid, parallel assessment of multiple catalytic systems while controlling variables. | Pre-weighed metal/ligand combinations in microtiter plates for cross-coupling reactions. |

| Anisole or Mesitylene (Internal Standard) | Common, inert internal standard for reaction calorimetry to determine adiabatic temperature rise. | Used in the "synthetic method" to assess thermal hazard and scale-up energy parameters. |

| Solvent Purification Systems | Provides consistent, anhydrous solvent quality, reducing variability in reaction efficiency and waste. | Critical for moisture-sensitive reactions (e.g., organometallic catalysis) to ensure reproducibility. |

Comparative Analysis of Green Chemistry Metrics for API Route Scouting

Within the context of a comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes, data collection on solvent use, reagent stoichiometry, and energy inputs forms the critical foundation for evaluating environmental and process efficiency. This guide compares experimental data for two alternative synthetic routes to a common intermediate, Methyl 4-(aminomethyl)benzoate, highlighting key green chemistry metrics.

Experimental Protocols for Data Generation

Route A (Reductive Amination):

- Reaction: Charge a 1L reactor with Methyl 4-formylbenzoate (50.0 g, 1.0 eq) and methanol (500 mL, 10 vol). Cool to 0-5°C.

- Amine Addition: Slowly add a 28% aqueous ammonia solution (equivalent to 5.0 eq NH₃) over 30 minutes, maintaining temperature <10°C.

- Reduction: Add sodium borohydride (1.2 eq) in portions, controlling gas evolution. Stir for 12 hours at ambient temperature.

- Work-up: Quench by careful addition of 2M HCl (300 mL). Concentrate under reduced pressure to remove methanol. Adjust pH to 10 with 2M NaOH and extract with ethyl acetate (3 x 200 mL).

- Isolation: Dry the combined organic layers over anhydrous MgSO₄, filter, and concentrate to yield the crude product as a white solid.

Route B (Catalytic Hydrogenation):

- Reaction: Charge a 500 mL Parr hydrogenation reactor with Methyl 4-cyanobenzoate (50.0 g, 1.0 eq), Raney nickel catalyst (5 wt%), and concentrated aqueous ammonia (150 mL, 3.0 eq NH₃) in tetrahydrofuran (250 mL, 5 vol).

- Hydrogenation: Purge the vessel with N₂, then H₂ (3x). Pressurize with H₂ to 50 bar and heat to 80°C. Stir at 800 RPM for 8 hours.

- Work-up: Cool the reactor, vent H₂, and filter the reaction mixture through a Celite pad to remove the catalyst.

- Isolation: Wash the filter cake with THF (50 mL). Separate the organic layer, wash with brine (100 mL), dry over anhydrous Na₂SO₄, and concentrate under reduced pressure to yield the crude product.

Performance Comparison Data

Table 1: Solvent and Reagent Stoichiometry Comparison

| Parameter | Route A (Reductive Amination) | Route B (Catalytic Hydrogenation) | Ideal Target |

|---|---|---|---|

| Key Solvent | Methanol (10 vol) | Tetrahydrofuran (5 vol) | Minimize Volume |

| Aux. Solvent (Work-up) | Ethyl Acetate (12 vol) | Brine Wash (<1 vol) | Minimize & Use Benign |

| Stoichiometry (Reducing Agent) | NaBH₄ (1.2 eq) | H₂ (Catalytic, excess pressure) | Catalytic, Atom Economic |

| Amine Source (eq.) | NH₃ (5.0 eq, aq.) | NH₃ (3.0 eq, aq.) | Minimize Excess |

| Theoretical E-factor (kg waste/kg product)* | 42 | 18 | < 25 |

| Process Mass Intensity (PMI) | 58 | 32 | Minimize |

*Calculated for isolated yield before purification. E-factor = (total mass of raw materials - mass of product) / mass of product.

Table 2: Energy Input and Performance Data

| Parameter | Route A (Reductive Amination) | Route B (Catalytic Hydrogenation) |

|---|---|---|

| Reaction Temperature | 0°C → 25°C (Ambient) | 80°C |

| Reaction Time | 12 hours | 8 hours |

| Specialized Equipment | Standard Jacketed Reactor | High-Pressure Hydrogenation Reactor |

| Energy Intensity (Relative) | Moderate (Cooling, then ambient) | High (Heating, High-Pressure Gas Handling) |

| Isolated Yield | 78% | 92% |

| Purity (HPLC, area %) | 85% | 96% |

Visualization of Route Comparison and LCA Context

Title: API Synthesis Route Data Flow into Comparative LCA

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Green Metrics Data Collection

| Item | Function in Data Collection |

|---|---|

| Automated Reaction Calorimeter | Precisely measures heat flow (energy input/ output) and enables safe scale-up by monitoring exotherms. |

| High-Pressure Hydrogenation Reactor (e.g., Parr Series) | Enables catalytic hydrogenation route scouting with precise control of H₂ pressure, temperature, and stirring. |

| Process Mass Spectrometry (MS) Gas Analysis | Monitors gas uptake (H₂) or evolution in real-time, providing precise stoichiometric and kinetic data. |

| Automated Solvent/Reagent Dosing System | Ensures accurate and reproducible delivery of liquid reagents and solvents for consistent volumetric data. |

| Green Chemistry Metric Calculator Software (e.g., ACS GCI) | Automates calculation of E-factor, PMI, Atom Economy, and other metrics from experimental input data. |

| Rotary Evaporator with Dry Ice Condenser | Efficiently recovers and measures solvent volumes post-reaction for accurate mass balance closure. |

Comparative Analysis of Continuous Flow Reactor vs. Batch Reactor for API Intermediate Synthesis

Within the context of a Comparative Life Cycle Assessment (LCA) of API synthetic routes, the choice between continuous flow and batch reaction operations is pivotal, impacting yield, purity, energy consumption, and solvent waste.

Experimental Protocol: Synthesis of 4-(4-Fluorophenyl)-4-oxobutanoic Acid (Key Intermediate)

- Batch Method: A 1L glass reactor was charged with fluorobenzene (1.0 mol) and succinic anhydride (1.05 mol) in dichloromethane (500 mL). Aluminum chloride (2.2 mol) was added portionwise at 0°C over 30 minutes. The reaction was stirred for 12 hours at ambient temperature, then quenched with ice-cold 2M HCl.

- Continuous Flow Method: Two reagent streams were prepared: Stream A (fluorobenzene and succanic anhydride in DCM) and Stream B (AlCl3 in DCM). Streams were fed via precision pumps into a 10 mL PFA coil reactor (residence time: 30 minutes) maintained at 25°C. The output was directly quenched in a static mixer with a flowing stream of 2M HCl.

Quantitative Performance Comparison Table 1: Reaction Unit Operation Performance Data

| Performance Metric | Batch Reactor | Continuous Flow Reactor |

|---|---|---|

| Reaction Yield | 82% ± 3% | 91% ± 2% |

| Space-Time Yield (kg m⁻³ h⁻¹) | 12.4 | 148.7 |

| Reaction Solvent Volume (L/kg product) | 15.2 | 8.5 |

| Cooling Energy Demand (kJ/kg product) | 1850 | 420 |

| Estimated E-Factor (Reaction Only) | 23.1 | 11.8 |

Comparison of Purification Techniques: Recrystallization vs. Continuous Chromatography

Downstream purification significantly influences LCA outcomes through solvent recovery and energy intensity.

Experimental Protocol: Purification of the Crude Friedel-Crafts Product

- Traditional Recrystallization: Crude product (50 g) was dissolved in a minimum volume of hot ethyl acetate (~300 mL), treated with activated carbon, filtered, and allowed to cool slowly to 4°C for 18 hours. Crystals were isolated by filtration and washed with cold solvent.

- Simulated Moving Bed (SMB) Chromatography: A Lab-SMB unit with 4 columns (C18 stationary phase) was used. The mobile phase was a gradient of acetonitrile and water. The feed concentration was 50 g/L. The system was run continuously for 24 hours to achieve steady-state separation.

Quantitative Performance Comparison Table 2: Purification Unit Operation Performance Data

| Performance Metric | Batch Recrystallization | SMB Chromatography |

|---|---|---|

| Final API Intermediate Purity | 99.2% | 99.5% |

| Product Recovery Yield | 78% | 92% |

| Primary Solvent Consumption (L/kg) | 28.0 | 15.0* |

| Solvent Recovery Efficiency | 60% (energy-intensive) | 95% (integrated system) |

| Process Time (hrs/kg) | 24 | 6 (continuous) |

*Includes solvent from mobile phase, assuming 90% recovery.

The Scientist's Toolkit: Research Reagent Solutions for API Route Development

Table 3: Essential Materials for Modeling API Unit Operations

| Item | Function & Rationale |

|---|---|

| PFA Tubing Coil Reactors | Enables continuous flow chemistry; offers excellent chemical resistance, visibility, and controlled residence time. |

| Precision Syringe Pumps | Provides accurate, pulseless delivery of reagents for continuous flow processes and kinetic studies. |

| Process Analytical Technology (PAT) | In-line IR or UV probes enable real-time reaction monitoring, critical for process optimization and control. |

| High-Performance Liquid Chromatography (HPLC) | Standard for quantifying reaction conversion, impurity profiling, and assessing separation efficiency. |

| Simulated Moving Bed (SMB) System | Allows for continuous, high-throughput chromatographic separation, reducing solvent use and improving yield. |

| Differential Scanning Calorimetry (DSC) | Determines melting points and polymorph purity of crystals, crucial for designing recrystallization protocols. |

Experimental Workflow for Comparative Unit Operation Analysis

Diagram 1: API Route Development & Comparison Workflow

Signaling Pathway for Solvent Selection in Unit Operations

Diagram 2: Solvent Selection Decision Pathway

Incorporating Upstream Impacts of Raw Material Production

This comparison guide is framed within a thesis on the Comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes. Traditional LCA for APIs often focuses on the direct chemical synthesis steps (cradle-to-gate). However, a holistic evaluation must incorporate the upstream environmental burdens from the production of key raw materials, as these can dominate the overall impact profile. This guide objectively compares the performance of two synthetic routes for a model API, Ibuprofen, by integrating upstream raw material production data.

Experimental Protocol for Comparative LCA

- Goal & Scope Definition: The functional unit is 1 kilogram of pharmaceutical-grade Ibuprofen. System boundaries include raw material extraction (cradle) through to the final API at the manufacturing gate.

- Inventory Analysis (LCI): Primary data is collected for each synthesis step (yields, energy, solvent use). Secondary data for upstream raw material production (e.g., petrochemical feedstocks, catalyst metals) is sourced from commercial LCA databases (e.g., Ecoinvent, GaBi).

- Impact Assessment (LCIA): Impacts are calculated using the ReCiPe 2016 Midpoint (H) method. Key categories include Global Warming Potential (GWP), Fossil Resource Scarcity (FRS), and Water Consumption.

- Interpretation: Results are compared per route, with contribution analysis to identify hotspots, particularly from upstream processes.

Comparison of Ibuprofen Synthetic Routes

Route A: Boots/Hoechst Celanese Process (Traditional 6-step synthesis) Route B: BHC Process (Green chemistry, 3-step catalytic synthesis)

Table 1: Key Inventory Data per 1 kg Ibuprofen

| Inventory Item | Route A (Boots) | Route B (BHC) | Data Source / Assumption |

|---|---|---|---|

| Total Raw Material Mass (kg) | ~4.2 | ~1.5 | LCI from literature & database |

| Solvent Use (kg) | ~25 (mostly dichloromethane, hydrocarbons) | ~5 (primarily acetic acid) | Jiménez-González et al. (2004) |

| Catalyst Use | Stoichiometric AlCl₃, HF | Catalytic HF, Raney Ni | |

| Major Upstream Feedstocks | Isobutylbenzene, acetic anhydride, acetyl chloride | Isobutylbenzene, acetic acid, CO, H₂ |

Table 2: Life Cycle Impact Assessment Results (per 1 kg Ibuprofen)

| Impact Category | Unit | Route A (Boots) | Route B (BHC) | Reduction in Route B |

|---|---|---|---|---|

| Global Warming Potential (GWP) | kg CO₂-eq | ~8.5 | ~3.1 | 63% |

| Upstream Contribution | % | ~65% | ~75% | |

| Fossil Resource Scarcity | kg oil-eq | ~12.6 | ~4.8 | 62% |

| Upstream Contribution | % | ~85% | ~88% | |

| Water Consumption | m³ | ~0.85 | ~0.31 | 64% |

| Upstream Contribution | % | ~55% | ~60% |

Note: Upstream contribution refers to impacts originating from the production of raw materials and chemicals prior to the synthesis steps. Data synthesized from comparative LCA studies (e.g., Kralisch et al., 2005; American Chemical Society Green Chemistry Institute case study).

Diagram: System Boundary for API LCA with Upstream Inclusion

Title: LCA System Boundaries with Upstream Processes

The Scientist's Toolkit: LCA & Green Chemistry Research Reagents

Table 3: Essential Reagents & Tools for Comparative API Route Analysis

| Item | Function in Research Context |

|---|---|

| LCA Software (e.g., OpenLCA, SimaPro) | Models material/energy flows and calculates environmental impacts using integrated databases. |

| Ecoinvent Database | Provides high-quality, transparent life cycle inventory data for chemicals, materials, and energy. |

| Green Chemistry Metrics Calculator | Calculates Atom Economy, Process Mass Intensity (PMI), and E-factor from experimental data. |

| Catalyst Libraries (e.g., Pd, Ni, Enzymes) | Enable screening for greener, more efficient catalytic steps to replace stoichiometric reagents. |

| Bio-Based Solvents (e.g., 2-MeTHF, Cyrene) | Drop-in alternatives for fossil-based solvents like dichloromethane or DMF in reaction optimization. |

| Process Simulation Software (e.g., Aspen Plus) | Models energy and mass balance for scaled-up processes, providing input data for LCI. |

Software and Databases for Pharmaceutical LCA (e.g., GaBi, SimaPro)

Within the broader thesis on Comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes, the selection of software and databases is a critical methodological decision. These tools enable researchers to model complex chemical processes, inventory resource use and emissions, and assess environmental impacts from cradle-to-gate. This guide objectively compares prominent LCA software solutions—GaBi and SimaPro—alongside emerging alternatives, focusing on their application in pharmaceutical route selection.

Software Platform Comparison

The following table summarizes the core features, databases, and pharmaceutical applicability of leading LCA software.

Table 1: Comparison of LCA Software for Pharmaceutical Applications

| Feature / Software | GaBi (sphera) | SimaPro | OpenLCA | Brightway2 |

|---|---|---|---|---|

| Primary Vendor | Sphera | PRé Sustainability | GreenDelta | Open Source |

| Core Modeling Approach | Process flow diagram | Input-output & process tree | Process flow diagram | Python-based, flexible matrices |

| Key Pharma-Relevant Databases | GaBi Databases, including specialty chemicals; EF 3.0 | Ecoinvent, USLCI, ReCiPe 2016 | Ecoinvent, Agri-Footprint, own DB creation | Compatible with multiple DBs (ecoinvent, etc.) |

| API Synthesis Modeling Strength | Detailed unit operation modeling; integrated chemistry data | Robust impact assessment for toxicity categories | Good for combining different database sources | High customization for novel algorithms |

| Primary Impact Assessment Methods | CML, ReCiPe, EF, TRACI | ReCiPe, IMPACT World+, CML, Eco-indicator 99 | LC-Impact, ReCiPe, CML, ILCD | User-defined, all standard methods |

| Learning Curve | Moderate | Steep | Moderate to Steep | Very Steep (requires coding) |

| Cost Model | High commercial license | High commercial license | Freemium / Commercial | Free (open source) |

| Interoperability | Good with SAP, ERP | Good with data import/export | High via open API | Excellent (Python ecosystem) |

| Recent Update Focus (2023-2024) | Integration of EF 3.1, enhanced circularity metrics | Improved Monte Carlo uncertainty analysis, regionalization | Nexus library for data sharing, improved UI | Development of the Brightway2.5 ecosystem |

Database Critical Analysis for Pharmaceutical LCA

The accuracy of an API route LCA hinges on the background and foreground data. The table below compares essential databases.

Table 2: Key LCA Database Suitability for Pharmaceutical Research

| Database Name | Type | Inclusion of Pharma-Relevant Data | Strengths for API Route Comparison | Limitations |

|---|---|---|---|---|

| Ecoinvent v3.9+ | Background | Solvents (e.g., Acetonitrile, THF), basic chemicals, energy. | High granularity on chemical production routes. | Lacks specific, high-purity pharmaceutical intermediates. |

| GaBi Databases | Background & Foreground | Extended data on specialty chemicals and processes. | Strong alignment with GaBi software; consistent modeling. | Proprietary; difficult to use outside GaBi ecosystem. |

| USLCI | Background | US-specific energy and chemical production data. | Useful for geographically specific assessments in the US. | Less comprehensive on fine chemicals. |

| ReCiPe 2016 | Impact Assessment | Detailed human toxicity and ecotoxicity characterization factors. | Essential for evaluating API synthesis environmental toxicity. | Complexity in interpretation of midpoint vs. endpoint results. |

| EF 3.0/3.1 (EU) | Impact Assessment | Standardized method for EU Product Environmental Footprint. | Critical for regulatory compliance in European markets. | Less established for sector-specific toxicity assessment. |

Experimental Protocol: Software-Based Comparative LCA of API Routes

This methodology outlines a standard protocol for comparing two hypothetical API synthetic routes (Route A: Traditional; Route B: Green Chemistry-based) using LCA software.

1. Goal and Scope Definition:

- Objective: Quantify and compare the environmental impacts of two distinct synthetic routes for Example-API from raw material extraction to purified API at factory gate (cradle-to-gate).

- Functional Unit: 1 kilogram of Example-API with ≥99.5% purity.

- System Boundaries: Include all reagent production, solvent use and recovery, energy consumption for reactions and purification (e.g., distillation, chromatography), and waste treatment. Exclude capital equipment and human labor.

2. Life Cycle Inventory (LCI) Compilation:

- Foreground Data (Primary): Collect mass and energy balances from laboratory or pilot-scale experiments for each route. Key parameters: stoichiometry, solvent volumes, reaction yields, energy for heating/cooling/stirring, and purification losses.

- Background Data (Secondary): Source data for upstream production of reagents, solvents (e.g., methanol, dichloromethane), and electricity from selected databases (e.g., ecoinvent). Use region-specific grid mixes (e.g., U.S. national average).

3. Modeling in Software:

- Platform Setup: Create parallel projects in the compared software (e.g., GaBi vs. SimaPro).

- Process Modeling: Build a flow diagram (GaBi) or process tree (SimaPro) mirroring the synthetic steps.

- Data Linking: Link each foreground flow (e.g., Input: 5 kg Acetonitrile) to the corresponding background dataset.

- Allocation: Apply mass-based allocation for multi-output processes. If solvent recovery is modeled, use system expansion or avoided burden approach.

4. Life Cycle Impact Assessment (LCIA):

- Apply the ReCiPe 2016 (H) Midpoint method in both software platforms to ensure comparability. Key impact categories for pharmaceuticals:

- Global Warming Potential (GWP100)

- Fine Particulate Matter Formation

- Freshwater Ecotoxicity

- Human Carcinogenic Toxicity

- Water Consumption

5. Interpretation & Uncertainty:

- Conduct contribution analysis to identify environmental hotspots (e.g., specific reaction steps, solvent use).

- Perform sensitivity analysis on critical parameters (e.g., solvent recycling rate, source of electricity).

- Run Monte Carlo simulations (where supported, e.g., SimaPro) to assess statistical significance of differences between Route A and Route B.

Title: Workflow for Comparative API Route LCA Using Software

The Scientist's Toolkit: Research Reagent Solutions for LCA Modeling

Table 3: Essential "Reagents" for Pharmaceutical LCA Computational Studies

| Item / Solution | Function in Pharmaceutical LCA | Example Source / Note |

|---|---|---|

| Process Mass & Energy Balance Data | The primary foreground data. Accurate lab/pilot measurements are non-negotiable for credible modeling. | Internal lab notebooks, process development reports, pilot plant logs. |

| High-Quality Solvent LCI Datasets | To model the major environmental burden of API synthesis. | ecoinvent ("acetonitrile, production"), GaBi "Basic Chemicals" database. |

| Specialty Chemical Datasets | For catalysts, ligands, and complex intermediates. Often the largest data gap. | Literature LCA studies, GaBi extension databases, or proxy data from similar chemicals. |

| Toxicity Characterization Factors | To assess human and ecotoxicity impacts, crucial for pharmaceutical waste. | Integrated within ReCiPe or USEtox methods in the software. |

| Energy Mix Profiles | To model electricity and steam demand for reactions and separations. | ecoinvent ("market for electricity, medium voltage"), country-specific datasets. |

| Software Scripting/API Tools | For automating repetitive tasks or customizing calculations. | Brightway2 (Python), OpenLCA's JSON-LD API, SimaPro's Python SDK. |

| Uncertainty Distributions | To define ranges for key parameters (e.g., yield, energy) in stochastic modeling. | Literature values, experimental standard deviations, expert judgment. |

Title: Addressing Data Gaps for Pharmaceutical Intermediates

For the comparative LCA of API synthetic routes, GaBi offers an integrated platform with strong process modeling and chemistry-focused databases, beneficial for detailed engineering analyses. SimaPro provides unparalleled flexibility in impact assessment and robust uncertainty analysis, favored for academic research and comprehensive toxicity evaluation. Open-source alternatives like Brightway2 are powerful for customizable, script-driven analyses but require significant programming expertise. The choice ultimately depends on the research's specific focus: process engineering detail (GaBi), comprehensive impact methodology (SimaPro), or algorithmic flexibility (Brightway2). All studies must rigorously address the critical data gap for pharmaceutical intermediates through transparent proxy selection and sensitivity analysis.

Within the broader thesis on the Comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes, this guide objectively compares two modern synthetic approaches for Ibrutinib, a Bruton's tyrosine kinase inhibitor. The comparison focuses on efficiency, environmental impact, and scalability, supported by experimental data.

Route A (Traditional Amide Coupling Route): This route involves a linear synthesis starting from a pyrazolo[1,5-a]pyrimidine core. The key steps are a nucleophilic aromatic substitution (SNAr) followed by a peptide coupling reagent-mediated amide bond formation to attach the acrylamide pharmacophore.

Route B (Convergent Suzuki-Miyaura Coupling Route): This more convergent route constructs the molecule via a late-stage Suzuki-Miyaura cross-coupling between a complex aryl boronic ester/acid and a halogenated acrylamide precursor. This approach aims to improve atom economy and reduce step count.

Comparative Experimental Data

Table 1: Key Performance Indicators for Ibrutinib Synthesis

| Parameter | Route A (Amide Coupling) | Route B (Suzuki-Miyaura) | Measurement Method |

|---|---|---|---|

| Overall Yield | 42% (over 8 steps) | 68% (over 6 steps) | Isolated yield of final API after purification |

| Process Mass Intensity (PMI) | 285 kg/kg API | 152 kg/kg API | Total mass of materials used per kg of API produced |

| E-Factor | 284 | 151 | (Total mass of waste / mass of product); PMI - 1 |

| Key Isolation/Purification Steps | 7 | 4 | Number of intermediate isolations |

| Purity (HPLC) | 99.5% | 99.8% | Area percent, USP method |

| Total Estimated Cost | High | Moderate | Relative cost of goods (COGs) at pilot scale |

Table 2: Environmental Impact Snapshot (per kg API)

| Impact Category | Route A | Route B | Reduction |

|---|---|---|---|

| Global Warming Potential (GWP) | 850 kg CO2-eq | 520 kg CO2-eq | ~39% |

| Cumulative Energy Demand (CED) | 12,500 MJ | 8,200 MJ | ~34% |

Experimental Protocols for Key Steps

Protocol for Route A (Amide Coupling):

- SNAr Reaction: Charge reactor with core pyrimidine (1.0 eq), piperazine derivative (1.2 eq), and DIPEA (2.0 eq) in NMP (10 vol). Heat to 110°C for 6 hours. Monitor by HPLC. Quench in water, extract with EtOAc, dry (Na2SO4), and concentrate.

- Amide Coupling: Dissolve SNAr product (1.0 eq) and acrylic acid derivative (1.1 eq) in DCM (15 vol). Cool to 0°C. Add HATU coupling reagent (1.2 eq) followed by DIPEA (2.5 eq). Stir at 0°C to RT for 12 hours. Wash sequentially with 5% citric acid, 5% NaHCO3, and brine. Purify by silica gel chromatography.

Protocol for Route B (Suzuki-Miyaura Coupling):

- Boronic Ester Synthesis: Treat halogenated core (1.0 eq) with bis(pinacolato)diboron (1.5 eq), KOAc (3.0 eq), and Pd(dppf)Cl2 catalyst (0.03 eq) in 1,4-dioxane (12 vol). Heat to 90°C under N2 for 8 hours. Filter through Celite and concentrate. Use crude product in next step.

- Suzuki Coupling: Charge reactor with boronic ester (1.0 eq), vinyl halide acrylamide (1.05 eq), and K2CO3 (2.0 eq) in a 3:1 mixture of toluene/water (10 vol total). Degas with N2. Add Pd(PPh3)4 (0.02 eq). Heat to 85°C for 4 hours. Cool, separate layers, and extract aqueous layer with toluene. Combine organics, wash with brine, and crystallize product from heptane/EtOAc.

Visualizations

Title: Route A: Linear Amide Coupling Synthesis

Title: Route B: Convergent Suzuki Coupling Synthesis

Title: Simplified LCA Framework for API Routes

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for API Route Development

| Reagent/Material | Function/Application | Key Consideration |

|---|---|---|

| HATU | Peptide coupling reagent for amide bond formation (Route A). | Efficient but generates costly and potentially genotoxic waste. |

| Pd(dppf)Cl2 | Palladium catalyst for borylation (Route B). | Air-stable, effective for C-B bond formation. Ligand choice is critical. |

| Pd(PPh3)4 | Catalyst for Suzuki-Miyaura cross-coupling (Route B). | Handles a wide range of substrates but can be sensitive to air. |

| Bis(pinacolato)diboron (B2Pin2) | Source of boron for boronic ester synthesis. | Shelf-stable, commonly used transmetalating agent. |

| DIPEA (Hünig's Base) | Non-nucleophilic base for coupling and SNAr reactions. | Minimizes side reactions compared to bases like triethylamine. |

| Chelating Silica Gel | For purification of metal-containing reaction mixtures. | Essential for removing residual palladium to meet ICH guidelines (<10 ppm). |

Overcoming Common LCA Challenges and Optimizing API Synthesis

Addressing Data Gaps and Uncertainty in Early-Stage Development

In the context of a Comparative Life Cycle Assessment (LCA) of Active Pharmaceutical Ingredient (API) synthetic routes, early-stage development is fraught with data scarcity. Direct, head-to-head environmental performance data for novel routes are rarely available. This guide compares methodologies to generate proxy data and model uncertainty, providing a framework for early comparative analysis.

Comparison of Predictive Models for Early-Stage LCA Inventory

| Model / Approach | Key Principle | Data Requirements | Typical Uncertainty Range (kg CO₂-eq/kg API) | Best Use Case |

|---|---|---|---|---|

| Stoichiometric Mass-Balance | Calculates inputs/outputs based on reaction equations & yields. | Synthetic route diagram, theoretical yields. | ± 40-60% | Screening of route alternatives in preclinical phase. |

| Process Simulation (e.g., CHEMCAD, Aspen) | Rigorous thermodynamic & equipment modeling. | Physical/chemical properties, estimated operating conditions. | ± 20-35% | Pilot-scale process design and solvent selection. |

| Economic Input-Output LCA (EIO-LCA) | Uses economic sector data to estimate environmental impact. | Estimated cost of goods (COGs) for the API step. | ± 50-100% | When process details are highly confidential or unknown. |

| Hybrid (Process-based + Literature Proxy) | Combines known step data with proxy data for novel steps from similar chemistry. | Data for 1-2 key steps; literature data for analogous reactions. | ± 30-50% | Development of routes containing both established and novel steps. |

Experimental Protocols for Generating Primary Data

To reduce uncertainty, targeted experiments can be conducted to generate primary LCA inventory data.

Protocol 1: Solvent Recovery Efficiency Determination

- Objective: Quantify the mass of solvent recoverable after a key reaction or workup step for LCA allocation.

- Method:

- Perform the reaction at 1-10g scale under controlled conditions.

- Upon reaction completion, employ a standardized isolation procedure (e.g., distillation, crystallization).

- Collect all distillate or mother liquor fractions.

- Analyze the composition of recovered fractions using Gas Chromatography (GC) with a flame ionization detector (FID).

- Calculate the percentage recovery of the primary solvent: (Mass of Recovered Solvent / Mass of Solvent Input) × 100%.

- Data for LCA: The recovery percentage directly informs the net solvent consumption (Fresh Solvent Input - Recovered Solvent) used in the life cycle inventory.

Protocol 2: Catalyst Leaching and Fate Analysis

- Objective: Determine the fate of precious metal catalysts (e.g., Pd, Pt) to quantify resource depletion and ecotoxicity impacts.

- Method:

- After a catalytic reaction, separate the reaction mixture into the product stream and the spent catalyst (if heterogeneous).

- For both homogeneous and heterogeneous systems, digest all liquid and solid waste streams in concentrated nitric acid.

- Analyze the resulting solutions using Inductively Coupled Plasma Mass Spectrometry (ICP-MS).

- Quantify the concentration of the catalyst metal in the product, recovered catalyst, and each waste stream.

- Data for LCA: The distribution (e.g., % in product, % recovered, % to wastewater) provides precise allocation for toxicity impacts and guides waste treatment modeling.

Workflow for Early-Stage Comparative LCA

Title: Decision Workflow for Early-Stage LCA Data

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in Data Generation for LCA |

|---|---|

| Simulation Software (e.g., Aspen Plus) | Models mass/energy balances, predicts utility consumption (steam, cooling water) for inventory. |

| EATOS (Environmental Assessment Tool for Organic Syntheses) | Specialized software to calculate environmental indices (mass index, energy consumption) directly from reaction schemes. |

| Life Cycle Inventory Databases (e.g., ecoinvent, GaBi) | Provide background data (electricity grid, solvent production impacts) for hybrid modeling. |

| Lab-Scale Distillation Kit | Essential for executing Protocol 1 to determine solvent recovery rates under realistic conditions. |

| ICP-MS Standard Solutions | Certified reference materials for calibrating ICP-MS to accurately trace metal catalyst fate (Protocol 2). |

| Green Chemistry Solvent Guide (ACS) | Informs solvent substitution to fill data gaps with lower-impact proxy solvents in modeling. |

This comparison guide, framed within a thesis on the Comparative Life Cycle Assessment (LCA) of different Active Pharmaceutical Ingredient (API) synthetic routes, evaluates methodologies for identifying environmental hotspots. It is crucial for researchers and scientists to determine which process steps or inputs contribute most significantly to the overall environmental footprint.

Comparison of Sensitivity Analysis Methods for LCA Hotspot Identification

| Method | Primary Function | Data Requirements | Key Strength | Key Limitation | Typical Output |

|---|---|---|---|---|---|

| One-at-a-Time (OAT) Sensitivity | Varies one input parameter at a time while holding others constant. | Baseline LCA model data. | Simple, intuitive, and easy to implement. | Cannot detect parameter interactions. | Ranked list of sensitive parameters (e.g., contribution to variance). |

| Global Sensitivity Analysis (GSA) | Applies statistical methods to vary all input parameters simultaneously across their entire range. | Probability distributions for all key input parameters. | Quantifies interaction effects and overall contribution to output variance. | Computationally intensive and requires robust statistical knowledge. | Sobol indices (e.g., Total-effect index > 0.1 indicates a hotspot). |

| Scenario-Based Sensitivity | Compares distinct, pre-defined scenarios (e.g., different energy grids or solvent recovery rates). | LCA models for each defined scenario. | Easy to communicate and directly informs decision-making between alternatives. | Does not probe continuous parameter uncertainty. | Comparative impact results (e.g., GWP of Scenario A vs. B). |

| Pedigree Matrix / Data Quality Assessment | Qualitatively assesses the uncertainty of input data based on reliability, completeness, and temporal correlation. | Metadata on data sources and collection methods. | Systematic approach to prioritize data refinement efforts. | Subjective and does not directly quantify output variance. | Data Quality Indicators (DQI) scores guiding hotspot refinement. |

Experimental Protocol: Global Sensitivity Analysis (GSA) for API Route Comparison

This protocol details a Monte Carlo-based GSA to identify hotspots in the carbon footprint of competing API syntheses.

- Goal & Scope: Define the functional unit (e.g., 1 kg of API at 99.5% purity) and system boundaries (cradle-to-gate).

- Parameter Selection: Identify key uncertain input parameters (e.g., yield of Step 3, energy consumption per kg of solvent recycled, transportation distance for a key precursor).

- Define Probability Distributions: Assign appropriate distributions (e.g., normal, log-normal, triangular) to each parameter based on primary data variability or literature ranges.

- Monte Carlo Simulation: Using LCA software (e.g., openLCA, SimaPro), run 5,000-10,000 iterations. In each iteration, values for all parameters are randomly sampled from their defined distributions, and the total Global Warming Potential (GWP) is calculated.

- Statistical Analysis: Calculate sensitivity indices (e.g., Sobol indices) from the simulation results. The Total-Effect Index quantifies a parameter's total contribution to the output variance, including all interaction effects. A threshold (e.g., >0.1) is used to classify parameters as environmental hotspots.

- Interpretation: Parameters with high total-effect indices are prioritized for further data refinement, process optimization, or green chemistry innovation.

Visualization: GSA Workflow for API Synthesis LCA

Title: Workflow for Global Sensitivity Analysis in LCA

The Scientist's Toolkit: Key Reagents & Software for Sensitivity Analysis

| Item | Function in Sensitivity Analysis | Example/Note |

|---|---|---|

| LCA Modeling Software | Core platform for building the life cycle model and running simulations. | openLCA, SimaPro, GaBi. Essential for Monte Carlo analysis. |

| Statistical Software / Libraries | Calculates advanced sensitivity indices and visualizes results. | R (with sensitivity package), Python (SALib library), MATLAB. |

| High-Quality LCI Databases | Provide background data (e.g., energy, chemicals) with uncertainty information. | Ecoinvent, GaBi Databases, USLCI. Critical for defining parameter ranges. |

| Process Mass Intensity (PMI) Data | Primary experimental data from lab/pilot-scale API synthesis. | Measured solvent, reagent, and energy use per kg of intermediate. Forms the baseline model. |

| Pedigree Matrix Template | Standardized form for qualitative data quality assessment. | Based on ISO 14044 guidelines. Used to score data reliability, completeness, etc. |

Within the comprehensive thesis on the Comparative Life Cycle Assessment (LCA) of Different API Synthetic Routes, the optimization of solvent use is a critical leverage point. Solvent selection and recovery directly influence environmental impact metrics such as cumulative energy demand (CED), waste generation (E-factor), and greenhouse gas (GHG) emissions. This guide compares the performance of solvent recovery systems and alternative solvent choices, providing experimental data to inform sustainable route selection for researchers and development professionals.

Comparative Analysis of Solvent Recovery Technologies

Effective solvent recovery reduces virgin material consumption and waste. The following table compares two dominant industrial recovery techniques.

Table 1: Performance Comparison of Solvent Recovery Technologies

| Technology | Typical Recovery Yield (%) | Energy Consumption (kWh/kg solvent) | Purity of Recovered Solvent (%) | Capital Cost Index (Relative) | Best for Solvent Classes |

|---|---|---|---|---|---|

| Batch Distillation | 80 - 92 | 0.8 - 1.5 | 98 - 99.5 | 1.0 (Baseline) | High-boiling point (≥150°C), wide-boiling mixtures |