Green Chemistry Metrics in Pharma: A Guide to the ACS Roundtable's Tools and Impact

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the implementation of green chemistry metrics, spearheaded by the ACS Green Chemistry Institute Pharmaceutical Roundtable.

Green Chemistry Metrics in Pharma: A Guide to the ACS Roundtable's Tools and Impact

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on the implementation of green chemistry metrics, spearheaded by the ACS Green Chemistry Institute Pharmaceutical Roundtable. It covers the foundational principles and drivers behind the green chemistry movement, explores the key methodologies and tools like PMI and LCA for practical application, addresses common challenges and optimization strategies in process development, and validates progress through comparative case studies and industry benchmarks. The content synthesizes current trends and future directions, empowering professionals to make data-driven decisions for more sustainable pharmaceutical manufacturing.

The Why and What: Foundations of Green Chemistry and the Pharma Roundtable

The ACS Green Chemistry Institute Pharmaceutical Roundtable (ACS GCIPR) stands as a seminal initiative where global pharmaceutical and allied industries collaborate to advance the sustainability of manufacturing medicines. Established in 2005, its mission is to serve as a forum dedicated to "catalyzing green chemistry and engineering in the global pharmaceutical industry" [1] [2]. This mission is executed in a unique precompetitive space, allowing competitors to collaboratively tackle shared technical challenges related to the environmental impact of drug development and manufacturing [2]. The Roundtable's work is fundamentally aligned with the UN Sustainable Development Goal of Good Health and Well-Being, recognizing that the health of patients is intrinsically linked to the health of the planet [3]. From an initial group of three companies, the ACS GCIPR has grown to include approximately 50 member organizations, a testament to the critical importance of its mission [2].

The Evolving Framework: Strategic Priorities and Research Roadmaps

The Roundtable's mission is operationalized through three core strategic priorities designed to create a synergistic effect on the industry.

Core Strategic Priorities

- Informing and Influencing the Research Agenda: The GCIPR identifies critical knowledge gaps and funds academic research in key areas to stimulate innovation that the entire industry can leverage [2]. This includes an annual grants program targeting specific research needs.

- Defining and Delivering Tools for Innovation: A major output has been the development of standardized, quantitative tools and metrics—such as the Process Mass Intensity (PMI)—that enable chemists and engineers to measure and improve the environmental profile of their processes [1] [2].

- Educating Future and Current Leaders: Through workshops, webinars, and symposia, the Roundtable disseminates knowledge on green chemistry principles and the application of its tools, ensuring that sustainable practices are adopted by the next generation of scientists [1] [4].

Future Outlook: The 2025 Strategic Roadmap

Looking forward, the GCIPR is developing a strategic road map to guide its next 20 years. This roadmap aims to outline high-impact opportunities to drive decarbonization and incorporate circularity across chemical industry operations. The goals are ambitious, focusing on reducing chemical hazards, developing sustainable alternative technologies, using renewable feedstocks, enhancing efficiency, and reducing waste, all while maintaining cost-effective manufacturing [2]. This vision was a central topic of discussion at member meetings throughout 2025 [5].

The Metric that Defined an Industry: A Deep Dive into Process Mass Intensity (PMI)

The development and adoption of robust, standardized metrics is one of the ACS GCIPR's most significant contributions to sustainable medicine manufacturing. Without a common yardstick, quantifying "greenness" is subjective and unreliable. The Roundtable's adoption and refinement of Process Mass Intensity (PMI) provided the industry with a simple, yet powerful tool to benchmark and drive improvement.

PMI Definition and Calculation

PMI is defined as the total mass of materials used to produce a specified mass of product. It is a holistic metric that accounts for all inputs, including reagents, solvents, and water, into a process. The formula is straightforward:

PMI = Total Mass of Inputs (kg) / Mass of Product (kg)

A lower PMI indicates a more efficient process with less waste. This metric was strategically adopted by the Roundtable to allow for meaningful cross-company and cross-process benchmarking, revealing that solvents were the primary driver of mass inefficiency in pharmaceutical synthesis [2].

The PMI-LCA Tool: Integrating Life Cycle Assessment

To make PMI an even smarter metric, the ACS GCIPR developed the Process Mass Intensity Life Cycle Assessment (PMI-LCA) Tool. This free, publicly available tool provides a high-level estimation of not only the PMI but also the environmental life cycle impacts of a synthetic process [6]. It allows chemists to:

- Compare synthetic routes during early development.

- Understand the environmental trade-offs between different chemical choices.

- Make data-driven, sustainable decisions in real-time by evaluating impacts on factors like carbon emissions and water use alongside mass efficiency [6].

The following diagram illustrates how the PMI-LCA Tool integrates into a sustainable process development workflow, creating a feedback loop for continuous environmental improvement.

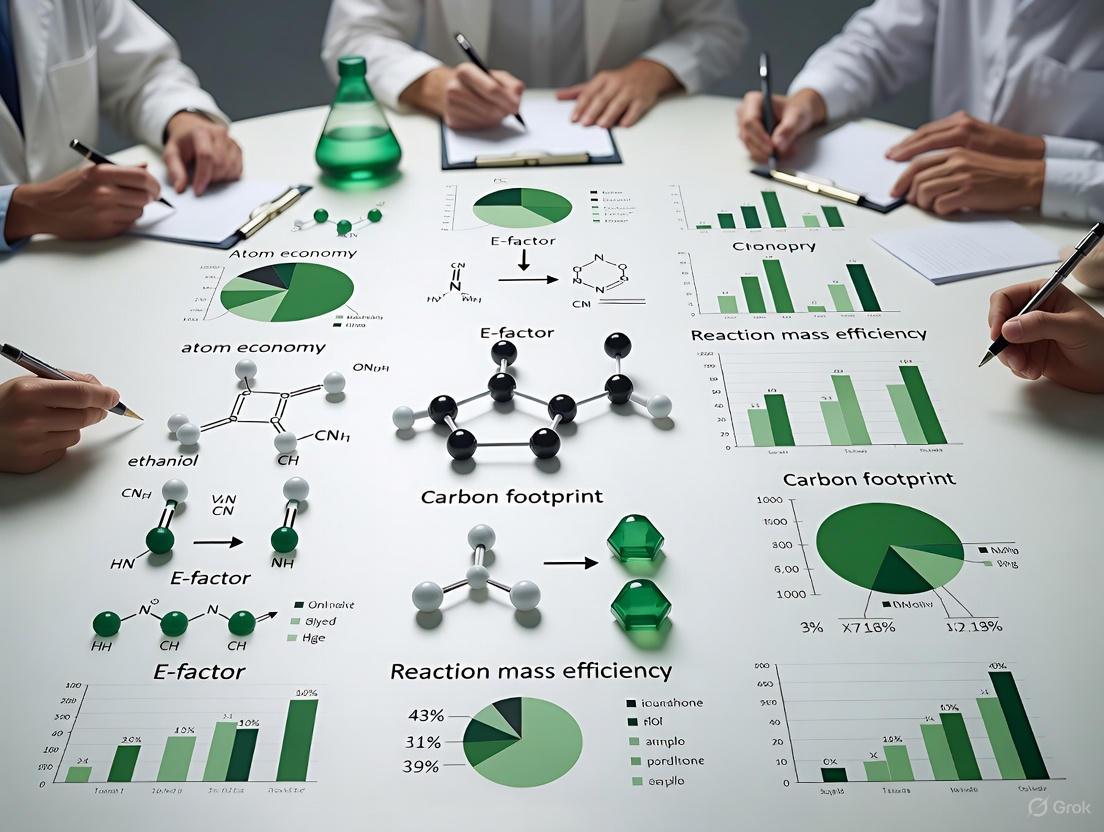

Comparison of Key Green Chemistry Metrics

While PMI is a cornerstone metric, the ACS GCIPR recognizes that a suite of tools is necessary for a comprehensive assessment. The table below compares key metrics advocated and developed by the Roundtable.

Table 1: Comparison of Key Green Chemistry Metrics from ACS GCIPR

| Metric | Definition | Primary Use Case | Advantages | Limitations |

|---|---|---|---|---|

| Process Mass Intensity (PMI) | Total mass of inputs per mass of product [2] | Overall process efficiency benchmarking | Simple to calculate, holistic (includes all inputs) | Does not differentiate between input hazards |

| PMI with Life Cycle Assessment (LCA) | PMI combined with environmental impact profiles [6] | Comparing environmental trade-offs between routes | Provides context on carbon, water, and energy impacts | Requires more data; higher complexity |

| Solvent Selection Guide | A ranked guide of solvent environmental, health, and safety (EHS) profiles [2] | Selecting greener solvents during process design | Directly addresses the largest mass driver in API synthesis | Qualitative; requires expert interpretation |

| Circularity Metrics | Metrics focusing on waste reduction and renewable feedstocks [2] | Guiding long-term sustainable manufacturing goals | Aligns with decarbonization and circular economy goals | Still under development and standardization |

Experimental Protocols & Case Studies: Green Chemistry in Action

The theoretical framework of green chemistry is validated through its practical application. The following case studies, drawn from recent ACS GCIPR award winners, provide experimental protocols that demonstrate the tangible impact of applying the Roundtable's principles and tools.

Case Study 1: Sustainable Manufacturing of an ADC Drug-Linker (Merck)

- Objective: Develop a greener and more scalable manufacturing process for the linker in the antibody-drug conjugate (ADC) Sacituzumab tirumotecan (MK-2870), which faced a significant production bottleneck [7].

- Experimental Protocol & Methodology:

- Route Scouting: Replaced a 20-step synthetic sequence with a new route starting from a widely available natural product.

- Process Intensification: Redesigned the final purification, which originally relied on energy-intensive and low-yielding chromatography.

- Green Principles Applied: Focused on atom economy, reducing steps, and designing for energy efficiency.

- Key Reagent Solutions:

- Natural Product Starting Material: A readily available, complex precursor that reduced synthetic steps.

- Greener Catalysts: Employed catalysts to improve efficiency and reduce step count.

- Results and Data: The new process achieved a ~75% reduction in Process Mass Intensity (PMI) and a >99% reduction in chromatography time, increasing production capacity from less than 100 g/month to a scalable level [7].

Case Study 2: Biocatalytic Peptide Synthesis (Olon S.p.A.)

- Objective: Create a more sustainable platform for manufacturing therapeutic peptides compared to traditional Solid-Phase Peptide Synthesis (SPPS) [7].

- Experimental Protocol & Methodology:

- Technology Platform: Developed a microbial fermentation platform using recombinant DNA technology for peptide expression.

- Genetic Construction: Designed and expressed chimeric proteins in microbial hosts.

- Green Principles Applied: Eliminated protecting groups, minimized solvent use, and leveraged bio-catalysis.

- Key Reagent Solutions:

- Master Cell Bank (MCB): A library of engineered microbial strains allowing for logarithmic proliferation and high-yield production.

- Microbial Fermenters: Bioreactors for scalable, aqueous-based peptide production.

- Results and Data: The platform demonstrated a significantly improved overall PMI compared to SPPS by eliminating the need for excess building blocks and hazardous solvents, offering a promising solution for producing drugs like GLP-1 agonists [7].

Case Study 3: AgroChemical Synthesis from Renewable Feedstocks (Corteva)

- Objective: Design a sustainable manufacturing process for Adavelt active, an agrochemical, using green chemistry principles [7].

- Experimental Protocol & Methodology:

- Feedstock Replacement: Sourced three renewable feedstocks: furfural, alanine, and ethyl lactate.

- Route Re-engineering: Eliminated three protecting groups and four steps from the first-generation synthesis.

- Reagent Substitution: Replaced undesirable reagents with greener alternatives and removed precious metals.

- Key Reagent Solutions:

- Furfural: A renewable platform chemical derived from biomass.

- Ethyl Lactate: A biodegradable, renewable solvent.

- Alanine: A naturally occurring amino acid used as a chiral building block.

- Results and Data: The new process achieved a 92% reduction in waste generation and incorporated 41% renewable carbon content into the final active ingredient [7].

The ACS GCIPR has curated and developed a suite of resources to empower scientists and researchers to implement green chemistry and engineering principles effectively. The following table details key tools and reagent solutions that form the core of a sustainable laboratory's toolkit.

Table 2: Essential Research Reagent Solutions and Tools for Green Chemistry

| Tool / Reagent Category | Specific Example | Function & Rationale | Access / Source |

|---|---|---|---|

| Metric Calculators | PMI-LCA Tool [6] | Quantifies mass efficiency and environmental impact to guide decision-making | Free online tool from ACS GCI |

| Solvent Selection Guides | GCIPR Solvent Selection Tool [2] | Ranks solvents based on EHS criteria to facilitate choice of safer alternatives | Publicly available guide |

| Educational Platforms | Green Chemistry & Engineering Learning Platform (GChELP) [6] | Provides interactive training materials on green and sustainable methodologies | Free, shareable platform |

| Renewable Feedstocks | Furfural, Ethyl Lactate [7] | Reduces reliance on fossil-fuel-based inputs, lowering carbon footprint | Commercial chemical suppliers |

| Biocatalysts | Engineered enzymes [8] | Enables highly selective and efficient reactions under mild aqueous conditions | Specialty enzyme suppliers or in-house engineering |

| Continuous Flow Reactors | Flow chemistry systems [2] | Improves heat/mass transfer, enhances safety, and reduces waste compared to batch | Laboratory equipment suppliers |

Over the past two decades, the ACS GCIPR has profoundly influenced how the pharmaceutical industry approaches the design and manufacture of medicines. By providing a collaborative space, a clear mission, and practical tools like the PMI-LCA metric, it has enabled quantifiable progress in reducing waste, improving efficiency, and minimizing environmental impact [6] [2]. The case studies from award-winning teams at Merck, Olon, and Corteva are not isolated successes but rather exemplars of an industry-wide transformation.

The future trajectory, as outlined in the 2025 strategic roadmap, points towards deeper decarbonization, the integration of circular economy principles, and the adoption of disruptive technologies like biocatalysis, continuous manufacturing, and AI-driven process optimization [2] [7]. As the Roundtable continues to educate future leaders and define the research agenda, its role in catalyzing sustainable medicine manufacturing remains more critical than ever. The ultimate success of this mission ensures that the industry not only safeguards patient health but also fulfills its responsibility to protect the planetary systems upon which all health depends.

The global pharmaceutical industry, while vital for human health, is a significant contributor to environmental impact, generating an estimated 10 billion kilograms of waste annually from the production of active pharmaceutical ingredients (APIs) alone [9]. This waste, coupled with high energy consumption and reliance on hazardous chemicals, has intensified the focus on sustainable molecular design and manufacturing. Green chemistry provides a foundational framework for this transformation, defined as "the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances" [10].

The twelve principles of green chemistry, established by Paul Anastas and John Warner, offer a comprehensive roadmap for integrating sustainability across the drug development lifecycle [11] [10]. This article examines core principles from atom economy to design for degradation within the context of modern pharmaceutical research, providing comparative data and methodological guidance for implementation. The industry's leading organizations, such as the ACS GCI Pharmaceutical Roundtable, champion these principles to catalyze the adoption of green chemistry and engineering, driving innovation that aligns economic viability with ecological responsibility [1].

Core Principles and Quantitative Metrics

Foundational Principles for Drug Development

Several principles of green chemistry are particularly transformative for pharmaceutical synthesis and design. The table below summarizes their core objectives, key metrics, and implementation challenges.

Table 1: Core Green Chemistry Principles in Pharmaceutical Context

| Principle | Core Objective | Key Pharmaceutical Metrics | Common Implementation Challenges |

|---|---|---|---|

| Prevention [11] | Prevent waste at source rather than treat or clean up after creation. | Process Mass Intensity (PMI); E-Factor [11] [12]. | High PMI in traditional multi-step syntheses; technical hurdles in waste stream valorization. |

| Atom Economy [11] | Maximize incorporation of all starting materials into the final product. | Percent Atom Economy [11]. | Prevalent use of protection/deprotection steps; reliance on stoichiometric reagents over catalysts. |

| Less Hazardous Syntheses [11] | Design methods that use/generate substances with low human and environmental toxicity. | Globally Harmonized System (GHS) classification; Process Mass Intensity (PMI) [12]. | Intrinsic reactivity-hazard relationship; disinterest in solvent/auxiliary choices [11]. |

| Designing Safer Chemicals [11] | Preserve efficacy while reducing product toxicity. | In vitro and in vivo toxicity endpoints; predictive toxicology models. | Requirement for trans-disciplinary knowledge (chemistry & toxicology); balancing efficacy with reduced hazard. |

| Safer Solvents & Auxiliaries [9] | Minimize or eliminate auxiliary substances or use safer alternatives. | Solvent selection guides; life cycle assessment (LCA) data. | Solvents comprise 80-90% of mass in pharmaceutical manufacturing [10]. Performance of safer alternatives. |

| Design for Degradation [13] | Design products to break down into innocuous degradation products. | OECD biodegradability standards; persistence (P) and bioaccumulation (B) criteria [12]. | Conflict between product stability during shelf-life and rapid degradation in the environment. |

Measuring Green Performance: E-Factor and Process Mass Intensity

Quantitative metrics are essential for benchmarking and driving improvement. Two central metrics for assessing waste efficiency are the E-Factor and Process Mass Intensity (PMI).

- E-Factor, introduced by Roger Sheldon, measures the total kilograms of waste produced per kilogram of desired product [11] [12]. The pharmaceutical industry historically has some of the highest E-Factors, often 25 to over 100, indicating 25-100 kg of waste for every 1 kg of API produced [10].

- Process Mass Intensity (PMI), favored by the ACS GCI Pharmaceutical Roundtable, is a related but more comprehensive metric. It is the total mass of materials (water, solvents, raw materials, reagents) used in a process per mass of API produced [11]. A lower PMI indicates higher resource efficiency.

The following diagram illustrates the relationship between core principles and the metrics used to quantify their implementation success in a pharmaceutical development workflow.

Comparative Analysis of Green Chemistry Performance

Case Studies in Pharmaceutical Synthesis

The application of green chemistry principles has led to dramatic improvements in the sustainability profile of several key pharmaceutical manufacturing processes. The following table compares traditional processes with their redesigned, greener counterparts, highlighting the quantitative gains achieved.

Table 2: Performance Comparison: Traditional vs. Green Chemistry Processes in Pharma

| API / Process | Traditional Method | Redesigned Green Method | Key Green Principles Applied | Experimental Outcome & Data |

|---|---|---|---|---|

| Sertraline (Zoloft)Pfizer [11] | Original process: 3 steps, extensive solvent and reagent use. | New process: 3 steps with solvent substitution and reduction. | Safer Solvents; Prevention; Atom Economy. | - Solvent use reduced from 60,000 gallons to 6,000 gallons per ton of API.- Yield increased.- Eliminated use of 440 tons/year of TiO₂, 150 tons/year of HCl. |

| SimvastatinCodexis & Prof. Yi Tang [11] | Traditional multi-step synthesis using hazardous reagents. | Efficient biocatalytic process using an engineered enzyme. | Catalysis; Less Hazardous Synthesis; Energy Efficiency. | - Waste reduced by >70%.- Yield increased from 65% to >97%.- Eliminated several chemical steps and hazardous reagents. |

| Sitagliptin (Januvia)Merck [13] | Synthetic route involving a metal catalyst and purification steps. | Streamlined route using a novel enzymatic transaminase. | Catalysis; Safer Solvents; Reduction of Derivatives; Atom Economy. | - Productivity increased by 50%.- Waste reduced by 20%.- Eliminated the need for a metal catalyst and purification steps. |

| Microwave-Assisted Synthesis of Heterocycles [10] | Conventional heating: long reaction times (hours/days), lower yields. | Microwave irradiation: rapid, volumetric heating. | Energy Efficiency; Prevention. | - Reaction time reduced from hours/days to minutes.- Yield and Purity improved.- Cleaner reaction profiles with easier purification. |

The Evolution from Green to White Analytical Chemistry (WAC)

While Green Chemistry principles provide a crucial foundation, Green Analytical Chemistry (GAC) has faced challenges in balancing environmental goals with analytical performance (e.g., accuracy, sensitivity) [14]. This has led to the emergence of White Analytical Chemistry (WAC), a holistic framework that equally weights three pillars:

- Red (Analytical Performance): Accuracy, precision, sensitivity, robustness.

- Green (Environmental Impact): Use of hazardous chemicals, waste generation, energy consumption.

- Blue (Practical & Economic Feasibility): Cost, time, skill requirement, availability [14].

WAC provides a more balanced approach for evaluating analytical methods used in quality control (e.g., HPLC), encouraging the replacement of toxic solvents like acetonitrile with greener alternatives without compromising the method's analytical validity or practical utility [14].

Experimental Protocols for Green Chemistry Principles

Protocol: Atom Economy Calculation for a Synthesis

Objective: To quantify the efficiency of a synthetic route in incorporating starting materials into the final product, providing a simple metric for comparing alternative routes during process development [11].

Principle Demonstrated: Atom Economy.

Methodology:

- Write the balanced chemical equation for the reaction.

- Determine the molecular weights (g/mol) of all reactants and the desired product.

- Apply the formula for Percent Atom Economy:

- % Atom Economy = (Molecular Weight of Desired Product / Sum of Molecular Weights of All Reactants) × 100 [11]

Sample Calculation: For a classic substitution reaction: H₃C-CH₂-CH₂-CH₂-OH + NaBr + H₂SO₄ → H₃C-CH₂-CH₂-CH₂-Br + NaHSO₄ + H₂O

- Molecular weight of desired product (butyl bromide, C₄H₉Br): 137 g/mol

- Sum of molecular weights of reactants (C₄H₉OH + NaBr + H₂SO₄): 74 + 103 + 98 = 275 g/mol

- % Atom Economy = (137 / 275) × 100 = 50% [11]

Interpretation: Even with a 100% yield, half of the mass of the reactants is wasted in unwanted by-products (NaHSO₄ and H₂O), highlighting the need for more atom-economical route design, such as the use of catalysis or rearrangement reactions [11].

Protocol: Microwave-Assisted Synthesis of Nitrogen Heterocycles

Objective: To demonstrate a rapid, energy-efficient synthesis of pharmacologically relevant five-membered nitrogen heterocycles (e.g., pyrroles, indoles) with reduced waste and improved yield [10].

Principles Demonstrated: Design for Energy Efficiency; Prevention; Safer Solvents.

Materials and Reagents:

- Research Reagent Solutions:

- Polar Solvents (e.g., Ethanol, DMF): High microwave absorption for efficient heating [10].

- Appropriive reaction components (e.g., amines, carbonyl compounds).

- Catalyst (if required): Often heterogeneous catalysts are suitable.

- Equipment:

- Microwave Synthesizer

- Reaction Vials (sealed)

- Standard purification equipment (e.g., HPLC, flash chromatography).

Experimental Workflow:

Key Parameters and Observations:

- Reaction Time: Reduced from hours/days under conventional heating to minutes under microwave irradiation [10].

- Yield and Purity: Typically higher yields and cleaner reaction profiles are observed, minimizing downstream purification waste [10].

- Solvent Volume: Often lower volumes can be used compared to traditional reflux setups.

The Scientist's Toolkit: Essential Reagents & Methodologies

Table 3: Key Research Reagent Solutions for Green Chemistry in Pharma

| Tool / Reagent Category | Function in Green Synthesis | Example(s) | Rationale for Green Classification |

|---|---|---|---|

| Biocatalysts (Enzymes) | Selective catalysis under mild conditions. | Engineered transaminases (Sitagliptin synthesis); hydrolytic enzymes [13]. | High selectivity reduces derivatives/protecting groups; operates in water at ambient T/P. |

| Renewable Feedstocks | Sustainable raw material source. | Plant-based sugars; bio-derived organic acids; algal extracts [13]. | Reduces reliance on petrochemicals; leverages carbon-neutral biomass. |

| Green Solvents | Replacement for hazardous VOCs. | Water, Ethanol, 2-MeTHF, Cyrene, supercritical CO₂ [13]. | Lower toxicity, higher biodegradability, reduced environmental persistence and hazard. |

| Supported & Heterogeneous Catalysts | Facilitation of reactions with easy recovery/reuse. | Immobilized metal catalysts; solid-acid catalysts. | Reduces metal leaching and waste; simplifies separation, lowering PMI and cost. |

| Microwave Reactors | Non-conventional energy source for heating. | Sealed-vessel microwave synthesizers. | Enables rapid, energy-efficient heating, drastically reducing reaction times and energy consumption [10]. |

The integration of core green chemistry principles—from maximizing atom economy to designing for degradation—is no longer an optional pursuit but a strategic imperative for the pharmaceutical industry [9] [13]. The quantitative comparisons and experimental protocols outlined demonstrate that greener processes consistently lead to reduced waste, lower costs, improved efficiency, and enhanced safety profiles. Frameworks like White Analytical Chemistry (WAC) further ensure that environmental goals are balanced with analytical performance and practical feasibility [14].

The ongoing work of consortia like the ACS GCI Pharmaceutical Roundtable and the development of advanced assessment tools, such as the Estée Lauder Companies' updated "Green Score" which now incorporates waste and biodegradability metrics, underscore the dynamic evolution of this field [1] [12]. For researchers and drug development professionals, the continued application and innovation of these principles are fundamental to building a pharmaceutical sector that is both therapeutically powerful and ecologically responsible.

In the modern pharmaceutical industry, the adoption of green chemistry is no longer merely an ethical consideration but a strategic imperative driven by a convergence of regulatory pressures, Environmental, Social, and Governance (ESG) objectives, and the relentless pursuit of operational efficiency [15] [9]. For researchers, scientists, and drug development professionals, this triad of drivers necessitates a robust framework for quantifying and comparing the environmental performance of synthetic processes. The ACS Green Chemistry Institute (GCI) Pharmaceutical Roundtable has emerged as the leading organization in catalyzing this transformation, developing standardized metrics and tools that enable informed decision-making [1]. This guide objectively compares the application of these metrics against traditional development approaches, providing experimental data and protocols that underscore the tangible benefits of embedding sustainability into pharmaceutical research and development.

The Driving Forces Behind Green Chemistry Adoption

Regulatory Pressure

The regulatory landscape is increasingly stringent, compelling the industry to transform its manufacturing practices [15]. Regulations such as the European Union's REACH impose restrictions on hazardous solvents like Dimethylformamide (DMF) and N-Methyl-2-pyrrolidone (NMP), which are common in peptide therapeutics manufacturing [15]. Furthermore, active pharmaceutical ingredients (APIs) are now being named as priority substances in European water regulations, following studies showing that 43% of global river water sampling sites had drug levels exceeding safe ecological thresholds [15]. This regulatory shift forces companies to adopt green chemistry strategies to maintain compliance and avoid reputational damage and fines.

ESG Goals

ESG targets have become a central component of corporate strategy, with genuine commitment offering a competitive edge [15]. GlobalData’s ESG Sentiment Polls from Q1 2025 revealed that 50% of respondents believe most companies still only value ESG as a marketing exercise, creating an opportunity for firms to build authentic brand loyalty with clients and investors who prioritize sustainability [15]. The pharmaceutical industry, accounting for nearly 5% of global greenhouse gas emissions, faces significant scrutiny, leading major companies like Merck, Roche, and Novo Nordisk to set ambitious carbon neutrality and net-zero goals [16]. These ESG commitments are now key determinants in attracting investment and ensuring long-term market viability.

Operational Efficiency

Beyond compliance and branding, a powerful business case for green chemistry exists in its ability to enhance operational efficiency and reduce costs [17]. Designing out hazards leads to lower costs associated with waste disposal, hazardous material handling, specialized equipment, training, and insurance [17]. The global production of APIs, estimated at 65–100 million kilograms annually, generates approximately 10 billion kilograms of waste, with disposal costs around $20 billion [9]. Green chemistry principles, such as atom economy and catalysis, directly address this inefficiency by maximizing the incorporation of reactant atoms into the final product and reducing waste [15] [9]. This synergy between environmental and economic benefits makes green chemistry a cornerstone of lean and efficient pharmaceutical manufacturing.

Quantitative Comparison: Traditional vs. Green Chemistry-Led Development

The following tables synthesize experimental data and case studies from industry awards and publications, comparing the performance of traditional development approaches versus those guided by green chemistry metrics.

| Metric | Traditional Process | Green Chemistry-Led Process | Data Source / Case Study |

|---|---|---|---|

| Process Mass Intensity (PMI) | Baseline | ~75% reduction [18] | Sacituzumab tirumotecan (MK-2870) Production [18] |

| Process Steps | 20-step synthesis | Streamlined to 3 OEB-5 handling steps [18] | Sacituzumab tirumotecan (MK-2870) Production [18] |

| Chromatography Time | Baseline | >99% reduction [18] | Sacituzumab tirumotecan (MK-2870) Production [18] |

| Productivity & Waste | Baseline | +56% productivity, -19% waste generation [16] | Industry-wide Green Chemistry Application [16] |

Table 2: Solvent and Reagent Impact Comparison

| Parameter | Traditional Reagents | Green Alternatives | Experimental Outcome & Protocol |

|---|---|---|---|

| Solvents (e.g., Peptide Synthesis) | DMF, NMP (Reprotoxic, restricted under REACH) [15] | DMF/NMP-free methods, Bio-based surfactants, Safer solvents [19] [15] | Protocol: Solid-phase peptide synthesis using alternative solvent systems. Outcome: Maintained efficiency and yield while eliminating substances of very high concern (SVHC). [15] |

| Catalysts | Precious metals, Stoichiometric reagents [9] [18] | Enzymes (Biocatalysis), Engineered microbes [19] [15] | Protocol: Enzyme screening and process optimization for asymmetric synthesis. Outcome: Higher selectivity, reduced waste, lower energy consumption, and avoidance of precious metals. [15] [18] |

| Synthetic Methodology | Solvent-intensive batch reactions [19] | Mechanochemistry (solvent-free), In-water/on-water reactions [19] | Protocol: Ball milling for solvent-free synthesis of imidazole-dicarboxylic acid salts. Outcome: High yields, reduced solvent usage, lower energy input. [19] |

Experimental Protocols for Key Green Chemistry Methodologies

Protocol: Biocatalysis Integration for Sustainable Drug Synthesis

Biocatalysis utilizes enzymes as naturally occurring biological catalysts to drive chemical transformations.

- Objective: To provide a greener, more efficient alternative to traditional petroleum-based synthetic steps.

- Methodology:

- Enzyme Screening: A library of enzymes is screened against the target substrate to identify optimal activity and selectivity. This can be automated via high-throughput experimentation [19].

- Process Optimization: Reaction conditions (pH, temperature, co-solvents, substrate concentration) are systematically optimized for the selected enzyme(s).

- Scale-Up Production: The engineered enzyme is produced at an industrial scale. The biocatalytic step is integrated into the synthesis route, either replacing a specific step or constituting an entirely new, streamlined process [15].

- Key Data & Outcomes: Biocatalysis offers significant advantages including lower energy consumption, reduced waste and byproducts, and safer process conditions. Its flexibility allows for the generation of chiral molecules with high specificity, leading to higher yields and a reduced number of synthetic steps [15].

Protocol: Continuous Manufacturing and Process Intensification

This protocol replaces traditional batch processing with a continuous flow system.

- Objective: To significantly reduce waste, energy consumption, and production footprint while accelerating manufacturing.

- Methodology:

- Reactor Design: A continuous-flow reactor is designed, with reagents pumped through a series of temperature-controlled modules or tubes.

- Parameter Optimization: Residence time, flow rates, and temperature are optimized to maximize conversion and selectivity, often using real-time analytical monitoring.

- Integration: The continuous process is integrated with workup and isolation steps, such as in-line extraction and crystallization, to create an end-to-end continuous process [20].

- Key Data & Outcomes: Continuous manufacturing is a hallmark of sustainable pharma manufacturing, leading to a leaner and cleaner process. It reduces waste, demands less energy, and accelerates production, thereby lowering the overall carbon footprint of operations [20].

The Scientist's Toolkit: Essential Research Reagent Solutions

The implementation of green chemistry relies on a suite of specialized reagents and tools. The following table details key solutions for enabling sustainable research.

Table 3: Key Research Reagent Solutions for Green Chemistry

| Item / Solution | Function in Green Chemistry | Example & Rationale |

|---|---|---|

| Engineered Enzymes | Biocatalysts for specific, efficient, and selective transformations. | Codexis enzymes: Tailored for industrial-scale synthesis, enabling highly selective reactions that reduce waste and avoid precious metal catalysts [15] [18]. |

| Deep Eutectic Solvents (DES) | Customizable, biodegradable solvents for extraction and synthesis. | Mixtures of Choline Chloride and Urea: Used for extracting critical metals from e-waste or bioactive compounds from biomass, offering a low-toxicity alternative to strong acids or VOCs [19]. |

| Water-Based Reaction Systems | Non-toxic, non-flammable medium for chemical reactions. | Silver nanoparticle synthesis in water: Replaces organic solvents, leveraging water's unique properties (hydrogen bonding, polarity) to facilitate transformations [19]. |

| AI/ML Optimization Tools | Software for predicting sustainable reaction pathways and optimizing conditions. | Tools trained on sustainability metrics (atom economy, energy efficiency): Suggest safer synthetic pathways and optimal conditions (temp, solvent), reducing trial-and-error waste [19] [9]. |

| Process Mass Intensity (PMI) LCA Tool | A standardized metric to quantify the total mass used per mass of product. | ACS GCI PR Tool: Enables chemists to measure, compare, and improve the environmental footprint of synthetic processes, factoring in the full life cycle [21] [22]. |

Visualizing the Decision-Making Workflow: Integrating Metrics into R&D

The following diagram illustrates the logical workflow for integrating green chemistry metrics into pharmaceutical research and development, from initial design to final process selection.

Green Chemistry Decision Workflow

The integration of green chemistry metrics, driven by regulatory pressure, ESG goals, and operational efficiency, is fundamentally reshaping pharmaceutical development. The quantitative comparisons and experimental protocols detailed in this guide demonstrate conclusively that sustainable practices are not a constraint on innovation but a powerful enabler of it. By adopting the tools and methodologies championed by the ACS GCI Pharmaceutical Roundtable, researchers and scientists can make faster, smarter, and more sustainable decisions [21] [22]. This evidence-based approach allows the industry to simultaneously advance human health and environmental stewardship, turning the triple bottom line of economic, social, and environmental sustainability into a achievable reality [9].

The pharmaceutical industry faces a critical environmental challenge, accounting for nearly 5% of global greenhouse gas (GHG) emissions—a footprint that exceeds that of the automotive sector [16]. This impact is growing rapidly, with the global pharmaceutical carbon footprint increasing by 77% from 1995 to 2019 [23]. Simultaneously, the industry's water-intensive operations pose significant sustainability concerns, particularly in water-stressed regions where manufacturing facilities are often located [24] [25]. This analysis examines the carbon and water footprints of pharmaceutical operations through the lens of green chemistry metrics, providing researchers and drug development professionals with comparative performance data and methodologies to guide sustainable development decisions.

The environmental burden is disproportionately distributed across the pharmaceutical value chain. Scope 3 emissions—those originating from supply chains—represent the most significant challenge, comprising up to 95% of the sector's total carbon impact and being 5.4 times greater than direct (Scope 1 and 2) emissions combined [26] [25]. Similarly, pharmaceutical water consumption is substantial, with the global pharmaceutical water market valued at approximately $40.18 billion in 2024 and projected to reach $76.04 billion by 2034, reflecting a compound annual growth rate of 8.30% [24]. This growth underscores the tension between expanding pharmaceutical production and managing environmental resources sustainably.

Table 1: Global Pharmaceutical Environmental Impact Metrics

| Environmental Metric | Current Value | Trend | Primary Sources |

|---|---|---|---|

| Sector GHG Emissions | 397 million tCO₂-e (2023) | Increasing | [26] |

| Pharma Share of Global Emissions | 4.4-5% | Projected to triple by 2050 without intervention | [16] |

| Scope 3 Contribution | 95% of total footprint | Increasing focus | [26] [25] |

| Pharmaceutical Water Market | $40.18 billion (2024) | 8.30% CAGR to 2034 | [24] |

| Water Reduction Targets | 15-20% at leading companies | Progressive improvement | [25] [16] |

Comparative Analysis of Corporate Environmental Performance

Carbon Emissions Profiles

Major pharmaceutical companies have made varying progress in addressing their carbon footprints, with distinct strategies for Scope 1, 2, and 3 emissions. The Science-Based Targets initiative (SBTi) has guided many organizations toward aligning with the Paris Agreement's goal of limiting global warming to 1.5°C. Recent data reveals that 31% of biotech and pharma companies have now set medium-term targets aligned with a 1.5°C pathway, a significant increase from just 10 companies the previous year [26].

Novartis has demonstrated substantial progress, reporting 298 ktCO₂e in Scope 1 and 2 emissions and 4,529 ktCO₂e in Scope 3 emissions for 2023 [27]. The company aims to achieve carbon neutrality for Scope 1 and 2 emissions by 2025 and reduce these emissions by 90% from 2022 levels by 2030, with an additional target of a 42% reduction in Scope 3 emissions from suppliers and product use [27]. Similarly, AstraZeneca reported a reduction in gross Scope 1 and 2 GHG emissions from 200,838 tonnes in 2023 to 139,594 tonnes in 2024, representing a 77.5% reduction since 2015 [27]. The company aims for a 98% reduction in these direct emissions by 2026 and ultimately plans to become carbon negative by 2030 [27].

Table 2: Corporate Carbon Performance Comparison (Q1 2025)

| Company | Scope 1 & 2 Emissions | Scope 3 Emissions | Reduction Targets | Renewable Electricity |

|---|---|---|---|---|

| Novartis | 298 ktCO₂e (2023) | 4,529 ktCO₂e (2023) | Carbon neutrality by 2025 (Scope 1 & 2); 90% reduction by 2030; 42% Scope 3 reduction | 100% by 2025 target |

| AstraZeneca | 139.6 ktCO₂e (2024) | 5,897.8 ktCO₂e (2024) | 98% reduction by 2026 (Scope 1 & 2); Carbon negative by 2030 | 97% at company sites |

| GSK | Not specified in search results | 95% of total footprint | Net positive water impact in water-stressed basins by 2050 | Not specified |

| Sector Average | Varies by company size | 5.4x Scope 1 & 2 combined | 31% of companies aligned with 1.5°C pathway | Increasing adoption |

Water Stewardship Initiatives

Water stewardship has emerged as a critical focus area, particularly for facilities located in water-stressed regions. GSK has implemented comprehensive water management strategies, with all its sites achieving good water stewardship status as defined by the Alliance for Water Stewardship [25]. The company has committed to being water neutral in its own operations and at key suppliers in water-stressed regions by 2030, defined through three criteria: achieving AWS Standard certification, reducing water use by 20%, and replenishing water quantity in the basin equivalent to the site's 2030 footprint [25].

Sanofi has demonstrated notable success in water reduction, decreasing its global water withdrawals by 18% in 2023, surpassing its 2030 target of a 15% reduction [16]. This achievement was facilitated through water recycling systems, including rainwater harvesting and optimized cooling systems. Similarly, Novartis has implemented reverse osmosis units in Singapore to recycle water, contributing to a broader industry trend of adopting membrane technologies for water purification and reuse [16].

The expansion of pharmaceutical manufacturing in water-stressed regions presents both challenges and opportunities for innovation. In India, where many key suppliers are involved in water-intensive production of active pharmaceutical ingredients (APIs), GSK has partnered with the Watershed Organisation Trust (WOTR) on water replenishment projects designed to improve ecosystem conditions and enhance climate resilience [25]. The company also co-founded the Women + Water Collaborative in India to leverage women's leadership in improving access to clean water and sanitation [25].

Green Chemistry Metrics and Experimental Protocols

Multi-Dimensional Assessment Methodology

Green chemistry principles provide a framework for evaluating and improving the environmental performance of pharmaceutical processes. A recent methodological advancement introduces a multi-dimensional assessment approach for evaluating the environmental sustainability of chemical transformations and entire processes [28]. This framework moves beyond one-dimensional analyses that often lead to incorrect conclusions, instead providing a systematic method for identifying environmental hotspots and guiding research priorities.

The methodology employs a practical, systematic approach that uses available data and simulates missing information to enable fair comparisons between processes. When tested against more complex Life Cycle Assessment (LCA) methodologies, this approach has proven reliable in identifying environmental hotspots across entire portfolios of industrial companies [28]. The implementation of this methodology enables data-driven decision-making on a large scale, particularly valuable when multiple technology options are available for a given transformation, each with different environmental footprints and investment requirements.

Diagram 1: Green Chemistry Multi-Metric Assessment (100/100 characters)

Advanced Water Treatment Experimental Protocols

The removal of pharmaceutical residues from wastewater requires advanced treatment methodologies. Recent research has evaluated multiple technologies for their efficiency in eliminating recalcitrant pharmaceutical compounds [29]. The experimental protocols for these technologies provide valuable benchmarks for comparing performance across different treatment approaches.

Advanced Oxidation Processes (AOPs) employ chemical oxidants such as ozone, hydrogen peroxide, and ultraviolet radiation to degrade pharmaceutical compounds through generation of hydroxyl radicals. The standard experimental protocol involves spiking distilled water or actual wastewater effluent with target pharmaceutical compounds at concentrations ranging from 100-500 μg/L. The reaction is typically conducted in batch mode with controlled pH (typically 3-8) and temperature (20-25°C), with samples collected at predetermined time intervals for analysis of parent compound degradation and transformation products [29].

Biochar-Based Treatment Systems utilize pyrolyzed biomass (typically agricultural waste) as adsorbents. Experimental protocols involve preparing biochar from various feedstocks at pyrolysis temperatures between 300-700°C, followed by characterization of surface area, pore size distribution, and surface functional groups. Batch adsorption experiments are conducted using pharmaceutical solutions of known concentration, with agitation at constant temperature and sampling at time points from 5 minutes to 24 hours. Kinetics models (pseudo-first order and pseudo-second order) and isotherm models (Langmuir and Freundlich) are then applied to quantify adsorption capacity and mechanisms [29].

Membrane Technologies including reverse osmosis (RO) and nanofiltration (NF) are evaluated using cross-flow filtration systems with standardized membranes. Experimental protocols involve preparing synthetic wastewater containing target pharmaceuticals, adjusting pH and ionic strength to simulate real conditions, and operating the system at constant pressure while monitoring permeate flux. Sampling of both permeate and retentate streams at regular intervals allows for calculation of rejection efficiencies for each pharmaceutical compound [29].

Table 3: Pharmaceutical Removal Efficiency by Treatment Technology

| Treatment Technology | Representative Compounds | Removal Efficiency | Key Operational Parameters | Limitations |

|---|---|---|---|---|

| Advanced Oxidation Processes | Carbamazepine, Diclofenac | 85-99% | OH radical exposure, pH, catalyst dose | Byproduct formation, high energy cost |

| Biochar-Based Systems | Ibuprofen, Sulfamethoxazole | 70-95% | Biochar surface area, pore size, contact time | Variable performance based on feedstock |

| Membrane Technologies | Broad spectrum | 90-99% | Membrane type, pressure, pH | Concentrate disposal, fouling potential |

| Conventional Activated Sludge | Acetaminophen, Caffeine | 20-80% (compound dependent) | Sludge retention time, temperature | Poor removal of recalcitrant compounds |

The Scientist's Toolkit: Research Reagent Solutions

- Reverse Osmosis Membranes: Polyamide thin-film composite membranes used for purifying water to purified water (PW) standards by removing ions, microorganisms, and organic contaminants [24] [30].

- Electrodeionization (EDI) Stacks: Continuous electrochemical separation devices that remove ionized species from water without chemical regeneration, used for producing high-purity water [24].

- UV Oxidation Systems: Ultraviolet light reactors that generate hydroxyl radicals to destroy trace organic contaminants and reduce total organic carbon (TOC) in pharmaceutical water systems [24].

- Biochar Adsorbents: Pyrolyzed biomass materials with high surface area and specific surface functionalities used for removing pharmaceutical residues from wastewater streams [29].

- Ion Exchange Resins: Polymer-based beads functionalized with ionic groups for removing specific contaminants and achieving required water quality specifications [30].

- Ozone Generators: Systems producing ozone (O₃) for advanced oxidation processes in wastewater treatment, particularly effective against recalcitrant pharmaceutical compounds [24] [29].

- Membrane Bioreactors: Integrated systems combining biological treatment with membrane filtration for advanced wastewater treatment with small footprint [30].

- Environmental Sampling Kits: Equipment for collecting water samples from various points in treatment systems for pharmaceutical residue analysis, including solid-phase extraction materials for analyte concentration [29].

The pharmaceutical industry's environmental imperative requires integrated approaches that address both carbon emissions and water stewardship throughout the value chain. The comparative data presented in this analysis demonstrates that while progress varies across companies, systematic measurement using green chemistry metrics, implementation of advanced treatment technologies, and multi-stakeholder collaboration represent the most promising pathways toward sustainability.

For researchers and drug development professionals, the experimental protocols and assessment methodologies provide practical tools for evaluating and improving environmental performance. The transition to sustainable pharmaceutical manufacturing depends on continued innovation in green chemistry principles, circular economy implementation, and transparent reporting of environmental metrics. As regulatory pressures increase and water scarcity intensifies in key manufacturing regions, the industry's commitment to addressing its carbon and water footprints will become increasingly central to its operational viability and social license to operate.

The How: Key Metrics, Tools, and Practical Application in R&D

Within the pharmaceutical industry and fine chemical production, the adoption of green chemistry principles is crucial for minimizing environmental impact and promoting sustainable development [31]. The twelve principles of green chemistry provide a conceptual framework for designing safer chemical processes, but they are inherently qualitative [32]. To translate these principles into practical, measurable outcomes, researchers and process chemists rely on specific green chemistry metrics [33]. These metrics serve as essential tools for quantifying the environmental performance and efficiency of chemical processes, allowing for objective comparison between different synthetic routes and identification of areas for improvement [34] [35].

The American Chemical Society Green Chemistry Institute (ACS GCI) Pharmaceutical Roundtable has been instrumental in advancing the application of these metrics within drug development, establishing standardized approaches for evaluating and comparing process sustainability [33] [6]. This guide provides a detailed comparison of three fundamental metrics—Atom Economy, E-Factor, and Process Mass Intensity (PMI)—which form the cornerstone of green chemistry evaluation in pharmaceutical research and development.

Metric Fundamentals: Definitions, Calculations, and Theoretical Foundations

Atom Economy

Atom Economy (AE) was formulated by Barry Trost as a theoretical framework to guide chemists toward designing synthetic routes that maximize the incorporation of starting materials into the final product [34] [33]. It is a predictive metric calculated from the reaction stoichiometry, without requiring experimental data.

Calculation Formula:

Atom Economy (%) = (Molecular Weight of Desired Product / Sum of Molecular Weights of All Reactants) × 100%[34]Theoretical Basis: Atom Economy is rooted in the principle of conservation of mass. In an ideal reaction with 100% atom economy, all atoms from the reactants are incorporated into the desired product, resulting in no byproducts [34]. A simplified variant is Carbon Economy, which focuses specifically on the fate of carbon atoms from reactants to products [34].

E-Factor

The E-Factor (Environmental Factor), developed by Roger Sheldon, directly quantifies the waste generated by a process [34] [31]. It provides a clear measure of process efficiency from an environmental standpoint.

Calculation Formula:

E-Factor = Total Mass of Waste (kg) / Mass of Product (kg)[34]Waste Definition: A critical aspect of the E-Factor is the definition of "waste," which encompasses all substances produced by the process except the desired product [34]. A key distinction is often made between including and excluding water from the waste calculation, as processes involving aqueous streams can otherwise appear disproportionately wasteful [31].

Process Mass Intensity (PMI)

Process Mass Intensity (PMI) is a comprehensive mass-based metric endorsed by the ACS GCI Pharmaceutical Roundtable as a key green metric for the pharmaceutical industry [33]. It measures the total mass of materials used to produce a unit mass of the product.

Calculation Formula:

PMI = Total Mass of Materials Used in the Process (kg) / Mass of Product (kg)[31]Relationship to E-Factor: PMI and E-Factor are directly interrelated. The total mass of inputs equals the total mass of outputs (product + waste). Therefore,

E-Factor = PMI - 1[31]. PMI shifts the focus from managing waste to minimizing the consumption of all materials, including reagents, solvents, and process aids, right from the process design stage [33].

Comparative Analysis of Metrics

The following tables provide a consolidated comparison of the three core metrics, highlighting their key characteristics, strengths, and limitations.

Table 1: Direct Comparison of Atom Economy, E-Factor, and Process Mass Intensity

| Feature | Atom Economy (AE) | E-Factor | Process Mass Intensity (PMI) |

|---|---|---|---|

| Definition | Theoretical incorporation of reactant atoms into the product [34] | Mass of waste produced per mass of product [34] | Total mass of inputs required per mass of product [31] [33] |

| Primary Focus | Reaction pathway design & stoichiometry | Waste output | Resource consumption & input efficiency |

| Calculation Basis | Stoichiometry & molecular weights | Experimental mass balance | Experimental mass balance |

| Scope | Single reaction (can be extended to multi-step) | Process-wide | Process-wide |

| Ideal Value | 100% | 0 | 1 |

| Includes Solvents? | No | Yes (depending on definition) | Yes |

Table 2: Strengths and Limitations of Each Metric

| Metric | Strengths | Limitations |

|---|---|---|

| Atom Economy | - Simple, quick to calculate from stoichiometry- Powerful for early route scouting- Highlights inherent byproduct formation [34] [32] | - Purely theoretical; ignores yield, reagents, solvents, and energy [34]- Can be misleading for reactions with high yield but poor AE, and vice-versa [32] |

| E-Factor | - Simple, intuitive concept of waste generation- Highlights waste disposal cost and environmental impact [34] [31] | - Does not differentiate between benign and hazardous waste [34]- Waste tracking can be complex [31] |

| Process Mass Intensity | - Comprehensive; accounts for all process inputs- Directly promotes resource conservation- ACS GCI PR recommended; enables benchmarking [33] | - Requires detailed inventory of all materials- Does not account for environmental impact of specific substances [35] |

Table 3: Typical Metric Values Across Chemical Industry Sectors [34] [31]

| Industry Sector | Annual Production (Tonnes) | E-Factor (kg waste/kg product) | Implied PMI (kg input/kg product) |

|---|---|---|---|

| Oil Refining | 10⁶ – 10⁸ | < 0.1 | < 1.1 |

| Bulk Chemicals | 10⁴ – 10⁶ | < 1 - 5 | < 2 - 6 |

| Fine Chemicals | 10² – 10⁴ | 5 - > 50 | 6 - > 51 |

| Pharmaceuticals | 10 – 10³ | 25 - > 100 | 26 - > 101 |

Experimental Protocols for Metric Determination

Workflow for Green Metrics Assessment

The following diagram illustrates the standard workflow for determining and analyzing green metrics in process development.

Case Study: Application in Fine Chemical Synthesis

A 2022 study analyzing catalytic processes for fine chemical production provides exemplary experimental data for these metrics [36]. The synthesis of dihydrocarvone from limonene-1,2-epoxide using a dendritic zeolite catalyst serves as a model protocol.

- Reaction Setup: A reactor was charged with limonene-1,2-epoxide, solvent (e.g., a benign alcohol or acetone), and the dendritic zeolite d-ZSM-5/4d catalyst. The reaction was conducted under controlled temperature and stirring.

- Workup and Isolation: Upon reaction completion, the catalyst was recovered by filtration. The solvent was removed from the filtrate via distillation under reduced pressure. The crude product was then purified, and the mass of pure dihydrocarvone was recorded.

- Data Recording and Calculation:

- Masses Recorded: Mass of all reactants, solvent, catalyst, and final pure product.

- Atom Economy Calculation: Based on the balanced equation for the conversion, the molecular weight of dihydrocarvone was divided by the molecular weight of limonene-1,2-epoxide. For this simple transformation with no stoichiometric byproducts, the AE was calculated to be 1.0 (or 100%) [36].

- PMI and E-Factor Calculation: Using the total mass of all inputs (reactant, solvent, catalyst), the PMI was calculated. With a product yield of 63%, the study reported an RME of 0.63. From this, the PMI can be derived as

1/RME ≈ 1.59, and the E-Factor asPMI - 1 ≈ 0.59[36].

This case demonstrates that even a reaction with perfect Atom Economy does not automatically result in a low PMI or E-Factor, as the experimental yield and the mass of solvent/catalyst significantly influence the final process metrics.

Implementing green chemistry metrics effectively requires access to specific tools and databases. The following table details key resources recommended for researchers.

Table 4: Essential Tools and Reagents for Green Chemistry Research

| Tool/Resource Name | Type/Function | Role in Green Metrics & Process Development |

|---|---|---|

| CHEM21 Metrics Toolkit [37] [38] | Standardized Spreadsheet | A comprehensive, free toolkit for holistic sustainability assessment of reactions, covering mass metrics, life cycle, and safety hazards. |

| PMI-LCA Tool [6] | Software Calculator | A free tool from ACS GCI PR that estimates Process Mass Intensity and provides environmental life cycle data for synthetic routes. |

| ACS GCI Solvent Selection Guide | Decision Guide | Informs solvent choice to reduce environmental impact and health hazards, directly improving E-Factor and PMI. |

| AI4Green ELN [39] | Electronic Lab Notebook | An open-source platform that integrates reaction data archival with automatic green metrics calculation. |

| Biocatalysis Guide [39] | Reaction Guide | A guide from ACS GCI PR to help chemists incorporate highly selective, efficient biocatalysts, improving atom economy and reducing waste. |

| Chem21 Solvent Selection Guide [39] | Decision Guide | Ranks solvents based on safety, health, and environmental criteria from a multi-company consortium, aiding in greener input selection. |

Atom Economy, E-Factor, and Process Mass Intensity are complementary, not competing, metrics. Atom Economy is an invaluable tool for the initial design of a synthetic route, while E-Factor and PMI provide a reality check on the actual efficiency of the implemented process [34] [33] [32]. The pharmaceutical industry's preference for PMI underscores the importance of a holistic view that captures all material inputs, not just waste outputs [33].

For a truly comprehensive sustainability assessment, these mass-based metrics must be integrated with other tools. The CHEM21 Metrics Toolkit represents the leading edge of this effort, combining mass efficiency with life cycle impact, safety, and health considerations [37] [38]. Furthermore, advanced methodologies like Life Cycle Assessment (LCA) are crucial for understanding the broader environmental footprint, including energy use and global warming potential [6] [32]. By adopting this multi-faceted metrics approach, researchers and drug development professionals can make informed, objective decisions to advance the goals of green chemistry and foster sustainable innovation in the pharmaceutical industry.

Within the pharmaceutical industry, the drive towards sustainable manufacturing is increasingly guided by the robust metrics developed through initiatives like the American Chemical Society Green Chemistry Institute (ACS GCI) Pharmaceutical Roundtable. The integration of green chemistry principles into active pharmaceutical ingredient (API) development requires practical tools that enable researchers to make faster, smarter, and more sustainable decisions during process development [40]. While simple mass-based metrics such as Process Mass Intensity (PMI) have been widely adopted, there is growing recognition that they provide an incomplete picture of environmental performance, leading to the development of more comprehensive assessment methodologies that incorporate life cycle thinking [41] [42]. The PMI-LCA Tool represents a significant advancement in this field, bridging the gap between simplistic metrics and data-intensive life cycle assessment to provide a more holistic view of process impacts while maintaining practicality for synthetic chemists and engineers [40].

The PMI-LCA Tool is a high-level estimator of Process Mass Intensity and environmental life cycle information that can be customized to fit a wide variety of linear and convergent processes for the synthesis of small molecule active pharmaceutical ingredients (APIs) [43]. Developed by the ACS GCI Pharmaceutical Roundtable, this freely available tool utilizes an ecoinvent dataset as the source for life cycle impact assessment (LCIA) data, enabling users to bypass the lengthy timelines typically required for full LCA studies [43] [40].

Key Technical Specifications

Table 1: Core Features of the PMI-LCA Tool

| Feature | Description | Data Source |

|---|---|---|

| Primary Function | High-level estimation of PMI and environmental LCA information | ACS GCI Pharmaceutical Roundtable [43] |

| System Boundary | Cradle-to-gate (focused on API synthesis) | Tool documentation [44] |

| LCA Data Source | Ecoinvent database | Tool documentation [43] |

| Environmental Indicators | Mass net, energy, global warming potential (GWP), acidification, eutrophication, water depletion | ACS GCI Nexus Blog [40] |

| Process Flexibility | Handles linear and convergent syntheses, multiple output streams, and recycle streams | User Requirements Document [45] |

A key innovation of the PMI-LCA Tool is its user-friendly design aimed at chemists and engineers rather than Excel or LCA specialists [40]. The workbook format makes it transferable across organizations and allows users to compare multiple synthetic routes simply by creating copies of the workbook. Once process steps and materials are entered, automatic calculations generate customizable charts with both PMI and LCA results, enabling users to easily identify and prioritize steps that are less efficient or have greater life cycle impacts [40].

Comparative Analysis: PMI-LCA Tool vs. Alternative Assessment Methods

To objectively evaluate the PMI-LCA Tool's performance, it is essential to compare its capabilities against other available approaches for assessing environmental sustainability in pharmaceutical development.

Table 2: Method Comparison for Environmental Assessment of API Synthesis

| Assessment Method | System Boundaries | Data Requirements | Output Metrics | Time Investment | Key Limitations |

|---|---|---|---|---|---|

| PMI-LCA Tool | Cradle-to-gate [44] | Moderate (process inputs) | PMI + 6 LCA indicators [40] | Hours to days | Uses average values for material classes [40] |

| Traditional PMI | Gate-to-gate [41] | Low (mass inputs/outputs) | Mass intensity only | Hours | Misses upstream impacts [41] |

| Full LCA | Cradle-to-grave [42] | High (complete inventory) | Multiple impact categories | Weeks to months | Data-intensive; expensive [42] [46] |

| FLASC Tool | Cradle-to-gate | Moderate | LCA indicators | Days | Uses proxies for missing data [46] |

| ChemPager | Gate-to-gate | Low to moderate | PMI-focused | Hours | Limited LCA integration [46] |

The PMI-LCA Tool occupies a strategic middle ground between simplistic mass-based metrics and comprehensive LCA. While traditional PMI calculations with gate-to-gate boundaries have been shown to poorly approximate environmental impacts, the PMI-LCA Tool's incorporation of upstream resource consumption through life cycle inventory data significantly strengthens its correlation with actual environmental impacts [41]. However, recent research indicates that even expanded mass-based metrics cannot fully capture the multi-criteria nature of environmental sustainability, as different environmental impacts are approximated by distinct sets of key input materials [41].

Quantitative Performance Benchmarks

In practical applications, the PMI-LCA Tool has demonstrated significant utility in guiding process optimization. A notable case study involving the development of MK-7264 API showed a reduction of PMI from 366 to 88 over the course of process development when using the tool to prioritize improvements [44]. The tool's ability to provide rapid feedback enables iterative assessment throughout process development, starting when a chemical route has been established and continuing through commercialization to ensure environmental metrics trend positively [40].

Methodology: Experimental Protocol for Tool Application

To ensure consistent and reproducible results when using the PMI-LCA Tool, researchers should follow a structured experimental protocol for tool application and data collection.

Data Collection and Input Specifications

- Process Deconstruction: Break down the synthetic route into discrete steps, identifying all input materials (reactants, reagents, catalysts, solvents) and outputs (products, by-products) for each step [40].

- Mass Balancing: Calculate precise mass quantities for all materials involved in the process, normalized to a fixed amount of final API (typically 1 kg) [46].

- Material Classification: Categorize input materials according to the tool's classification system (e.g., solvents, reagents, catalysts) to ensure appropriate LCA impact factors are applied [40].

- Process Topology Definition: Specify the relationships between process steps, including linear sequences, convergent syntheses, and recycle streams, using the tool's topology features [45].

- Impact Assessment: Run the automated calculation engine to generate PMI and LCA results, then review error flags or warnings for data inconsistencies [40].

Validation and Quality Control Procedures

- Error Checking: Address all data-entry error notifications provided by the tool's automated detection system before finalizing calculations [40].

- Sensitivity Analysis: Test the influence of key assumptions by varying critical parameters and observing their impact on final results.

- Cross-Verification: For critical processes, compare tool outputs with results from other assessment methods where feasible [46].

- Documentation: Maintain comprehensive records of all input assumptions, material classifications, and calculation settings to ensure reproducibility.

Successful application of the PMI-LCA Tool requires integration with complementary resources and data sources that support comprehensive sustainability assessment.

Table 3: Essential Research Reagent Solutions and Resources

| Resource Category | Specific Examples | Function in Sustainability Assessment |

|---|---|---|

| LCA Databases | Ecoinvent database | Provides life cycle inventory data for common chemicals and materials [43] |

| Solvent Selection Guides | ACS GCI Solvent Selection Guide | Informs substitution of hazardous solvents with greener alternatives [42] |

| Reagent Assessment Tools | ACS GCI Reagent Guide | Evaluates environmental and safety aspects of reagent choices [42] |

| Chemical Inventory Systems | Internal company databases | Tracks chemical properties, hazards, and handling requirements |

| Process Mass Tracking | Laboratory information management systems (LIMS) | Captures experimental mass data for input into PMI calculations |

The PMI-LCA Tool is designed to function effectively with the pre-loaded LCA data sourced from ecoinvent, but users should recognize that this database contains primarily standard chemical production data that may not fully reflect the higher purity and stricter specifications of pharmaceutical-grade materials [45]. For specialized materials, users may need to supplement with additional data sources or apply appropriate adjustment factors.

Future Development and Strategic Direction

The ACS GCI Pharmaceutical Roundtable is actively working to enhance the PMI-LCA Tool's capabilities and accessibility. A significant development initiative is underway to transform the tool from its current Excel-based format to a web-based application [45]. This transition aims to address current limitations related to version control, benchmarking capabilities, and handling of data entry errors while maintaining the tool's core functionality [45].

The planned web version would allow for regular updates with the most recent LCA data and facilitate the development of a common database of benchmark information from Roundtable members [40]. This evolution aligns with the broader research direction suggesting that future work should focus on simplified LCA methods that more directly reflect environmental performance, rather than relying solely on mass-based proxies [41]. As the pharmaceutical industry continues its transition toward a defossilized future, the accuracy and applicability of sustainability assessment tools will be critical for ensuring genuine environmental benefits [41].

The PMI-LCA Tool represents a significant advancement in green chemistry metrics, offering pharmaceutical researchers a practical yet comprehensive approach to evaluating the environmental performance of synthetic routes. By integrating traditional mass-based PMI calculations with life cycle assessment principles, the tool provides a more holistic perspective on process impacts while maintaining the practicality essential for iterative process development. When applied according to standardized experimental protocols and complemented with appropriate research resources, the PMI-LCA Tool enables effective identification of environmental hotspots and guides prioritization of development efforts. As the field continues to evolve, the tool's planned transition to a web-based platform promises to further enhance its accessibility and functionality, strengthening its role in promoting sustainable by design pharmaceutical manufacturing.

The pharmaceutical industry faces increasing pressure to mitigate its substantial environmental footprint, characterized by extensive waste generation and high energy consumption. Traditional mass-based metrics, such as Process Mass Intensity (PMI) and E-factor, have been cornerstone tools for measuring waste and material efficiency in Active Pharmaceutical Ingredient (API) synthesis. While these metrics are valuable for providing a quick snapshot of material use, they offer a limited view of the broader environmental impact, as they do not account for factors like reagent toxicity, energy consumption, or supply chain effects [47] [9].

To address this gap, the industry is transitioning towards more comprehensive Life Cycle Assessment (LCA) methodologies. However, conducting a full LCA is often data-intensive and time-consuming, creating a significant barrier to its adoption during early-stage process development where decisions have the greatest impact on sustainability. This guide examines two advanced methodologies designed to bridge this gap: the Fast Life Cycle Assessment of Synthetic Chemistry (FLASC) tool and the Innovation Green Aspiration Level (iGAL 2.0) metric. These tools provide researchers with the means to integrate more holistic environmental considerations into pharmaceutical development without compromising the fast pace of drug discovery and process optimization [47] [48].

The following table summarizes the core characteristics of these two complementary tools.

Table 1: Fundamental Characteristics of FLASC and iGAL

| Feature | FLASC (Fast Life Cycle Assessment of Synthetic Chemistry) | iGAL 2.0 (Innovation Green Aspiration Level) |

|---|---|---|

| Primary Developer | GlaxoSmithKline (GSK) | Developed in 2021; finds broad adoption in pharmaceutical process development [47] |

| Core Function | Simplified, cradle-to-gate Life Cycle Assessment [47] | Benchmarking new processes against industry-average sustainability performance [47] |

| Methodological Approach | Life Cycle Inventory (LCI) methodology to solve limited data availability; uses class-averages as proxies for missing data [47] [46] | Compares mass-based metrics (PMI and complete E-factor), yield, and process convergence of new processes to existing processes [47] |

| Key Output | Estimates environmental impact categories (e.g., Global Warming Potential) [47] | Relative Process Greenness (RPG) Index, expressing comparison result as a quantitative score [47] |

| Main Advantage | Provides a broader environmental perspective than mass-based metrics alone, tailored to pharmaceutical processes [47] | Provides a clear, quantitative benchmark for evaluating and communicating process innovation and greenness [47] |

Detailed Methodologies and Workflows

The FLASC Tool Protocol

The FLASC tool was developed specifically to address two key challenges in pharmaceutical manufacturing: limited data availability for precursors and the high time-pressure of drug development [47]. Its methodology can be broken down into three key phases:

- Life Cycle Inventory (LCI) Compilation: The process begins by creating an inventory of all material and energy inputs for the API synthesis. For chemicals present in standard LCA databases (e.g., ecoinvent), primary data is used. For novel or complex intermediates typically absent from these databases, FLASC employs a proxy methodology, using environmental impact data from analogous chemical classes to fill the data gaps [47] [46].

- Impact Assessment Calculation: The tool then performs a cradle-to-gate analysis. This calculates the environmental impact associated with all stages from raw material extraction ("cradle") up to the factory gate of the API. It utilizes the compiled LCI to quantify impacts across categories such as Global Warming Potential (GWP), which is measured in kg CO₂-equivalent, and other relevant indicators [47] [46].

- Result Interpretation and Hotspot Identification: The final output provides an environmental profile of the process, allowing scientists to identify "hotspots"—specific steps or reagents that contribute most significantly to the overall environmental impact. This enables targeted process optimization for sustainability [47].

The workflow for implementing FLASC in process development is visualized below.

The iGAL 2.0 Metric Protocol

The iGAL 2.0 metric introduces a benchmarking approach designed to measure how a new process compares against established industry standards. Its procedure is as follows:

- Define the Aspiration Level: iGAL 2.0 first establishes a "green aspiration level," which is a benchmark based on the average PMI and E-factor of a wide array of existing pharmaceutical processes. This baseline represents current typical industry performance [47].

- Calculate Process Mass Intensity (PMI): The PMI for the new process is calculated. PMI is defined as the total mass of materials used to produce a specified mass of product, including reactants, solvents, and reagents. It is a key mass-based metric for material efficiency [47].

- Formula: PMI = Total Mass Input (kg) / Mass of Product (kg)

- Compute the Relative Process Greenness (RPG): The tool compares the PMI and other metrics (like E-factor and convergence) of the new process to the established iGAL baseline. The output of this comparison is the Relative Process Greenness (RPG) index. An RPG greater than 1 indicates that the new process is greener than the industry average, while an RPG less than 1 shows there is room for improvement [47].

The logical sequence for determining a process's greenness using iGAL is shown in the diagram below.

Comparative Analysis: Performance and Application

Quantitative Comparison of Outputs and Data Requirements

The choice between FLASC and iGAL depends heavily on project goals, data availability, and the desired type of environmental insight. The table below provides a detailed, side-by-side comparison to guide this decision.

Table 2: Detailed Comparative Analysis of FLASC and iGAL 2.0

| Aspect | FLASC | iGAL 2.0 |

|---|---|---|

| Primary Output | Estimated impacts for LCA categories (e.g., GWP, ODP, AP) [47]. | Relative Process Greenness (RPG) Index, a single score for benchmarking [47]. |

| Strengths | - Provides a broader, multi-criteria environmental perspective [47].- Tailored to the chemical complexity of pharma processes [47].- Helps identify specific environmental hotspots beyond mass [47]. | - Provides a clear, easy-to-communicate benchmark for process innovation [47].- Simple data inputs (mass-based) [47].- Fast and easy to adopt in early-phase route assessment [47]. |

| Limitations | - Relies on proxy data for novel chemicals, which can affect accuracy [46].- More complex than simple mass metrics, requiring LCA expertise [47]. | - Does not directly assess toxicity, energy, or other LCA impact categories [47].- Relies on the quality and representativeness of the industry-average baseline [47]. |