Green Chemistry and the Pollution Prevention Act: A Sustainable Framework for Modern Drug Development

This article explores the critical synergy between the Pollution Prevention Act (PPA) of 1990 and the principles of Green Chemistry, providing a strategic framework for researchers, scientists, and drug development...

Green Chemistry and the Pollution Prevention Act: A Sustainable Framework for Modern Drug Development

Abstract

This article explores the critical synergy between the Pollution Prevention Act (PPA) of 1990 and the principles of Green Chemistry, providing a strategic framework for researchers, scientists, and drug development professionals. It details how the PPA's foundational mandate for source reduction is operationally implemented in biomedical R&D through Green Chemistry methodologies. The content covers the historical and policy context, practical application of the 12 Principles in drug design and synthesis, strategies to overcome industry adoption barriers, and validation through award-winning case studies. By integrating these concepts, the pharmaceutical industry can achieve significant environmental benefits, cost savings, and develop more sustainable therapeutic solutions.

The Policy and Philosophy of Prevention: From the PPA to Green Chemistry

The Pollution Prevention Act (PPA) of 1990 represents a transformative moment in United States environmental policy, marking a decisive shift from managing pollution after it is generated to preventing its creation in the first place [1]. Enacted on November 5, 1990, as part of the Omnibus Budget Reconciliation Act, this legislation established a national policy that prioritizes source reduction over conventional end-of-pipe treatment and disposal methods [2] [3]. The fundamental premise of the Act is that preventing pollution at the source is fundamentally different and more desirable than waste management and pollution control [4]. This legislative framework emerged from Congressional findings that the United States spent tens of billions of dollars annually controlling pollution while significant opportunities for cost-effective prevention through changes in production, operation, and raw materials use remained largely untapped [4] [3].

The Act's significance extends beyond its immediate regulatory impact, serving as the statutory foundation for emerging disciplines like green chemistry. By emphasizing the reduction or elimination of hazardous substance production at the design stage, the PPA provided the philosophical and legal underpinning for a more sustainable approach to chemical research, manufacturing, and consumption [5] [6]. This article examines the core provisions, implementation mechanisms, and scientific applications of the PPA, with particular attention to its relevance for researchers, scientists, and drug development professionals engaged in advancing green chemistry principles.

Core Legislative Framework and Key Definitions

Statutory Findings and National Policy

The Pollution Prevention Act established a clear hierarchy for environmental management, declaring it the national policy of the United States that [4] [3]:

- Pollution should be prevented or reduced at the source whenever feasible

- Pollution that cannot be prevented should be recycled in an environmentally safe manner whenever feasible

- Pollution that cannot be prevented or recycled should be treated in an environmentally safe manner whenever feasible

- Disposal or other release into the environment should be employed only as a last resort and should be conducted in an environmentally safe manner

This policy marked a radical departure from previous environmental regulations that primarily focused on waste treatment and disposal, creating what is often described as the pollution prevention hierarchy [4]. Congress justified this new approach with specific findings, noting that source reduction opportunities were often not realized because existing regulations focused industrial resources on compliance with treatment and disposal requirements rather than prevention [3].

Key Definitions Under the PPA

The Act established precise definitions that have shaped its implementation and application, particularly for scientific and industrial contexts.

Table: Key Definitions in the Pollution Prevention Act of 1990

| Term | Definition | Significance |

|---|---|---|

| Source Reduction | Any practice that: (i) reduces amount of hazardous substance entering waste streams or released to environment; (ii) reduces hazards to public health and environment associated with such releases [4]. | Core concept of the Act; distinguishes prevention from management |

| Source Reduction Techniques | Equipment/technology modifications, process/procedure modifications, product reformulation/redesign, raw material substitution, improvements in housekeeping/maintenance/training/inventory control [4] [3]. | Provides specific categories for implementation |

| Multimedia | Water, air, and land [4] | Emphasizes cross-media approach rather than single-medium focus |

| Toxic Chemical | Any substance on the list described in section 313(c) of the Superfund Amendments and Reauthorization Act of 1986 (SARA) [3] | Links PPA to existing regulatory framework |

Crucially, the statute explicitly excludes from the definition of source reduction any practice that alters the physical, chemical, or biological characteristics or volume of a hazardous substance through processes not integral to and necessary for production or service provision [4]. This distinction maintains the focus on fundamental process changes rather than incremental adjustments to existing waste streams.

EPA Implementation Framework and Programs

Organizational Structure and Strategic Functions

The PPA mandated the Environmental Protection Agency (EPA) to establish an independent office to carry out the Administrator's functions under the Act, with authority to review and advise the Agency's single-medium program offices on multimedia approaches to source reduction [4] [3]. This organizational structure was designed to overcome the historical lack of attention to source reduction and ensure a coordinated approach across traditional regulatory domains.

The Act charged the EPA Administrator with developing and implementing a comprehensive strategy to promote source reduction, including specific functions [4] [3]:

- Establishing standard methods of measurement for source reduction

- Coordinating source reduction activities across agency offices and other federal agencies

- Facilitating technology adoption by businesses through clearinghouse and state matching grants

- Developing improved methods for data coordination and public access

- Establishing a training program on source reduction opportunities for officials

- Identifying and recommending elimination of barriers to source reduction

- Establishing an annual award program to recognize outstanding company programs

Key EPA Programs Established Under the PPA

The implementation of the PPA has led to the creation of numerous programs and initiatives designed to advance pollution prevention across various sectors.

Table: Select EPA Programs Implementing Pollution Prevention Act Mandates

| Program Name | Primary Focus | Key Functions | Relevance to Research |

|---|---|---|---|

| Pollution Prevention (P2) Grant Program | Funding state, tribal, and business implementation of P2 strategies [1] | Provides matching grants for technical assistance programs [4] | Supports research translation to practical applications |

| Safer Choice Program | Consumer and industrial product safety [1] | Certifies and labels safer cleaning products and alternatives [1] | Creates market for greener chemical formulations |

| Green Chemistry Program | Advancement of sustainable chemistry [1] | Promotes development of safer, non-toxic chemicals; awards for innovation [1] [6] | Direct research application and recognition |

| Toxics Release Inventory (TRI) | Tracking hazardous substance use and release [1] | Mandates reporting on toxic substance releases and reduction efforts [4] | Provides data for research and baseline measurements |

The Green Chemistry Program, launched under the auspices of the PPA, deserves particular emphasis for researchers. This program originated from the EPA's Alternative Synthetic Pathways for Pollution Prevention research program in 1991, which emphasized reducing or eliminating hazardous substance production rather than managing chemicals after their release [6]. The program later expanded to include development of greener solvents and safer chemicals, formally adopting the name "green chemistry" in 1996 [6].

Technical Implementation and Measurement Frameworks

Source Reduction and Recycling Data Collection

The PPA significantly expanded the Toxics Release Inventory (TRI) reporting requirements under the Emergency Planning and Community Right-to-Know Act (EPCRA). Facility owners or operators required to file annual toxic chemical release forms must now include a toxic chemical source reduction and recycling report for the preceding calendar year [4]. This section took effect with the first full calendar year beginning after November 5, 1990 [4].

The required report must set forth specific information on a facility-by-facility basis for each toxic chemical [4] [3]:

- Quantity of the chemical entering any waste stream prior to recycling, treatment, or disposal during the calendar year, with percentage change from previous year

- Amount of the chemical recycled (at the facility or elsewhere), percentage change from previous year, and recycling process used

- Source reduction practices used, categorized as:

- Equipment, technology, process, or procedure modifications

- Reformulation or redesign of products

- Substitution of raw materials

- Improvements in housekeeping, maintenance, training, inventory control, materials handling, or other operational phases

- Amount expected to be reported for the two subsequent calendar years, expressed as percentage change

- Production ratio (reporting year to previous year) or appropriate alternative index

- Techniques used to identify source reduction opportunities (employee recommendations, audits, team management, material balance audits)

The Act specifies that when actual measurements of chemical quantities entering waste streams are not readily available, reasonable estimates should be made based on best engineering judgment [4].

Source Reduction Clearinghouse and Information Dissemination

The PPA mandated the establishment of a Source Reduction Clearinghouse to compile information including a computer database containing management, technical, and operational approaches to source reduction [4]. The Administrator is required to use the clearinghouse to [4]:

- Serve as a center for source reduction technology transfer

- Mount active outreach and education programs by states

- Collect and compile information on state program operation and success

The clearinghouse database must be made available to the public and permit entry and retrieval of information to any person, facilitating the dissemination of successful pollution prevention strategies across industrial sectors [4].

The Scientist's Toolkit: Research Reagent Solutions for Green Chemistry

The implementation of green chemistry principles under the PPA framework has driven the development and adoption of specific research reagents and methodologies that align with source reduction goals. The following table details key research solutions relevant to scientists and drug development professionals.

Table: Key Research Reagent Solutions for Pollution Prevention aligned with PPA Goals

| Reagent/Methodology | Function | Source Reduction Benefit | Research Application |

|---|---|---|---|

| Renewable Feedstocks | Biomass-derived starting materials [6] | Reduces dependency on finite resources; often biodegradable [6] | Synthesis of pharmaceutical intermediates from bio-based sources |

| Green Solvents (e.g., water, supercritical CO₂) | Alternative reaction media [6] | Replaces volatile organic compounds and toxic solvents [6] | Safer extraction and reaction processes in drug development |

| Selective Catalysts | Increase reaction efficiency [6] | Reduces energy consumption and unwanted byproducts [6] | Enables atom-economic synthesis pathways for complex molecules |

| Real-Time Analysis | In-process monitoring [6] | Prevents formation of hazardous substances; allows immediate correction [6] | Process analytical technology (PAT) for manufacturing optimization |

These research tools directly support the 12 Principles of Green Chemistry formulated by Paul Anastas and John Warner in 1998, which provide a specific research agenda for advancing the pollution prevention goals of the PPA [6]. Of these principles, atom economy—originally suggested by Barry Trost in 1973—has become a central concept, providing a more reliable indicator of reaction efficiency than traditional yield calculations by accounting for all reactants and products [6].

Experimental Protocol: Framework for Source Reduction Implementation

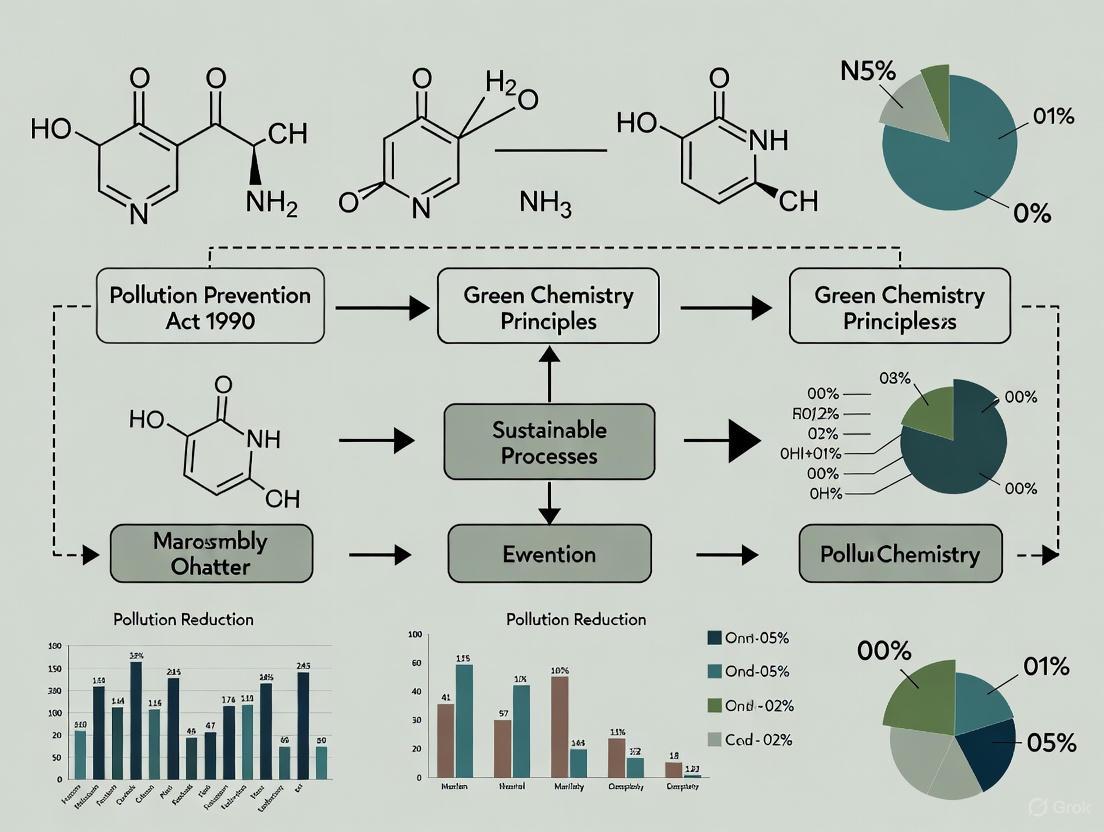

The following diagram outlines a systematic methodology for implementing source reduction strategies in research and development contexts, aligning with PPA objectives:

Process Framework for Source Reduction Implementation

This framework provides a structured approach for researchers to identify, implement, and validate source reduction opportunities in laboratory and industrial settings. The process emphasizes continuous improvement through measurement and iteration, reflecting the PPA's focus on ongoing pollution prevention rather than one-time interventions.

Material Balance Audit Methodology

The initial assessment phase requires a comprehensive material balance audit to quantify all inputs and outputs of a process [4]. This experimental protocol involves:

- Input Documentation: Record masses and volumes of all raw materials, solvents, catalysts, and reagents entering the process

- Output Characterization: Quantify all products, by-products, waste streams, and emissions

- Reconciliation Analysis: Account for mass discrepancies, which often represent unmeasured waste streams or fugitive emissions

- Hazard Assessment: Evaluate the toxicity, persistence, and bioaccumulation potential of all output streams

This methodology directly supports the PPA's reporting requirements for facilities to document "the quantity of the chemical entering any waste stream prior to recycling, treatment, or disposal" [4]. For pharmaceutical researchers, this approach enables identification of inefficient synthetic steps where atom economy can be improved.

Source Reduction Opportunity Assessment

The evaluation phase involves systematic analysis of potential source reduction strategies categorized under the PPA [4] [3]:

- Equipment/Technology Modifications: Install more efficient reactors, separation equipment, or monitoring systems

- Process/Procedure Modifications: Optimize reaction conditions (temperature, pressure, time) to improve yields

- Product Reformulation/Redesign: Modify molecular structures to reduce toxicity while maintaining efficacy

- Raw Material Substitution: Replace hazardous starting materials with safer alternatives

- Operational Improvements: Enhance inventory control, maintenance procedures, and training protocols

For each opportunity, researchers should document the anticipated environmental benefits, technical feasibility, and economic impact—including potential savings from reduced raw material, pollution control, and liability costs identified in the PPA's findings [4].

Pollution Prevention Hierarchy and Implementation Pathway

The conceptual framework established by the Pollution Prevention Act creates a clear hierarchy for environmental management, visualized in the following diagram:

Pollution Prevention Hierarchy under PPA

This hierarchy visually represents the fundamental policy declaration of the PPA, which establishes source reduction as the most desirable approach, followed by recycling, treatment, and finally disposal or release as a last resort [4] [3]. This conceptual framework guides researchers in prioritizing their pollution prevention efforts and aligns scientific innovation with statutory preferences.

The Pollution Prevention Act of 1990 provides the foundational policy framework for advancing green chemistry principles in research and industrial applications. By establishing source reduction as national policy, the PPA created both a mandate and opportunity for scientists to develop innovative approaches that prevent pollution at the design stage rather than managing it after generation [6]. The Act's implementation mechanisms—including technical assistance programs, the Source Reduction Clearinghouse, and expanded reporting requirements—create infrastructure supporting the translation of research innovations into practical applications [4] [1].

For drug development professionals and researchers, the PPA's emphasis on multimedia approaches and cross-media coordination encourages holistic thinking about the environmental impacts of chemical processes beyond single-issue concerns [4]. The integration of PPA objectives with green chemistry research represents a powerful convergence of policy and science, driving innovation toward more sustainable molecular design, synthetic methodologies, and manufacturing processes. This alignment between regulatory frameworks and scientific advancement continues to yield substantial environmental and economic benefits, fulfilling the Congressional finding that "there are significant opportunities for industry to reduce or prevent pollution at the source through cost-effective changes in production, operation, and raw materials use" [4].

The Pollution Prevention Act (PPA) of 1990 established a national policy that fundamentally reoriented environmental protection in the United States, declaring that pollution should be prevented or reduced at the source whenever feasible [4] [3]. This policy elevates source reduction—defined as any practice that reduces the amount of any hazardous substance, pollutant, or contaminant entering any waste stream or released into the environment prior to recycling, treatment, or disposal—as the most desirable approach in the environmental management hierarchy [4] [7] [3].

For researchers, scientists, and drug development professionals, source reduction is not merely a regulatory concept but a core principle of Green Chemistry. It aligns with goals of designing chemical syntheses and processes to be more efficient, less wasteful, and inherently safer. The PPA specifically outlines the modification of equipment, processes, and products as central techniques for achieving source reduction [4] [3]. This guide provides a technical examination of these core strategies, offering a framework for their application within industrial and research settings, particularly in the chemically intensive pharmaceutical sector.

Core Principles and Regulatory Foundation

The Pollution Prevention Act of 1990: A Legislative Framework

The PPA marked a pivotal shift from managing pollution after it is created to preventing its generation in the first place [1]. The Congress found that significant opportunities exist for industry to reduce pollution at the source through cost-effective changes in production, operation, and raw materials use, offering substantial savings in raw material, pollution control, and liability costs [4] [3]. The Act defines source reduction through key practices that form the basis of this guide [3]:

- Equipment and technology modifications

- Process and procedure modifications

- Reformulation or redesign of products

- Substitution of raw materials

- Improvements in housekeeping, maintenance, training, or inventory control

The Act explicitly excludes from this definition practices that alter a hazardous substance through processes not integral to production, thereby distinguishing true prevention from end-of-pipe treatment [3].

The Source Reduction Hierarchy and Green Chemistry

The PPA establishes a clear environmental management hierarchy, where source reduction is the top priority, followed by recycling, treatment, and as a last resort, disposal or release into the environment [4] [7]. This hierarchy is visually represented in the diagram below, which illustrates the multi-faceted approach to source reduction and its position as the preferred strategy.

Green Chemistry principles provide the scientific and technical means to operationalize this policy. The pursuit of atom economy, less hazardous chemical syntheses, and the design of safer chemicals are all manifestations of source reduction in practice [1] [8]. For the pharmaceutical industry, this translates to developing synthetic pathways that maximize the incorporation of starting materials into the final product, thereby minimizing waste generation at the source.

Technical Approaches to Source Reduction

The PPA categorizes source reduction activities into several key areas. The following sections detail these approaches with specific methodologies and examples relevant to chemical and pharmaceutical research.

Equipment and Technology Modifications

This strategy involves altering or upgrading physical equipment to enhance efficiency and reduce waste generation. In a research or pilot-scale environment, this often means designing and employing apparatus that improves reaction efficiency, enables solvent recovery, or minimizes losses.

Experimental Protocol: Implementing Closed-Loop Solvent Recovery Systems

- Objective: To reduce the volume of waste solvent generated in a multi-step synthesis process through on-site recovery and reuse.

- Materials:

- Reaction vessels and associated equipment for synthesis

- Distillation apparatus (fractionating column, condenser, receiving flasks)

- Solvent compatibility chart

- Analytical equipment (GC-MS, HPLC) for purity analysis

- Methodology:

- Waste Stream Characterization: Collect and segregate waste solvents from specific reaction steps. Analyze composition using GC-MS to identify primary components and contaminants.

- Compatibility Assessment: Cross-reference the chemical composition with material compatibility data to ensure the distillation equipment can safely handle the solvent mixture.

- Batch Distillation: Transfer the waste solvent to the distillation apparatus. Heat gradually, collecting fractions based on known boiling points of the constituent solvents.

- Purity Analysis: Analyze each distilled fraction using HPLC or GC-MS to determine purity. Establish a purity threshold (e.g., >99%) for reuse in synthetic steps.

- Reintegration: Reuse the purified solvent in the original or a less critical synthetic step (e.g., initial extraction vs. final crystallization). Monitor reaction yield and purity to ensure no adverse effects.

- Data Recording: Document the volume of waste collected, volume and purity of solvent recovered, and the success of its reuse in subsequent reactions.

Table 1: Quantitative Impact of Equipment Modification Techniques

| Technique | Industry Example | Reported Outcome | Relevance to Pharmaceutical R&D |

|---|---|---|---|

| Equipment Modification | A wood cabinet manufacturer moved a production line to a booth that increased the efficiency of its spray machines [9]. | Resulted in less waste of solvents like n-butyl alcohol [9]. | Optimizing reactor and isolation equipment design to improve material transfer and yield, reducing raw material use. |

| Technology Modification | A commercial gravure printer scheduled shifts to allow continuous equipment operation at peak temperatures [9]. | Reduced the frequency of cleanings, minimizing toluene waste generation [9]. | Employing flow chemistry or continuous processing to minimize solvent and material losses during batch-to-batch changeovers. |

| Process & Equipment Optimization | Facilities report "optimizing reaction conditions and modifying equipment, layout, or piping" [9]. | Reduces the amount of solvents like n-butyl alcohol or dichloromethane needed for a process [9]. | Implementing in-line analytics and process control to maintain optimal reaction conditions, maximizing yield and minimizing by-products. |

Process and Procedure Modifications

This involves changing operational parameters to increase efficiency and minimize waste. For scientists, this is the core of reaction optimization.

Experimental Protocol: Optimizing Reaction Parameters for Yield Maximization

- Objective: To systematically optimize a key synthetic reaction to maximize yield and atom economy, thereby reducing the generation of unwanted by-products.

- Materials:

- Starting materials and reagents

- Solvents

- Lab-scale reactor system (e.g., carousel, parallel reactor) with temperature and stirring control

- Analytical standards and equipment (HPLC, NMR) for yield and purity determination

- Methodology:

- Baseline Establishment: Run the reaction under standard literature or previously established conditions to determine baseline yield and by-product profile.

- Parameter Screening (Design of Experiments - DoE): Instead of one-variable-at-a-time, use a statistical DoE approach to vary critical parameters simultaneously (e.g., temperature, reaction time, reagent stoichiometry, catalyst loading, solvent volume).

- High-Throughput Experimentation: Utilize parallel reactor systems to conduct multiple experimental conditions concurrently.

- Analysis and Modeling: Analyze the yield and purity outcomes for each experiment. Use statistical software to build a predictive model identifying the optimal parameter set.

- Verification: Run the reaction at the predicted optimum conditions to verify the model's accuracy and reproducibility.

- Data Recording: Record all reaction parameters, yields, and analytical data for each experiment. The model's R² value and the confirmation run results should be documented.

Table 2: Impact of Process and Procedure Modification Techniques

| Technique | Industry Example | Reported Outcome | Relevance to Pharmaceutical R&D |

|---|---|---|---|

| Operational Procedure | A wood kitchen cabinet manufacturer improved employee trainings to increase transfer efficiency [9]. | Reduced the amount of toluene used on site [9]. | Enhancing scientist and technician training on precise measurement and handling of high-value or hazardous reagents. |

| Process Optimization | A commercial printer continuously ran equipment at peak temperatures [9]. | Resulted in fewer cleanings that generate toluene waste [9]. | Optimizing work-up and purification sequences to reduce solvent and material use. |

| Input Material Change | Substitution of disputed chemicals in a recipe with more suitable ones [10]. | Reduces wastewater load and treatment costs [10]. | Replacing hazardous or persistent solvents with safer, bio-based alternatives (e.g., ethanol/water mixtures). |

Product Reformulation and Raw Material Substitution

This strategy focuses on redesigning the final product or replacing hazardous raw materials with safer, more environmentally benign alternatives. In drug development, this can relate to salt selection, excipient choice, or even active pharmaceutical ingredient (API) structural modification for better biodegradability.

Experimental Protocol: Substituting a Hazardous Solvent in a Reaction Step

- Objective: To identify and validate a safer, less toxic solvent alternative for a specific reaction step without compromising yield or purity.

- Materials:

- API intermediate

- Original solvent (e.g., dichloromethane, DMF)

- Candidate alternative solvents (e.g., 2-MeTHF, cyclopentyl methyl ether (CPME), ethyl acetate, water)

- Reaction and work-up equipment

- Analytical equipment (HPLC, NMR)

- Methodology:

- Solvent Selection: Consult a solvent selection guide (e.g., Pfizer's or CHEM21's) to identify potential substitutes with improved environmental, health, and safety (EHS) profiles.

- Small-Scale Screening: Perform the reaction at a small scale (e.g., 100 mg) using the original solvent and a panel of 3-5 candidate solvents.

- Performance Evaluation: Isolate the product and determine reaction yield and purity for each solvent. Compare results against the baseline.

- Work-up and Isolation Assessment: Evaluate the ease of work-up and product isolation in the promising alternative solvent(s). This may involve assessing partitioning, crystallization, or distillation behavior.

- Scale-Up and Purity Verification: Scale up the reaction using the most promising alternative solvent(s) to a gram-scale to confirm performance and ensure the isolated product meets all quality specifications.

- Data Recording: Document all solvent properties, reaction yields, purity data, and observations on work-up and isolation for each solvent tested.

Table 3: EPA-Reported Source Reduction Activities by Chemical (2019-2023) Data from the Toxics Release Inventory (TRI) shows how different chemicals are targeted by various source reduction activities. [9]

| Chemical | Primary Source Reduction Activity | Industry Sector Example |

|---|---|---|

| n-Butyl Alcohol | Process and Equipment Modifications | Optimizing reaction conditions and modifying equipment to reduce solvent needs [9]. |

| Styrene | Material Substitutions and Modifications | Replacing styrene in the manufacturing of plastics [9]. |

| Antimony & Compounds | Material Substitutions and Modifications | Replacing antimony compounds used in flame retardants, batteries, and electronics [9]. |

| Dichloromethane | Process and Equipment Modifications | Modifying equipment, layout, or piping to reduce the amount needed [9]. |

| Ammonia | Material Substitutions and Modifications | A rubber product manufacturer replaced ammonia with a non-TRI reportable chemical [9]. |

The relationships between these technical approaches and their implementation pathway are summarized in the following workflow, which maps the strategic decision-making process for source reduction.

The Scientist's Toolkit: Research Reagent Solutions for Source Reduction

Implementing source reduction in research requires specific tools and materials. The following table details key reagent solutions that facilitate the transition to greener chemistry practices.

Table 4: Essential Reagents and Technologies for Source Reduction in Research

| Tool/Reagent | Function in Source Reduction | Example Application |

|---|---|---|

| Bio-Based/Eco-Friendly Solvents | Substitute for hazardous conventional solvents (e.g., DCM, DMF, NMP), reducing toxicity and waste handling burdens. | Use of 2-Methyltetrahydrofuran (2-MeTHF) (from renewables) in place of THF for Grignard reactions or extractions. Use of Cyrene (dihydrolevoglucosenone) as a replacement for dipolar aprotic solvents. |

| Safer Catalysts | Replace toxic heavy metal catalysts (e.g., Pd, Cr, Hg) with more abundant, less toxic alternatives, reducing hazardous waste. | Use of iron or copper catalysts in cross-coupling reactions. Use of enzymes (biocatalysts) for stereoselective syntheses under mild conditions. |

| Renewable Starting Materials | Derive chemical feedstocks from biomass instead of petrochemical sources, conserving resources and closing the carbon cycle. | Using succinic acid or lactic acid derived from fermentation as building blocks for polymer or molecular synthesis. |

| In-line Analytics (PAT) | Enable real-time monitoring of reactions (Process Analytical Technology) to optimize conditions and endpoints, minimizing by-products and over-consumption of reagents. | Using in-line FTIR or Raman spectroscopy to track reaction progress and precisely quench upon completion, avoiding decomposition or side reactions. |

The Pollution Prevention Act of 1990 provides a powerful policy framework that makes source reduction the cornerstone of environmental protection. For the scientific community, particularly in drug development, this is not a regulatory burden but an opportunity to innovate. By systematically pursuing equipment and technology modifications, process and procedure modifications, and product reformulation or raw material substitution, researchers can design more efficient, economical, and environmentally sound processes. Embracing these principles, supported by the tools and methodologies outlined in this guide, is essential for advancing the goals of both the PPA and Green Chemistry, ultimately leading to a more sustainable future for the chemical sciences.

The paradigm of environmental management underwent a fundamental shift in 1990 with the United States Congress's approval of the Pollution Prevention Act [11]. This legislation officially established that the most effective method of environmental protection was to avoid generating pollution at its source, rather than relying on "end-of-pipe" control strategies [11]. This strategic pivot created the necessary policy framework for the emergence of Green Chemistry—a scientific and technical discipline dedicated to designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances [11].

Green Chemistry represents the scientific execution of pollution prevention, providing chemists and engineers with a practical framework of principles to implement this strategy at the molecular level. The approach recognizes chemistry's strategic role in achieving a sustainable civilization by redesigning existing chemical processes to align with environmental and economic objectives [11]. This technical guide explores the core principles, methodologies, metrics, and applications of Green Chemistry as a pollution prevention strategy for researchers, scientists, and drug development professionals.

The Principles of Green Chemistry as a Pollution Prevention Framework

The foundational framework of Green Chemistry was codified in the 12 Principles [11], which serve as actionable guidelines for designing chemical processes that prevent pollution and minimize environmental impact.

Core Principles for Research and Development

For experimental scientists, several principles hold particular significance in translating pollution prevention into laboratory practice:

Principle #1: Prevent Waste: It is better to prevent waste formation than to treat or clean up waste after it is formed. This principle establishes the foundational concept of pollution prevention as superior to pollution control [11].

Principle #2: Atom Economy: Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product. This principle emphasizes efficient material use at the molecular level [11].

Principle #5: Safer Solvents and Auxiliaries: The use of auxiliary substances should be made unnecessary wherever possible and innocuous when used [11]. Solvent selection represents one of the most impactful decisions in designing green synthetic protocols.

Principle #9: Catalysis: Catalytic reagents are superior to stoichiometric reagents due to their ability to promote higher efficiencies, lower energy requirements, and reduced waste generation [11].

Table: The 12 Principles of Green Chemistry as Applied to Pollution Prevention

| Principle Number | Principle | Pollution Prevention Application |

|---|---|---|

| 1 | Prevent Waste | Design syntheses to minimize by-product formation |

| 2 | Atom Economy | Maximize incorporation of starting materials into final product |

| 3 | Less Hazardous Syntheses | Design syntheses using and generating non-toxic substances |

| 4 | Designing Safer Chemicals | Design products to maintain efficacy while reducing toxicity |

| 5 | Safer Solvents | Minimize or eliminate solvent use; prefer water or green solvents |

| 6 | Energy Efficiency | Minimize energy requirements through ambient conditions |

| 7 | Renewable Feedstocks | Use biomass and renewable resources instead of depleting feedstocks |

| 8 | Reduce Derivatives | Avoid blocking/protecting groups that require additional reagents |

| 9 | Catalysis | Prefer catalytic over stoichiometric reagents |

| 10 | Design for Degradation | Design products to break down into innocuous degradation products |

| 11 | Real-time Analysis | Develop analytical methods for real-time pollution monitoring |

| 12 | Inherently Safer Chemistry | Choose substances that minimize accident potential |

Metrics for Quantifying Pollution Prevention

To evaluate the environmental impact of chemical processes and meaningfully compare alternatives, Green Chemistry employs quantitative metrics that provide objective measurements of pollution prevention effectiveness [11].

Key Environmental Performance Metrics

The Environmental factor (E-factor), introduced by Sheldon, is one of the most informative metrics for assessing process efficiency from a pollution prevention perspective [11]. It is defined as the ratio of kilograms of waste produced per kilogram of desired product. This simple calculation provides immediate insight into the environmental cost of a chemical process, with higher E-factors indicating greater waste generation and lower environmental efficiency.

Atom Economy is another crucial metric that calculates the proportion of reactant atoms that are incorporated into the final desired product, providing a theoretical minimum for waste generation potential [11]. Processes with high atom economy inherently generate less waste by molecular design.

Table: E-factor Values Across Chemical Industries

| Industry Sector | Annual Production (kg) | Typical E-factor | Waste Generated per kg Product (kg) |

|---|---|---|---|

| Oil Refining | 10⁶-10⁸ | ~0.1 | 0.1 |

| Bulk Chemicals | 10⁴-10⁶ | <1-5 | 1-5 |

| Fine Chemicals | 10²-10⁴ | 5-50 | 5-50 |

| Pharmaceuticals | 10¹-10³ | 25-100+ | 25-100+ |

Source: Adapted from Sheldon [11]

Green Chemistry in Practice: Methodologies and Experimental Protocols

Solvent Selection and Reduction Strategies

Solvents typically constitute the largest contribution to waste in chemical processes, particularly in pharmaceutical and fine chemical syntheses [11]. The phytochemistry community's response to Green Chemistry insights demonstrates both progress and ongoing challenges. While highly hazardous solvents like diethyl ether, benzene, and carbon tetrachloride have largely disappeared from use since 2010, problematic solvents such as chloroform, dichloromethane, and hexane remain regularly employed in purification procedures [12].

Experimental Protocol: Solvent-Free Heterogeneous Catalysis

Catalyst Preparation: Immobilize homogeneous catalyst on a solid support (e.g., silica, polystyrene) designed to maintain structural integrity without swelling under solvent-free conditions [11].

Reactor Setup: Employ a continuous-flow reactor system with temperature control and pressure monitoring capabilities [11].

Reaction Execution: Pass neat substrates through the solid catalyst bed under optimized flow conditions (typically 0.1-1.0 mL/min) and temperature (varies by reaction).

Product Isolation: Collect effluent and separate products using minimal solvent (primarily for catalyst rinsing).

Catalyst Reuse: Regenerate catalyst in-line or ex-situ for subsequent reaction cycles.

This methodology addresses multiple Green Chemistry principles by eliminating solvents, enabling catalysis, facilitating energy efficiency, and allowing continuous processing [11].

Advanced Reactor Technologies for Pollution Prevention

Continuous-flow reactors in micro or miniaturized systems offer significant pollution prevention advantages over traditional batch processes, including higher throughput per unit volume and time, enhanced safety profiles, and reduced waste generation [11].

This integrated reactor system exemplifies the scientific execution of pollution prevention by combining multiple green chemistry principles: energy efficiency, waste prevention, catalysis, and real-time analysis.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table: Green Chemistry Research Reagents and Materials

| Reagent/Material | Function | Green Chemistry Advantage |

|---|---|---|

| Heterogeneous Catalysts (Immobilized metals, enzymes) | Accelerate reactions without contamination | Reusable, separable, reduce metal waste |

| Bio-based Solvents (Cyrene, 2-MeTHF, limonene) | Replace traditional VOCs | Renewable feedstocks, reduced toxicity |

| Water as Reaction Medium | Solvent for aqueous-phase chemistry | Non-toxic, non-flammable, inexpensive |

| Renewable Feedstocks (Biomass, agricultural waste) | Raw materials for synthesis | Reduce petroleum dependence, carbon neutral |

| Solid Supported Reagents | Facilitate purification without solvents | Enable solvent-free reactions, easy separation |

Industrial Applications and Market Implementation

The translation of Green Chemistry principles from research laboratories to industrial practice has created substantial economic value while advancing pollution prevention objectives. The global green chemicals market is projected to grow from USD 14.2 billion in 2025 to approximately USD 30.2 billion by 2035, reflecting a compound annual growth rate (CAGR) of 7.8% [13].

Market Adoption by Sector

The construction sector represents the largest application segment for green chemicals, accounting for 26.6% of market demand in 2025 [13]. This dominance is driven by green building certification programs (LEED, BREEAM), regulatory requirements for VOC reduction, and increasing demand for energy-efficient buildings [13].

The bio-alcohols segment leads product adoption with 34.7% market share in 2025, serving as versatile, sustainable alternatives to petroleum-based alcohols in solvents, fuels, and chemical intermediates [13]. Their established production technologies and cost competitiveness make them foundational to many green chemistry initiatives.

Table: Green Chemicals Market Growth by Country/Region

| Country/Region | Projected CAGR (2025-2035) | Key Growth Drivers |

|---|---|---|

| China | 10.5% | Massive industrial scale, government support, carbon neutrality goals |

| India | 9.8% | Agricultural feedstock availability, sustainability initiatives |

| Germany | 9.0% | Technological innovation, circular economy policies |

| France | 8.2% | Biorefinery development, agricultural valorization |

| United Kingdom | 7.4% | Sustainable chemistry research, innovation priorities |

| United States | 6.6% | Established bio-based infrastructure, corporate sustainability |

| Brazil | 5.9% | Agricultural resources, biofuel programs |

Source: Adapted from Future Market Insights [13]

Green Chemistry in Drug Development: Specialized Applications

The pharmaceutical industry presents unique challenges and opportunities for Green Chemistry implementation, particularly given the high E-factors (25-100+) associated with drug synthesis [11].

Solvent Substitution in Phytochemistry Research

Analysis of highly cited phytochemistry papers from 1990-2019 reveals significant advances in extraction procedures, with elimination of highly hazardous solvents like diethyl ether, benzene, and carbon tetrachloride in post-2010 publications [12]. However, purification procedures have shown less progress, with chloroform, dichloromethane, and hexane remaining in regular use [12].

Experimental Protocol: Green Extraction of Natural Products

Sample Preparation: Plant material is lyophilized and ground to consistent particle size (0.5-2.0 mm).

Green Solvent Selection: Employ ethanol-water mixtures or ethyl acetate as replacements for hexane, chloroform, or dichloromethane [12].

Extraction Technique: Use ultrasound-assisted extraction (40 kHz, 30-60°C) or microwave-assisted extraction (300-500W, controlled temperature) to reduce extraction time and solvent consumption.

Solvent Recovery: Implement fractional distillation or membrane separation for solvent recycling (75-90% recovery achievable).

Analysis: Utilize HPLC-MS or GC-MS with green solvent-compatible columns for metabolite profiling.

This approach can reduce hazardous solvent use by 60-80% while maintaining extraction efficiency of target natural products [12].

This decision-making protocol provides a systematic approach to solvent selection that aligns with the pollution prevention goals of the 1990 Act by prioritizing elimination, then substitution, and finally optimization of solvent use.

Future Directions and Research Priorities

The continued evolution of Green Chemistry as the scientific execution of pollution prevention depends on advancing several key research areas:

Technological Innovations

Advanced Biocatalysis: Engineered enzymes with expanded substrate scope and stability in non-aqueous media will enable more efficient biotransformations with reduced waste generation [13].

Continuous-flow Bioprocessing: Integration of biological and chemical synthesis in continuous-flow systems will minimize solvent use, enhance energy efficiency, and improve process control [11].

Circular Economy Integration: Designing chemicals and processes that incorporate end-of-life considerations, including biodegradability and recyclability, will close material loops and reduce waste accumulation [13].

Educational and Cultural Shifts

Wider adoption of Green Chemistry requires foundational changes in how chemistry is taught and practiced. The "12 Principles" must become integrated into core chemistry curricula rather than being treated as a specialized topic [11]. Furthermore, research assessment criteria should value environmental performance metrics alongside traditional measures like yield and selectivity.

Green Chemistry represents the essential scientific framework for executing the pollution prevention mandate established by the 1990 Pollution Prevention Act. By providing principles, metrics, and methodologies for designing chemical products and processes that minimize environmental impact, it transforms the abstract goal of pollution prevention into practical, implementable science. For researchers, scientists, and drug development professionals, embracing this approach is not merely regulatory compliance but an opportunity for innovation that aligns economic, environmental, and scientific objectives. As the field continues to evolve through advances in biotechnology, reactor design, and circular economy principles, Green Chemistry will increasingly become the standard practice for chemistry rather than a specialized alternative—fulfilling the promise of pollution prevention through molecular design.

The Pollution Prevention Act (PPA) of 1990 marked a transformative shift in United States environmental policy, establishing a national mandate that "pollution should be prevented or reduced at the source whenever feasible" [4] [14]. This legislative framework moved beyond traditional end-of-pipe pollution control strategies to prioritize source reduction—any practice that reduces the amount of hazardous substances entering any waste stream prior to recycling, treatment, or disposal [4] [1]. The PPA defined source reduction through specific technological and operational approaches including equipment modifications, process improvements, product reformulation, and raw material substitution [4].

It was within this regulatory context that green chemistry emerged as a scientific discipline. In 1991, the U.S. Environmental Protection Agency (EPA) launched the Alternative Synthetic Pathways for Pollution Prevention research program under the auspices of the PPA [6]. This program represented a radical departure from previous initiatives by emphasizing reduction or elimination of hazardous substance production rather than managing these chemicals after release into the environment [6]. The term "green chemistry" was officially adopted in 1996, and the discipline was crystallized in 1998 when Paul Anastas and John Warner formulated the 12 Principles of Green Chemistry [15] [6]. These principles provide a systematic framework for designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances [14].

The 12 Principles of Green Chemistry: A Technical Framework

The 12 Principles of Green Chemistry translate the pollution prevention mandate of the PPA into specific, actionable guidelines for chemical research, development, and design. These principles serve as the foundation for sustainable molecular design across pharmaceutical, materials, and industrial chemistry sectors [15] [16].

Principle 1: Prevention

It is better to prevent waste than to treat or clean up waste after it has been created [15]. This principle embodies the core philosophy of the PPA, focusing on waste avoidance rather than remediation. In pharmaceutical manufacturing, where waste generation historically exceeded 100 kilos per kilo of active pharmaceutical ingredient (API), applying this principle has achieved dramatic reductions—sometimes as much as ten-fold [15].

Table 1: Waste Measurement Metrics in Green Chemistry

| Metric | Calculation | Ideal Value | Application |

|---|---|---|---|

| E-Factor | Total waste mass (kg) / Product mass (kg) | 0 | Oil refining: <0.1; Pharmaceuticals: 25-100 [17] |

| Process Mass Intensity (PMI) | Total mass in process (kg) / Product mass (kg) | 1 | Preferred by ACS Green Chemistry Institute Pharmaceutical Roundtable [15] |

Principle 2: Atom Economy

Synthetic methods should be designed to maximize incorporation of all materials used in the process into the final product [15]. Developed by Barry Trost, atom economy provides a more comprehensive efficiency measure than traditional yield calculations by accounting for all reactants [15] [6]. A reaction with 100% yield may have only 50% atom economy, meaning half the mass of reactant atoms is wasted [15].

Atom Economy (%) = (FW of atoms utilized / Sum of FW of all reactants) × 100 [17]

Principle 3: Less Hazardous Chemical Syntheses

Wherever practicable, synthetic methods should be designed to use and generate substances that possess little or no toxicity to human health and the environment [15]. This principle encourages chemists to consider the inherent hazards of all substances in a synthetic pathway, not just the desired transformation [15].

Principle 4: Designing Safer Chemicals

Chemical products should be designed to preserve efficacy of function while reducing toxicity [15]. This requires understanding structure-activity relationships and applying toxicological principles during molecular design [15]. For example, designing chemicals to be less bioavailable or more readily metabolized to non-toxic compounds reduces hazard potential [15].

Principle 5: Safer Solvents and Auxiliaries

The use of auxiliary substances (e.g., solvents, separation agents) should be made unnecessary wherever possible and innocuous when used [14]. Solvents often account for the majority of waste in pharmaceutical production [18]. The move toward solvent-free mechanochemistry and water-based reactions represents significant progress in this area [18].

Principle 6: Design for Energy Efficiency

Energy requirements of chemical processes should be recognized for their environmental and economic impacts and should be minimized [14]. This includes conducting reactions at ambient temperature and pressure whenever possible [14].

Principle 7: Use of Renewable Feedstocks

A raw material or feedstock should be renewable rather than depleting whenever technically and economically practicable [14]. Renewable feedstocks are often agricultural products or wastes from other processes, while depleting feedstocks typically come from fossil fuels [14].

Principle 8: Reduce Derivatives

Unnecessary derivatization (use of blocking groups, protection/deprotection, temporary modification of physical/chemical processes) should be minimized or avoided if possible [14]. Such derivatives require additional reagents and generate waste [14].

Principle 9: Catalysis

Catalytic reagents (as selective as possible) are superior to stoichiometric reagents [14]. Catalysts carry out a single reaction many times and are preferable to stoichiometric reagents, which are used in excess and carry out a reaction only once [15] [14].

Principle 10: Design for Degradation

Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment [14]. This principle addresses concerns about persistent, bioaccumulative compounds such as PFAS ("forever chemicals") [18].

Principle 11: Real-time Analysis for Pollution Prevention

Analytical methodologies need to be further developed to allow for real-time, in-process monitoring and control prior to the formation of hazardous substances [14]. This enables immediate process adjustments to minimize byproduct formation [14].

Principle 12: Inherently Safer Chemistry for Accident Prevention

Substances and the form of a substance used in a chemical process should be chosen to minimize the potential for chemical accidents, including releases, explosions, and fires [14]. This includes considering physical properties (solid, liquid, gas) to enhance safety [14].

Figure 1: Conceptual relationship between the Pollution Prevention Act of 1990, the 12 Principles of Green Chemistry, and their application in sustainable molecular design.

Quantitative Assessment Frameworks for Green Chemistry

Implementing the 12 principles requires robust metrics to evaluate and compare chemical processes. Several standardized assessment tools have been developed to quantify the "greenness" of synthetic methodologies.

Table 2: Green Chemistry Assessment Metrics

| Metric | Calculation | Parameters Considered | Optimal Value |

|---|---|---|---|

| Atom Economy [15] [17] | (FW desired product / Σ FW reactants) × 100 | Molecular weights of reactants and products | 100% |

| E-Factor [17] | Total waste mass / Product mass | All non-product outputs (excluding water) | 0 |

| Process Mass Intensity (PMI) [15] [17] | Total process mass / Product mass | All materials including water, solvents, reagents | 1 |

| EcoScale [17] | 100 - Σ penalty points | Yield, cost, safety, technical setup, temperature/time, workup | 100 |

The EcoScale metric provides a particularly comprehensive assessment, assigning penalty points across multiple categories [17]:

- Yield: (100 - %yield)/2

- Price of reaction components: Inexpensive (<$10)=0; Expensive ($10-50)=3; Very expensive (>$50)=5

- Safety: Based on hazard warnings (N=5, T=5, F=5, E=10, F+=10, T+=10)

- Technical setup: Common setup=0; Specialized equipment=1-3

- Temperature/time: Room temperature, <1h=0; Heating/cooling=2-5

- Workup and purification: None=0; Simple operations=1-3; Complex purification=10

Emerging Methodologies and Experimental Approaches

Recent advancements in green chemistry have translated the theoretical principles into practical experimental methodologies with applications across pharmaceutical development and materials science.

Mechanochemistry: Solvent-Free Synthesis

Mechanochemistry utilizes mechanical energy through grinding or ball milling to drive chemical reactions without solvents [18]. This approach eliminates the environmental impacts of solvents while enabling novel transformations.

Experimental Protocol: Solvent-Free Imidazole Salt Synthesis

- Equipment: Ball mill reactor, milling media (e.g., zirconia balls)

- Reagents: Imidazole derivatives, dicarboxylic acids

- Procedure:

- Charge reactants in stoichiometric ratios into milling jar

- Add milling media (typically 10-30% of jar volume)

- Seal jar and initiate milling at optimized frequency (15-30 Hz)

- Monitor reaction completion via in-situ Raman spectroscopy or ex-situ NMR

- Recover product by dissolving in minimal water and precipitation

- Advantages: 85-95% yield achieved without solvent; energy consumption reduced by 60% compared to solution synthesis; high purity products [18]

In-Water and On-Water Reactions

Water represents a non-toxic, non-flammable alternative to organic solvents. Recent research demonstrates that many reactions proceed efficiently in aqueous environments, leveraging water's unique hydrogen bonding and interfacial properties [18].

Experimental Protocol: Aqueous Diels-Alder Reaction

- Reagents: Diene, dienophile, water as solvent

- Procedure:

- Dissolve water-soluble reactants in deionized water

- For water-insoluble reactants, create fine emulsion via vigorous stirring

- React at room temperature or moderate heating (25-60°C)

- Monitor reaction by TLC or HPLC

- Extract product with minimal ethyl acetate or isolate via filtration

- Key Finding: Reaction rates accelerated up to 300% compared to organic solvents due to hydrophobic effect and hydrogen bonding [18]

AI-Guided Reaction Optimization

Artificial intelligence transforms reaction design by predicting sustainable pathways and optimizing conditions before laboratory experimentation.

Experimental Protocol: AI-Assisted Green Synthesis

- Tools: Machine learning algorithms, high-throughput experimentation robotics

- Procedure:

- Train model on existing reaction databases with green chemistry metrics

- Define optimization parameters: atom economy, energy efficiency, toxicity

- Generate predictive reaction pathways

- Validate top predictions via automated high-throughput screening

- Iterate model based on experimental results

- Outcome: Development of catalysts for greener ammonia production with 40% reduction in energy consumption [18]

Table 3: Research Reagent Solutions for Green Chemistry Applications

| Reagent/Category | Function | Green Alternative | Application Example |

|---|---|---|---|

| Organic Solvents | Reaction medium | Water, supercritical CO₂, deep eutectic solvents | Extraction, reaction medium [18] [16] |

| Stoichiometric Reagents | React in exact amounts | Catalytic systems | Hydrogenation, oxidation [14] |

| Rare Earth Elements | Permanent magnets | Iron nitride (FeN), tetrataenite (FeNi) | Electric vehicle motors, wind turbines [18] |

| PFAS Compounds | Surfactants, coatings | Bio-based surfactants, fluorine-free coatings | Textiles, food packaging [18] |

| Traditional Catalysts | Reaction acceleration | Biocatalysts, engineered enzymes | Pharmaceutical synthesis [15] [18] |

Figure 2: Experimental workflow for implementing green chemistry principles, showing transition from traditional synthesis to sustainable methodologies and their applications.

Implementation in Pharmaceutical Research and Development

The pharmaceutical industry has emerged as a leader in adopting green chemistry principles, driven by both environmental concerns and economic imperatives. Significant advances have been achieved in API (Active Pharmaceutical Ingredient) synthesis through innovative process redesign.

Case Study: Sertraline Redesign

Pfizer's redesign of sertraline manufacturing demonstrates multiple green chemistry principles in action [15]:

- Original process: 3 solvents, multiple separation steps, low overall efficiency

- Redesigned process: 1 solvent (ethanol), 3-fold yield improvement, elimination of several unit operations

- Principles applied:

- Prevention (reduced waste)

- Safer solvents (ethanol instead of multiple hazardous solvents)

- Energy efficiency (fewer processing steps)

- Catalysis (improved selectivity)

Case Study: Simvastatin Biocatalytic Production

Codexis and Professor Yi Tang developed an efficient biocatalytic process for simvastatin manufacturing [15]:

- Traditional synthesis: Multiple protection/deprotection steps, stoichiometric reagents

- Biocatalytic route: Single enzymatic transformation using engineered lovastatin hydrolase

- Green chemistry advantages:

- Atom economy increased from 30% to >80%

- Process mass intensity reduced by 65%

- Elimination of hazardous reagents (e.g., chlorine gas, heavy metals)

The 12 Principles of Green Chemistry provide a comprehensive framework for implementing the pollution prevention mandate established by the Pollution Prevention Act of 1990. By addressing environmental concerns at the molecular design stage, green chemistry moves beyond pollution control to pollution prevention [14]. The continuing evolution of green chemistry methodologies—including mechanochemistry, aqueous systems, renewable feedstocks, and AI-guided design—demonstrates the scientific community's commitment to sustainable molecular design.

For researchers and drug development professionals, adopting these principles offers both environmental and economic benefits through reduced waste generation, lower energy consumption, and minimized use of hazardous materials. As green chemistry continues to evolve, its integration with emerging technologies will further enhance its potential to transform chemical practice and contribute to a more sustainable future.

The Pollution Prevention Act (PPA) of 1990 marked a transformative shift in United States environmental policy, establishing a national strategy that prioritized preventing pollution at its source rather than managing it after generation [4] [1]. This legislative framework emerged from congressional findings that recognized significant opportunities for industry to reduce pollution through cost-effective changes in production, operation, and raw materials use [4]. The Act's declaration that pollution "should be prevented or reduced at the source whenever feasible" provided the foundational philosophy that would catalyze the green chemistry movement [4] [14].

Green chemistry, defined as "the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances," represents the scientific embodiment of the PPA's prevention philosophy [14]. The field originated as a direct response to the PPA, with the U.S. Environmental Protection Agency (EPA) launching research grants in 1991 to encourage the redesign of chemical products and processes, thus operationalizing the Act's principles through scientific innovation [19]. This alignment between regulatory policy and scientific advancement created a synergistic relationship that has driven sustainable molecular design for over three decades, fundamentally changing how chemists approach the design of materials, processes, and products.

The Pollution Prevention Act of 1990: A Foundational Shift

Legislative Intent and Core Provisions

The Pollution Prevention Act represented a fundamental reorientation in environmental management strategy. Prior to its passage, environmental legislation such as the Clean Air Act and Clean Water Act had primarily focused on controlling pollution through end-of-pipe treatment and disposal methods [1]. Congress explicitly found that these existing regulations often failed to realize source reduction opportunities because they focused industrial resources on compliance with treatment and disposal requirements rather than prevention [4].

The Act established a clear national policy hierarchy that continues to guide environmental management:

- Pollution should be prevented or reduced at the source whenever feasible

- Pollution that cannot be prevented should be recycled in an environmentally safe manner whenever feasible

- Pollution that cannot be prevented or recycled should be treated in an environmentally safe manner whenever feasible

- Disposal or other release into the environment should be employed only as a last resort [4] [14]

Central to the Act's implementation was its definition of "source reduction" as any practice that reduces the amount of hazardous substances entering any waste stream or released into the environment prior to recycling, treatment, or disposal, while also reducing hazards to public health and the environment [4]. This definition specifically includes equipment modifications, process improvements, product reformulation, raw material substitution, and improvements in maintenance and inventory control [4].

Key Implementation Mechanisms

To translate policy into practice, the PPA established several key mechanisms within the EPA:

- Office Establishment: Required the Administrator to establish an independent office to carry out PPA functions and review single-medium program offices [4]

- Strategy Development: Mandated development and implementation of a comprehensive strategy to promote source reduction [4]

- Grants Program: Authorized matching grants to states for technical assistance programs [4]

- Source Reduction Clearinghouse: Created a central repository for information on management and technical approaches to source reduction [4]

- Reporting Requirements: Enhanced Toxic Release Inventory (TRI) reporting to include source reduction and recycling data [4]

These mechanisms provided the structural foundation for implementing the pollution prevention hierarchy and creating channels for disseminating prevention technologies and methodologies.

The Emergence and Evolution of Green Chemistry

From Policy to Scientific Discipline

The PPA's emphasis on prevention provided the philosophical and regulatory impetus for the systematic development of green chemistry as a distinct scientific discipline. In 1991, the EPA's Office of Pollution Prevention and Toxics launched a research grant program specifically encouraging the redesign of chemical products and processes, marking the first formal scientific response to the PPA [19]. This program, developed in partnership with the National Science Foundation, provided critical early funding for basic research in what would become green chemistry.

The field was formally articulated in 1998 with the publication of Paul Anastas and John Warner's seminal work, Green Chemistry: Theory and Practice, which established the 12 Principles of Green Chemistry [20] [21] [19]. These principles provided a comprehensive design framework for implementing pollution prevention at the molecular level:

- Prevent waste

- Maximize atom economy

- Design less hazardous chemical syntheses

- Design safer chemicals and products

- Use safer solvents and reaction conditions

- Increase energy efficiency

- Use renewable feedstocks

- Avoid chemical derivatives

- Use catalysts, not stoichiometric reagents

- Design chemicals and products to degrade after use

- Analyze in real time to prevent pollution

- Minimize the potential for accidents [14]

The institutionalization of green chemistry accelerated with the introduction of the Presidential Green Chemistry Challenge Awards in 1996, which recognized and incentivized both academic and industrial innovations [19]. This was followed by the establishment of international research conferences, specialized journals, and academic networks that solidified green chemistry as a global scientific endeavor [19].

Quantitative Impact Assessment

The table below summarizes key quantitative data points that demonstrate the impact of the alignment between the PPA and green chemistry research:

Table 1: Pollution Prevention and Green Chemistry Impact Metrics

| Metric Category | Data Points | Source/Context |

|---|---|---|

| Economic Findings | "Tens of billions of dollars per year" spent controlling pollution | PPA Congressional Findings [4] |

| Health Impacts | >1.6 million lives and 45 million disability-adjusted life years lost globally each year | World Health Organization estimates [21] |

| Economic Impact | Health damage from chemical exposures costs up to 10% of global GDP | United Nations data [21] |

| Policy Timeline | 17 years from initial concept to passage of Sustainable Chemistry R&D Act | Legislative history [21] |

| Research Advancement | Development of degradable silicon-based polymers with labile Si–O–C linkages | Recent research review [22] |

Methodological Framework: Green Chemistry in Practice

Experimental Design Principles

Implementing green chemistry principles requires systematic methodological approaches that integrate sustainability considerations at each stage of chemical design and process development. The following experimental framework embodies the convergence of regulatory policy and scientific innovation:

Table 2: Green Chemistry Experimental Protocol Framework

| Protocol Stage | Methodological Approach | Pollution Prevention Alignment |

|---|---|---|

| Molecular Design | Incorporate hydrolyzable linkages (e.g., Si–O–C, Si–O–C(O)) for controlled degradation | Designs chemicals to degrade after use (Principle 10) [22] |

| Catalyst Selection | Prefer earth-abundant metals or metal-free catalytic systems over stoichiometric reagents | Uses catalysts, not stoichiometric reagents (Principle 9) [22] |

| Solvent Systems | Implement solvent-free conditions or benign alternative solvents | Uses safer solvents and reaction conditions (Principle 5) [14] |

| Feedstock Sourcing | Utilize bio-based or waste-derived raw materials | Uses renewable feedstocks (Principle 7) [14] |

| Process Monitoring | Employ in-process, real-time analytical monitoring | Analyzes in real time to prevent pollution (Principle 11) [14] |

| Hazard Assessment | Apply predictive toxicology early in design process | Designs safer chemicals and products (Principle 4) [19] |

Research Reagent Solutions for Sustainable Chemistry

The implementation of green chemistry methodologies requires specialized reagents and materials that enable reduced hazard and enhanced sustainability:

Table 3: Essential Research Reagents for Green Chemistry Applications

| Reagent/Material | Function in Experimental Protocols | Sustainability Advantage |

|---|---|---|

| Silicon-based Monomers | Building blocks for degradable polymers via step-growth polymerization | Enable controlled degradation without compromising performance [22] |

| Earth-Abundant Metal Catalysts | Catalytic systems for polymerization and synthesis | Reduce reliance on precious metals; lower toxicity [22] |

| Bio-Based Solvents | Reaction media derived from renewable resources | Replace petroleum-derived solvents; reduced hazardous waste [14] |

| Enzymatic Catalysts | Biocatalysts for selective transformations | Biodegradable; operate under mild conditions [23] |

| CO₂-Based Feedstocks | Utilization of carbon dioxide as chemical building block | Greenhouse gas utilization; renewable carbon source [23] |

| Predictive Toxicology Tools | Computational assessment of chemical hazard | Enables early identification of potential hazards before synthesis [19] |

Convergence in Action: Case Studies and Experimental Applications

Degradable Silicon-Based Polymers

Recent advances in degradable silicon-based polymers exemplify the successful alignment of regulatory-driven design with scientific innovation. These materials integrate labile Si–O–C and Si–O–C(O) linkages into polymer backbones, enabling controlled degradation without compromising performance—directly addressing the PPA's mandate to prevent pollution through molecular design [22]. The experimental workflow for developing these sustainable polymers follows a systematic approach that reflects both regulatory requirements and chemical innovation:

Diagram 1: Sustainable Polymer Development Workflow

The development of these polymers employs multiple green chemistry strategies, including step-growth and chain-growth polymerization techniques that maximize atom economy [22]. The incorporation of hydrolytically cleavable linkages ensures that materials break down to innocuous substances after use, directly implementing Principle 10 of green chemistry while fulfilling the PPA's pollution prevention hierarchy [22] [14]. This approach demonstrates how regulatory pressure for pollution prevention has driven molecular innovation to create materials with engineered end-of-life scenarios.

Catalytic System Advancements

The shift from stoichiometric reagents to catalytic systems represents another convergence point between policy and science. The PPA's emphasis on reducing hazardous substances in waste streams aligns with the green chemistry principle favoring catalytic reactions [4] [14]. Recent research has developed increasingly sophisticated catalytic systems for sustainable chemistry applications, ranging from noble metals to earth-abundant and metal-free catalysts [22]. These catalytic approaches minimize waste by carrying out numerous reaction cycles with small catalyst amounts, contrasting with traditional stoichiometric methods that generate significant byproducts.

The experimental protocol for catalytic system evaluation typically includes:

- Catalyst Screening: Assessing multiple catalyst families for efficiency and selectivity

- Reaction Optimization: Minimizing energy inputs while maximizing yield

- Lifecycle Analysis: Evaluating environmental impacts across the catalyst lifespan

- Recovery and Reuse: Developing methods for catalyst recycling to minimize resource consumption

This methodology reflects the integrated systems thinking that characterizes the policy-science alignment, where molecular-level innovations are evaluated within broader environmental and economic contexts.

Regulatory Evolution and Scientific Response

From Pollution Prevention to Sustainable Chemistry

The initial framework established by the PPA has evolved through subsequent legislative and regulatory developments. The Sustainable Chemistry Research and Development Act of 2021 represents the most significant policy advancement since the PPA, creating a government-wide initiative to support sustainable chemistry R&D, commercialization, and education [21]. This legislation passed as part of the National Defense Authorization Act after nearly 17 years of legislative effort, indicating both the complexity and importance of institutionalizing sustainable chemistry [21].

The international regulatory landscape has also evolved substantially, with the European Union's Chemicals Strategy for Sustainability (CSS) introducing the "Safe and Sustainable by Design (SSbD)" framework [23]. This approach goes beyond traditional risk assessment to require intrinsic safety and sustainability from the earliest stages of R&D, creating a parallel policy track that reinforces the PPA's original prevention philosophy while expanding its scope [23].

The Business Case for Green Chemistry

While regulatory policy provided the initial impetus for green chemistry, economic drivers have become increasingly significant in sustaining its advancement. The business case for green chemistry includes:

- Reduced liability costs through decreased toxic tort exposure and product liability claims [20]

- Lower operational costs from reduced waste disposal, hazardous material handling, and regulatory reporting [20]

- Enhanced worker safety with associated reductions in training costs, specialized equipment, and insurance premiums [20]

- Supply chain security through decreased dependence on hazardous substances with uncertain availability [23]

This economic dimension has created a self-reinforcing cycle where regulatory signals stimulate scientific innovation, which demonstrates economic advantages, thereby driving further innovation independent of regulatory mandates [20]. This explains why green chemistry continues to advance even during periods of regulatory uncertainty or political transition.

Future Directions: An Integrated Research Agenda

Emerging Research Priorities

The convergence of regulatory policy and scientific innovation continues to evolve, with several emerging research priorities representing the next frontier in sustainable chemistry:

- Predictive Toxicology: Developing computational methods to assess chemical hazards during the design phase rather than after synthesis [19]

- Circular Feedstocks: Designing chemicals and processes that utilize waste streams or renewable resources as inputs [23]

- Digital Compliance: Integrating regulatory requirements into chemical design software to enable real-time sustainability assessment [23]

- Multi-Principle Optimization: Moving beyond single-parameter improvements to develop systems that simultaneously address multiple green chemistry principles [19]

These research directions reflect an increasingly sophisticated understanding of sustainability as a multidimensional challenge requiring integrated solutions across molecular design, process engineering, and product lifecycle management.

Policy-Science Integration Framework

The continued alignment between regulatory policy and scientific innovation requires intentional structuring of their relationship. The following framework illustrates how these domains interact in an ideal innovation ecosystem:

Diagram 2: Policy-Science Innovation Cycle

This framework highlights the iterative relationship between policy and science, where regulatory signals stimulate research, leading to technological applications that generate performance data to refine subsequent policy approaches. Maintaining this virtuous cycle requires ongoing coordination between government agencies, academic institutions, and industry partners.