Green Solvents in HPTLC: A Sustainable Paradigm for Enhanced Analytical Performance in Pharmaceutical and Food Analysis

This article provides a comprehensive analysis of the performance and application of green solvents in High-Performance Thin-Layer Chromatography (HPTLC) compared to traditional organic solvents.

Green Solvents in HPTLC: A Sustainable Paradigm for Enhanced Analytical Performance in Pharmaceutical and Food Analysis

Abstract

This article provides a comprehensive analysis of the performance and application of green solvents in High-Performance Thin-Layer Chromatography (HPTLC) compared to traditional organic solvents. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles of Green Analytical Chemistry (GAC) driving this shift, presents practical methodologies for implementing eco-friendly mobile phases, and addresses common troubleshooting and optimization challenges. The content critically validates the analytical performance of green solvents against traditional methods using modern sustainability metrics like AGREE, GAPI, and NEMI, demonstrating that green HPTLC methods do not compromise—and can even enhance—analytical robustness while significantly reducing environmental impact. This synthesis of foundational knowledge, practical application, and rigorous validation offers a clear roadmap for adopting sustainable practices in analytical laboratories.

The Green Imperative: Foundations of Sustainable HPTLC Analysis

Historical Development and Philosophical Evolution

The evolution of sustainable practices in analytical chemistry has progressed from a singular environmental focus to a holistic, multi-criteria framework. Green Analytical Chemistry (GAC) emerged as the initial paradigm, directly applying the twelve principles of green chemistry established by Paul Anastas and John Warner in the 1990s to analytical laboratories [1]. Its primary objective was the reduction of environmental impact through minimizing hazardous chemical use, waste generation, and energy consumption [1]. While GAC provides the crucial ecological foundation, a key limitation observed in practice is the potential trade-off where stringent application of GAC principles can sometimes lead to compromised analytical performance, such as reduced sensitivity, precision, or accuracy [1].

White Analytical Chemistry (WAC) emerged in 2021 as an integrated evolution to address these limitations [2]. WAC expands the sustainability concept beyond ecological considerations to create a balanced framework that equally weights environmental soundness, analytical performance, and practical/economic feasibility [1] [2]. The term "white" symbolizes the purity and completeness of this holistic approach, aiming to reconcile the sometimes-competing demands of green chemistry and functional utility [2]. This philosophical shift encourages scientists to evaluate their methods through a more comprehensive lens, ensuring they are not only environmentally responsible but also analytically sound and practically viable.

Core Principles and Conceptual Frameworks

The Twelve Principles of Green Analytical Chemistry

Green Analytical Chemistry is guided by a set of twelve principles that serve as a framework for implementing sustainable practices. These principles provide the environmental foundation for GAC and include directives such as eliminating the use of hazardous chemicals, minimizing waste generation, optimizing energy efficiency, and prioritizing direct analysis techniques to reduce sample preparation steps [1]. The SIGNIFICANCE mnemonic (Figure 1) offers a practical summary of these principles, facilitating their adoption in routine analytical practice [1]. These principles collectively drive methodologies toward reduced ecological footprints, influencing choices in solvents, energy consumption, and waste management throughout the analytical lifecycle.

The RGB Model of White Analytical Chemistry

White Analytical Chemistry introduces a innovative three-dimensional assessment model using the Red-Green-Blue (RGB) color model as its conceptual foundation [1] [2]. In this framework, each color represents a critical domain of methodological evaluation:

- The Green Component incorporates the traditional GAC principles, focusing on environmental impact parameters such as solvent toxicity, waste generation, energy consumption, and operator safety [1] [2].

- The Red Component addresses analytical performance criteria, including fundamental validation parameters like accuracy, precision, sensitivity, selectivity, and robustness [1] [2]. This dimension ensures the method produces reliable, high-quality data.

- The Blue Component encompasses practical and economic considerations, evaluating factors such as cost-effectiveness, analysis time, ease of use, automation potential, and operational simplicity [1] [2].

The ultimate goal within the WAC paradigm is to achieve "method whiteness" - a balanced optimization across all three domains where the methodological profile appears "white" when visualized using the RGB model [1] [2]. This indicates a methodology that successfully integrates environmental sustainability, analytical excellence, and practical feasibility.

Figure 1: The WAC RGB Model. This diagram visualizes the three core domains of White Analytical Chemistry and their contribution to the overall "whiteness" of an analytical method.

Comparative Analysis: GAC vs. WAC

Table 1: Fundamental Comparison Between GAC and WAC Frameworks

| Aspect | Green Analytical Chemistry (GAC) | White Analytical Chemistry (WAC) |

|---|---|---|

| Primary Focus | Environmental impact reduction [1] | Holistic balance of environmental, analytical, and practical criteria [1] [2] |

| Core Philosophy | Eco-centric | Sustainable and functional balance [3] |

| Assessment Dimensions | Single (Environmental) | Three (RGB Model: Environmental, Analytical, Practical) [1] [2] |

| View on Performance Trade-offs | Environmental goals may supersede performance [1] | Seeks equilibrium; avoids sacrificing performance for greenness [1] [3] |

| Key Metrics/Tools | NEMI, Eco-Scale, GAPI, AGREE [1] [3] [2] | RGB model, RGBfast, White Score [1] [4] |

| Typical Output | Greenness profile/pictogram | Whiteness profile/RGB pictogram [1] |

Practical Applications and Experimental Data

Case Study in Pharmaceutical Analysis

The practical implementation of WAC principles is illustrated by the development of a green RP-HPLC method for the simultaneous analysis of azilsartan, medoxomil, chlorthalidone, and cilnidipine in human plasma. Researchers employed a WAC-assisted Analytical Quality by Design (AQbD) strategy, which systematically integrated understanding of method parameters and their impact on critical quality attributes [1]. This approach resulted in a validated procedure that was sustainable, cost-effective, and achieved an excellent white WAC score by successfully balancing the red (analytical performance for multiple compounds), green (reduced solvent consumption and waste), and blue (cost-effectiveness and practicality for routine use) criteria [1].

Case Study in Food and Environmental Analysis

A comparative study evaluated a method for determining manganese (Mn) and iron (Fe) in beef samples using ultrasound-assisted extraction (UAE) and Microwave-Induced Plasma Atomic Emission Spectroscopy (MP AES) [3]. The method was validated and proved to be simple and fast, requiring no external heating and only diluted acids [3]. The application of both GAC (AGREEprep) and WAC metrics provided complementary insights. While the AGREEprep tool effectively highlighted the environmental advantages of the sample preparation, the WAC holistic approach revealed the overall strengths of the analytical technique across all three RGB dimensions, demonstrating its superiority over traditional, more resource-intensive methods [3].

Table 2: Experimental Data from Comparative Studies Applying GAC and WAC Principles

| Methodology / Parameter | Traditional HPLC | HPTLC for Multi-Plant Formulations [5] | UAE-MP AES for Metal Analysis [3] |

|---|---|---|---|

| Analytical Performance (Red) | High sensitivity and precision | LOD: 0.0020 µg/band, LOQ: 0.0067 µg/band; Validated for ephedrine alkaloids [5] | Accurate measurement of Mn and Fe at a >1:100 ratio [3] |

| Environmental Impact (Green) | High solvent consumption & waste | Limited solvent/reagent use; screens 19 samples simultaneously [5] | Diluted acids only; no harsh extractants or heating; minimal waste [3] |

| Practical & Economic (Blue) | High operational cost & time | Cost-effective; low requirement method; simple & rapid [5] | Fast (10 min); uses common lab equipment (ultrasonic bath) [3] |

| Overall GAC/WAC Assessment | Low greenness score | High alignment with GAC/WAC due to minimal resource use [5] | Excellent greenness (AGREEprep) and whiteness (WAC) scores [3] |

The Scientist's Toolkit: Key Reagents and Metrics

Green Solvents and Sample Preparation Solutions

The shift toward sustainable analytical chemistry has driven the adoption of greener solvents and miniaturized sample preparation techniques. Key developments include:

- Supercritical Fluid Chromatography (SFC): Utilizes supercritical carbon dioxide (sCO₂) as the primary mobile phase, drastically reducing or eliminating the need for traditional organic solvents [6].

- Natural Deep Eutectic Solvents (NADES): Emerging as green alternatives for extraction and sample preparation, offering advantages of biodegradability and low toxicity compared to conventional solvents [6].

- Micellar Liquid Chromatography (MLC): Employs surfactant solutions above their critical micellar concentration as mobile phases, reducing the consumption of toxic organic solvents like acetonitrile [6].

- Microextraction Techniques: Methods such as Solid-Phase Microextraction (SPME) and Liquid-Phase Microextraction (LPME) significantly reduce solvent and sample volume requirements, aligning with the principles of green sample preparation (GSP) [6].

Essential Assessment Metrics and Tools

A variety of metrics have been developed to quantitatively evaluate the environmental and holistic profile of analytical methods.

Table 3: Key Metrics for Evaluating Greenness and Whiteness

| Metric Name | Type | Brief Description | What it Measures |

|---|---|---|---|

| Analytical Eco-Scale [3] [2] | GAC | Points-based system; penalizes hazardous reagents, energy, and waste. Score >75 = acceptable green method [2]. | Environmental Impact |

| AGREE & AGREEprep [3] | GAC | Pictogram based on 12 GAC principles; provides a final score (0-1) and color code [3]. | Environmental Impact |

| GAPI & ComplexGAPI [1] [2] | GAC | Comprehensive pictogram covering entire method lifecycle from sampling to waste [1] [2]. | Environmental Impact |

| RGB Model / RGBfast [1] [4] | WAC | Holistic assessment based on the Red, Green, and Blue criteria to calculate a "white" score [1] [4]. | Holistic (RGB) |

| BAGI (Blue Applicability Grade Index) [2] | WAC (Blue) | Assesses practical aspects like cost, time, and ease of use, resulting in a blue-tinted pictogram [2]. | Practicality & Economics |

| RAPI (Red Analytical Performance Index) [2] | WAC (Red) | Evaluates analytical performance parameters such as trueness, precision, and recovery [2]. | Analytical Performance |

The paradigm of sustainable analytical chemistry is dynamically evolving. Circular Analytical Chemistry (CAC) is emerging as a further extension, aiming to transition from a linear "take-make-dispose" model to a circular framework that minimizes waste and keeps materials in use [7]. However, this transition faces challenges, including a lack of clear direction and coordination failures among stakeholders like manufacturers, researchers, and policymakers [7].

To bridge the gap between GAC/WAC principles and their widespread implementation, innovative support mechanisms are being proposed. The Green Financing for Analytical Chemistry (GFAC) model suggests creating dedicated funds to sponsor innovations aligned with GAC and WAC goals, helping to overcome the financial barriers that often hinder the adoption of sustainable technologies [1].

In conclusion, while Green Analytical Chemistry established the vital foundation for reducing the environmental footprint of analytical practices, White Analytical Chemistry represents a more mature and comprehensive framework. By systematically balancing the three pillars of the RGB model—environmental impact (Green), analytical performance (Red), and practical feasibility (Blue)—WAC provides a robust pathway for developing analytical methods that are not only ecologically sound but also analytically excellent and economically viable, thereby fostering truly sustainable science.

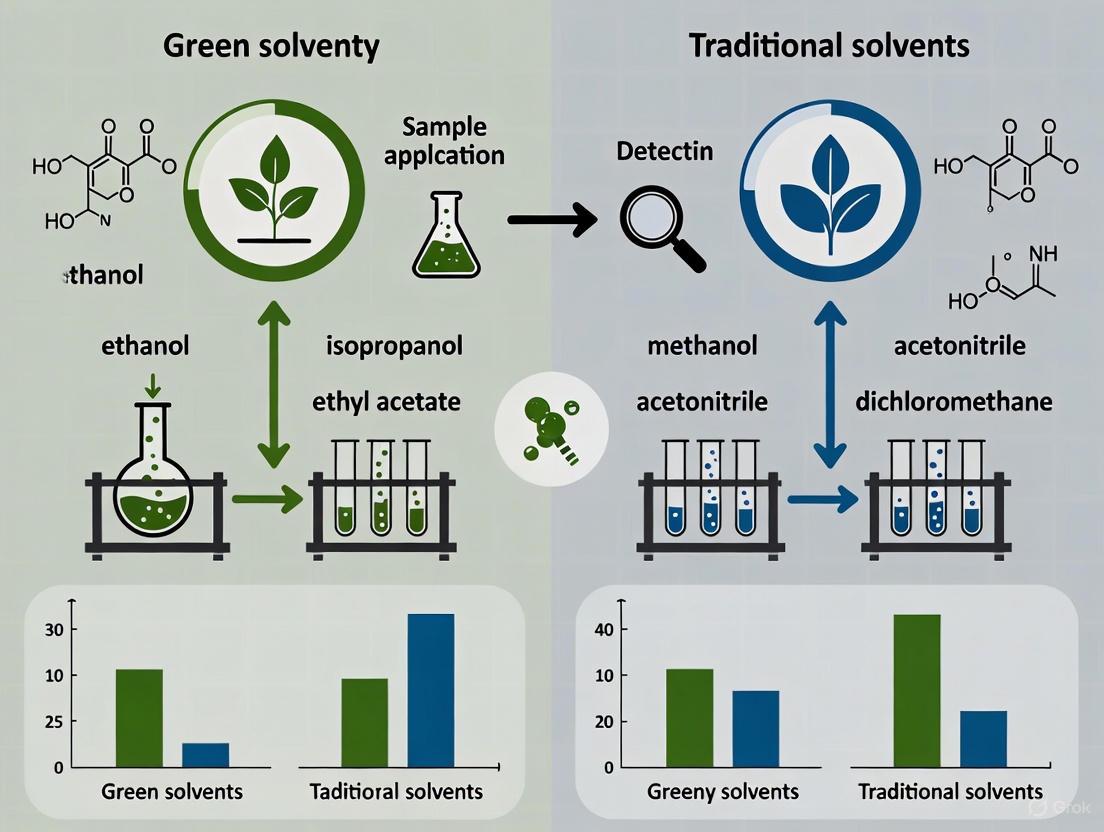

The adoption of green solvents in High-Performance Thin-Layer Chromatography (HPTLC) represents a significant advancement in aligning analytical chemistry with the principles of environmental sustainability. Green analytical chemistry (GAC) emphasizes reducing the environmental impact of analytical methods by minimizing hazardous waste, decreasing energy consumption, and utilizing safer solvents [8]. Within pharmaceutical analysis and natural product research, HPTLC has emerged as a particularly suitable platform for implementing green chemistry principles due to its minimal solvent consumption, capacity for parallel sample processing, and reduced operational costs compared to other chromatographic techniques [6] [9]. The strategic selection of mobile phase components is fundamental to developing eco-friendly HPTLC methods, with ethanol, water, ethyl acetate, and bio-based solvents increasingly replacing traditional hazardous solvents like chloroform, acetonitrile, and n-hexane [10] [9].

The transition to green solvents in HPTLC methodologies is driven by both environmental concerns and practical analytical benefits. These solvents typically exhibit lower toxicity, higher biodegradability, reduced bioaccumulation potential, and are often derived from renewable resources [6]. From an analytical perspective, they must provide comparable or superior chromatographic performance in terms of separation efficiency, peak symmetry, and reproducibility. Modern green HPTLC methods have successfully demonstrated that environmentally responsible solvent choices do not compromise analytical performance while significantly reducing the ecological footprint of pharmaceutical quality control and natural product analysis [8] [10].

Classification and Properties of Green Solvents for HPTLC

Solvent Selection Framework

Green solvents for HPTLC are categorized based on their origin, toxicity profile, and environmental impact. The selection process prioritizes solvents that align with the 12 principles of green analytical chemistry, with particular emphasis on waste prevention, safer chemical design, and inherently benign substance selection [8] [9]. Several assessment tools have been developed to quantitatively evaluate the greenness of analytical methods, including the Analytical GREEnness (AGREE) approach, which incorporates all 12 GAC principles, Analytical Eco-Scale, Green Analytical Procedure Index (GAPI), and the National Environmental Method Index (NEMI) [11] [9]. These metrics provide researchers with standardized frameworks for comparing the environmental performance of different solvent systems and guiding method development toward more sustainable practices.

Principal Green Solvent Classes

Water and Aqueous Solutions: Water stands as the ultimate green solvent due to its non-toxic, non-flammable, and renewable properties. In HPTLC applications, water is frequently used as a component in binary or ternary mobile phase systems, particularly in reversed-phase chromatography. The polarity and hydrogen-bonding capacity of water make it ideal for separating polar compounds, and its properties can be modified through pH adjustment using ammonia or other benign additives [8] [10]. For instance, ethanol/water/ammonia solutions (50:45:5 v/v/v) have demonstrated excellent chromatographic performance for pharmaceutical compounds like tenoxicam, with an AGREE score of 0.75, indicating an outstanding greenness profile [8].

Bio-Based Alcohols: Ethanol is arguably the most versatile and widely adopted green solvent in HPTLC applications. Derived from renewable biomass through fermentation, ethanol offers favorable environmental credentials combined with excellent chromatographic properties. It exhibits moderate polarity, good dissolving power for many organic compounds, and low toxicity compared to traditional solvents like methanol or acetonitrile [10] [12]. Ethanol/water mixtures in various proportions (typically 55:45 to 80:20 v/v) have been successfully employed for analyzing diverse analytes, including caffeine, ertugliflozin, and other pharmaceuticals [10] [9]. Isopropanol represents another bio-based alcohol option, though it is less commonly used than ethanol in HPTLC methods [11].

Esters and Ketones: Ethyl acetate, derived from renewable resources, serves as an excellent green alternative to more hazardous solvents like dichloromethane. Its moderate polarity and favorable volatility characteristics make it suitable for normal-phase HPTLC separations [13] [14]. Similarly, acetone offers green credentials as a solvent with low toxicity and high biodegradability. Ethyl acetate/ethanol/ammonia mixtures (2.0:8.0:0.5 by volume) have demonstrated effective separation of alfuzosin and solifenacin in pharmaceutical formulations [13].

Natural Deep Eutectic Solvents (NADES): NADES represent an emerging class of green solvents composed of natural primary metabolites such as sugars, amino acids, and organic acids. These solvents are characterized by their biodegradability, low toxicity, and sustainability [6]. While application in HPTLC is still developing, NADES show significant promise as extraction media and potential mobile phase components, particularly in natural product analysis.

Table 1: Properties of Common Green Solvents in HPTLC Applications

| Solvent | Origin | Toxicity | Biodegradability | Typical HPTLC Use | Key Advantages |

|---|---|---|---|---|---|

| Water | Inorganic | Non-toxic | High | Reversed-phase mobile phase component | Non-flammable, renewable, safe |

| Ethanol | Bio-based | Low | High | Both normal and reversed-phase systems | Renewable, versatile, good dissolving power |

| Ethyl Acetate | Bio-based | Low | High | Normal-phase separations | Moderate polarity, renewable source |

| Acetone | Synthetic/Bio-based | Low | High | Normal-phase systems | Low toxicity, good volatility |

| Isopropanol | Synthetic/Bio-based | Low | Moderate | Normal-phase systems | Good dissolving power for APIs |

Comparative Performance Data: Green vs Traditional Solvent Systems

Chromatographic Performance Metrics

Direct comparisons between green and traditional solvent systems in HPTLC applications reveal that environmentally friendly alternatives can provide comparable, and in some cases superior, chromatographic performance. System suitability parameters such as retardation factor (Rf), asymmetry factor (As), and theoretical plates per meter (N/m) provide quantitative measures of chromatographic efficiency [8] [9].

For the analysis of tenoxicam, the green mobile phase ethanol/water/ammonia (50:45:5 v/v/v) demonstrated excellent performance with an asymmetry factor of 1.07 and theoretical plates per meter of 4971, indicating sharp, well-resolved peaks [8]. In the case of ertugliflozin analysis, a comprehensive comparison between normal-phase (chloroform/methanol) and reversed-phase (ethanol/water) systems revealed that the green RP-HPTLC method outperformed the NP method in terms of linearity range (25-1200 ng/band vs 50-600 ng/band), sensitivity, and theoretical plates (4652 N/m vs 4472 N/m) [9].

Greenness Assessment Metrics

Multiple studies have employed standardized greenness assessment tools to quantitatively compare the environmental performance of HPTLC methods. The AGREE metric, which incorporates all 12 principles of green analytical chemistry, has become a benchmark for comprehensive environmental evaluation [8] [10] [9].

For caffeine analysis using an ethanol/water (55:45 v/v) mobile phase, the AGREE score was 0.80, indicating an excellent greenness profile [10] [12]. Similarly, the tenoxicam method with ethanol/water/ammonia mobile phase achieved an AGREE score of 0.75 [8]. Comparative assessment of ertugliflozin methods demonstrated that the green RP-HPTLC approach (ethanol/water) was significantly more environmentally friendly than the NP-HPTLC method (chloroform/methanol) across multiple metrics including AGREE, Analytical Eco-Scale, NEMI, and ChlorTox [9].

Table 2: Performance Comparison of Green vs Traditional Solvent Systems in HPTLC

| Analyte | Green Solvent System | Traditional Solvent System | Key Performance Metrics | Greenness Score (AGREE) |

|---|---|---|---|---|

| Tenoxicam | Ethanol/water/ammonia (50:45:5 v/v/v) | Chloroform/methanol-based systems | As=1.07, N/m=4971, Rf=0.85 | 0.75 [8] |

| Caffeine | Ethanol/water (55:45 v/v) | Ethyl acetate/methanol | Linear range=50-800 ng/band, LOD=0.98 ng/band | 0.80 [10] [12] |

| Ertugliflozin | Ethanol/water (80:20 v/v) | Chloroform/methanol (85:15 v/v) | Linear range=25-1200 ng/band (RP) vs 50-600 ng/band (NP), N/m=4652 (RP) vs 4472 (NP) | Superior for RP method [9] |

| Carvedilol | Toluene/isopropanol/ammonia (7.5:2.5:0.1 v/v/v) | Chloroform-based systems | Linear range=20-120 ng/band, Rf=0.44±0.02 | Acceptable by NEMI, AGREE, GAPI [11] |

Experimental Protocols for Green HPTLC Methods

Method Development and Optimization

The development of green HPTLC methods follows a systematic approach that balances chromatographic performance with environmental considerations. Initial method scoping involves identifying potentially green solvent systems based on literature data and solvent selection guides. For tenoxicam analysis, researchers evaluated multiple binary and ternary mixtures including ethanol/water, acetone/water, cyclohexane/ethyl acetate, and their combinations with ammonia as a modifier [8]. The optimization process typically investigates different proportions of these solvent systems to achieve optimal separation efficiency, peak symmetry, and retention characteristics.

Experimental parameters including chamber saturation time, migration distance, application volume, and detection wavelength are systematically optimized. For the analysis of alfuzosin and solifenacin, the mobile phase ethyl acetate/ethanol/ammonia (2.0:8.0:0.5 by volume) provided optimal separation after chamber saturation for 30 minutes [13]. Method validation according to ICH guidelines confirms that the green methods meet required standards for linearity, accuracy, precision, robustness, and sensitivity [8] [10].

Detailed Protocol: Green HPTLC for Caffeine Analysis

Materials and Equipment: Caffeine standard; ethanol and water (HPLC grade); commercial energy drinks and formulations; HPTLC system (CAMAG); reverse-phase silica gel 60 F254S plates (10 × 20 cm) [10] [12].

Mobile Phase Preparation: Prepare ethanol/water mixture in proportion of 55:45 (v/v). Mix thoroughly and transfer to twin-trough glass chamber. Saturate chamber for 30 minutes at 22°C to establish equilibrium [10] [12].

Standard Solution Preparation: Dissolve caffeine standard in ethanol/water (55:45 v/v) to obtain stock solution of 100 μg/mL. Prepare calibration standards in range of 50-800 ng/band by appropriate dilution [10].

Sample Preparation: For energy drinks: degas samples using ultrasonic bath, lyophilize for five days, reconstitute in methanol/water (25:75 v/v), extract caffeine using chloroform, concentrate using rotary evaporator at 40°C. For formulations: powder tablets, extract with chloroform, concentrate, reconstitute in chloroform [10].

Chromatographic Procedure:

- Pre-wash HPTLC plates with methanol and activate at 80°C for 15 minutes

- Apply samples as 6 mm bands using automatic applicator (application rate: 150 nL/s)

- Develop plates to distance of 80 mm in saturated chamber

- Dry plates and scan at 275 nm using TLC scanner (scanning rate: 20 mm/s, slit dimensions: 4 × 0.45 mm) [10] [12]

Data Analysis: Plot peak area versus concentration to generate calibration curve. Determine caffeine content in samples using regression equation. Validate method according to ICH Q2(R1) guidelines [10].

Diagram 1: Green HPTLC Method Development and Analysis Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Equipment for Green HPTLC

| Item | Specification | Function in Green HPTLC | Example Applications |

|---|---|---|---|

| Green Solvents | Ethanol (HPLC grade), Water (HPLC grade), Ethyl acetate, Acetone | Mobile phase components with reduced environmental impact | Tenoxicam analysis [8], Caffeine determination [10], Ertugliflozin quantification [9] |

| HPTLC Plates | Silica gel 60 F254 (normal phase), RP-18 F254S (reversed phase) | Stationary phase for chromatographic separation | Reverse-phase for caffeine [10], Normal phase for carvedilol [11] |

| Application System | Automatic applicator (e.g., CAMAG Linomat) with precision syringe | Precise sample application as narrow bands | All referenced methods [8] [10] [9] |

| Development Chamber | Twin-trough glass chamber with saturation capability | Controlled mobile phase development | Saturation for 30 min for tenoxicam [8] |

| Detection System | TLC Scanner with deuterium lamp | Densitometric quantification of separated compounds | Scanning at 275 nm for caffeine [10], 375 nm for tenoxicam [8] |

| Greenness Assessment Tools | AGREE calculator, GAPI, NEMI | Quantitative evaluation of method environmental impact | All green methods validation [8] [11] [9] |

The comprehensive evaluation of green solvents in HPTLC applications demonstrates that environmentally responsible alternatives can successfully replace traditional hazardous solvents without compromising analytical performance. Ethanol, water, ethyl acetate, and their mixtures have proven effective across diverse pharmaceutical applications, providing satisfactory chromatographic parameters including retention factors, peak symmetry, and theoretical plate counts [8] [10] [9]. The quantitative greenness assessment using tools like AGREE, GAPI, and NEMI provides standardized metrics for comparing environmental performance and guiding future method development [11] [9].

Future directions in green HPTLC methodology will likely focus on several key areas: expanding the application of novel green solvents like Natural Deep Eutectic Solvents (NADES), developing integrated assessment tools that combine greenness with practical analytical metrics, and creating standardized guidelines for implementing green chemistry principles in routine pharmaceutical analysis [6]. The continued advancement of green HPTLC methods will further establish this technique as both an environmentally responsible and analytically powerful tool for pharmaceutical quality control, natural product analysis, and biomedical research.

The adoption of green solvents in High-Performance Thin-Layer Chromatography (HPTLC) represents a critical convergence of environmental responsibility, economic practicality, and analytical performance in pharmaceutical and natural product analysis. Traditional chromatographic techniques frequently rely on hazardous organic solvents such as acetonitrile, methanol, and chloroform, which pose significant environmental and health risks while generating substantial waste disposal costs [6] [15]. In response to these challenges, the principles of Green Analytical Chemistry (GAC) have emerged as a transformative framework, guiding researchers toward more sustainable practices without compromising analytical efficacy [16]. This guide provides a comprehensive comparison of green solvent performance against traditional alternatives in HPTLC applications, examining their relative environmental impacts, economic benefits, and analytical performance characteristics to support informed adoption within the scientific community.

The transition to greener methodologies is no longer merely an academic exercise but a necessity driven by regulatory pressures, escalating solvent costs, and growing corporate sustainability mandates [17] [15]. Green solvents—including bio-based ethanol, ethyl acetate, and novel natural deep eutectic solvents (NADES)—offer significantly reduced toxicity profiles, lower waste generation, and often superior economic profiles throughout their lifecycle [18]. This evaluation synthesizes current research to objectively compare these alternatives across multiple dimensions, providing researchers with evidence-based guidance for implementing sustainable HPTLC practices in drug development and quality control environments.

Green vs. Traditional Solvents: A Comparative Framework

Environmental and Health Impact Profiles

The environmental and health characteristics of solvents constitute a primary differentiator between traditional and green alternatives. Traditional solvents commonly used in HPTLC, such as acetonitrile, methanol, and chloroform, present substantial concerns regarding toxicity, environmental persistence, and occupational hazards [6] [15]. These solvents contribute significantly to laboratory pollution, pose health risks to personnel through inhalation and dermal exposure, and necessitate costly specialized disposal procedures to mitigate environmental contamination [18].

Green solvents, including ethanol, ethyl acetate, and dimethyl carbonate, demonstrate markedly improved environmental and safety profiles. Bio-based solvents derived from renewable resources (e.g., cereals, vegetable oils, or wood) offer enhanced biodegradability, lower volatility, reduced flammability, and minimal ecosystem impact [18]. The production processes for these solvents generally consume less energy and utilize renewable feedstocks, further reducing their overall environmental footprint from cradle to grave [18].

Table 1: Environmental and Health Impact Comparison of Solvents Used in HPTLC

| Solvent Type | Example Solvents | Toxicity Profile | Biodegradability | Environmental Persistence | Occupational Hazards |

|---|---|---|---|---|---|

| Traditional | Acetonitrile, Methanol, Chloroform | Moderate to High | Slow | Moderate to High | Respiratory irritation, systemic toxicity, suspected carcinogens |

| Green Alternatives | Ethanol, Ethyl Acetate, Dimethyl Carbonate | Low to Moderate | Rapid | Low | Minimal with proper handling; primarily irritants |

Economic Considerations: Direct and Indirect Costs

The economic argument for transitioning to green solvents in HPTLC encompasses both direct financial benefits and indirect cost savings. While acquisition costs for some green solvents may be comparable to traditional options, the most significant economic advantages emerge in waste management and regulatory compliance [17]. Proper disposal of hazardous traditional solvents often costs 3-5 times more than disposal of benign green alternatives due to their classification as hazardous waste, requiring specialized treatment facilities and transportation protocols [15].

The global market for high-purity solvents is projected to grow from $32.7 billion in 2025 to $45 billion by 2030, driven largely by pharmaceutical and biotechnology applications [17]. This expanding market share for green solvents reflects not only regulatory pressures but also recognized economic advantages throughout the product lifecycle. Additionally, reduced environmental footprint translates to diminished liability and potential cost savings under evolving regulatory frameworks that incentivize sustainable practices through tax advantages and reduced compliance burden [17] [16].

Table 2: Economic Comparison of Solvent Use in HPTLC

| Cost Factor | Traditional Solvents | Green Solvents | Economic Implications |

|---|---|---|---|

| Acquisition Cost | Moderate ($20-50/L for HPLC grade) | Moderate to Low ($15-40/L) | Minor advantage for green solvents |

| Disposal Cost | High ($5-15/L for hazardous waste) | Low ($1-3/L for non-hazardous) | Significant savings with green solvents |

| Regulatory Compliance | Extensive documentation, monitoring, and reporting | Simplified requirements | Reduced administrative burden and cost |

| Health & Safety Measures | Engineering controls, personal protective equipment, medical surveillance | Basic laboratory precautions | Lower capital and operational costs |

Analytical Performance Metrics

A critical consideration in solvent substitution is maintaining or enhancing analytical performance. Recent research demonstrates that green solvents can achieve separation efficiency comparable to traditional solvents when appropriately implemented. In a study evaluating the separation of non-polar and polar substances, ethanol and dimethyl carbonate demonstrated equivalent chromatographic performance to acetonitrile and methanol across multiple stationary phases, including C18, diphenyl, and perfluorinated phenyl columns [19].

HPTLC methods utilizing green solvent systems have been successfully validated according to International Council for Harmonisation (ICH) guidelines for pharmaceutical applications. For example, a recently developed HPTLC method for simultaneous quantification of bisoprolol fumarate and amlodipine besylate employed an eco-friendly mobile phase of ethyl acetate-ethanol (7:3, v/v), achieving excellent separation with Rf values of 0.72 ± 0.01 and 0.83 ± 0.01, respectively [20]. The method demonstrated linearity (R² ≥ 0.9995), precision (RSD ≤ 2%), and detection limits suitable for pharmaceutical quality control, confirming that green solvent systems do not compromise analytical rigor [20].

Experimental Evidence and Protocol Comparison

Case Study: Pharmaceutical Analysis with Green HPTLC

A direct comparison of experimental protocols reveals the practical advantages of green HPTLC methodologies. A conventional HPTLC method for salivary caffeine analysis utilized a mobile phase containing acetone/toluene/chloroform (4:3:3, v/v/v) [21], which incorporates chlorinated solvents with known toxicity and environmental concerns. Sample preparation involved complex extraction procedures with organic solvents, generating significant waste [21].

In contrast, a green HPTLC method for quantifying bisoprolol fumarate, amlodipine besylate, and mutagenic impurities employed a simplified mobile phase of ethyl acetate-ethanol (7:3, v/v) [20]. This solvent system eliminates halogenated compounds while maintaining exceptional separation efficiency. The methodology was comprehensively assessed using multiple green metrics, including AGREE, ComplexGAPI, and NEMI, achieving perfect environmental scores while meeting stringent regulatory requirements for pharmaceutical impurity quantification [20].

Greenness Assessment Tools and Metrics

Objective evaluation of method environmental performance has been standardized through several validated assessment tools. The Analytical GREEnness (AGREE) metric incorporates all 12 principles of GAC into a holistic algorithm, providing a single-score evaluation supported by intuitive graphic output [16]. The Green Analytical Procedure Index (GAPI) offers visual, semi-quantitative evaluation through a color-coded pictogram that considers the entire analytical workflow [16]. These tools enable objective comparison between conventional and green methods, with recent studies confirming the superior environmental profile of green HPTLC methods [22] [20].

A comparative study of green versus conventional solvents in reversed-phase liquid chromatography employed the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) algorithm to integrate multiple criteria, including chromatographic run time, tailing ratios, resolution, and solvent-related environmental hazards [19]. This multi-criteria decision analysis confirmed that ethanol and dimethyl carbonate could effectively replace traditional solvents without compromising separation performance, providing a robust analytical foundation for sustainable method development [19].

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of green HPTLC methodologies requires specific reagents and materials optimized for sustainable separation science. The following toolkit details essential components for developing and deploying green HPTLC methods in pharmaceutical and natural product analysis.

Table 3: Essential Research Reagents and Materials for Green HPTLC

| Item | Function | Green Characteristics | Application Notes |

|---|---|---|---|

| Ethanol (Bio-based) | Mobile phase component | Renewable feedstock, low toxicity, biodegradable | Often replaces methanol; suitable for normal and reversed-phase systems |

| Ethyl Acetate | Mobile phase modifier | Low persistence, low bioaccumulation potential | Effective for medium-polarity separations; commonly paired with ethanol |

| Dimethyl Carbonate | Mobile phase component | Biodegradable, low toxicity, non-ozone depleting | Alternative to acetonitrile in reversed-phase systems |

| Natural Deep Eutectic Solvents (NADES) | Extraction & mobile phase | Biodegradable, low toxicity, renewable origin | Emerging application in natural product analysis; tunable properties |

| Water | Mobile phase component | Non-toxic, non-flammable, zero cost | Primary green solvent; often enhanced with modifiers |

| Silica Gel HPTLC Plates | Stationary phase | Standard chromatography substrate | Compatible with green solvent systems; minimal environmental impact |

| CAMAG HPTLC System | Instrumentation | Reduced solvent consumption, minimal waste generation | Automated application, development, and detection optimized for miniaturization |

Methodological Workflow for Green HPTLC Implementation

The transition from traditional to green HPTLC methods follows a systematic workflow that integrates sustainability considerations with analytical performance requirements. This structured approach ensures method robustness while maximizing environmental and economic benefits.

The comprehensive comparison presented in this guide demonstrates that green solvents offer a viable, often superior alternative to traditional solvents in HPTLC applications across environmental, economic, and performance dimensions. The environmental advantages—including reduced toxicity, enhanced biodegradability, and diminished waste generation—translate directly into economic benefits through lower disposal costs, reduced regulatory burden, and diminished liability. Critically, these benefits do not require analytical performance compromise, as evidenced by multiple validated methods for pharmaceutical compounds and natural products.

The ongoing evolution of green solvent technologies, coupled with increasingly sophisticated assessment metrics, provides researchers with robust tools for implementing sustainable chromatography practices. As regulatory pressures intensify and the global scientific community prioritizes environmental responsibility, the adoption of green HPTLC methodologies represents both an ethical imperative and a strategic advantage for drug development professionals and analytical scientists. By embracing these approaches, the scientific community can significantly reduce the environmental footprint of chemical analysis while maintaining the rigorous standards required for pharmaceutical research and quality control.

In the pursuit of sustainability within analytical laboratories, High-Performance Thin-Layer Chromatography (HPTLC) has evolved from a simple chromatographic technique into a versatile, multimodal platform aligned with Green Analytical Chemistry (GAC) principles [23]. This transformation addresses a critical challenge in modern analysis: the significant environmental footprint of traditional methods. Conventional techniques like High-Performance Liquid Chromatography (HPLC) are often constrained by labor-intensive processes, extended analysis times (typically exceeding 30 minutes), and substantial consumption of organic solvents [23]. In contrast, HPTLC offers a paradigm shift, providing distinct advantages in speed, simplicity, and environmental sustainability [23]. The core of its green credentials lies in its minimal solvent consumption and inherent capacity for high-throughput analysis, making it particularly suitable for sustainable food, herbal, and pharmaceutical quality assurance programs that require decentralized operation and rapid results [23].

Quantitative Comparison: HPTLC Versus Traditional Chromatography

A direct comparison of solvent consumption and operational efficiency reveals HPTLC's significant environmental and practical advantages over traditional chromatographic methods.

Table 1: Solvent Consumption and Throughput Comparison

| Analytical Method | Typical Solvent Volume per Analysis | Typical Analysis Time | Sample Throughput per Run | Key Greenness Metrics |

|---|---|---|---|---|

| HPTLC | < 10 mL [23] | 5–15 minutes [23] | Multiple samples in parallel [24] | High AGREE scores, superior Analytical Eco-Scale [9] [25] |

| Traditional HPLC | Often > 500 mL/day per instrument [26] | > 30 minutes per sample sequence [23] | Single sample per injection (sequential) | Lower greenness scores due to high organic solvent use [9] |

The data in Table 1 underscores a fundamental difference: HPTLC's parallel processing capability allows multiple samples to be analyzed simultaneously using a single, small volume of mobile phase. This stands in stark contrast to the sequential nature of HPLC, which consumes solvent continuously throughout the analysis of each sample, leading to an average of 0.5 L of organic waste daily per instrument [26]. Furthermore, the drastically shorter analysis time of HPTLC (5-15 minutes) translates to lower energy consumption, further enhancing its green profile [23].

Experimental Evidence: Showcasing Solvent Reduction and High-Throughput

The theoretical advantages of HPTLC are consistently demonstrated in practical, peer-reviewed methodologies. The following case studies highlight how HPTLC methods are developed with green principles as a core objective.

Table 2: Experimental Case Studies of Green HPTLC Methods

| Analytical Target | Mobile Phase Composition | Total Mobile Phase Volume | Sample Throughput & Linearity | Greenness Assessment |

|---|---|---|---|---|

| Ertugliflozin (Antidiabetic) | Ethanol–Water (80:20 v/v) [9] | Not specified (RP-18F254S plate) | Linear range: 25–1200 ng/band [9] | AGREE score: 0.82 (out of 1.0); superior to NP-HPTLC and HPLC [9] |

| Remdesivir, Linezolid, Rivaroxaban (COVID-19 drugs) | Dichloromethane–Acetone (8.5:1.5, v/v) [25] | ~10 mL per development | Three drugs quantified simultaneously in spiked human plasma [25] | Validated by Analytical Eco-Scale, GAPI, and AGREE metrics [25] |

| Meloxicam & Piroxicam (NSAIDs) | Hexane–Ethyl Acetate–Glacial Acetic Acid (65:30:5, v/v/v) [27] | 10 mL [27] | LOD: 0.04-0.05 µg/band; cost-effective and eco-friendly [27] | Described as a simple, sensitive, stable, cost-effective, and eco-friendly method [27] |

A key experimental insight is the conscious selection of greener solvent systems. For instance, a study comparing Normal-Phase (NP-) and Reversed-Phase (RP-) HPTLC for the analysis of Ertugliflozin found that the RP-HPTLC method using a less hazardous ethanol-water mobile phase was not only more robust and sensitive but also significantly greener than the NP-HPTLC method that used a chloroform-methanol mixture [9]. This demonstrates how the choice of stationary phase directly influences the greenness of the final method.

Detailed Experimental Protocol: Green HPTLC Analysis of Pharmaceuticals

The following workflow, demonstrated in methods for drugs like Meloxicam and Ertugliflozin, outlines a typical green HPTLC protocol [9] [27]:

- Stationary Phase: HPTLC plates (e.g., silica gel 60 F254 or RP-18F254S), 10x20 or 20x20 cm.

- Sample Application: Using an automatic applicator (e.g., CAMAG Linomat 5), samples are applied as bands (e.g., 2-10 µL band volume) under a stream of inert gas.

- Chromatographic Development: The plate is developed in a twin-trough chamber previously saturated for 15-30 minutes with the mobile phase (e.g., Ethanol-Water (80:20) or Hexane-Ethyl Acetate-Glacial Acetic Acid (65:30:5)). The total mobile phase volume required is typically 10-20 mL per development [9] [27].

- Detection & Documentation: After development and drying, plates are visualized under UV light at 254 nm or 366 nm, or using a TLC visualizer and scanner.

- Quantification: Densitometric scanning is performed at the appropriate wavelength (e.g., 199 nm for Ertugliflozin, 230 nm for Meloxicam/Piroxicam), and calibration curves are constructed from the peak areas [9] [27].

Diagram Title: HPTLC Green Analysis Workflow

The Scientist's Toolkit: Essential Reagents for Green HPTLC

Developing a green HPTLC method relies on a thoughtful selection of materials and reagents to minimize environmental impact while maintaining analytical performance.

Table 3: Essential Research Reagents and Materials for Green HPTLC

| Item | Function | Green Considerations & Examples |

|---|---|---|

| RP-HPTLC Plates (e.g., RP-18F254S) [9] | Stationary phase enabling use of aqueous mobile phases. | Facilitates use of ethanol-water systems, avoiding more hazardous chlorinated solvents [9]. |

| Green Solvents (e.g., Ethanol, Water) [9] [6] | Components of the mobile phase. | Safer, biodegradable, and less toxic alternatives to solvents like chloroform or acetonitrile [9] [6]. |

| Automated Applicator (e.g., CAMAG Linomat) [27] | Precisely applies sample bands onto the HPTLC plate. | Ensures high reproducibility and minimizes human error, reducing reagent waste from repeated analyses [24]. |

| Automated Developing Chamber (e.g., CAMAG ADC 2) [27] | Houses the plate during development with the mobile phase. | Provides safety, excellent reproducibility, and controlled solvent use, independent of environmental effects [27]. |

| Densitometer Scanner (e.g., CAMAG TLC Scanner 3) [25] | Quantifies the separated analyte bands directly on the plate. | Enables highly sensitive detection (in nanograms per band) without the need for elution or additional reagents [25] [24]. |

The evidence from contemporary research solidifies the position of HPTLC as a cornerstone of green analytical chemistry. Its inherent design, characterized by minimal solvent consumption (<10 mL per run) and high-throughput parallel analysis, provides a tangible and effective strategy for laboratories to drastically reduce their environmental footprint without compromising analytical quality [23]. The advancement of "HPTLC+" multimodal platforms, which integrate mass spectrometry or Raman spectroscopy, further enhances its capability, transforming it into a high-resolution, information-rich analytical tool [23]. When combined with a conscious selection of green solvents like ethanol-water systems, HPTLC methodologies consistently achieve high scores on modern greenness assessment tools such as AGREE and Analytical Eco-Scale [9] [25]. For researchers and drug development professionals committed to sustainability, HPTLC represents a proven, efficient, and eco-friendly platform for today's analytical challenges.

Practical Implementation: Developing Robust HPTLC Methods with Green Solvents

The adoption of green solvent systems in High-Performance Thin-Layer Chromatography (HPTLC) represents a critical advancement toward sustainable pharmaceutical analysis. Driven by the principles of Green Analytical Chemistry (GAC), this shift addresses the environmental and safety concerns associated with traditional solvents like acetonitrile and methanol, which are toxic, generate significant waste, and pose health risks [6] [28]. Green HPTLC methods prioritize solvents with lower toxicity, higher biodegradability, and reduced environmental impact without compromising analytical performance.

The movement toward sustainability is further supported by the framework of White Analytical Chemistry (WAC), which seeks a balance among analytical performance (red), environmental impact (green), and practical applicability (blue) [20] [16]. This holistic approach ensures that newly developed methods are not only environmentally sound but also robust, cost-effective, and suitable for routine use in quality control laboratories. This guide provides a comparative analysis of common mobile phase combinations, supported by experimental data and detailed protocols, to assist researchers in selecting optimal green solvent systems for their HPTLC applications.

Comparison of Green vs. Traditional Solvent Systems

The following table summarizes experimental data for various green mobile phase combinations in HPTLC, demonstrating their effectiveness in separating multiple active pharmaceutical ingredients (APIs) across different therapeutic categories.

Table 1: Experimental Data for Green HPTLC Mobile Phase Combinations

| Drug Analytes (Therapeutic Category) | Green Mobile Phase Composition (v/v/v) | Retardation Factor (Rf) Values | Linearity Range (ng/band) | Detection Wavelength (nm) | Citation |

|---|---|---|---|---|---|

| Lidocaine HCl & Diltiazem HCl (Anal Fissure Treatment) | Toluene: Methanol: Ethyl Acetate (7:2:1) + 2 drops ammonia | LID: 0.59, DIL: 0.48 | 400–1200 (for both) | 220 | [29] |

| Bisoprolol Fumarate, Amlodipine Besylate, & Mutagenic Impurity (Cardiovascular) | Ethyl Acetate: Ethanol (7:3, v/v) | HBZ: 0.29, AML: 0.72, BIP: 0.83 | Not Specified | 220 | [20] |

| Phenylephrine HCl & Doxylamine Succinate (Allergic Rhinitis) | Ethanol: Methylene Chloride: Ammonia 30% (7:2.5:0.5) | PHE: 0.76, DOX: 0.65, DOX DEG: 0.16 | 4000–26000 (PHE, DOX), 500–10000 (DEG) | 260 | [30] |

| Hydroxyzine HCl, Ephedrine HCl, & Theophylline (Anti-Asthmatic) | Chloroform: Ammonium Acetate Buffer pH 6.5 (9.5:0.5, v/v) | EPH: 0.15, THP: 0.40, HYX: 0.65 | Not Specified | 220 | [31] |

| Carvedilol (Cardiovascular) | Toluene: Isopropanol: Ammonia (7.5:2.5:0.1, v/v/v) | Carvedilol: 0.44 ± 0.02 | 20–120 | 220 | [11] |

The data in Table 1 illustrates the successful application of green solvents. For instance, a mixture of ethyl acetate and ethanol enabled the baseline separation of three components, including a genotoxic impurity, with excellent resolution [20]. Similarly, a system using ethanol, methylene chloride, and ammonia proved effective as a stability-indicating method, successfully separating doxylamine from its oxidative degradation product [30]. These combinations often replace more hazardous solvents like pure chloroform or methanol-based systems.

When comparing performance, methods employing solvents like ethanol and ethyl acetate frequently achieve analytical performance on par with traditional methods. They demonstrate excellent linearity, precision (often with RSD ≤ 2%), and low detection limits [20] [30]. The key distinction lies in their enhanced sustainability profile, as reflected in high scores on greenness assessment tools such as AGREE and GAPI [11] [20].

Detailed Experimental Protocols for Key Green HPTLC Methods

Protocol for Simultaneous Analysis of Cardiovascular Drugs

This method [20] is designed for the concurrent quantification of Bisoprolol Fumarate (BIP), Amlodipine Besylate (AML), and a mutagenic impurity, 4-hydroxybenzaldehyde (HBZ).

- Instrumentation: CAMAG system with Linomat 5 autosampler, TLC Scanner 3, and WinCATS software (v. 3.15).

- Chromatographic Conditions:

- Stationary Phase: Silica gel 60 F₂₅₄ plates (10 × 10 cm, 0.2 mm thickness).

- Mobile Phase: Ethyl acetate–ethanol (7:3, v/v).

- Development: In an ADC2 automated development chamber, pre-saturated for 25 minutes at 25°C and 40% relative humidity.

- Detection: Densitometry at 220 nm in reflectance-absorbance mode.

- Sample Preparation:

- Accurately weigh standard powders of BIP, AML, and HBZ.

- Dissolve in an appropriate solvent (e.g., methanol) to prepare stock solutions of 1 mg/mL.

- Dilute serially with the same solvent to obtain working standard solutions.

- Application and Analysis:

- Apply samples as 8 mm bands onto the HPTLC plate using the Linomat 5 autosampler.

- Develop the plate in the pre-saturated chamber to a distance of 80 mm.

- Dry the plate and scan at 220 nm.

- Determine analyte concentrations using calibration curves of peak area versus concentration.

Protocol for Analysis of Anti-Allergy Drugs with Degradant

This method [30] separates Phenylephrine HCl (PHE), Doxylamine Succinate (DOX), and its oxidative degradation product (DOX DEG).

- Instrumentation: CAMAG HPTLC system with Linomat 5 autosampler and TLC Scanner 3.

- Chromatographic Conditions:

- Stationary Phase: TLC silica gel 60 F₂₅₄ aluminum sheets (20 × 20 cm).

- Mobile Phase: Ethanol, methylene chloride, and 30% ammonia (7:2.5:0.5, v/v/v).

- Detection: Densitometry at 260 nm.

- Preparation of Degradation Product:

- Reflux 100 mg of DOX in ethanol with 30% hydrogen peroxide for 7 hours.

- Evaporate the mixture to dryness.

- Dissolve the residue in ethanol and dilute to 100 mL to create a 1 mg/mL stock solution.

- Sample Application and Development:

- Spot the standard and sample solutions as 6 mm bands on the TLC plate.

- Develop the plate in a chamber pre-saturated with the mobile phase for 20 minutes.

- After development, dry the plate and scan.

Workflow for Green HPTLC Method Development

The following diagram illustrates the logical workflow for developing a green HPTLC method, from initial solvent selection to final validation and greenness assessment.

Essential Research Reagent Solutions

Successful implementation of green HPTLC methods requires specific reagents and materials. The following table details the key components of the research toolkit.

Table 2: Essential Research Reagent Solutions for Green HPTLC

| Reagent/Material | Function/Role in Green HPTLC | Examples from Studies |

|---|---|---|

| Ethanol | A common green solvent used as a less toxic alternative to methanol or acetonitrile in the mobile phase. | Used in mobile phases with ethyl acetate [20] and methylene chloride [30]. |

| Ethyl Acetate | A biodegradable solvent with favorable environmental and safety profiles, often used as a main component of the mobile phase. | Combined with ethanol (7:3) for cardiovascular drug analysis [20]. |

| Silica Gel 60 F₂₅₄ Plates | The standard stationary phase for HPTLC. The F₂₅₄ indicator allows for UV visualization. | Used across all cited studies [29] [20] [30]. |

| Ammonia Solution | A common modifier used in small quantities to control pH and improve peak shape by suppressing silanol interactions. | Added in small proportions (e.g., 0.1-0.5% v/v) to mobile phases [11] [29] [30]. |

| Water & Buffer Salts | Used in aqueous-organic mobile phases or to create pH-controlled buffer systems for better separation of ionizable compounds. | Ammonium acetate buffer used with chloroform [31]. |

| Greenness Assessment Tools | Software and metrics (e.g., AGREE, GAPI, BAGI) used to quantitatively evaluate the environmental and practical performance of the developed method. | AGREE and GAPI used to validate greenness of methods [11] [20] [16]. |

The transition to green solvent systems in HPTLC is a feasible and scientifically rigorous pursuit. As demonstrated, mobile phases incorporating ethanol, ethyl acetate, and other sustainable solvents can achieve the high-performance separations required for modern pharmaceutical analysis, including stability-indicating methods and impurity detection. The experimental protocols and data provided offer a practical foundation for researchers to implement these methods.

The ongoing development and adoption of green HPTLC methods, guided by comprehensive sustainability assessments, pave the way for more environmentally responsible and safer analytical practices in drug development and quality control.

The adoption of Green Analytical Chemistry (GAC) principles is driving a significant transformation in modern laboratories, particularly in the field of high-performance thin-layer chromatography (HPTLC). Traditional analytical methods often rely on hazardous, toxic, and environmentally damaging solvents, creating substantial ecological and occupational health concerns. This case study objectively examines the replacement of a traditional chloroform-methanol system with a greener ethanol-water alternative in HPTLC applications, evaluating both analytical performance and environmental sustainability. The transition to green solvents like ethanol and water represents a critical shift toward sustainable science, reducing toxicity and environmental impact while maintaining, and in some cases enhancing, analytical efficacy [18]. Within this framework, HPTLC has emerged as a particularly promising technique due to its inherently lower solvent consumption, capacity for parallel sample processing, and minimal waste generation compared to other chromatographic methods [6] [32].

Methodology: Experimental Protocols for Solvent System Comparison

HPTLC Instrumentation and General Conditions

The comparative data presented in this study are synthesized from rigorously controlled experiments conducted using standard HPTLC instrumentation. The core system typically consisted of CAMAG HPTLC equipment, including an Automatic TLC Sampler 4 (ATS4) for precise sample application, an Automatic Developing Chamber 2 (ADC2) for controlled mobile phase migration, and a TLC Scanner III with winCATS software for densitometric analysis [9] [10] [33]. For methods employing the ethanol-water system, separation was typically performed on reverse-phase (RP) HPTLC plates, specifically silica gel 60 RP-18 F254S, whereas methods using chloroform-methanol employed normal-phase (NP) HPTLC plates, specifically silica gel 60 F254S [9] [34]. Chamber saturation time was consistently maintained at 20-30 minutes at room temperature (22±2 °C), with a migration distance of 80 mm being standard across compared methods [10].

Sample Preparation Protocols

For the analysis of pharmaceutical compounds such as ertugliflozin, standard solutions were prepared by dissolving an accurately weighed quantity of the reference standard in an appropriate solvent (often methanol or the mobile phase itself) to obtain a primary stock solution of 100 μg/mL [9] [10]. Subsequent serial dilutions were performed to create working standards covering the required calibration range (e.g., 25-1200 ng/band for RP-HPTLC and 50-600 ng/band for NP-HPTLC). Commercial tablet formulations were processed using a standard protocol: ten tablets were weighed and finely powdered, a quantity equivalent to one tablet was accurately weighed and transferred to a volumetric flask, the powder was extracted via sonication with a suitable solvent, and the resulting extract was filtered and diluted to volume before application onto HPTLC plates [8] [9].

Greenness Assessment Methods

The environmental profiles of the solvent systems were evaluated using multiple validated greenness assessment tools. The Analytical GREEnness (AGREE)* method was employed as a comprehensive metric, which incorporates all 12 principles of GAC to generate a score between 0 (least green) and 1 (most green) [8] [9] [16]. Supplementary assessments included the Analytical Eco-Scale, which assigns penalty points for hazardous reagents and energy consumption [33], and the National Environmental Method Index (NEMI) [34]. These tools collectively provide a multi-faceted evaluation of each method's environmental impact, considering factors such as solvent toxicity, waste generation, energy consumption, and operator safety [16].

Results and Discussion: Performance and Environmental Impact

Direct Performance Comparison of Solvent Systems

The analytical performance of ethanol-water and chloroform-methanol systems was directly compared in a study quantifying the antidiabetic drug ertugliflozin, providing robust experimental data for this case study [9]. The results demonstrate that the greener ethanol-water system generally outperformed the traditional chloroform-methanol system across multiple chromatographic parameters.

Table 1: Chromatographic Performance Comparison for Ertugliflozin Analysis

| Parameter | Chloroform-Methanol (85:15) | Ethanol-Water (80:20) |

|---|---|---|

| System Type | Normal-Phase (NP-HPTLC) | Reversed-Phase (RP-HPTLC) |

| Retardation Factor (Rf) | 0.29 ± 0.01 | 0.68 ± 0.01 |

| Theoretical Plates per Meter (N/m) | 4,472 ± 4.22 | 4,652 ± 4.02 |

| Asymmetry Factor (As) | 1.06 ± 0.02 | 1.08 ± 0.03 |

| Linearity Range (ng/band) | 50-600 | 25-1200 |

| LOD (ng/band) | 7.91 | 4.85 |

| LOQ (ng/band) | 23.97 | 14.69 |

| Assay Result (%) | 87.41 | 99.28 |

The data reveal that the ethanol-water system provided superior efficiency, evidenced by the higher number of theoretical plates per meter (4,652 vs. 4,472) [9]. Additionally, the reversed-phase system demonstrated significantly enhanced sensitivity, with a lower limit of detection (4.85 ng/band vs. 7.91 ng/band) and a wider linearity range (25-1200 ng/band vs. 50-600 ng/band) [9]. The accuracy of the method was also better with the green system, yielding a more accurate assay result (99.28% vs. 87.41%) when analyzing commercial tablet formulations [9].

Greenness Profile Assessment

The environmental advantages of the ethanol-water system are substantial and quantifiable through multiple greenness assessment metrics. In the ertugliflozin study, the AGREE score for the ethanol-water system was significantly higher than that of the chloroform-methanol system, reflecting its superior environmental profile [9]. Similar results were observed in other pharmaceutical applications, including methods for tenoxicam and caffeine analysis [8] [10].

Table 2: Greenness Assessment of Solvent Systems

| Assessment Tool | Chloroform-Methanol System | Ethanol-Water System |

|---|---|---|

| AGREE Score | Lower (Specific value not reported) [9] | 0.75-0.80 [8] [10] |

| NEMI Profile | Fails due to PBT and hazardous concerns [34] | Passes all categories [34] |

| Hazard Considerations | Chloroform: toxic, carcinogenic, environmental persistent [9] [18] | Ethanol: low toxicity, biodegradable, renewable [18] [10] |

| Waste Concerns | High environmental impact, hazardous waste disposal required [16] | Low environmental impact, simpler waste stream [16] |

Ethanol is classified as a green solvent due to its low toxicity, biodegradability, and derivation from renewable plant-based materials, while water is inherently safe, non-toxic, and environmentally benign [18] [10]. In contrast, chloroform is a hazardous solvent with significant toxicity concerns, including potential carcinogenicity and environmental persistence [9]. Methanol, while less problematic than chloroform, still presents higher toxicity compared to ethanol [18]. The stark difference in environmental and safety profiles between these solvent systems is clearly reflected in their greenness scores and regulatory classifications.

Robustness and Applications Across Pharmaceutical Analyses

The ethanol-water system has demonstrated excellent robustness and versatility across various pharmaceutical applications. In the analysis of tenoxicam, a ternary mixture of ethanol/water/ammonia solution (50:45:5 v/v/v) produced outstanding chromatographic results with an asymmetry factor of 1.07, theoretical plates per meter of 4971, and well-defined peaks at Rf 0.85 [8]. This method was successfully validated according to ICH guidelines and applied to commercial tablets and capsules with accuracy between 98.46-101.24% [8]. Similarly, for caffeine analysis in energy drinks and formulations, a binary ethanol-water (55:45 v/v) system provided excellent linearity (50-800 ng/band), precision (% RSD: 0.87-1.02), and an impressive AGREE score of 0.80 [10]. These consistent results across different drug molecules highlight the robustness and broad applicability of ethanol-water systems in pharmaceutical HPTLC analysis.

Diagram 1: Decision workflow for solvent system selection in HPTLC method development, highlighting the comparative assessment of traditional versus green alternatives.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of green HPTLC methods requires specific reagents and materials optimized for environmentally conscious analytical chemistry.

Table 3: Essential Research Reagents and Materials for Green HPTLC

| Item | Function/Purpose | Green Considerations |

|---|---|---|

| Ethanol (Bio-based) | Green mobile phase component | Renewable resource, low toxicity, biodegradable [18] [10] |

| Water (HPLC Grade) | Green mobile phase component | Non-toxic, environmentally benign [10] |

| RP-HPTLC Plates | Stationary phase for reversed-phase chromatography | Compatible with ethanol-water mobile phases [9] |

| Ammonia Solution | Mobile phase modifier for peak symmetry | Used in minimal quantities (e.g., 5%) [8] |

| Standard Reference Materials | Method validation and calibration | Required for ICH-compliant validation [8] [10] |

| CAMAG HPTLC System | Automated separation and detection | Reduces human error, enhances reproducibility [32] |

This comprehensive case study demonstrates that ethanol-water systems represent a viable, and often superior, alternative to traditional chloroform-methanol systems in HPTLC analysis. The experimental data clearly show that ethanol-water systems can provide equivalent or better chromatographic performance in terms of efficiency, sensitivity, and accuracy while offering substantial environmental benefits. The significantly higher AGREE scores (0.75-0.80) for ethanol-water systems confirm their alignment with GAC principles, supporting the transition toward more sustainable laboratory practices in pharmaceutical analysis [8] [9] [10]. As the field of analytical chemistry continues to prioritize sustainability, ethanol-water systems and other green solvent approaches are poised to become the new standard for HPTLC method development, successfully replacing hazardous traditional solvents without compromising analytical performance.

High-Performance Thin-Layer Chromatography (HPTLC) has evolved from a simple qualitative tool into a sophisticated versatile platform for pharmaceutical analysis, offering rapid, cost-efficient, and sustainable screening of active pharmaceutical ingredients (APIs) and their impurities [23]. This advanced technique meets the stringent demands of modern drug development and quality control, where identifying and quantifying impurities—substances unintentionally present in APIs due to synthesis processes, excipients, residual solvents, or degradation products—is crucial for ensuring drug safety, efficacy, and stability [35]. The technique's inherent simplicity, unlimited compatibility with advanced detection methods, and alignment with Green Analytical Chemistry (GAC) principles have positioned HPTLC as a powerful alternative to traditional chromatographic methods like HPLC and GC-MS [23].

The systematic process of impurity profiling has become a critical component of pharmaceutical development, requiring highly sensitive, selective, and efficient analytical techniques to detect trace amounts of impurities that may pose significant toxicological risks [35]. Even at minute quantities, impurities can interfere with therapeutic activity, reduce drug efficacy, or accelerate product degradation, making robust analytical methods essential for regulatory compliance and public health protection [35]. HPTLC addresses these challenges through its unique capability for parallel sample processing, minimal solvent consumption, and flexibility in detection modalities, establishing it as an indispensable tool for pharmaceutical analysts and drug development professionals [23] [36].

Comparative Performance: HPTLC Versus Alternative Techniques

Analytical Capabilities and Practical Considerations

When selecting an analytical technique for pharmaceutical analysis, researchers must consider multiple factors including resolution, throughput, cost, and environmental impact. The table below provides a structured comparison of HPTLC against other common chromatographic methods:

Table 1: Comparison of HPTLC with Other Chromatographic Techniques in Pharmaceutical Analysis

| Feature | HPTLC | HPLC | GC-MS | Traditional TLC |

|---|---|---|---|---|

| Analysis Time | 5-15 minutes [23] | >30 minutes [23] | >30 minutes [23] | 20-40 minutes |

| Solvent Consumption | <10 mL [23] | High (often hundreds of mL) [37] | Moderate (organic solvents) | 20-50 mL |

| Sample Throughput | High (multiple samples simultaneously) [36] | Low (sequential analysis) | Low (sequential analysis) | Moderate (multiple samples) |

| Quantitative Capability | Excellent (densitometric detection) [38] [36] | Excellent | Excellent | Poor to moderate |

| Detection Flexibility | Multiple modes (UV, VIS, fluorescence, MS, SERS) [23] | Typically single detection | Mass spectrometry | Primarily UV/VIS |

| Cost per Analysis | Low [36] [37] | High [37] | High | Very low |

| Greenness Profile | High (AGREE score 0.80-0.83) [37] [12] | Low to moderate | Low to moderate | Moderate |

| Impurity Detection Limit | 3.56-20.52 ng/band [37] | Varies (often lower) | Varies (often lower) | >100 ng/band |

Addressing Technical Limitations

Despite its advantages, HPTLC presents certain limitations that researchers must consider. The technique offers lower resolution for highly complex mixtures compared to advanced column chromatographic techniques like HPLC [36]. Some compounds may undergo irreversible adsorption onto the stationary phase, potentially leading to poor separation or sample loss [36]. Method development and optimization require careful consideration of factors including stationary phase selection, mobile phase composition, chamber saturation time, and detection parameters to ensure robust performance [38].

The integration of multimodal detection systems and advanced chemometric approaches has substantially addressed many traditional limitations of HPTLC. For instance, coupling with mass spectrometry (HPTLC-MS) provides structural identification capabilities, while Surface-Enhanced Raman Spectroscopy (HPTLC-SERS) enables molecular fingerprinting [23]. These hybrid platforms enhance HPTLC's sensitivity, selectivity, and throughput in complex pharmaceutical matrices, making it increasingly competitive with more established techniques [23].

Green Solvent Performance in HPTLC

Greenness Assessment Metrics and Methodologies

The evaluation of analytical method environmental impact has evolved significantly, with several standardized metrics now available to quantify greenness profiles. The Analytical GREEnness (AGREE) approach utilizes all twelve principles of green analytical chemistry, providing a comprehensive 0-1 scoring system where higher values indicate superior environmental performance [9] [12]. Additional assessment tools include the National Environmental Method Index (NEMI), Analytical Eco-Scale (AES), and ChlorTox methodologies, which collectively evaluate factors such as hazardous reagent usage, waste generation, and toxicity [9].

The movement toward greener analytical methods in pharmaceutical analysis reflects broader industry trends toward sustainability and environmental responsibility. HPTLC inherently supports these goals through reduced solvent consumption, minimal energy requirements, and the capacity for parallel sample processing [23]. Quantitative assessments using the Modified Green Analytical Procedure Index (MoGAPI) and AGREE metrics consistently demonstrate HPTLC's high greenness ratings, particularly when green solvent systems are employed [23].

Experimental Data on Solvent System Performance

Recent research provides compelling experimental data on the environmental benefits of green solvent systems in HPTLC. The following table summarizes quantitative greenness assessment scores for different HPTLC methods:

Table 2: Greenness Assessment Scores for HPTLC Methods Using Different Solvent Systems

| Analytical Application | Solvent System | AGREE Score | NEMI | Other Metrics | Reference |

|---|---|---|---|---|---|

| Ertugliflozin quantification | Chloroform/methanol (85:15) | 0.72 | - | AES: <75 | [9] |

| Ertugliflozin quantification | Ethanol-water (80:20) | 0.81 | - | AES: >75 | [9] |

| Caffeine estimation | Ethanol-water (55:45) | 0.80 | - | - | [12] |

| Bisoprolol, Amlodipine, HBZ quantification | Ethyl acetate-ethanol (7:3) | 0.83 | Perfect | Carbon footprint: 0.037 kg CO₂/sample | [37] |

| Hydroxyzine, Ephedrine, Theophylline | Chloroform-ammonium acetate | 0.65 | - | - | [38] |

A direct comparison of normal-phase versus reversed-phase HPTLC for ertugliflozin analysis demonstrated the significant environmental advantages of green solvent systems. The normal-phase method utilizing chloroform/methanol (85:15 v/v) showed inferior greenness profiles across all assessment metrics compared to the reversed-phase method using ethanol-water (80:20 v/v) [9]. The RP-HPTLC approach was found to be more robust, accurate, precise, linear, sensitive, and eco-friendly than the NP-HPTLC method, with results from four greenness tools confirming its superior environmental profile [9].

Green HPTLC Protocol for Caffeine Analysis

A validated green HPTLC method for caffeine quantification in commercial energy drinks and formulations exemplifies the practical application of sustainable principles [12]. The method employs ethanol-water (55:45 v/v) as the mobile phase, with detection at 275 nm, and demonstrates linearity in the range of 50-800 ng/band [12]. The AGREE score of 0.80 confirms the method's excellent greener profile, while validation according to ICH guidelines establishes its reliability for routine analysis [12].

Sample Preparation Protocol:

- Energy Drink Processing: Degas commercial samples using an ultrasonic bath, followed by lyophilization for five days [12].

- Reconstitution: Dissolve dried samples in methanol-water (25:75 v/v) [12].

- Liquid-Liquid Extraction: Extract caffeine using chloroform, collect chloroform fractions [12].

- Concentration: Dry under reduced pressure using a rotary evaporator at 40°C [12].

- Analysis: Reconstitute in appropriate solvent for HPTLC analysis [12].

Chromatographic Conditions:

- Stationary Phase: 10 × 20 cm glass plates precoated with reverse-phase silica gel 60 F254S [12].

- Mobile Phase: Ethanol-water (55:45, v/v) [12].

- Application Rate: 150 nL/s as 6 mm bands [12].

- Development: Automatic Developing Chamber 2, 80 mm distance, 30 min saturation at 22°C [12].

- Detection: 275 nm at scanning rate of 20 mm/s, slit size 4 × 0.45 mm [12].

HPTLC Workflows for API and Impurity Analysis

Standardized Operational Procedures

The analytical process in HPTLC follows a systematic workflow that ensures reproducibility and reliability. The diagram below illustrates the generalized HPTLC workflow for pharmaceutical analysis:

Diagram 1: HPTLC Pharmaceutical Analysis Workflow

The workflow begins with sample preparation, which varies based on the pharmaceutical matrix but typically involves dissolution, extraction, and filtration steps [12]. For tablet formulations, this includes computing the average weight of tablets, powdering, extraction with appropriate solvents (e.g., chloroform), concentration, and reconstitution [12]. Energy drinks and liquid formulations require degassing and often lyophilization before extraction [12].

Method development and optimization represent critical phases where parameters are systematically refined:

- Mobile Phase Optimization: Investigate different solvent combinations and ratios to achieve optimal separation [38].

- Stationary Phase Selection: Choose between normal-phase (silica gel) and reversed-phase (RP-18) plates based on analyte polarity [9].

- Detection Wavelength: Test various wavelengths (e.g., 215 nm, 220 nm, 254 nm) to determine optimal sensitivity [38].

- Chamber Saturation: Standardize saturation time (typically 20-30 minutes) to ensure reproducible migration [38] [37].

- Derivatization Reagents: Select appropriate reagents (e.g., anisaldehyde, polyethylene glycol) for enhanced detection of specific compound classes [39].

Advanced HPTLC Integration for Impurity Profiling

The integration of HPTLC with complementary analytical techniques has significantly enhanced its capability for impurity profiling. HPTLC-MS combines the rapid separation of HPTLC with the high-resolution molecular specificity of mass spectrometry, enabling structural identification and trace quantification of impurities [23]. This coupling provides a synergistic mechanism where HPTLC pre-separates complex matrices, reducing ion suppression effects in MS by isolating target analytes from interfering substances [23].

HPTLC-bioautography represents another advanced integration, enabling function-directed screening of bioactive compounds and impurities [23]. This approach addresses the disconnect between conventional chemical fingerprinting and biological activity assessment, allowing simultaneous chemical separation and activity assessment on the same chromatographic plate [23]. The combination is particularly valuable for detecting minor phytochemicals with potent biological effects that might remain undetected in workflows focused solely on chemical characterization [23].