Green Analytical Chemistry Metrics for HPLC: A Practical Guide for Sustainable Pharmaceutical Analysis

This article provides a comprehensive guide to the principles, tools, and practical applications of Green Analytical Chemistry (GAC) in High-Performance Liquid Chromatography (HPLC) for researchers and drug development professionals.

Green Analytical Chemistry Metrics for HPLC: A Practical Guide for Sustainable Pharmaceutical Analysis

Abstract

This article provides a comprehensive guide to the principles, tools, and practical applications of Green Analytical Chemistry (GAC) in High-Performance Liquid Chromatography (HPLC) for researchers and drug development professionals. It explores foundational GAC concepts and established greenness assessment metrics like AGREE, GAPI, and Analytical Eco-Scale. The content covers methodological strategies for greening HPLC methods, including solvent replacement, miniaturization, and waste reduction. It also addresses common troubleshooting challenges and optimization techniques, and concludes with frameworks for validating green methods and comparing their performance and sustainability, supporting the pharmaceutical industry's transition towards more environmentally responsible analytical practices.

The Principles and Pillars of Green Analytical Chemistry in HPLC

The Foundation of Green Analytical Chemistry

Green Analytical Chemistry (GAC) emerged as a specialized discipline applying the philosophy of green chemistry specifically to analytical practices [1] [2]. It focuses on minimizing the environmental footprint of analytical activities while maintaining robust analytical performance [3] [4]. This approach represents a fundamental shift in how analytical challenges are addressed, integrating environmental responsibility directly into method development [4]. The core objective is to reduce or eliminate hazardous solvents, reagents, and materials while developing rapid, energy-saving methodologies that preserve essential validation parameters [2].

The framework for GAC is structured around 12 guiding principles that provide a systematic approach to designing environmentally benign analytical methods [1] [4]. These principles address the entire analytical workflow, from sample collection to final detection, emphasizing safety, efficiency, and sustainability throughout the analytical process [4].

The 12 Principles of Green Analytical Chemistry

The table below summarizes the twelve principles of GAC, which serve as critical design criteria for developing sustainable analytical methods.

Table 1: The 12 Principles of Green Analytical Chemistry

| Principle Number | Principle Name | Core Objective |

|---|---|---|

| 1 | Direct Techniques | Use direct analytical techniques to minimize sample preparation [4]. |

| 2 | Reduced Sample Size | Minimize sample size and number of samples [4]. |

| 3 | In Situ Measurements | Perform measurements in situ to avoid transport [4]. |

| 4 | Waste Minimization | Minimize waste generation at every stage [4]. |

| 5 | Safer Solvents/Reagents | Select safer solvents and reagents to reduce toxicity [4]. |

| 6 | Avoid Derivatization | Avoid derivatization to limit chemical use and waste [4]. |

| 7 | Energy Efficiency | Minimize energy consumption through efficient instrumentation [4]. |

| 8 | Miniaturization/Reagent-Free | Develop reagent-free or miniaturized methods [4]. |

| 9 | Automation/Integration | Use automation and integration to enhance efficiency [4]. |

| 10 | Multi-analyte Approach | Adopt multi-analyte or multi-parameter methods [4]. |

| 11 | Real-time Analysis | Pursue real-time analysis for timely decision-making [4]. |

| 12 | Greenness Assessment | Apply greenness metrics to quantify environmental performance [4]. |

Greenness Assessment Metrics for Analytical Chemistry

Evaluating the environmental impact of analytical methods requires specialized metrics tailored to analytical workflows. Several tools have been developed to quantify and visualize the greenness of analytical procedures, enabling researchers to make informed, sustainable choices [3] [2].

Table 2: Key Greenness Assessment Metrics for Analytical Chemistry

| Assessment Tool | Primary Focus | Output Type | Key Features |

|---|---|---|---|

| NEMI (National Environmental Methods Index) [2] | Basic environmental criteria | Binary pictogram | Simple, user-friendly; indicates pass/fail for four criteria [2]. |

| Analytical Eco-Scale [2] | Non-green attributes | Numerical score (penalty-based) | Assigns penalty points for hazardous reagents, energy demand, etc.; score of 100 is ideal [2]. |

| GAPI (Green Analytical Procedure Index) [2] [4] | Entire analytical workflow | Color-coded pictogram | Visualizes impact from sampling to detection; helps identify high-impact stages [2] [4]. |

| AGREE (Analytical GREEnness) [2] [4] | 12 GAC principles | Numerical score (0-1) & radial pictogram | Comprehensive; provides a single, unified score based on all 12 principles [2] [4]. |

| AGREEprep [2] [4] | Sample preparation | Numerical score & pictogram | First dedicated tool for evaluating the sample preparation step [2] [4]. |

GAC Application in HPLC: Experimental Protocols

High-Performance Liquid Chromatography (HPLC) is ubiquitous in pharmaceutical analysis and food control but traditionally relies on hazardous solvents and generates significant waste [4]. Applying GAC principles to HPLC involves strategic modifications across the analytical workflow.

Protocol: transitioning to Greener Solvent Systems

Objective: Replace hazardous solvents like acetonitrile and methanol with safer alternatives without compromising chromatographic performance [4].

Materials:

- HPLC System: Configured with appropriate tubing and seal compatibility for alternative solvents.

- Columns: C18 or specialized columns suitable for green solvent mixtures.

- Green Solvents: Ethanol, water, ethyl acetate, acetone, propylene carbonate.

- Additives: e.g., Ammonium acetate or trifluoroacetic acid for mobile phase modulation.

Methodology:

- Scouting Runs: Begin with a water/ethanol gradient as a baseline. Ethanol is a preferred alternative due to its lower toxicity and renewable origin [4].

- Modify Selectivity: If ethanol/water does not provide adequate separation, incorporate small percentages of other green solvents like ethyl acetate or acetone to fine-tune selectivity.

- Adjust pH and Ionic Strength: Use minimal amounts of acidic or basic additives to sharpen peaks and improve resolution for ionizable compounds.

- Column Temperature Optimization: Increase column temperature (e.g., 40-60°C) to reduce mobile phase viscosity, thereby lowering backpressure and improving efficiency with viscous solvents like ethanol.

- System Suitability Test: Validate the final method to ensure it meets all required analytical performance criteria (precision, accuracy, sensitivity).

Protocol: Method Miniaturization and Instrument Automation

Objective: Reduce solvent consumption and waste generation through scale-down and improve throughput with automation.

Materials:

- UPLC or Micro-HPLC System: Capable of handling low flow rates (e.g., < 0.5 mL/min) and smaller particle size columns [4].

- Microbore or Capillary Columns: (e.g., 2.1 mm or 1.0 mm internal diameter).

- Autosampler: For high-throughput, unattended operation.

Methodology:

- Method Transfer: Scale down a conventional HPLC method (using a 4.6 mm ID column) to a 2.1 mm ID column.

- Flow Rate Adjustment: Calculate and apply the new flow rate based on the squared ratio of the column diameters to maintain the same linear velocity.

- Gradient Re-equilibration: Optimize the re-equilibration time for the lower flow rate to maintain cycle time while ensuring reproducibility.

- Injection Volume: Adjust the injection volume proportionally to the column volume change to prevent overloading.

- Automated Sequence Setup: Program the autosampler to run a large batch of samples, integrating data acquisition and processing for maximum efficiency.

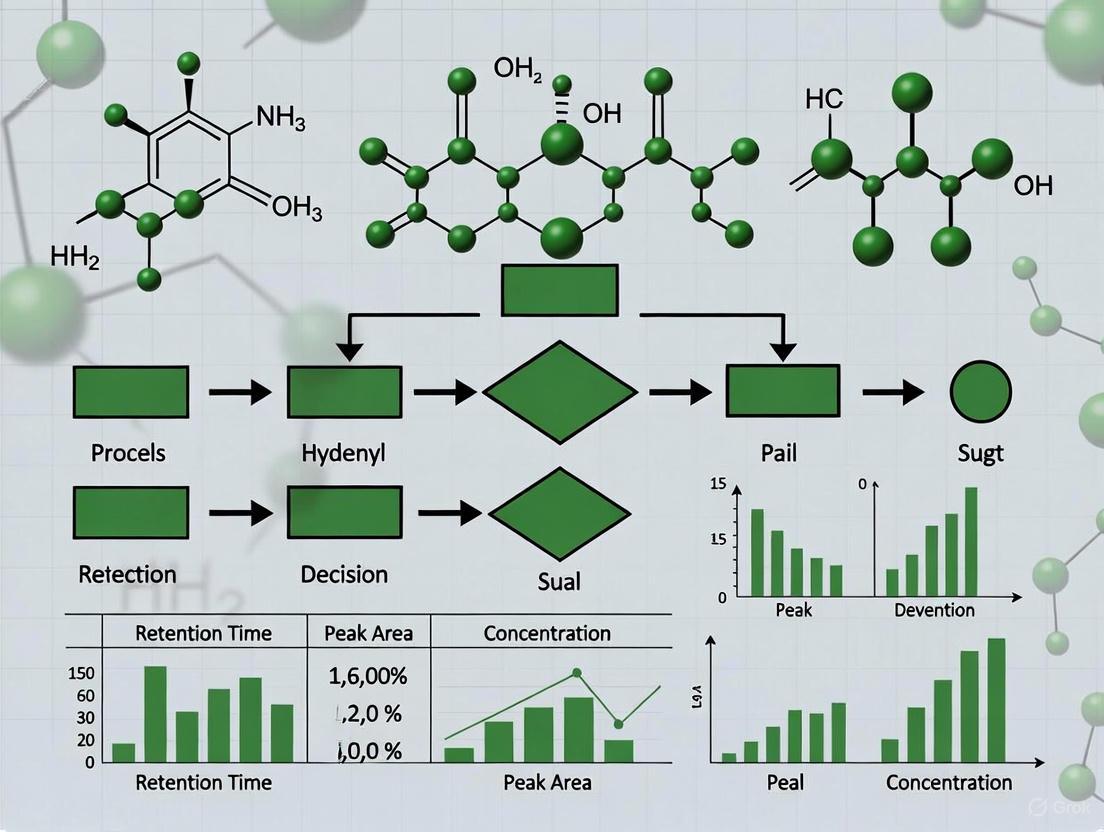

The following workflow diagram illustrates the decision-making process for implementing these green strategies in HPLC method development.

The Scientist's Toolkit: Essential Reagents and Materials for Green HPLC

Table 3: Key Research Reagent Solutions for Green HPLC

| Item | Function/Application | Green Rationale |

|---|---|---|

| Ethanol | Primary organic modifier in reversed-phase mobile phases [4]. | Biobased, biodegradable, and less toxic than acetonitrile or methanol [4]. |

| Water | Primary weak solvent in reversed-phase mobile phases. | Non-toxic, non-flammable, and inexpensive. |

| Ethyl Acetate | Solvent for liquid-liquid extraction or mobile phase modifier [4]. | Safer profile compared to chlorinated solvents; can be derived from renewable resources [4]. |

| Propylene Carbonate | Alternative green organic solvent for normal-phase or mixed-mode chromatography. | Low volatility, low toxicity, and biodegradable. |

| Supercritical CO₂ | Mobile phase in Supercritical Fluid Chromatography (SFC). | Non-toxic, non-flammable, and easily removed post-analysis; enables solvent-free separations [4]. |

| Solid-Phase Microextraction (SPME) Fibers | Solvent-free sample preparation and concentration [4]. | Eliminates need for large volumes of organic solvents in sample prep [4]. |

High-Performance Liquid Chromatography (HPLC) stands as a fundamental analytical technique that has revolutionized chemical analysis across pharmaceutical, environmental, and food safety sectors. Despite its analytical indispensability, conventional HPLC presents a significant ecological footprint due to its substantial consumption of organic solvents, high energy demands, and generation of chemical waste [5]. Traditional methodologies often heavily rely on toxic solvents like acetonitrile and methanol, derived from non-renewable resources and requiring specialized disposal, creating environmental and economic pressures on laboratories [6] [7]. The transition to green chromatography is not merely an ethical preference but an essential evolution toward sustainable and responsible analytical practices that align with global sustainability goals, without compromising the critical performance required for precise quantification and separation [8] [5].

The Pillars of Green HPLC

Green Solvent Alternatives and Mobile Phase Optimization

A primary strategy for greening HPLC focuses on replacing hazardous solvents with safer, sustainable alternatives. Ethanol and methanol, with their lower toxicity and better biodegradability, are increasingly used as replacements for acetonitrile in reversed-phase chromatography [6] [9]. Supercritical fluid chromatography (SFC), utilizing carbon dioxide as a non-toxic, reusable mobile phase, dramatically minimizes harmful solvent use [8]. Another advancement is Micellar Liquid Chromatography (MLC), which employs surfactants to form micelles, reducing organic solvent consumption to minimal levels [8]. Method optimization also plays a crucial role; simple adjustments to gradient programs can significantly cut total solvent use per analysis [6].

Instrumentation and Column-Based Reductions

Technological advancements in HPLC hardware and column design enable substantial reductions in resource consumption. Transitioning from standard 4.6-mm internal diameter (i.d.) columns to narrow-bore (e.g., 2.1-mm i.d.) columns can reduce solvent usage by up to 80% for continuous operation [7]. The adoption of columns packed with sub-2-μm particles, core-shell particles, and monolithic stationary phases enhances separation efficiency, allowing faster run times and lower solvent consumption [7] [10]. Furthermore, solvent recycling systems can intercept and purify clean mobile phase exiting the detector, achieving up to 80% solvent savings without compromising analytical integrity [6].

Green Sample Preparation

The sample preparation stage is often resource-intensive. Implementing green principles here involves adopting miniaturized techniques such as Solid Phase Microextraction (SPME) and Liquid Phase Microextraction (LPME), which drastically reduce solvent and sample volume requirements [8]. The use of Natural Deep Eutectic Solvents (NADES) offers biodegradable and low-toxicity alternatives for extraction [8]. Additionally, strategies like parallel sample processing and automation increase throughput and reduce energy consumption per sample [11].

Metrics for Greenness Assessment

Evaluating the environmental performance of analytical methods is crucial for meaningful progress in green HPLC. Multiple standardized metrics have been developed to provide quantitative and qualitative assessments.

Table 1: Key Green Analytical Chemistry Assessment Metrics

| Metric Name | Type of Output | Key Parameters Assessed | Strengths | Limitations |

|---|---|---|---|---|

| NEMI (National Environmental Methods Index) | Pictogram (pass/fail for 4 criteria) | PBT chemicals, hazardous waste, corrosivity, waste amount [12] | Simple, visual, easy to interpret [2] | Qualitative, lacks granularity, doesn't cover full workflow [12] |

| Analytical Eco-Scale | Numerical score (0-100) | Reagent toxicity, energy consumption, waste generation [5] | Semi-quantitative, allows direct method comparison [2] | Relies on expert judgment for penalty points [2] |

| GAPI (Green Analytical Procedure Index) | Color-coded pictogram (5 sections) | Entire analytical process from sampling to detection [5] [2] | Comprehensive, visualizes impact across workflow stages [2] | No overall score, some subjectivity in color assignment [2] |

| AGREE (Analytical GREEnness) | Numerical score (0-1) + circular pictogram | All 12 principles of GAC [5] [2] | Comprehensive, user-friendly, combines score with visual [12] [2] | Subjective weighting of criteria, limited pre-analytical coverage [2] |

| AGREEprep | Numerical score (0-1) + pictogram | 10 criteria specific to sample preparation [11] [2] | Focuses on often-overlooked sample prep stage [2] | Must be used with other tools for full method assessment [2] |

| BAGI (Blue Applicability Grade Index) | Numerical score + "asterisk" pictogram | Practical aspects (cost, throughput, availability, automation) [5] | Assesses practical viability for real-world labs [5] | Does not directly measure environmental impact [5] |

The progression from simple tools like NEMI to comprehensive frameworks like AGREE and AGREEprep highlights a maturation in the field, enabling a more holistic view of method sustainability [2]. The concept of White Analytical Chemistry (WAC) has emerged, seeking to balance the three key dimensions: red (analytical performance), green (environmental sustainability), and blue (method practicality and cost-effectiveness) [13] [5]. An ideal "white" method harmonizes all three aspects.

Detailed Experimental Protocol: Greening an HPLC Method for Pharmaceutical Analysis

This protocol outlines the development and validation of a green HPLC method for the determination of Letrozole in tablets, based on a published study [9]. The method replaces traditional toxic solvents with ethanol.

Research Reagent Solutions and Materials

Table 2: Essential Materials and Reagents

| Item | Specification/Function |

|---|---|

| HPLC System | Standard HPLC with UV/Vis detector or DAD [9] |

| Analytical Column | Inertsil ODS-3 C18 (5 µm, 150 × 4.6 mm) or equivalent [9] |

| Mobile Phase | Ethanol:Water (50:50, v/v) [9] |

| Solvents | Absolute Ethanol (HPLC grade), Purified Water (HPLC grade) [9] |

| Analytical Standard | Letrozole reference standard (high purity) [9] |

| Samples | Letrozole tablet formulations [9] |

| Volumetric Glassware | For precise preparation of standard and mobile phase |

Step-by-Step Procedure

Step 1: Mobile Phase and Standard Preparation

- Mobile Phase: Accurately measure 500 mL of HPLC-grade ethanol and 500 mL of HPLC-grade water. Mix thoroughly and degas by sonication for 10 minutes or by sparging with inert gas.

- Standard Solution: Precisely weigh approximately 10 mg of Letrozole reference standard into a 100 mL volumetric flask. Dissolve and dilute to volume with mobile phase to obtain a primary stock solution of 100 µg/mL. Prepare working standards in the range of 0.1–40.0 µg/mL by serial dilution with mobile phase [9].

- Sample Solution: Weigh and finely powder not less than 20 tablets. Transfer an accurately weighed portion of the powder, equivalent to about 10 mg of Letrozole, to a 100 mL volumetric flask. Add about 70 mL of mobile phase, sonicate for 15 minutes with intermittent shaking, dilute to volume with mobile phase, and mix well. Filter a portion through a 0.45-µm membrane filter, discarding the first few mL of the filtrate [9].

Step 2: Instrumental Configuration and Chromatographic Conditions

- Column Oven Temperature: Ambient (or specified temperature if available)

- Detection Wavelength: 230 nm [9]

- Flow Rate: 1.0 mL/min (or optimized for the specific column)

- Injection Volume: 10–20 µL

- Run Time: 3.0 minutes [9] Equilibrate the system with the mobile phase until a stable baseline is achieved.

Step 3: System Suitability and Analysis

- Perform injections of the standard solution to ensure the system is suitable. Parameters including retention time reproducibility, theoretical plates, and tailing factor should meet acceptance criteria.

- Separately inject the standard and sample solutions in duplicate or triplicate. A typical chromatogram should show a sharp peak for Letrozole at approximately 2.2 minutes, allowing a total run time of just 3 minutes [9].

Step 4: Method Validation (ICH Guidelines)

Validate the method as per ICH guidelines [9]:

- Linearity: Inject working standard solutions across the 0.1–40.0 µg/mL range. Plot peak area versus concentration. The correlation coefficient (r) should be not less than 0.999.

- Accuracy: Perform recovery studies by spiking a pre-analyzed sample with known amounts of standard at three different levels (e.g., 80%, 100%, 120%). Average recovery should be 98–102%.

- Precision: Determine repeatability (intra-day) and intermediate precision (inter-day) by analyzing multiple preparations of the same sample. The relative standard deviation (RSD) should be ≤2.0%.

- Specificity: Demonstrate that the peak for Letrozole is pure and free from interference from excipients or degradation products, using diode array detector spectral analysis if available.

Greenness Assessment of the Developed Method

Upon validation, the green profile of the method is evaluated using multiple metrics [9]:

- AGREE: The use of ethanol-water and a short run time yields a high score, reflecting strong alignment with GAC principles.

- GAPI: The pictogram shows mostly green segments, indicating low environmental impact across the analytical workflow.

- ChlorTox Scale & NQS Indicator: The method scores favorably by avoiding chlorinated solvents and aligning with UN Sustainable Development Goals.

The following workflow diagram illustrates the comprehensive process of developing and validating a green HPLC method.

The greening of HPLC is an achievable and critical objective for modern analytical laboratories. By adopting the strategies and metrics outlined in this document—including solvent substitution, hardware and column optimization, green sample preparation, and rigorous greenness assessment—researchers can significantly reduce the environmental impact of their analyses. A 2025 study of standard methods from CEN, ISO, and Pharmacopoeias revealed that 67% scored below 0.2 on the AGREEprep scale (where 1 is ideal), highlighting the urgent need for updating official methods to incorporate contemporary, greener techniques [11]. Future progress depends on continued innovation, interdisciplinary collaboration, and a fundamental shift in mindset from a linear "take-make-dispose" model to a circular, sustainable framework for analytical chemistry [11].

The integration of Green Analytical Chemistry (GAC) principles into high-performance liquid chromatography (HPLC) research represents a critical evolution toward sustainable laboratory practices in pharmaceutical development. GAC focuses on minimizing the environmental impact of analytical procedures by reducing energy consumption, hazardous waste generation, and the use of toxic reagents while maintaining analytical performance [2]. The evaluation of these environmental factors requires specialized metrics that can translate complex methodological parameters into accessible, comparable assessments.

Within the framework of a broader thesis on green analytical chemistry metrics for HPLC research, this application note provides detailed protocols for three pivotal assessment tools: the Analytical GREEnness (AGREE) metric, the Green Analytical Procedure Index (GAPI), and the Analytical Eco-Scale. Each tool offers distinct advantages, assessment methodologies, and output formats, enabling researchers to select the most appropriate metric for their specific application needs. Their proper implementation allows drug development professionals to quantify environmental sustainability, compare alternative methods, and make informed decisions that align with both regulatory requirements and corporate environmental responsibility initiatives [3] [2].

Metric Fundamentals and Comparison

Greenness assessment metrics have evolved from simple binary evaluations to sophisticated tools that provide comprehensive environmental profiling of analytical methods. The table below summarizes the fundamental characteristics of the three primary metrics discussed in this application note.

Table 1: Fundamental Characteristics of Key Greenness Assessment Metrics

| Metric | Development Year | Assessment Basis | Scoring System | Output Format | Primary Application Scope |

|---|---|---|---|---|---|

| Analytical Eco-Scale | 2012 [2] | Penalty points for non-green parameters | Base of 100 minus penalty points; higher scores indicate greener methods [2] | Numerical score | Comparative method assessment |

| GAPI | 2019 [2] | 5 stages of analytical process | Qualitative color coding (green-yellow-red) [2] | Pictogram with 5 sections | Visual assessment of entire analytical workflow |

| AGREE | 2020 [14] | 12 SIGNIFICANCE principles of GAC | 0-1 scale; higher scores indicate greener methods [14] | Circular pictogram with 12 segments and overall score [14] | Comprehensive evaluation with user-defined weighting |

The progression of these metrics demonstrates a clear trend toward more comprehensive, visual, and user-friendly assessment tools. The National Environmental Methods Index (NEMI), an early binary metric, established the foundation with its simple pictogram indicating whether a method met four basic environmental criteria [2]. The Analytical Eco-Scale introduced a quantitative approach through its penalty point system, while GAPI provided a more detailed visual representation of environmental impact across the entire analytical workflow. AGREE represents the most recent advancement, incorporating all 12 principles of green analytical chemistry into a unified, flexible scoring system with an intuitive visual output [14].

For HPLC research, the selection of an appropriate metric depends on the specific assessment goals. AGREE offers the most comprehensive evaluation, GAPI provides quick visual identification of problematic methodological steps, and the Analytical Eco-Scale enables straightforward numerical comparison between alternative methods.

Detailed Metric Protocols

AGREE (Analytical GREEnness) Metric

Principles and Scoring Methodology

The AGREE metric evaluates analytical procedures against all 12 principles of green analytical chemistry, known by the acronym SIGNIFICANCE [14]. Each principle is transformed into a score on a 0-1 scale, where 1 represents ideal greenness. The final overall score is calculated based on the weighted performance across all principles, resulting in a comprehensive assessment of the method's environmental impact [14].

The software for AGREE is freely available and open-source, downloadable from https://mostwiedzy.pl/AGREE [14]. This user-friendly interface guides analysts through the assessment process and automatically generates the characteristic clock-like pictogram that visually represents the greenness profile.

Table 2: Detailed Assessment Criteria for AGREE Based on the 12 SIGNIFICANCE Principles

| Principle Number | GAC Principle Description | Key Assessment Parameters | Scoring Approach |

|---|---|---|---|

| 1 | Direct analytical techniques should be applied to avoid sample treatment | Sample preparation requirements: remote sensing, non-invasive analysis, in-field analysis, on-line/at-line/off-line analysis, external pretreatment [14] | 0.0-1.0 scale based on pretreatment intensity; remote sensing without damage scores 1.0, multistep external pretreatment scores 0.0 [14] |

| 2 | Minimal sample size and minimal number of samples are goals | Sample size and number of samples [14] | Based on sample mass/volume with equations transforming to 0-1 scale [14] |

| 3 | In-situ measurements should be performed | Measurement location relative to sample source | Categorical scoring based on deployment capability |

| 4 | Integration of analytical processes and operations should be pursued | Level of process integration and automation | Higher scores for streamlined, integrated workflows |

| 5 | Automated and miniaturized methods should be selected | Degree of automation and miniaturization | Scoring based on manual vs. automated and conventional vs. miniaturized |

| 6 | Derivatization should be avoided | Derivatization requirements | Binary scoring with penalties for derivatization steps |

| 7 | Generation of a large volume of waste should be avoided | Waste volume and management | Volume-based scoring with waste treatment considerations |

| 8 | Multi-analyte or multi-parameter methods should be selected | Method multiplexing capability | Throughput-based scoring favoring multi-analyte approaches |

| 9 | Consumption of energy should be minimized | Energy requirements per analysis | Quantitative energy consumption scoring |

| 10 | Reagents obtained from renewable sources should be preferred | Reagent origin and renewability | Preference for bio-based, renewable reagents |

| 11 | Toxic reagents should be eliminated or replaced | Reagent toxicity and hazard | Penalties for toxic, hazardous, or persistent compounds |

| 12 | Worker safety should be increased | Operator exposure risks | Assessment of containment and safety measures |

A distinctive feature of AGREE is its flexible weighting system, which allows users to assign different levels of importance to each of the 12 principles based on specific analytical requirements or environmental priorities [14]. These weights are visually represented in the output pictogram through varying segment widths, providing immediate insight into which principles were prioritized during assessment.

Experimental Implementation Protocol

Step 1: Data Collection Compile complete methodological details for the HPLC procedure being evaluated, including: sample volume/injection, mobile phase composition and flow rate, sample preparation steps, analysis time, energy consumption of instrumentation, waste generation volumes, and safety data for all reagents [14].

Step 2: Software Input Launch the AGREE calculator and input the collected data into the corresponding fields for each of the 12 principles. Apply appropriate weighting factors (default is equal weighting) to reflect assessment priorities [14].

Step 3: Score Calculation The software automatically calculates scores for each principle and computes the overall score based on the weighted inputs. The algorithm transforms diverse input parameters to the unified 0-1 scale using predefined transformation functions [14].

Step 4: Results Interpretation Interpret the output pictogram (Figure 1) by examining: (a) The overall score (0-1) in the center, where higher values indicate superior greenness; (b) The color of each segment, which reflects performance for that principle (green = favorable, red = unfavorable); (c) The width of each segment, which indicates the assigned weight for that principle [14].

Figure 1: AGREE Metric Implementation Workflow

GAPI (Green Analytical Procedure Index)

Principles and Scoring Methodology

The Green Analytical Procedure Index (GAPI) employs a comprehensive pictogram consisting of five colored sections that represent the main stages of the analytical process: sample collection, preservation, transport, and preparation; sample preparation; instrumentation used for analysis; compound identification and quantification; and method type and scope [2]. Each section is divided into several sub-criteria that are evaluated individually.

GAPI utilizes a three-level color scheme (green, yellow, red) similar to a traffic light system, where green indicates high environmental friendliness, yellow represents moderate environmental impact, and red signifies significant environmental concerns [2]. This visual approach enables rapid identification of methodological steps with the highest environmental impact, guiding optimization efforts toward areas with the greatest potential for improvement.

Unlike AGREE, GAPI does not generate a single numerical score but provides a qualitative visual assessment of greenness across the entire analytical workflow. This approach helps researchers quickly identify which specific stages of their HPLC methods require environmental optimization.

Experimental Implementation Protocol

Step 1: Sample Collection and Preparation Assessment Evaluate the initial stage of the analytical process concerning: (a) Sample collection method (direct sampling scores green; extensive preservation and transport scores red); (b) Sample pretreatment requirements (no pretreatment scores green; multiple pretreatment steps score red) [2].

Step 2: Sample Treatment and Extraction Evaluation Assess the sample preparation phase based on: (a) Extraction technique (solventless methods score green; classical liquid-liquid extraction scores red); (b) Solvent consumption (<1 mL scores green; >10 mL scores red); (c) Solvent character (green solvents score green; hazardous solvents score red) [2].

Step 3: Instrumentation and Reagent Analysis Examine the instrumental analysis parameters including: (a) Energy consumption (<0.1 kWh per sample scores green; >1.5 kWh scores red); (b) Instrument size (miniaturized systems score green; large footprint instruments score red); (c) Reagent toxicity (non-toxic reagents score green; highly toxic reagents score red) [2].

Step 4: Quantification and Method Type Assessment Evaluate the final stage considering: (a) Detection technique (direct determination scores green; derivatization-required methods score red); (b) Method scope (multi-analyte approaches score greener than single-analyte methods) [2].

Step 5: Pictogram Construction Using the GAPI template, color each segment according to the assessment results to create the visual output that summarizes the method's environmental profile across all analytical stages.

Analytical Eco-Scale

Principles and Scoring Methodology

The Analytical Eco-Scale employs a penalty points system to quantify the environmental impact of analytical methods [2]. The assessment begins with a base score of 100 points representing an ideal green method. Points are then subtracted for each parameter that deviates from ideal green conditions, including hazardous reagent usage, energy consumption, waste generation, and operator hazards.

The calculation follows this formula: Analytical Eco-Scale score = 100 - Total penalty points

Interpretation of the final score follows these guidelines:

- >75 points: Excellent green method

- >50 points: Acceptable green method

- <50 points: Inadequate green method [2]

This straightforward numerical output facilitates direct comparison between alternative HPLC methods, with higher scores always indicating superior environmental performance.

Experimental Implementation Protocol

Step 1: Reagent Penalty Calculation Identify all reagents used in the HPLC method and assign penalty points based on their quantity and hazard characteristics: (a) For reagents used in volumes >10 mL, assign penalty points according to hazard level (non-hazardous = 0; highly hazardous = 6); (b) For reagents used in volumes <10 mL, assign reduced penalty points (non-hazardous = 0; highly hazardous = 3) [2].

Step 2: Instrumentation and Energy Assessment Evaluate energy consumption based on instrument operation time and power requirements: (a) Assign 0 points for energy consumption <0.1 kWh per sample; (b) Assign 1 point for 0.1-1.5 kWh per sample; (c) Assign 2 points for >1.5 kWh per sample [2].

Step 3: Occupational Hazard and Waste Penalty Assign penalty points for: (a) Occupational hazards (1 point if applicable); (b) Waste generation (0 points for <1 mL; 3 points for 1-10 mL; 5 points for >10 mL) with additional points if waste is not treated [2].

Step 4: Final Score Calculation and Interpretation Sum all penalty points and subtract from 100 to obtain the final Analytical Eco-Scale score. Classify the method according to the scoring guidelines and compare with alternative methods to identify the most environmentally sustainable option.

Table 3: Penalty Points System for Analytical Eco-Scale Assessment

| Parameter | Assessment Criteria | Penalty Points |

|---|---|---|

| Reagents (volume >10 mL) | Non-hazardous | 0 |

| Hazardous | 3 | |

| Highly hazardous | 6 | |

| Reagents (volume <10 mL) | Non-hazardous | 0 |

| Hazardous | 1 | |

| Highly hazardous | 3 | |

| Energy Consumption (per sample) | <0.1 kWh | 0 |

| 0.1-1.5 kWh | 1 | |

| >1.5 kWh | 2 | |

| Occupational Hazards | Applicable | 1 |

| Waste Generation (per sample) | <1 mL | 0 |

| 1-10 mL | 3 | |

| >10 mL | 5 | |

| Waste Treatment | No treatment | Additional 3 points |

Applications in HPLC Research

Case Study: Comparative Evaluation of HPLC Methods

A recent evaluation of HPLC methods for pharmaceutical analysis demonstrated the complementary nature of these assessment tools [2]. A method employing sugaring-out-induced homogeneous liquid-liquid microextraction (SULLME) for antiviral compounds was assessed using multiple metrics, yielding the following results:

- AGREE score: 56/100 - The method benefited from miniaturization, semi-automation, and avoided derivatization, but was penalized for using toxic solvents and generating moderate waste [2].

- Analytical Eco-Scale: Moderate performance - The method received penalties for reagent toxicity and waste generation, but scored well on energy consumption and miniaturization [2].

- GAPI assessment - Visualized the specific methodological steps with the highest environmental impact, particularly highlighting sample preparation and waste management as areas requiring optimization [2].

This multi-metric approach provided a comprehensive environmental profile that would not be apparent from any single assessment tool, enabling researchers to identify specific aspects of the method for green optimization while maintaining analytical performance.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagent Solutions for Green HPLC Research

| Reagent Category | Green Alternatives | Function | Environmental Benefit |

|---|---|---|---|

| Mobile Phase Solvents | Bio-based ethanol, Ethyl lactate, Plant-derived acetonitrile | Mobile phase composition | Reduced toxicity, renewable sourcing, biodegradable [11] |

| Extraction Solvents | Supercritical CO₂, Natural deep eutectic solvents (NADES), Cyclopentyl methyl ether | Sample preparation and extraction | Reduced VOC emissions, lower toxicity, renewable sources [2] |

| Derivatization Agents | Microwave-assisted synthesis, Bio-catalyzed derivatization | Analyte detection enhancement | Reduced energy consumption, milder reaction conditions |

| Calibration Standards | In-situ generated standards, Stable isotope-labeled standards | Quantification and method validation | Reduced waste generation, improved accuracy |

| Cleaning Solutions | Aqueous-based detergents, Bio-based solvents | HPLC system maintenance | Reduced hazardous waste, improved operator safety |

The implementation of greenness assessment metrics represents a fundamental shift toward environmentally responsible analytical chemistry in pharmaceutical research and development. AGREE, GAPI, and Analytical Eco-Scale offer complementary approaches that enable HPLC researchers to quantify, visualize, and improve the environmental sustainability of their analytical methods.

AGREE provides the most comprehensive assessment framework through its incorporation of all 12 GAC principles and flexible weighting system [14]. GAPI offers rapid visual identification of environmentally problematic methodological steps through its intuitive color-coded pictogram [2]. The Analytical Eco-Scale enables straightforward numerical comparison between alternative methods through its penalty-point scoring system [2].

For researchers engaged in HPLC method development, the strategic application of these metrics facilitates the design of analytical procedures that maintain rigorous performance standards while minimizing environmental impact. This balanced approach aligns with the broader objectives of sustainable drug development, addressing both regulatory requirements and corporate environmental responsibilities in the pharmaceutical industry.

As green analytical chemistry continues to evolve, these assessment tools will play an increasingly critical role in guiding the adoption of circular economy principles in analytical laboratories, promoting resource efficiency, waste minimization, and the development of environmentally benign analytical methodologies [11].

White Analytical Chemistry (WAC) represents a transformative, holistic paradigm in modern analytical science, moving beyond the purely environmental focus of Green Analytical Chemistry (GAC) to embrace a balanced framework that equally prioritizes analytical performance, ecological sustainability, and practical practicality [15] [16]. As the demand for sustainable laboratory practices grows, the fundamental limitation of GAC has become apparent: its primary focus on reducing environmental impact can sometimes come at the expense of analytical functionality and practical implementation [15]. WAC addresses this critical gap by introducing a unified assessment model that ensures methods are not only environmentally friendly but also analytically sound and operationally feasible for routine use [17].

The term "white" originates from the RGB (Red, Green, Blue) color model, where the combination of these three primary colors of light produces white light [15] [16]. Similarly, a "white" method successfully harmonizes the three crucial attributes: Red for analytical performance quality, Green for environmental impact, and Blue for practical and economic considerations [16]. This integrated approach is particularly valuable in regulated environments like pharmaceutical quality control, where methods must satisfy stringent performance criteria mandated by regulatory agencies while simultaneously advancing corporate sustainability objectives [18]. WAC provides a practical framework for developing and selecting methods that fulfill this dual mandate, representing a significant evolution toward truly sustainable analytical practices [17].

The RGB Model: Core Principles and Theoretical Framework

The Three Dimensions of Assessment

The RGB model forms the conceptual foundation of White Analytical Chemistry, evaluating analytical methods across three distinct but interconnected dimensions [15] [16]:

Red Component (Analytical Performance): This dimension encompasses the fundamental analytical figures of merit that determine the reliability and quality of analytical results. Key criteria include method sensitivity (limit of detection, limit of quantification), selectivity (ability to distinguish between analytes), accuracy (proximity to true value), precision (reproducibility), linearity, and robustness [16] [19]. The red component ensures that environmental sustainability does not compromise the primary analytical purpose of generating high-quality, reliable data.

Green Component (Environmental Impact): Derived from the 12 principles of Green Analytical Chemistry, this dimension assesses the ecological footprint of analytical methods [4]. It evaluates factors including hazardous chemical consumption, waste generation, energy efficiency, operator safety, and the use of renewable resources [15] [4]. This component directly addresses the growing imperative to minimize the environmental impact of analytical operations.

Blue Component (Practicality and Economics): This often-overlooked dimension focuses on the practical implementation of analytical methods in real-world laboratory settings [16] [20]. Key considerations include analysis time, equipment costs, ease of use, automation potential, sample throughput, reagent availability, and operational expenses [16] [18]. The blue component ensures that methods are economically viable and practically feasible for routine application.

The Twelve Principles of White Analytical Chemistry

WAC expands upon the 12 principles of GAC by incorporating analytical and practical considerations, creating a comprehensive 12-principle framework organized according to the RGB model [15]:

Table 1: The Twelve Principles of White Analytical Chemistry

| Dimension | Principle Number | Principle Description |

|---|---|---|

| Red (Analytical Performance) | R1 | Provides high sensitivity and low detection limits |

| R2 | Demonstrates excellent selectivity for target analytes | |

| R3 | Delivers high accuracy and precision | |

| R4 | Offers wide linear range and robustness | |

| Green (Environmental Impact) | G1 | Minimizes waste generation throughout the analytical process |

| G2 | Uses safer, less hazardous solvents and reagents | |

| G3 | Reduces energy consumption through efficient operation | |

| G4 | Prevents derivatization to limit chemical use | |

| Blue (Practicality & Economics) | B1 | Reduces analysis time and increases throughput |

| B2 | Minimizes equipment and operational costs | |

| B3 | Simplifies methodology for ease of use | |

| B4 | Enables automation and integration |

Conceptual Workflow of the WAC RGB Model

The following diagram illustrates the integrated assessment framework of the White Analytical Chemistry RGB model:

Assessment Tools and Metrics for WAC Implementation

Comprehensive Tool Comparison

Implementing WAC requires specialized metrics that collectively address all three RGB dimensions. While traditional green assessment tools focus solely on environmental aspects, the WAC framework employs complementary tools to evaluate the red, green, and blue attributes [21] [4]:

Table 2: Analytical Method Assessment Tools for WAC Implementation

| Tool Name | Primary Focus | Output Format | Key Evaluated Parameters | WAC Dimension |

|---|---|---|---|---|

| AGREE [4] | Environmental impact | Radial chart (0-1) with color code | All 12 GAC principles | Green |

| Analytical Eco-Scale [19] | Environmental impact | Numerical score (100=ideal) | Reagent hazards, energy, waste | Green |

| BAGI [16] [20] | Practical applicability | Numerical score + pictogram | Throughput, cost, automation, simplicity | Blue |

| RAPI [16] | Analytical performance | Not specified | Trueness, precision, recovery, matrix effects | Red |

| RGB Model [15] | Overall whiteness | Color scores + overall percentage | All RGB criteria integrated | Red, Green, Blue |

Practical Application in Pharmaceutical Analysis

The following case studies demonstrate successful WAC implementation in pharmaceutical analysis:

Case Study 1: Stability-Indicating RP-HPLC Method for Amitriptyline HCl A reverse-phase HPLC method for simultaneous assay and impurity profiling of amitriptyline hydrochloride was developed with explicit WAC alignment [19]. The method employed a Phenomenex Kinetex L1 column (150 × 4.6 mm, 2.6 µm) with isocratic elution using a phosphate buffer (pH 7.5) and acetonitrile (35:65 v/v) at 1 mL/min flow rate. The method achieved excellent linearity for amitriptyline hydrochloride (255.49–766.48 µg/mL) and its impurities (0.12–1.68 µg/mL), with a short run time that reduced solvent consumption [19]. Comprehensive greenness assessment using AGREE, Analytical Eco-Scale, and GAPI confirmed minimal environmental impact, while the RGB model quantified the balanced performance across all three dimensions [19].

Case Study 2: Simultaneous Quantification of Gabapentin and Methylcobalamin An RP-HPLC method for simultaneous quantification of gabapentin and methylcobalamin in pharmaceutical products demonstrated exceptional WAC alignment [18]. The method used a Zorbax Eclipse C8 column (150 × 4.6 mm, 3.5 μm) with a green mobile phase of potassium phosphate buffer (pH 6.9)/acetonitrile (95:5 v/v) at 2.0 mL/min. With total analysis time of 10 minutes and excellent linearity (3–50 µg/mL; R² > 0.9998), the method achieved outstanding scores across multiple metrics: AGREE (0.70), AGREEprep (0.71), and Analytical Eco-Scale (80) [18]. The extremely low organic solvent composition (only 5% acetonitrile) represented an over 80% reduction compared to conventional methods, significantly enhancing greenness while maintaining robust analytical performance [18].

Experimental Protocol: Implementing WAC in HPLC Method Development

Systematic Method Development with WAC Integration

Developing HPLC methods within the WAC framework requires simultaneous optimization of RGB dimensions throughout the development process:

Phase 1: Analytical Target Profile (ATP) Definition with RGB Balance

- Define critical analytical requirements: specificity, accuracy, precision, LOD/LOQ (Red criteria)

- Establish environmental constraints: solvent toxicity thresholds, waste generation limits (Green criteria)

- Specify practical parameters: maximum analysis time, cost constraints, automation compatibility (Blue criteria)

- Document acceptable ranges for each criterion before method development begins

Phase 2: Chromatographic Condition Optimization

- Column Selection: Prefer smaller particle columns (e.g., 2.6 µm) that provide higher efficiency, enabling shorter columns and reduced solvent consumption [19]

- Mobile Phase Optimization:

- Replace hazardous solvents (acetonitrile) with greener alternatives (ethanol) where feasible [4]

- Optimize pH and buffer concentration to enhance separation efficiency, reducing need for high organic modifiers

- Implement gradient elution only when necessary to minimize method complexity (Blue) and solvent consumption (Green)

- Flow Rate and Temperature: Balance analysis time (Blue) with separation efficiency (Red) and energy consumption (Green)

Phase 3: Sample Preparation Greenification

- Implement miniaturized techniques: micro-extraction, dilute-and-shoot approaches [16]

- Reduce solvent volumes: scale down from mL to µL volumes where possible

- Eliminate derivatization steps: develop direct detection approaches [4]

- Automate sample preparation: enhance throughput (Blue) and reproducibility (Red) while reducing manual handling of hazardous reagents (Green)

Phase 4: Comprehensive Method Validation with RGB Assessment

- Validate all ICH parameters: specificity, accuracy, precision, linearity, range, robustness (Red)

- Quantify environmental metrics: solvent consumption per analysis, waste generation, energy usage (Green)

- Document practical parameters: total analysis time, cost per analysis, operational complexity (Blue)

- Calculate overall whiteness score using RGB model

Essential Research Reagent Solutions

Table 3: Essential Reagents and Materials for WAC-Compliant HPLC

| Item | Function in WAC Implementation | Green & Practical Considerations |

|---|---|---|

| Ethanol | Green alternative to acetonitrile in mobile phases [4] | Biodegradable, less toxic, renewable source |

| Phosphate Buffers | Aqueous mobile phase component for reverse-phase HPLC | Replace ion-pairing reagents that generate hazardous waste |

| Core-Shell Particles | Stationary phase technology (e.g., 2.6 µm) | Enables shorter columns, reduced solvent consumption |

| Water Bath | Sample preparation without hazardous solvents | Energy-efficient alternative to evaporators |

| Micro-Scale Filters | Sample cleanup with minimal solvent use | Reduce waste generation versus conventional filtration |

| Automated Dilution Systems | Standard and sample preparation | Enhance precision (Red) and throughput (Blue) |

WAC Assessment Protocol: Quantitative Method Evaluation

Step-by-Step RGB Scoring Implementation

Step 1: Individual Principle Scoring Evaluate the method against each of the 12 WAC principles using a consistent scoring scale (0-4 points), where:

- 0 points: Principle not fulfilled

- 2 points: Partially fulfilled

- 4 points: Completely fulfilled

Step 2: Dimension Score Calculation Calculate the average score for each RGB dimension:

- Red Score (RS) = Average of principles R1-R4

- Green Score (GS) = Average of principles G1-G4

- Blue Score (BS) = Average of principles B1-B4

Step 3: Whiteness Percentage Determination Compute the overall whiteness percentage using the formula:

The division by 64 (4³, since each dimension has 4 principles with maximum 4 points each) normalizes the score to a percentage [15].

Step 4: Method Classification and Improvement

- >80%: Excellent white method - minimal compromises across all dimensions

- 60-80%: Good white method - acceptable balance with minor improvement areas

- <60%: Requires optimization - significant imbalances in one or more dimensions

Advanced Implementation: Design of Experiments (DoE) for WAC Optimization

For method development aiming to maximize whiteness, employ Analytical Quality by Design (AQbD) principles with DoE:

Factor Selection

- Critical Method Parameters (CMPs): column temperature, mobile phase composition, flow rate, gradient profile

- Critical Quality Attributes (CQAs): resolution (Red), solvent consumption (Green), run time (Blue)

Experimental Design

- Implement fractional factorial or response surface designs to model relationships between CMPs and CQAs

- Establish design space where all CQAs simultaneously meet RGB criteria

- Validate method robustness within design space boundaries

Multi-Criteria Decision Analysis

- Apply desirability functions to balance potentially conflicting RGB objectives

- Optimize for overall whiteness rather than individual dimension maximization

White Analytical Chemistry represents a paradigm shift in analytical method development and assessment, moving beyond unilateral greenness to embrace a balanced triad of analytical reliability, environmental sustainability, and practical feasibility [15] [16]. The RGB model provides both a theoretical framework and practical toolset for achieving this balance, enabling scientists to develop methods that are not only environmentally responsible but also functionally effective and economically viable [18].

The future evolution of WAC will likely include increased integration with Analytical Quality by Design (AQbD) principles, where RGB criteria are incorporated directly into method development from the initial design phase [17]. Additionally, the emerging concept of Green Financing for Analytical Chemistry (GFAC) proposes dedicated funding mechanisms to support the development and implementation of WAC-aligned methods, potentially accelerating adoption across the pharmaceutical industry [17].

As analytical chemistry continues to evolve in an increasingly sustainability-conscious world, WAC provides a comprehensive framework for balancing the competing demands of performance, planetary responsibility, and practical implementation—ensuring that analytical methods not only generate reliable data but also contribute positively to broader sustainability goals.

Regulatory Drivers and Industry Initiatives for Sustainable Analytical Practices

The integration of sustainable practices into analytical chemistry, particularly within High-Performance Liquid Chromatography (HPLC), represents a fundamental shift driven by regulatory pressures, industry initiatives, and the evolving paradigm of Green Analytical Chemistry (GAC). This transformation is critical as traditional analytical methods often involve energy-intensive processes, significant consumption of non-renewable resources, and substantial waste generation [11]. The field is increasingly moving from a linear "take-make-dispose" model toward a Circular Analytical Chemistry (CAC) framework, which emphasizes minimizing waste and keeping materials in use for as long as possible [11]. This document outlines the current regulatory and industry landscape, provides standardized protocols for implementing and evaluating sustainable HPLC practices, and visualizes the key workflows and metrics essential for researchers and drug development professionals.

Current Landscape: Drivers and Initiatives

Regulatory Drivers

Regulatory agencies play a critical role in driving the adoption of sustainable practices. A recent assessment of 174 standard methods from CEN, ISO, and Pharmacopoeias revealed that 67% scored below 0.2 on the AGREEprep metric (where 1 is the highest possible score), highlighting the urgent need to update these resource-intensive and outdated techniques [11]. In response, regulatory bodies are beginning to:

- Integrate green metrics into method validation and approval processes to ensure greener practices are required for compliance [11].

- Establish clear timelines for phasing out methods that score low on green metrics [11].

- Provide technical guidance and financial incentives, such as tax benefits or grants, to support laboratories in transitioning to greener methods [11].

Furthermore, global Environmental, Social, and Governance (ESG) standards are reshaping the HPLC instruments market, compelling manufacturers to invest in innovative designs that reduce solvent consumption, incorporate energy-efficient components, and utilize recyclable materials [22].

Industry-Led Initiatives and Collaborations

The transition to sustainable analytical chemistry requires collaboration among all stakeholders, including manufacturers, researchers, routine labs, and policymakers [11]. Key industry initiatives include:

- Green Metric Awards: Conferences like HPLC 2025 are attributing topical poster awards for contributions featuring assessments with green metrics, incentivizing the adoption and innovation of sustainable practices [23].

- Industry Leadership Tracks: Specialized sessions are being organized for industry leadership to share experiences and develop views on the sustainable lab of the future, focusing on lab automation, data management, and skill sets [23].

- University-Industry Partnerships: These collaborations are crucial for bridging the gap between academic research and market-ready products. They align academic expertise with market needs, unlocking the true innovation potential of sustainable analytical chemistry [11].

- Corporate Sustainability Commitments: Leading instrument manufacturers are now designing products with sustainability as a core principle. For example, Waters' ACQUITY QDa II Mass Detector has received a My Green Lab ACT label for its efficient design, which reduces energy consumption by up to 70% compared to other mass detectors on the market [24].

Quantitative Assessment of Greenness Metrics

A fundamental component of sustainable analytical practices is the objective evaluation of method environmental impact. Greenness assessment tools provide a standardized approach for this quantification, enabling researchers to benchmark and optimize their HPLC methods.

Table 1: Comparison of Key Greenness Assessment Tools

| Tool Name | Graphical Output | Scoring System | Key Focus Areas | Notable Features |

|---|---|---|---|---|

| NEMI [12] | Quartered circle pictogram | Qualitative (Pass/Fail per criterion) | PBT chemicals, hazardous waste, corrosivity, waste amount. | Simple, quick visual; lacks granularity. |

| Analytical Eco-Scale [4] [12] | Numerical score | Semi-quantitative (100-point ideal, penalty points subtracted) | Reagent toxicity, energy use, waste, occupational hazards. | Simple penalty-point system; good for routine analysis. |

| GAPI [4] [12] | Color-coded pictogram | Semi-quantitative (Visual impact via color) | Entire analytical workflow from sample collection to final determination. | Comprehensive visual summary of a method's environmental impact. |

| AGREE [4] | Radial chart with single score | Quantitative (0 to 1) | All 12 principles of GAC. | Holistic, user-friendly software, provides a single composite score. |

| AGREEprep [11] [4] | Pictogram with score | Quantitative (0 to 1) | Sample preparation procedures. | First dedicated metric for sample preparation; uses 10 assessment criteria. |

| BAGI [4] | "Asteroid" pictogram & % score | Quantitative (0 to 100%) | Practical applicability (cost, throughput, ease, skills). | Complements green metrics by evaluating practical viability. |

Table 2: Greenness Assessment of Example Analytical Methods Using Different Tools

| Analytical Method Description | NEMI Profile [12] | Analytical Eco-Scale Score [12] | AGREE Score | Assessment Summary |

|---|---|---|---|---|

| UPLC-MS/MS for pharmaceuticals in plasma (LLE) | 2/4 criteria met | Lower score (higher penalties) | Estimated Low (~0.3) | Solvent-intensive sample preparation (LLE) lowers greenness. |

| HPLC-UV for contaminants in food | 3/4 criteria met | Intermediate score | Estimated Intermediate (~0.5) | Improved over previous method but still has significant environmental impact. |

| UV spectrophotometry for drug formulations | 4/4 criteria met | Higher score (lower penalties) | Estimated High (~0.7) | Solvent-free, no complex sample prep; higher throughput and greenness. |

Experimental Protocols for Sustainable HPLC

Protocol 1: Implementing Green Solvent Systems in HPLC

Principle: Replace hazardous solvents like acetonitrile and methanol with safer alternatives without compromising chromatographic performance [4] [25].

Materials:

- HPLC system with mixing capabilities

- HPLC column (e.g., C18)

- Ethanol, bio-based solvents, or water-rich mobile phases

- Sample vials and solvents

Procedure:

- Scouting: Start with a water/ethanol gradient for a known mixture. Ethanol is a class 3 solvent with low toxicity and is often derived from renewable resources [4].

- Method Optimization: Adjust gradient profile, temperature, and flow rate (e.g., ≤ 1.0 mL/min) to achieve baseline separation. Use modeling software if available to predict optimal conditions and reduce experimental waste.

- Performance Validation: Ensure the new method meets system suitability criteria for resolution, peak symmetry, and sensitivity, comparable to the original method.

- Greenness Assessment: Calculate the AGREE score for the new method and compare it with the original method to quantify environmental improvement.

Protocol 2: Adopting Green Sample Preparation (GSP)

Principle: Adapt traditional sample preparation to align with the Twelve Principles of GSP, focusing on reducing energy consumption, solvent use, and waste generation [11].

Materials:

- Vortex mixer, ultrasonic bath, or microwave-assisted extraction system

- Miniaturized extraction devices (e.g., for µ-SPE)

- Automated liquid handling system (if available)

Procedure:

- Miniaturization: Scale down sample size and solvent volumes. For example, replace a 10 mL liquid-liquid extraction with a 1 mL or lower volume miniaturized alternative [11].

- Energy Efficiency: Apply assisting fields like vortex mixing or ultrasound to enhance extraction efficiency and speed up mass transfer, replacing energy-intensive techniques like Soxhlet extraction [11].

- Automation & Integration: Utilize automated systems or integrated workflows to process samples in parallel. This saves time, lowers reagent consumption, and reduces operator exposure to hazardous chemicals [11] [26].

- Waste Management: Segregate and recycle solvents where possible. Calculate the waste produced per sample and aim for a target of < 50 g per analysis, a benchmark used in metrics like NEMI [12].

Workflow Visualization

The following diagram illustrates the integrated decision-making workflow for developing and validating a sustainable HPLC method, incorporating regulatory, methodological, and assessment considerations.

Sustainable HPLC Method Development Workflow

The Scientist's Toolkit: Essential Reagents and Materials

The successful implementation of sustainable HPLC practices relies on a suite of reagents, instruments, and assessment tools.

Table 3: Essential Research Reagent Solutions for Sustainable HPLC

| Tool/Reagent | Function/Principle | Sustainable Advantage |

|---|---|---|

| Green Solvents (e.g., Ethanol, Bio-based solvents) [4] [25] | Mobile phase components for compound separation. | Lower toxicity, biodegradable, often derived from renewable feedstocks. |

| Water-Rich Mobile Phases [4] | Mobile phase to reduce organic solvent consumption. | Significantly reduces use and disposal of hazardous organic solvents. |

| Solid-Phase Microextraction (SPME) Devices [25] | Solvent-less or solvent-minimized sample preparation. | Eliminates or drastically reduces solvent use in sample prep, aligning with GSP principles. |

| Miniaturized LC Systems (e.g., micro-HPLC) [4] [26] | Analytical separation on a smaller scale. | Reduces mobile phase consumption, waste generation, and energy use per analysis. |

| AGREE & AGREEprep Software [4] | Open-source tools for quantifying method greenness. | Provides a standardized, quantitative score to guide and justify sustainable method development. |

| Energy-Efficient Detectors (e.g., ACQUITY QDa II) [24] | Detection and quantification of analytes. | Certified (e.g., My Green Lab ACT label) to consume significantly less energy. |

Practical Strategies for Developing Green HPLC Methods in Pharmaceutical Analysis

High-Performance Liquid Chromatography (HPLC) is a fundamental tool in analytical laboratories, but its environmental impact is significant due to the large volumes of hazardous organic solvents used in mobile phases [27]. Conventional solvents like acetonitrile and methanol pose substantial health risks to operators and generate hazardous waste that is costly to dispose of, often requiring high-temperature incineration [27] [28]. Green Analytical Chemistry (GAC) principles provide a framework for minimizing this environmental footprint by replacing hazardous solvents with safer alternatives while maintaining analytical performance [2]. This application note provides a structured guide for researchers and drug development professionals to identify, evaluate, and implement greener solvent alternatives in HPLC methods, framed within the context of green analytical chemistry metrics [3].

The drive toward green chromatography is motivated by three primary objectives: (i) reduce or eliminate hazardous solvents, (ii) decrease energy consumption, and (iii) minimize waste generation [28]. In reversed-phase HPLC (RP-HPLC), which represents the most commonly applied HPLC mode, the mobile phase constitutes the most significant environmental concern [27]. This guide presents systematic approaches for solvent substitution, detailed experimental protocols for method translation, and standardized metrics for evaluating environmental performance, enabling laboratories to advance their sustainability goals without compromising analytical quality.

Green Solvent Assessment and Selection

Conventional Solvents and Their Hazards

Table 1: Hazard Profiles of Conventional HPLC Solvents

| Solvent | Toxicity Concerns | Environmental Impact | Disposal Considerations | CHEM21 Classification |

|---|---|---|---|---|

| Acetonitrile | Toxic through ingestion, inhalation, or skin absorption; causes dizziness to respiratory distress; chronic exposure may cause long-term issues [27] | Highly soluble in water; can persist in aquatic systems and bioaccumulate [27] | Incineration; challenging to recycle due to analyte contaminants [27] | Problematic [27] |

| Methanol | Can cause nerve damage and blindness upon exposure [29] | Generates hazardous waste [29] | Requires closed waste systems; incineration [29] | Problematic |

| Tetrahydrofuran (THF) | Can form explosive peroxides when exposed to air [29] | - | Requires careful handling and stabilization [29] | Problematic |

| Hexane | Neurotoxic and potentially carcinogenic; ignitable [29] | - | Requires hazardous waste disposal [29] | Problematic |

Green Alternative Solvents

Table 2: Properties of Green Alternative Solvents for HPLC

| Green Solvent | Viscosity (cP) | UV Cutoff (nm) | Elution Strength (RP-HPLC) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Ethanol | 1.20 (higher viscosity) [27] | 210 [30] | Moderate | Renewable, biodegradable, low toxicity [27] | High viscosity, high UV cutoff, flammable [27] |

| Acetone | 0.32 [27] | 330 [27] | Moderate to high | Low viscosity, excellent solvating power [27] | High UV absorbance, flammable [27] |

| Propylene Carbonate | 2.5 [27] | 240 [27] | Moderate | High boiling point, low volatility [27] | High viscosity, limited water miscibility [27] |

| Ethyl Lactate | 2.4 [27] | 220 [27] | Moderate | Biodegradable, low toxicity, renewable [27] | High viscosity, limited availability in HPLC-grade [27] |

| Dimethyl Carbonate | 0.63 [27] | 240 [27] | Low to moderate | Biodegradable, low toxicity [27] | Limited water miscibility [27] |

| Cyrene (Dihydrolevoglucosenone) | - | - | Moderate | Renewable, biodegradable, low toxicity [27] | High viscosity, limited availability in HPLC-grade [27] |

| Glycerol | 950 [27] | 205 [27] | Very low | Non-toxic, non-flammable, renewable [27] | Very high viscosity, requires heating [27] |

Greenness Assessment Metrics for Solvent Selection

Table 3: Green Analytical Chemistry Assessment Tools

| Assessment Tool | Type of Output | Criteria Assessed | Advantages | Limitations |

|---|---|---|---|---|

| NEMI (National Environmental Methods Index) [2] | Pictogram (pass/fail 4 criteria) | Persistence, bioaccumulation, toxicity, waste generation [2] | Simple, visual, accessible [2] | Binary assessment lacks granularity [2] |

| Analytical Eco-Scale [2] | Numerical score (0-100) | Hazardous reagent use, energy consumption, waste [2] | Quantitative, facilitates comparison [2] | Relies on expert judgment for penalty points [2] |

| GAPI (Green Analytical Procedure Index) [3] [2] | Color-coded pictogram (5 sections) | Entire analytical process from sample collection to detection [2] | Comprehensive, visual identification of high-impact stages [2] | No overall score, some subjectivity in color assignment [2] |

| AGREE (Analytical GREENness) [2] | Pictogram and numerical score (0-1) | All 12 principles of GAC [2] | Comprehensive, user-friendly, facilitates comparison [2] | Doesn't fully account for pre-analytical processes [2] |

| AGREEprep [3] [2] | Pictogram and numerical score (0-1) | Sample preparation specifically [2] | Focuses on often overlooked high-impact stage [2] | Must be used with broader tools for full method evaluation [2] |

| AGSA (Analytical Green Star Analysis) [2] | Star-shaped diagram and score | Reagent toxicity, waste generation, energy use, solvent consumption [2] | Intuitive visualization, integrated scoring system [2] | - |

Experimental Protocols

Protocol 1: Direct Substitute Method Translation

Objective: Systematically replace acetonitrile or methanol with ethanol while maintaining separation quality [27].

Materials:

- HPLC system with quaternary pump capability

- C18 column (150 × 4.6 mm, 5 µm)

- HPLC-grade ethanol, acetonitrile, methanol, and water

- Standard mixture of target analytes

Procedure:

- Initial Method Assessment:

- Run the original method with acetonitrile or methanol mobile phase

- Record retention times, resolution, peak symmetry, and backpressure

Mobile Phase Preparation:

- Prepare ethanol-water mixtures at the same volume ratio as the original method

- Note: Ethanol-water mixtures have higher viscosity than acetonitrile-water [27]

- Filter through 0.45 µm PTFE or nylon membrane

- Degas by sonication for 10 minutes or using online degasser

Initial Method Translation:

- Inject the standard mixture using the original gradient profile

- Note the increase in backpressure due to higher viscosity of ethanol

- Observe changes in retention and selectivity

Method Optimization:

- If backpressure is too high: Reduce flow rate by 20-30% OR use column heating (30-40°C) to reduce viscosity [27]

- If retention is inadequate: Adjust initial organic modifier concentration (±5-10%)

- If selectivity changes: Fine-tune gradient profile slope and shape

- If UV detection issues occur: Adjust wavelength above 220 nm to avoid ethanol's UV cutoff [27]

Method Validation:

- Once optimal conditions established, validate according to ICH guidelines

- Pay special attention to precision, as viscosity changes can affect pump accuracy

Protocol 2: Greener Method Development Using Ternary Mixtures

Objective: Develop new methods using optimized mixtures of green solvents to balance elution strength, viscosity, and detection compatibility [27].

Materials:

- HPLC system with quaternary pump and column oven

- C18 column (100 × 4.6 mm, 3.5 µm)

- HPLC-grade ethanol, acetone, ethyl acetate, propylene carbonate, and water

- Test mixture representing analyte chemical diversity

Procedure:

- Solvent Screening:

- Test individual green solvents (ethanol, acetone, ethyl lactate) in water (50:50 v/v)

- Evaluate elution strength, peak shape, and backpressure for each analyte

Ternary Mixture Optimization:

- Prepare mixtures of ethanol with low-viscosity modifiers (e.g., acetone or ethyl acetate)

- Test at 5-15% modifier concentration in ethanol-water base

- Example: Water/ethanol/acetone (55/35/10, v/v/v)

Viscosity Management:

- Measure backpressure for each ternary mixture

- For high-viscosity mixtures (e.g., with propylene carbonate):

- Employ column heating (40-60°C)

- Consider reduced flow rates (0.8-1.0 mL/min for 4.6 mm ID column)

Detection Optimization:

- For UV detection: Select solvents with appropriate UV cutoffs (acetone unsuitable for low UV)

- For MS detection: Ensure complete miscibility and volatility compatibility

Greenness Assessment:

- Apply AGREE or GAPI metrics to final method

- Compare with conventional method using NEMI pictogram or Analytical Eco-Scale

Protocol 3: Microscale Method Translation for Solvent Reduction

Objective: Adapt conventional methods to microscale HPLC to dramatically reduce solvent consumption [27] [28].

Materials:

- UHPLC system capable of microflow rates

- C18 column (100 × 2.1 mm, 1.8 µm)

- HPLC-grade solvents

- Precision syringe for sample injection

Procedure:

- System Calibration:

- Verify pump accuracy at low flow rates (0.1-0.5 mL/min)

- Check detector cell compatibility with reduced flow rates

Method Scaling:

- Reduce column dimensions from 4.6 mm to 2.1 mm ID

- Adjust flow rate proportionally: F₂ = F₁ × (r₂²/r₁²)

- Example: 1.0 mL/min on 4.6 mm ID → 0.2 mL/min on 2.1 mm ID

- Scale injection volume proportionally to maintain sensitivity

Particle Size Optimization:

- Utilize sub-2µm particles for improved efficiency at reduced flow rates

- Adjust gradient profile to account for improved efficiency:

- Shorten gradient time by 30-50%

- Maintain same gradient steepness

Green Solvent Implementation:

- Apply scaled method with green solvent alternatives

- Note: Viscosity effects may be more pronounced at microscale

Performance Verification:

- Verify resolution, sensitivity, and precision match or exceed original method

- Quantify solvent reduction: Typically 75-85% reduction with 2.1 mm ID column

Visualization of Solvent Selection Workflow

Green Solvent Selection Workflow: This diagram outlines a systematic decision process for replacing hazardous solvents in HPLC methods, incorporating property assessment, method adjustment, and greenness evaluation using standardized metrics.

Research Reagent Solutions

Table 4: Essential Materials for Green HPLC Implementation

| Reagent/Material | Function/Purpose | Green Considerations | Example Application |

|---|---|---|---|

| Ethanol (HPLC-grade) | Primary green solvent replacement | Renewable, biodegradable, lower toxicity than acetonitrile [27] | Direct substitute for methanol or acetonitrile in RP-HPLC [27] |

| Acetone (HPLC-grade) | Modifier for viscosity reduction | Low viscosity, but high UV cutoff limits detection options [27] | Ternary mixtures with ethanol to reduce backpressure [27] |

| Ethyl Lactate | Biobased green solvent | Derived from renewable resources, biodegradable [27] | Alternative for medium-polarity separations [27] |

| Propylene Carbonate | High-boiling green solvent | Low volatility, reduced operator exposure [27] | Separations requiring high temperature operation [27] |

| Cyrene (Dihydrolevoglucosenone) | Novel biobased solvent | Renewable feedstock (cellulose), low toxicity [27] | Emerging alternative for polar analytes [27] |

| Natural Deep Eutectic Solvents (NADES) | Green solvent systems | Biocompatible, tunable properties [27] | Specialty separations with unique selectivity [27] |

| C18 Columns (Sub-2µm) | Stationary phase for UHPLC | Enables miniaturization and solvent reduction [27] | Microscale method translation [27] |

| Column Heater | Temperature control | Reduces mobile phase viscosity [27] | Essential for high-viscosity solvents like ethanol-water [27] |

The transition to green solvents in HPLC represents a significant opportunity to align analytical practice with environmental sustainability goals. Ethanol has emerged as the most established and practical alternative to acetonitrile and methanol, despite challenges related to its higher viscosity and UV cutoff [27]. For more advanced green solvent applications, ternary mixtures incorporating ethanol with modifiers like acetone or ethyl lactate can optimize viscosity and elution strength while maintaining green credentials [27].

The field of green chromatography continues to evolve with several promising trends. Supercritical fluid chromatography (SFC) using carbon dioxide as the primary mobile phase offers a virtually solvent-free alternative for suitable applications [28]. Ultrahigh-pressure liquid chromatography (UHPLC) with reduced column dimensions enables dramatic solvent reduction while maintaining performance [28]. Meanwhile, ongoing research into novel stationary phases including cellulose-based materials and metal-organic frameworks (MOFs) promises more sustainable separation platforms in the future [28].

Implementation of green solvent strategies should be guided by standardized assessment metrics such as AGREE, GAPI, and Analytical Eco-Scale to provide quantitative evaluation of environmental benefits [3] [2]. By adopting the protocols and selection criteria outlined in this application note, researchers and drug development professionals can systematically reduce the environmental footprint of their HPLC methods while maintaining the high-quality data required for pharmaceutical analysis.

The evolution of liquid chromatography has been profoundly shaped by the parallel drives towards miniaturization and sustainable analytical practices. Miniaturized Ultra-High-Performance Liquid Chromatography (UHPLC) and micro-flow techniques represent a transformative approach that fundamentally reimagines analytical methodologies by scaling down column dimensions and reducing solvent consumption while maintaining or even enhancing analytical performance. These techniques typically utilize columns with internal diameters ranging from 0.1 to 1.0 mm and flow rates from 1 to 100 µL/min, operating at pressures up to 1000 bar [31] [32] [33]. This strategic downscaling aligns perfectly with the core principles of Green Analytical Chemistry (GAC), which advocates for reducing hazardous substance use, minimizing waste generation, and considering the entire lifecycle environmental impact of analytical procedures [3] [34]. The integration of miniaturized columns within UHPLC systems has enabled unprecedented efficiency in pharmaceutical and biomedical research, particularly for applications involving limited sample availability such as tissue biopsies, tear fluid analysis, and single-cell metabolomics [34] [35].