Green Analytical Chemistry in Pharma: Implementing Sustainable Practices from Principles to Validation

This article provides a comprehensive roadmap for researchers, scientists, and drug development professionals to effectively implement Green Analytical Chemistry (GAC) principles in pharmaceutical analysis.

Green Analytical Chemistry in Pharma: Implementing Sustainable Practices from Principles to Validation

Abstract

This article provides a comprehensive roadmap for researchers, scientists, and drug development professionals to effectively implement Green Analytical Chemistry (GAC) principles in pharmaceutical analysis. It covers the foundational shift from traditional methods to the holistic White Analytical Chemistry (WAC) framework, details practical strategies for greening techniques like HPLC/UHPLC, addresses common troubleshooting and optimization challenges, and guides the validation of method greenness using modern metrics (AGREE, GAPI, BAGI). By synthesizing current trends and case studies, the content aims to equip laboratories with the knowledge to achieve robust, compliant, and environmentally sustainable analytical practices.

From Green to White: The Foundational Shift in Sustainable Pharmaceutical Analysis

The pharmaceutical industry faces increasing pressure to adopt sustainable practices that minimize environmental impact while maintaining scientific rigor and product quality. Green Analytical Chemistry (GAC) has emerged as a transformative framework for developing analytical methods that reduce or eliminate hazardous substances, decrease energy consumption, and improve operator safety. Within pharmaceutical research and quality control, High-Performance Liquid Chromatography (HPLC) represents a significant environmental concern due to its substantial consumption of organic solvents, which are often toxic and generate large volumes of hazardous waste [1]. The implementation of GAC principles addresses these issues by promoting alternative solvents, energy-efficient instrumentation, and waste reduction strategies without compromising analytical performance [2] [3] [1].

The urgency for adopting GAC principles stems from both environmental responsibility and regulatory alignment. With hundreds of chromatographic systems operating daily in pharmaceutical quality control laboratories worldwide, the cumulative environmental footprint of traditional analytical methods is substantial [1]. The 12 principles of GAC provide a systematic framework for introducing sustainability into analytical processes, focusing on minimizing hazardous chemical use, reducing energy requirements, and implementing proper waste management protocols [1]. This application note details practical strategies and protocols for implementing GAC principles in pharmaceutical analysis, specifically focusing on HPLC methodologies that align with sustainability goals.

GAC Implementation Strategies for HPLC Analysis

Alternative Solvent Systems

A primary strategy for greening HPLC methods involves replacing conventional organic solvents with safer alternatives. Micellar Liquid Chromatography (MLC) has gained prominence as an effective organic solvent-free approach that utilizes surfactants at concentrations above their critical micelle concentration as mobile phase components [2]. This technique employs environmentally benign surfactants such as sodium dodecyl sulfate (SDS) and Brij-35, which demonstrate low environmental persistence and biodegradability [2]. Research confirms that mixed micellar mobile phases containing both ionic and non-ionic surfactants can effectively separate complex drug mixtures without requiring organic solvents, significantly reducing toxicity and waste hazards [2].

Another established approach involves replacing hazardous solvents like acetonitrile, methanol, and tetrahydrofuran with green solvent alternatives such as ethanol or isopropanol, which offer improved safety profiles and reduced environmental impact [3] [1]. The effectiveness of these substitutions has been demonstrated in multiple pharmaceutical applications, including the analysis of clonazepam and its related substances, where a mobile phase composed of isopropanol, sodium dodecyl sulfate, and sodium acetate buffer successfully replaced more hazardous solvent systems while maintaining robust analytical performance [3].

Method Optimization and Miniaturization

Advanced optimization techniques like Design of Experiments (DOE) and Response Surface Methodology (RSM) enable development of highly efficient chromatographic methods with minimized environmental impact [2]. These statistical approaches facilitate understanding of factor interactions and systematic optimization of critical method parameters, resulting in reduced analysis time and solvent consumption [2]. The implementation of Central Composite Design (CCD) has proven particularly effective for optimizing surfactant concentrations, pH, and other variables to achieve optimal resolution while maintaining green principles [2].

Instrumentation miniaturization represents another significant advancement, with Ultra-High-Performance Liquid Chromatography (UHPLC) enabling faster analysis times and substantially reduced solvent consumption compared to conventional HPLC [1]. The convergence of alternative solvents, method optimization, and instrumentation advances provides pharmaceutical analysts with multiple pathways to implement GAC principles while maintaining methodological rigor.

Table 1: Comparison of Traditional vs. Green HPLC Approaches in Pharmaceutical Analysis

| Parameter | Traditional HPLC | Green HPLC Alternatives |

|---|---|---|

| Solvent Type | Acetonitrile, Methanol, Tetrahydrofuran [3] [1] | Aqueous Micellar Solutions, Ethanol, Isopropanol [2] [3] |

| Solvent Consumption | High (1-5 mL/min flow rates) [1] | Reduced (via UHPLC, method optimization) [1] |

| Toxicity | High toxicity, hazardous waste [3] [1] | Lower toxicity, biodegradable components [2] |

| Waste Generation | Substantial (50-500 mL/day) [1] | Minimal (10-100 mL/day) [1] |

| Key Advantages | Established methods, wide applicability | Reduced environmental impact, improved operator safety, lower disposal costs [3] |

Detailed Experimental Protocols

Protocol 1: Green Micellar HPLC for Antimicrobial Combination Therapy

This protocol details a green, organic solvent-free HPLC method for simultaneous determination of five antimicrobial drugs (Ciprofloxacin, Tinidazole, Dexamethasone Sodium Phosphate, Diloxanide Furoate, and Metronidazole) in pharmaceutical formulations [2].

Reagents and Materials:

- Sodium dodecyl sulfate (SDS): Anionic surfactant for micelle formation

- Brij-35: Non-ionic surfactant to enhance separation

- Orthophosphoric acid: For pH adjustment

- Reference standards: Pharmaceutical grade target analytes

- Mobile phase: 70.76 mM SDS and 21.38 mM Brij-35 in purified water, pH adjusted to 2.76

Instrumentation and Conditions:

- HPLC System: Alliance 2695 Separations Unit with photodiode array detector

- Column: Symmetry C18 (3.5 µm, 4.6 × 75 mm)

- Mobile Phase: Isocratic micellar solution of 70.76 mM SDS and 21.38 mM Brij-35, pH 2.76

- Flow Rate: 1.0 mL/min

- Temperature: 40°C ± 2°C

- Detection: 260 nm

- Injection Volume: 20 µL

Sample Preparation:

- Accurately weigh and transfer pharmaceutical formulation equivalent to 10 mg of each active ingredient into a 25 mL volumetric flask

- Add approximately 15 mL of mobile phase and sonicate for 10 minutes

- Dilute to volume with mobile phase and mix thoroughly

- Filter through 0.45 µm membrane filter before injection

Validation Parameters:

- Linearity: Prepare standard solutions at five concentration levels across the working range

- Precision: Perform six replicate injections of standard solution (%RSD < 2.0)

- Accuracy: Conduct recovery studies at 50%, 100%, and 150% of target concentration (acceptance criteria: 98-102%)

- Specificity: Demonstrate resolution from degradation products and excipients

- Robustness: Evaluate influence of small variations in pH (±0.2), temperature (±2°C), and surfactant concentrations (±5%)

This method successfully eliminates organic solvents from the mobile phase while maintaining robust performance characteristics, representing a significant advancement in green pharmaceutical analysis [2].

Protocol 2: Stability-Indicating HPLC Method for Clonazepam

This protocol describes a green stability-indicating HPLC method for determination of clonazepam and its related substances in pharmaceutical formulations [3].

Reagents and Materials:

- Sodium dodecyl sulfate: 2% solution in purified water

- Sodium acetate buffer: 0.05 M, pH 3.5 ± 0.05

- Isopropanol: HPLC grade

- Clonazepam reference standard

- Related compounds A and B

Instrumentation and Conditions:

- HPLC System: Shimadzu system with photodiode array detector

- Column: BDS C8 Hypersil (250 mm × 4.6 mm, 5 µm)

- Mobile Phase: Isopropanol:2% SDS:0.05 M sodium acetate buffer (20:25:55, v/v)

- Flow Rate: 1.5 mL/min

- Detection: 254 nm

- Injection Volume: 20 µL

- Temperature: Ambient

Forced Degradation Studies:

- Acidic Degradation: Expose sample solution in 1 M HCl at room temperature for 12 hours

- Basic Degradation: Expose sample solution in 1 M NaOH at room temperature for 12 hours

- Oxidative Degradation: Treat sample with 3% H₂O₂ at room temperature for 4 hours

- Photolytic Degradation: Expose sample to 1.2 million lux hours for 24 hours

- After degradation, neutralize solutions and dilute with mobile phase before analysis

Method Validation:

- Specificity: Verify separation of clonazepam from degradation products and related substances

- Linearity: Demonstrate linear response over concentration range of 4-140 µg/mL for clonazepam and 4-64 µg/mL for related compounds

- Quantitation Limits: Establish LOD and LOQ for clonazepam and related substances

- Solution Stability: Evaluate standard and sample solution stability over 24 hours

This method successfully replaces hazardous solvents like tetrahydrofuran and methanol traditionally used in clonazepam analysis, significantly reducing environmental impact and operator risk while maintaining stability-indicating capability [3].

Essential Research Reagent Solutions

Table 2: Key Reagents for Implementing Green HPLC Methods in Pharmaceutical Analysis

| Reagent | Function in Green HPLC | Environmental & Safety Advantages |

|---|---|---|

| Sodium Dodecyl Sulfate (SDS) | Anionic surfactant for micellar liquid chromatography [2] [3] | Low environmental persistence, biodegradable, not carcinogenic [2] |

| Brij-35 | Non-ionic surfactant in mixed micellar systems [2] | Low toxicity, biodegradable, low background UV absorption [2] |

| Ethanol | Greener organic solvent alternative [1] | Renewable source, lower toxicity compared to acetonitrile and methanol [1] |

| Isopropanol | Organic modifier in reversed-phase systems [3] | Less hazardous than acetonitrile or tetrahydrofuran [3] |

| Supercritical CO₂ | Mobile phase in supercritical fluid chromatography [1] | Non-toxic, non-flammable, easily removed from analytes [1] |

GAC Assessment Tools and Sustainability Evaluation

The implementation of GAC principles requires robust assessment tools to evaluate and compare the environmental friendliness of analytical methods. Several validated metrics have been developed specifically for this purpose:

Analytical Greenness Metric Approach (AGREE): This comprehensive assessment tool incorporates all twelve principles of GAC into a unified scoring system, providing an overall greenness score based on multiple criteria including energy consumption, waste generation, and reagent toxicity [1].

Green Analytical Procedure Index (GAPI): GAPI offers a visual representation of method greenness through a colored pictogram that evaluates environmental impact across the entire analytical process from sample collection to final determination [2] [1].

Analytic Eco-Scale Assessment (ESA): This semi-quantitative approach assigns penalty points to aspects of the method that deviate from ideal green conditions, with higher scores indicating greener methods [1].

National Environmental Methods Index (NEMI): NEMI uses a simple pictogram to indicate whether a method meets basic green criteria regarding persistence, bioaccumulation, toxicity, and waste generation [1].

Application of these assessment tools to the previously described protocols demonstrates their significant environmental advantages over traditional methods. The micellar HPLC method for antimicrobial drugs [2] and the clonazepam stability-indicating method [3] both show improved greenness profiles based on AGREE and GAPI evaluations, confirming their reduced environmental impact while maintaining analytical performance.

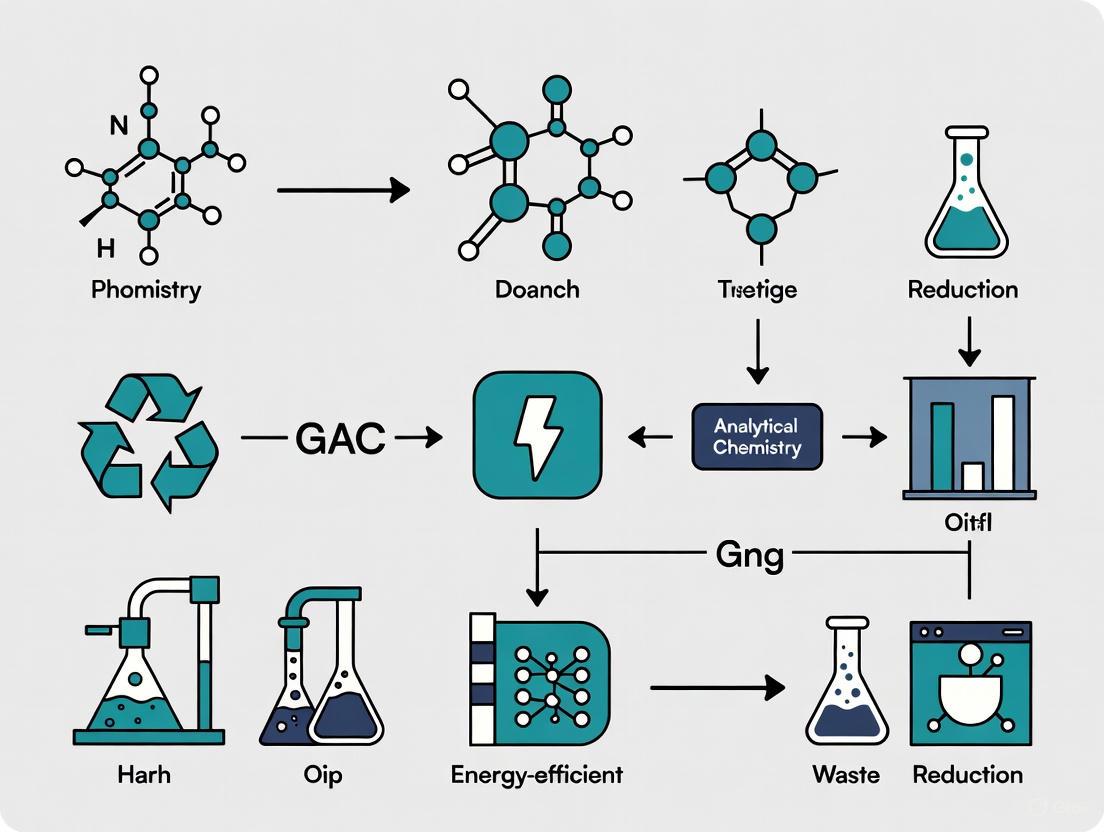

Visualizing GAC Implementation Workflows

GAC Implementation Workflow for Pharmaceutical Analysis

The implementation of Green Analytical Chemistry principles in pharmaceutical analysis represents both an environmental imperative and an opportunity for methodological innovation. The protocols and strategies detailed in this application note demonstrate that significant reductions in hazardous solvent consumption, waste generation, and energy use are achievable without compromising analytical performance. As regulatory focus on environmental sustainability intensifies and the pharmaceutical industry seeks to reduce its ecological footprint, GAC provides a structured framework for developing analytical methods that align with broader sustainability goals. The continued adoption and refinement of green analytical approaches will be crucial for advancing environmentally responsible pharmaceutical research and quality control while maintaining the highest standards of analytical science.

Green Analytical Chemistry (GAC) has emerged as a fundamental sub-discipline of green chemistry, focusing specifically on making analytical practices more environmentally sustainable [4]. In the pharmaceutical industry, where analytical methods are employed extensively for quality control, drug development, and regulatory compliance, the adoption of GAC principles presents significant opportunities to reduce environmental impact while maintaining analytical excellence [5]. The core philosophy of GAC aligns with the broader goals of sustainable development, emphasizing the need to minimize or eliminate hazardous substances, reduce energy consumption, and prevent waste generation throughout the analytical process [6] [7].

Traditional analytical methods in pharmaceutical settings often rely heavily on toxic reagents and solvents, generate substantial waste, and consume considerable energy [5]. The transition to greener alternatives is driven not only by environmental concerns but also by economic factors and workplace safety considerations [7]. This document outlines the 12 principles of GAC, provides practical applications for pharmaceutical analysis, and offers detailed protocols for implementing these principles in research and development settings.

The 12 Principles of Green Analytical Chemistry

The 12 principles of GAC were formulated as a revision of the original green chemistry principles to better address the specific needs and challenges of analytical chemistry [4] [6]. These principles provide a comprehensive framework for greening analytical practices in pharmaceutical research and other chemical analysis fields.

Table 1: The 12 Principles of Green Analytical Chemistry

| Principle Number | Principle Description | Key Focus Areas |

|---|---|---|

| 1 | Direct analytical techniques should be applied to avoid sample treatment [4] | Minimizing sample preparation, direct analysis |

| 2 | Minimal sample size and minimal number of samples are goals [4] | Microsampling, statistical sampling approaches |

| 3 | In situ measurements should be performed [4] | On-site analysis, field measurements |

| 4 | Integration of analytical processes and operations saves energy and reduces reagents [4] | Process integration, automated systems |

| 5 | Automated and miniaturized methods should be selected [4] | Lab automation, microfluidic devices |

| 6 | Derivatization should be avoided [4] | Direct detection methods |

| 7 | Generation of large waste volumes should be avoided and proper waste management should be implemented [4] | Waste reduction, recycling |

| 8 | Multi-analyte determinations should be preferred over single-analyte methods [4] | Multiplexed assays, multi-component analysis |

| 9 | Energy consumption should be minimized [4] | Energy-efficient instrumentation |

| 10 | Reagents from renewable sources should be preferred [4] | Bio-based solvents, natural reagents |

| 11 | Toxic reagents should be eliminated or replaced [4] | Alternative solvents, less hazardous chemicals |

| 12 | Operator safety should be increased [4] | Personal protection, exposure minimization |

These principles can be conveniently remembered using the mnemonic SIGNIFICANCE [4], which encapsulates the core values of green analytical practices:

- S - Sample treatment and size minimization

- I - In-situ measurements

- G - Green methodologies

- N - Non-heating and energy reduction

- I - Integration of processes

- F - Field portable equipment

- I - Independent identification

- C - Clean methods and waste reduction

- A - Automation and miniaturization

- N - Non-polluting methods

- C - Chemical and operator safety

- E - Eco-friendly and renewable reagents

Diagram 1: The 12 Principles of Green Analytical Chemistry organized by thematic categories.

Application Notes: Implementing GAC in Pharmaceutical Analysis

Green Sample Preparation Techniques

Sample preparation is often the most polluting stage in pharmaceutical analysis [5]. Implementing GAC principles at this stage can significantly reduce the environmental impact of analytical methods.

Solid Phase Microextraction (SPME) SPME represents a solvent-free sample preparation technique that combines extraction and enrichment into a single step [5]. This method utilizes a silica fiber coated with an appropriate adsorbent phase, which extracts analytes directly from the sample matrix. The efficiency of SPME depends on several factors including fiber type, sample stirring, and extraction time [5]. SPME can be coupled with various analytical techniques including HPLC, GC/MS, and LC-MS for pharmaceutical applications such as drug metabolite analysis and impurity profiling.

QuEChERS Extraction Methodology The QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) approach, originally developed for pesticide residue analysis, has found increasing application in pharmaceutical analysis [5]. This method involves two main stages: solvent extraction using acetonitrile with buffer salts, followed by a dispersive solid-phase extraction clean-up using primary secondary amine (PSA) and magnesium sulfate [5]. QuEChERS is considered a green extraction method due to its reduced solvent consumption compared to traditional extraction techniques and has been successfully applied to the extraction of various pharmaceuticals from biological matrices including blood and plasma [5].

Green Chromatographic Approaches

Chromatographic methods, particularly liquid chromatography (LC) and gas chromatography (GC), are workhorse techniques in pharmaceutical analysis that traditionally consume large volumes of organic solvents.

Ultra-High-Performance Liquid Chromatography (UHPLC) UHPLC represents a greener alternative to conventional HPLC through its use of smaller particle size columns (<2 μm) and higher operating pressures, resulting in faster analysis times, reduced solvent consumption, and decreased waste generation [5]. The migration from HPLC to UHPLC can reduce solvent consumption by 80-90% while maintaining or improving chromatographic resolution [6].

Green Solvent Selection The replacement of traditional hazardous solvents with greener alternatives is a key aspect of implementing GAC principles in chromatographic methods [5] [8]. Water and ethanol are preferred green solvents that can sometimes replace acetonitrile and methanol in reversed-phase chromatography [5]. Supercritical fluid chromatography (SFC) using supercritical CO₂ as the mobile phase represents another green alternative, particularly for chiral separations in pharmaceutical analysis [8].

Table 2: Green Alternatives to Traditional Analytical Techniques in Pharmaceutical Analysis

| Traditional Technique | Green Alternative | Environmental Benefits | Pharmaceutical Applications |

|---|---|---|---|

| Conventional HPLC | UHPLC | Reduced solvent consumption (80-90%), shorter run times, less waste [5] [6] | Potency assays, stability testing, impurity profiling |

| Organic solvent-based extraction | Solid Phase Microextraction (SPME) | Solvent-free, minimal waste, reduced exposure [5] | Bioanalysis, therapeutic drug monitoring |

| Liquid-liquid extraction | QuEChERS | Reduced solvent volume, faster processing [5] | Drug extraction from biological matrices |

| Normal-phase chromatography | Supercritical Fluid Chromatography (SFC) | Replaces hexane and other hazardous solvents with supercritical CO₂ [8] | Chiral separations, natural product analysis |

| Traditional sample preparation | Direct chromatographic methods | Elimination of sample preparation steps [5] | Analysis of clean pharmaceutical formulations |

Greenness Assessment Tools for Analytical Methods

Evaluating the environmental impact of analytical methods is essential for implementing GAC principles. Several metrics and assessment tools have been developed to quantify and compare the greenness of analytical methods [6] [9].

Analytical Eco-Scale The Analytical Eco-Scale is a semi-quantitative assessment tool that assigns penalty points to an analytical method based on the amounts of hazardous reagents and solvents used, energy consumption, and waste generated [9] [10]. An ideal green analysis would score 100 points, with points deducted for each parameter that deviates from ideal green conditions. Methods scoring above 75 are considered excellent green analysis, while scores below 50 represent inadequate greenness [9].

Green Analytical Procedure Index (GAPI) GAPI provides a comprehensive visual assessment of the greenness of an entire analytical method using a color-coded pictogram that covers five main areas: sample collection, preservation, transportation, and preparation; reagents and chemicals used; instruments and equipment; final product form; and waste treatment [6] [7]. Each category is assigned a color (green, yellow, red) representing the environmental impact, allowing for quick visual assessment of the method's greenness.

AGREE Metric The Analytical GREEnness (AGREE) metric is a more recent assessment tool that evaluates analytical methods against all 12 principles of GAC [6] [7]. This software-based tool provides a comprehensive score from 0 to 1, with 1 representing ideal adherence to GAC principles. The output includes a circular pictogram with 12 segments, each representing one GAC principle, providing an at-a-glance assessment of the method's environmental performance [7].

Diagram 2: Greenness assessment workflow for analytical methods using established metrics.

Experimental Protocols

Protocol: Green UHPLC Method for Pharmaceutical Analysis

Objective To develop and validate a green UHPLC method for the simultaneous determination of multiple active pharmaceutical ingredients (APIs) using principles of GAC.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Research Reagent Solutions for Green UHPLC Protocol

| Item | Function | Green Alternative |

|---|---|---|

| Ethanol or ethanol-water mixtures | Mobile phase component | Replaces acetonitrile or methanol [5] |

| Columns with sub-2μm particles | Stationary phase for UHPLC | Enables faster analysis with reduced solvent consumption [5] [6] |

| Phosphate-free buffers | Mobile phase modifiers | Reduce environmental impact [6] |

| Automated sample preparator | Sample preparation | Reduces solvent consumption and improves reproducibility [4] |

| Waste collection system | Solvent waste management | Enables recycling or proper disposal [4] |

Methodology

- Column Selection: Utilize a C18 column with sub-2μm particle chemistry (e.g., 1.7-1.8μm) with dimensions of 50-100mm × 2.1mm for optimal separation efficiency with reduced solvent consumption.

- Mobile Phase Preparation: Prepare mobile phase A using water with 0.1% formic acid and mobile phase B using ethanol or ethanol-water mixtures (e.g., 90:10 ethanol:water) instead of traditional acetonitrile or methanol [5].

- Method Optimization: Employ design of experiments (DoE) approaches to optimize separation conditions while minimizing solvent usage and analysis time. Focus on gradient elution programs that minimize high organic modifier content.

- System Suitability: Validate method performance according to ICH guidelines, ensuring resolution, precision, and accuracy meet acceptance criteria while maintaining green principles.

- Greenness Assessment: Evaluate the final method using AGREE or GAPI metrics to quantify environmental performance [6] [7].

Expected Outcomes

- Reduction in solvent consumption by 80-90% compared to conventional HPLC methods

- Analysis time reduction of 50-70% while maintaining chromatographic resolution

- Significant decrease in waste generation

- High scores on greenness assessment metrics (Eco-Scale >75, AGREE >0.8)

Protocol: Implementation of Green Sample Preparation Using SPME

Objective To implement solid-phase microextraction as a green alternative to conventional liquid-liquid extraction for the analysis of pharmaceuticals in biological matrices.

Methodology

- Fiber Selection: Choose appropriate SPME fiber coating based on the physicochemical properties of target analytes (e.g., PDMS for non-polar compounds, divinylbenzene for mid-polarity compounds).

- Sample Preparation: Adjust sample pH to ensure target analytes are in non-ionic form for optimal extraction efficiency. Use minimal sample volumes (100-500μL) to reduce biological waste.

- Extraction Conditions: Optimize extraction time, temperature, and agitation speed to maximize extraction efficiency while minimizing process time.

- Desorption Parameters: For GC applications, optimize thermal desorption time and temperature in the injector port. For LC applications, optimize desorption solvent, time, and composition for on-line or off-line analysis.

- Method Validation: Validate the SPME method for linearity, accuracy, precision, and sensitivity according to regulatory guidelines.

Greenness Assessment Compare the SPME method with traditional extraction approaches using the Analytical Eco-Scale, noting significant reductions in solvent consumption and hazardous waste generation.

The implementation of the 12 principles of Green Analytical Chemistry in pharmaceutical research represents a significant opportunity to align analytical practices with sustainability goals without compromising analytical performance. Through the adoption of green sample preparation techniques, miniaturized and automated instrumentation, alternative solvents, and comprehensive greenness assessment tools, pharmaceutical analysts can substantially reduce the environmental impact of their methods while maintaining regulatory compliance and scientific rigor. The protocols and application notes provided herein offer practical pathways for implementing GAC principles in pharmaceutical analysis, contributing to the broader adoption of sustainable practices in drug development and quality control.

White Analytical Chemistry (WAC) represents a paradigm shift in modern method development, emerging as a holistic framework that transcends the environmental focus of Green Analytical Chemistry (GAC). Established in 2021, WAC aims to reconcile ecological objectives with analytical performance and practical utility, providing a more complete evaluation framework for analytical procedures [11] [12]. The core philosophy of WAC is that a truly sustainable method must simultaneously excel across three critical dimensions: environmental impact, analytical capability, and practical implementation.

The term "white" symbolizes purity and the balanced integration of these aspects, moving beyond the singular "green" focus on environmental factors [11]. This approach acknowledges that a method with minimal environmental impact but poor analytical performance or impractical implementation requirements cannot be considered truly sustainable in laboratory practice [12]. WAC therefore strives for a compromise that avoids an unconditional increase in greenness at the expense of functionality, making it more aligned with the holistic concept of sustainable development [12].

The RGB Model: Core Framework of WAC

Theoretical Foundation

The operational framework of WAC is the Red-Green-Blue (RGB) model, inspired by the additive color theory where combining red, green, and blue light produces white light [12]. Similarly, in WAC, a "white" method emerges from the balanced integration of three primary dimensions, each representing a fundamental aspect of analytical method quality [11] [12]:

- Green Dimension: Encompasses environmental impact, safety, and sustainability parameters derived from GAC principles.

- Red Dimension: Represents analytical performance characteristics including sensitivity, selectivity, accuracy, and precision.

- Blue Dimension: Covers practical and economic considerations such as cost, time, simplicity, and operational requirements.

When these three dimensions are optimally balanced, the resulting method is considered "white" - indicating a coherent and synergistic combination of analytical, ecological, and practical attributes [12]. This RGB model provides scientists with a systematic approach to evaluate methods before validation and identifies specific areas needing improvement [11].

The 12 Principles of WAC

WAC proposes 12 principles as an alternative to the 12 principles of GAC, expanding the framework to include analytical and practical considerations [12]. These principles are distributed across the three RGB dimensions:

Green Principles (Environmental Focus)

- Direct analytical techniques should be applied to avoid sample treatment [13].

- Minimal sample size and minimal number of samples are goals [13].

- In-situ measurements should be performed [13].

- Integration of analytical processes saves energy and reduces reagent use [13].

- Automated and miniaturized methods should be selected [13].

- Derivatization should be avoided [13].

- Generation of large waste volumes should be avoided with proper waste management [13].

- Multi-analyte determinations are preferred over single-analyte methods [13].

Red Principles (Analytical Performance)

- Methods must provide high sensitivity and selectivity for target analytes [11].

- Methods must demonstrate accuracy, precision, and robustness [11].

- Methods should offer appropriate linear range and detection limits [11].

Blue Principles (Practical Considerations)

- Methods should be cost-effective, time-efficient, and simple to operate [11].

The following diagram illustrates the conceptual relationship between the RGB dimensions and the resulting "white" method:

Assessment Tools and Metrics for WAC

The RGB 12 Algorithm

The RGB 12 algorithm provides a systematic approach for quantifying method "whiteness" [14] [12]. This tool evaluates analytical methods against the 12 WAC principles, assigning scores for each dimension that are subsequently visualized in a circular diagram. The diagram features four concentric rings representing the score levels (0-3) and twelve segments corresponding to each principle [12]. The cumulative scores from each dimension are combined to calculate an overall whiteness percentage, enabling direct comparison between different methods [12].

The algorithm generates a final "whiteness" percentage that facilitates objective comparison between different analytical methods [12]. This quantitative approach helps researchers select the optimal method that balances all three dimensions rather than excelling in one at the expense of others.

Complementary Assessment Tools

Multiple specialized metrics have been developed to evaluate the individual dimensions of WAC, providing researchers with a comprehensive toolkit for method assessment:

Table 1: Assessment Tools for White Analytical Chemistry

| Tool Name | Focus Dimension | Key Parameters Assessed | Output Format |

|---|---|---|---|

| AGREE [9] | Green | 12 GAC principles | Pictogram with score (0-1) and color |

| AGREEprep [15] | Green | Sample preparation aspects | Numerical score (0-1) |

| BAGI [11] | Blue | Applicability, cost, time, simplicity | Pictogram with blue shading |

| RAPI [11] | Red | Reproducibility, trueness, recovery, matrix effects | Performance score |

| NEMI [9] | Green | PBT chemicals, hazardous waste, pH, waste amount | Circle with four quadrants |

| Analytical Eco-Scale [9] | Green | Reagents, energy, hazards, waste | Numerical score (ideal=100) |

| GAPI [11] | Green | Comprehensive lifecycle impacts | Colored pictogram |

| ComplexGAPI [11] | Green | Sample prep and instrumentation | Detailed pictogram |

These tools can be used individually for specific dimension assessment or in combination for a comprehensive WAC evaluation. For instance, a complete whiteness assessment might combine AGREE (green), RAPI (red), and BAGI (blue) to generate balanced insights across all three dimensions [9].

Experimental Protocol: Implementing WAC in Pharmaceutical Analysis

Case Study: HPLC-DAD and HPTLC Methods for Aspirin and Vonoprazan

The following protocol demonstrates the practical application of WAC principles to develop and validate chromatographic methods for the simultaneous analysis of aspirin (ASP) and vonoprazan (VON) in combined pharmaceutical dosage forms [14]. This case study exemplifies how WAC considerations can be integrated throughout method development.

Materials and Reagents

Table 2: Research Reagent Solutions for HPLC-DAD and HPTLC Analysis

| Item | Specification | Function | WAC Consideration |

|---|---|---|---|

| Vonoprazan fumarate | Purity ≥98% [14] | Active pharmaceutical ingredient | Quality ensures analytical performance (Red) |

| Aspirin | Purity ≥99% [14] | Active pharmaceutical ingredient | Quality ensures analytical performance (Red) |

| Acetonitrile | HPLC grade [14] | Mobile phase component | Minimize toxicity (Green) |

| Potassium dihydrogen orthophosphate | Analytical grade [14] | Buffer component | Reduce hazardous chemicals (Green) |

| Ethyl acetate | Analytical grade [14] | HPTLC mobile phase | Prefer less hazardous solvents (Green) |

| Ethanol (75%) | Analytical grade [14] | HPTLC mobile phase | Less toxic alternative to methanol (Green) |

| Ammonia solution | Analytical grade [14] | HPTLC mobile phase modifier | Minimize volume used (Green) |

| Laboratory-prepared tablets | ASP (100 mg) + VON (10 mg) [14] | Simulated dosage form | Avoid commercial unavailability issues (Blue) |

Instrumentation and Conditions

HPLC-DAD Method [14]

- Instrument: Agilent 1260 HPLC with Diode Array Detector

- Column: Reversed phase C18 (250 × 4.6 mm, 5 μm)

- Temperature: 30°C

- Mobile Phase: Phosphate buffer (pH 6.8, 0.01 M):acetonitrile (63:37 v/v)

- Flow Rate: 1 mL/min

- Detection: 230 nm

- Injection Volume: 30 μL

HPTLC Method [14]

- Stationary Phase: HPTLC silica gel 60 F254 plates

- Mobile Phase: Ethyl acetate:ethanol (75%):ammonia (5:5:0.05 v/v/v)

- Detection: Densitometric scanning at 230 nm

- Band Size: 5 mm

- Application Volume: 10 μL

Sample Preparation Protocol

- Prepare stock solutions of VON (20 mg/100 mL) and ASP (200 mg/100 mL) in water:acetonitrile (50:50 v/v) [14]

- Prepare calibration standards by appropriate dilution of stock solutions in the same solvent mixture:

- HPLC: VON (0.5-10 μg/mL), ASP (1-100 μg/mL)

- HPTLC: VON (0.1-2 μg/band), ASP (0.1-10 μg/band)

- For laboratory-prepared tablets, weigh and powder tablets, then extract an equivalent of one tablet containing 10 mg VON and 100 mg ASP into 100 mL solvent [14]

- Filter through 0.45 μm membrane filter, discard first few mL

- Further dilute filtrate to obtain concentrations within calibration range

The experimental workflow below outlines the key steps in this WAC-compliant analytical process:

Method Validation and WAC Assessment

Validate both methods according to ICH guidelines for linearity, precision, accuracy, specificity, LOD, and LOQ [14]. Following validation, conduct WAC assessment using the RGB 12 algorithm:

- Green Dimension Evaluation: Apply AGREE and NEMI to assess environmental impact [14] [9]

- Red Dimension Evaluation: Use validation parameters (linearity, accuracy, precision) to score analytical performance [14]

- Blue Dimension Evaluation: Assess practical aspects through BAGI focusing on cost, time, and operational simplicity [11]

- Whiteness Calculation: Combine dimension scores using RGB 12 algorithm to generate overall whiteness percentage [12]

Advanced Applications and Recent Developments

Green Sample Preparation in Pharmaceutical Analysis

The implementation of WAC principles has driven significant innovations in sample preparation, particularly through miniaturization and solvent reduction strategies [16]. Current trends include:

- Micro-extraction techniques: Fabric phase sorptive extraction (FPSE), magnetic SPE, capsule phase microextraction (CPME), and ultrasound-assisted microextraction dramatically reduce solvent consumption [11]

- Green solvents: Increased application of deep eutectic solvents (DES), supercritical fluids, and ionic liquids as safer alternatives to traditional organic solvents [16] [17]

- Miniaturized systems: Dramatic reduction of sample sizes and solvent volumes through microfluidic devices and lab-on-a-chip technologies [11]

- Automation and integration: Automated systems that reduce human intervention, minimize errors, and enhance safety [15]

Good Evaluation Practice (GEP) for WAC Assessment

As WAC assessment gains popularity, researchers should adhere to Good Evaluation Practice (GEP) guidelines to ensure meaningful and reliable results [18]. Key GEP principles include:

- Use quantitative indicators based on empirical data rather than estimations

- Combine multiple assessment models with different structures to compensate for individual limitations

- Ensure transparency by documenting all assumptions and calculation methods

- Contextualize results by comparing with existing methods for similar analytes

- Acknowledge limitations and avoid overinterpreting assessment results [18]

These practices help maintain scientific rigor in WAC assessments and prevent the misuse of metrics solely for publication purposes without genuine sustainability improvements.

White Analytical Chemistry represents a significant evolution beyond Green Analytical Chemistry by integrating environmental, analytical, and practical considerations into a unified framework. The RGB model provides a structured approach for developing and evaluating analytical methods that are not only environmentally friendly but also analytically sound and practically feasible. As demonstrated in the pharmaceutical analysis case study, implementing WAC principles leads to more sustainable and practical analytical methods without compromising performance. The ongoing development of assessment tools and methodologies continues to support the adoption of WAC across various analytical domains, promoting truly sustainable practices in analytical chemistry.

The implementation of Green Analytical Chemistry (GAC) principles in pharmaceutical analysis has evolved from a voluntary environmental initiative to a strategic imperative driven by regulatory requirements, compelling cost benefits, and significant competitive advantages. GAC focuses on designing analytical methods that minimize environmental impact through reduced hazardous waste generation, lower energy consumption, and safer chemicals while maintaining high-quality standards [19]. This paradigm shift represents a fundamental transformation in how pharmaceutical companies approach compliance and operational excellence, moving beyond merely meeting regulatory minimums to building robust, sustainable quality systems that deliver measurable business value.

The pharmaceutical industry currently invests approximately $50 billion annually in global compliance activities, with costs rising at 7.17% per year [20]. Within this context, GAC implementation offers a pathway to transform compliance from a cost center into a strategic advantage while addressing increasing regulatory scrutiny of environmental impacts and sustainable practices. Leading pharmaceutical manufacturers are discovering that GAC principles align with operational excellence, resulting in 22% reductions in quality-related costs and 15% improvements in gross margins for top performers [20].

Regulatory Framework: CGMP and Evolving Environmental Expectations

Current Good Manufacturing Practice Foundations

The Current Good Manufacturing Practice (CGMP) regulations enforced by the U.S. Food and Drug Administration (FDA) establish the foundational framework for pharmaceutical quality. These regulations contain minimum requirements for the methods, facilities, and controls used in manufacturing, processing, and packing of drug products, ensuring that products are safe for use and contain the ingredients and strength they claim to have [21]. The "C" in CGMP stands for "current," requiring companies to use technologies and systems that are up-to-date to comply with regulations, inherently encouraging the adoption of improved methodologies including environmentally sustainable approaches [22].

The CGMP regulations are structured throughout Title 21 of the Code of Federal Regulations, with key sections including:

- 21 CFR Part 210: Current Good Manufacturing Practice in Manufacturing, Processing, Packing, or Holding of Drugs

- 21 CFR Part 211: Current Good Manufacturing Practice for Finished Pharmaceuticals

- 21 CFR Part 314: Applications for FDA Approval to Market a New Drug [21]

While CGMP regulations primarily focus on product quality and safety, they establish a system of controls that provides the framework for implementing GAC principles through requirements for proper design, monitoring, and control of manufacturing processes and facilities [22].

International Regulatory Alignment

Globally, regulatory harmonization has advanced more rapidly than predicted, with organizations like the International Council for Harmonization (ICH) working to align technical requirements across markets [23]. The European Medicines Agency (EMA) has explicitly recognized environmental considerations, classifying solvents like methanol and tetrahydrofuran as hazardous and encouraging their replacement with safer alternatives [3]. This global regulatory alignment creates a consistent framework that enables pharmaceutical companies to implement unified GAC strategies across international operations.

Business Case: Quantifying the Value of GAC Implementation

Compliance Cost Avoidance

The business case for GAC implementation begins with significant cost avoidance through reduced compliance failures. The pharmaceutical industry has incurred $1.1 billion in penalties over the past five years due to compliance failures, with a single significant compliance misstep triggering remediation costs exceeding $12 million [20]. By implementing robust GAC methodologies that exceed minimum compliance requirements, companies can avoid these substantial financial impacts.

Table 1: Financial Impact of Compliance Performance

| Metric | Compliance Leaders | Industry Average | Business Impact |

|---|---|---|---|

| Batch Right-First-Time Rate | 98-99% | 85-90% | $2.1M annual savings in rework costs |

| Regulatory Inspection Success | <1 critical finding per 5 inspections | 2-3 critical findings per 5 inspections | Avoids $750K/day in remediation costs |

| Product Release Cycle | 5-7 days | 12-15 days | 40% reduction in inventory holding costs |

| Time-to-Market (New Products) | 15-18 months | 18-24 months | Captures 30% more market share [20] |

Operational Efficiency Gains

GAC implementation drives substantial operational efficiencies by reducing solvent consumption, minimizing waste disposal costs, and streamlining analytical procedures. Companies achieving top-quartile compliance performance report batch right-first-time rates of 98-99%, significantly higher than the industry average of 85-90% [20]. These efficiency gains directly impact profitability through reduced rework requirements and faster release cycles.

The transition to green liquid chromatography methods exemplifies these efficiency improvements. One study developing a stability-indicating HPLC method for clonazepam demonstrated that the green method was "not only ecofriendly but also faster than the conventional liquid chromatographic system official in the USP-36" [24]. This dual benefit of environmental improvement and operational efficiency characterizes the GAC value proposition.

Strategic Competitive Advantages

Beyond cost savings, GAC implementation delivers strategic competitive advantages including enhanced corporate reputation, faster time-to-market, and improved stakeholder relationships. Companies with leading compliance practices demonstrate 16% higher market share growth compared to industry averages [20]. Additionally, regulatory innovation in GAC methodologies can create barriers to entry for competitors and establish companies as industry leaders in sustainable pharmaceutical manufacturing.

Implementation Framework: GAC Integration Pathways

Green Analytical Chemistry Principles

GAC implementation follows 12 core principles that provide a comprehensive framework for developing sustainable analytical methods:

- Direct analytical techniques should be applied to avoid sample treatment

- Minimal sample size and minimal number of samples are goals

- Measurement should be performed in situ if possible

- Integration of analytical processes and operations saves energy and reduces waste

- Automated and miniaturized methods should be selected

- Derivatization should be avoided

- Generation of a large volume of waste should be avoided and proper management of waste should be provided

- Multi-analyte or multi-parameter methods are preferred versus methods using one analyte at a time

- The use of energy should be minimized

- Reagents obtained from renewable sources should be preferred

- Toxic reagents should be eliminated or replaced

- Worker safety should be increased [6]

These principles guide the development and optimization of analytical methods to align environmental objectives with analytical quality requirements.

Assessment Tools and Metrics

Several standardized tools have been developed to evaluate the greenness of analytical methods, enabling objective assessment and continuous improvement:

- NEMI (National Environmental Methods Index): Provides a simple pictogram indicating whether a method meets basic green chemistry criteria

- Analytical Eco-Scale: Offers a semi-quantitative assessment based on penalty points for hazardous practices

- GAPI (Green Analytical Procedure Index): Evaluates the environmental impact of each step in an analytical method

- AGREE (Analytical GREEnness Metric): Uses a multi-criteria assessment based on the 12 principles of GAC [6]

These assessment tools enable researchers to quantify the environmental performance of analytical methods and identify opportunities for improvement.

Application Note: Development of a Green Stability-Indicating HPLC Method for Clonazepam

Experimental Protocol

Objective: Develop and validate a green stability-indicating reversed-phase HPLC method for determining clonazepam and its related substances in pharmaceutical formulations [24].

Materials and Reagents:

- Clonazepam Reference Standard: USP-grade (99.88% purity)

- Related Compounds A and B: USP-reference standard materials

- Sodium Dodecyl Sulfate (SDS): HPLC grade, 2% solution in water

- Sodium Acetate Buffer: 0.05 M, pH 3.5 ± 0.05

- Isopropanol: HPLC grade

- Water: HPLC grade obtained through Milli-Q system

- Pharmaceutical Formulation: Clonazepam tablets

Instrumentation and Conditions:

- HPLC System: Shimadzu system equipped with CBM-20A system controller, LC-20A solvent delivery unit, DGU-20A degassing unit, SPD-M20A photo-diode array detector, and SIL-20A auto-sampler

- Column: BDS C8 Hypersil column (250 mm × 4.6 mm, 5 μm particle size)

- Mobile Phase: Isopropanol:2% SDS:0.05 M sodium acetate buffer pH 3.5 (20:25:55, v/v/v)

- Flow Rate: 1.5 mL/min

- Detection: DAD at 254 nm

- Injection Volume: 20 μL

- Temperature: Ambient [3]

Sample Preparation:

- Standard Solution: Prepare stock standard solution of clonazepam, related compound A, and related compound B in mobile phase at concentration of 0.2 mg/mL

- Working Standards: Prepare series of dilutions from stock solution in mobile phase to obtain concentration range of 4-140 μg/mL for clonazepam and 4-64 μg/mL for related compounds

- Tablet Sample Solution: Randomly select and weigh clonazepam tablets, dissolve and dilute with mobile phase to obtain concentration of 0.04 mg/mL

- Filtration: Filter all solutions through nylon sample filter (0.22 μm) before injection [3]

Forced Degradation Studies:

- Acidic Degradation: Prepare standard solution in 1 M hydrochloric acid, keep at ambient temperature for 12 hours

- Basic Degradation: Prepare standard solution in 1 M sodium hydroxide, keep at ambient temperature for 12 hours

- Oxidative Degradation: Prepare solution in 3% hydrogen peroxide solution, keep at ambient temperature for 4 hours

- Photolytic Degradation: Irradiate neutral solution at 1.2 million lux hours for 24 hours with distance between light source and sample maintained at 25 cm

- Sample Preparation for Chromatography: Dilute all stressed samples with mobile phase to final concentration of 40 μg/mL and inject into chromatographic system [3]

Method Validation:

- Linearity: Prepare thirteen standard solutions of clonazepam (4-140 μg/mL) and nine standard solutions of related compounds (4-64 μg/mL), inject each dilution in triplicate

- Precision:

- Repeatability (Intra-day): Perform assay of authentic sample solutions six times on same day

- Reproducibility (Inter-day): Analyze freshly prepared solutions at different days

- Accuracy: Spike placebo with clonazepam and related compounds at three concentration levels (30, 40, and 50 μg/mL), inject each solution in triplicate

- Specificity: Verify absence of excipient interference at retention times of clonazepam and related compounds

- Robustness: Evaluate effect of deliberate variations in flow rate (±0.01 mL/min) and buffer pH (±0.1 units)

- LOD/LOQ Determination: Calculate from linear calibration curve using residual standard deviation of regression line and slope [3]

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Research Reagents and Materials for GAC HPLC Method Development

| Item | Function | GAC Considerations |

|---|---|---|

| BDS C8 Hypersil Column | Stationary phase for chromatographic separation | Enables use of greener mobile phase components compared to traditional C18 columns |

| Sodium Dodecyl Sulfate (SDS) | Surfactant component of mobile phase | Replaces more hazardous solvents like tetrahydrofuran; biodegradable |

| Isopropanol | Organic modifier in mobile phase | Less hazardous alternative to acetonitrile; reduced environmental impact |

| Sodium Acetate Buffer | Aqueous component for pH control | Biodegradable and less toxic than ammonium-based buffers |

| Photo-diode Array Detector | Multi-wavelength detection for peak purity | Eliminates need for multiple detection methods or derivatization |

| Nylon Sample Filters | Particulate removal from samples | Reduced extractables compared to other membrane materials [3] |

Results and Green Profile Assessment

The developed method demonstrated excellent resolution between clonazepam, related substances, and degradation products with an expanded uncertainty of 0.33%. Validation results confirmed linearity (R² ≥ 0.999), precision (RSD < 1%), accuracy (recovery rates 98-102%), and robustness to minor method parameter variations [3].

The green profile assessment using GAPI and Analytical Eco-Scale tools demonstrated significant environmental advantages compared to the conventional USP method:

- Solvent Reduction: Elimination of tetrahydrofuran and methanol, classified as hazardous solvents by EMA

- Waste Minimization: Isocratic elution reduced solvent consumption compared to gradient methods

- Energy Efficiency: Shorter analysis time reduced energy consumption

- Safety Improvement: Replacement with less toxic solvents enhanced operator safety [3]

Implementation Workflow: Strategic Integration of GAC Principles

The following diagram illustrates the systematic workflow for implementing GAC principles in pharmaceutical analysis, from initial assessment to continuous improvement:

Diagram 1: GAC Implementation Workflow

Business Integration: From Compliance to Competitive Advantage

Technology-Enabled Compliance

Digital transformation plays a crucial role in scaling GAC implementation across pharmaceutical organizations. Companies embracing technology-enabled compliance report dramatic improvements, with electronic batch record systems reducing documentation time by up to 80% while simultaneously improving data integrity [20]. These technologies eliminate transcription errors, enforce procedural compliance, and enable real-time quality oversight while reducing paper consumption and storage requirements.

Advanced analytical systems incorporating GAC principles further enhance business value through:

- Predictive Compliance Models: AI systems that analyze patterns from regulatory observations to identify potential GAC compliance risks before they trigger regulatory action

- Continuous Process Verification: Real-time monitoring of analytical method parameters to detect trends before quality specifications are compromised

- Integrated Quality Management: Modern QMS platforms connecting previously siloed processes including document control, deviation management, and CAPA tracking [20]

Cultural Transformation

Successful GAC implementation requires more than technological change; it demands cultural transformation where quality and sustainability become shared values across the organization. The FDA cites quality culture deficiencies as a root cause in approximately 40% of significant compliance actions [20]. Companies where leadership actively champions GAC principles experience roughly half as many serious compliance issues as those where compliance is viewed merely as a regulatory requirement.

Cultural transformation strategies include:

- Leadership Engagement: Executives personally reviewing GAC metrics and recognizing employees who identify potential improvements

- Cross-Functional Collaboration: Integrating GAC objectives across R&D, manufacturing, quality control, and regulatory affairs

- Training and Development: Building GAC expertise through targeted programs addressing specific methodological approaches

- Performance Metrics: Incorporating GAC indicators into quality performance assessments and incentive structures [20]

The implementation of Green Analytical Chemistry principles represents a strategic opportunity for pharmaceutical companies to transform regulatory compliance from a cost center into a source of competitive advantage. By aligning environmental objectives with operational excellence, organizations can achieve simultaneous improvements in regulatory performance, cost efficiency, and sustainability metrics.

The business case for GAC implementation is compelling: industry leaders demonstrate 98-99% batch right-first-time rates, 22% reductions in quality-related costs, 15% improvements in gross margins, and 16% higher market share growth compared to industry averages [20]. These quantitative benefits, combined with enhanced regulatory standing and corporate reputation, create a powerful value proposition for strategic investment in GAC methodologies.

As regulatory expectations continue to evolve toward greater environmental accountability, pharmaceutical companies that proactively implement GAC principles will be better positioned to navigate the complex landscape of global compliance while building sustainable business models for long-term success. The integration of GAC into pharmaceutical analysis represents not merely a technical improvement, but a fundamental strategic approach to quality management in the modern healthcare ecosystem.

Practical Strategies: Greening HPLC, Sample Preparation, and Instrumentation

In the pharmaceutical industry, High-Performance Liquid Chromatography (HPLC) and Ultra-High-Performance Liquid Chromatography (UHPLC) are cornerstone techniques for drug analysis, quality control, and ensuring product safety [1] [25]. However, a significant environmental and safety concern stems from the prevalent use of acetonitrile (ACN) as an organic modifier in reversed-phase chromatography. Acetonitrile is toxic, flammable, and poses health risks to analysts through inhalation or skin contact, as it is metabolized in the body to cyanide, leading to cytotoxic anoxia [25] [26]. Furthermore, a single conventional HPLC system can generate approximately 500 liters of hazardous waste annually, creating a substantial environmental footprint and disposal burden [26].

This application note, framed within the broader thesis of implementing Green Analytical Chemistry (GAC) principles in pharmaceutical research, provides a structured guide for replacing acetonitrile with safer, more sustainable solvent alternatives. The content aligns with the 12 principles of GAC, which aim to minimize the use of hazardous chemicals, reduce energy consumption, and improve operator safety [1] [27]. We will explore the properties of various green solvents, detail practical protocols for method development and transfer, and provide tools for quantitatively assessing the environmental benefits of adopting these sustainable practices.

Green Solvent Alternatives: Properties and Selection

A successful transition from acetonitrile requires a deep understanding of the properties and chromatographic behaviors of potential replacement solvents. No single solvent is a perfect "drop-in" replacement; each has distinct advantages and limitations that must be considered during method development.

Table 1: Properties of Common HPLC Solvents and Green Alternatives

| Solvent | Greenness | Toxicity | UV Cut-Off (nm) | Viscosity (cP) | Elution Strength (RP-HPLC) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|---|---|

| Acetonitrile | Poor | High (Toxic) | 190 | 0.34 | Moderate | Low viscosity, low UV cut-off | Hazardous, toxic, high environmental impact |

| Methanol | Moderate | Moderate | 205 | 0.55 | Moderate | Readily available, lower cost than ACN | More toxic than other alternatives, higher UV cut-off |

| Ethanol | High | Low | 210 | 1.08 | Similar to MeOH | Bio-based, low toxicity, biodegradable, inexpensive [26] [28] | Higher viscosity, higher UV cut-off |

| Dimethyl Carbonate | High | Low | 235 | 0.63 | Lower than ACN | Biodegradable, low toxicity [29] [25] | Partial water miscibility, high UV cut-off |

| Propylene Carbonate | High | Low | 240 | 2.5 | Stronger elution | Green profile, high elution strength [29] | High viscosity, high UV cut-off, partial water miscibility |

| Glycerol | High | Very Low | 205 | 934 | N/A | Non-toxic, non-volatile, high polarity [25] | Very high viscosity, requires elevated temperature |

Detailed Solvent Profiles

Ethanol: Often regarded as the most desirable green solvent for liquid chromatography, ethanol is less toxic than ACN, has a lower vapor pressure, and is widely available from renewable bio-based sources [26] [28]. Chromatographically, it often provides similar selectivity to methanol. Its primary drawback is a higher viscosity, which can lead to increased backpressure, and a UV cut-off around 210 nm, which may limit its use for low-wavelength UV detection [26].

Carbonate Esters (Dimethyl Carbonate, Propylene Carbonate): These solvents represent a class of green alternatives with low toxicity and good environmental profiles [29] [25]. A critical consideration is their partial miscibility with water, requiring the use of a co-solvent (e.g., a small percentage of methanol or ACN) to maintain a single-phase mobile phase throughout a gradient elution. Their high UV cut-off can also be a limitation, but this can be managed by using longer detection wavelengths [29].

Glycerol: While its extremely high viscosity makes it unsuitable as a primary organic modifier, glycerol has been successfully used as a green mobile phase additive or modifier in aqueous mixtures (e.g., 7% glycerol). It can enhance the retention of hydrophilic compounds and is non-toxic and biodegradable [25].

The following decision diagram outlines the process for selecting an appropriate green solvent based on method requirements.

Quantitative Greenness Assessment Tools

Adopting GAC principles requires objective measurement. Several metrics have been developed to evaluate and compare the environmental friendliness of analytical methods.

Table 2: Greenness Assessment Metrics for Analytical Methods

| Metric Tool | Type of Output | Key Parameters Assessed | Advantages | Limitations |

|---|---|---|---|---|

| NEMI [30] [9] | Pictogram (4-quadrant) | PBT chemicals, hazardous waste, corrosivity, waste amount | Simple, visual, easy to interpret | Qualitative, lacks granularity |

| Analytical Eco-Scale [27] [9] | Score (0-100) | Reagent toxicity, energy use, waste | Quantitative, allows direct comparison | Relies on expert judgment for penalties |

| GAPI [27] [30] | Color-coded pictogram | Entire workflow from sampling to detection | Comprehensive, visualizes impact hotspots | No single overall score |

| AGREE [27] [30] [9] | Score (0-1) & circular pictogram | All 12 principles of GAC | Holistic, user-friendly, comprehensive | Subjective weighting of criteria |

| AGREEprep [30] [9] | Score (0-1) & pictogram | Sample preparation specifically | Focuses on often most polluting step | Must be used with another full-method tool |

Experimental Protocols

Protocol 1: Scouting the Viability of Ethanol as an ACN Replacement

This protocol provides a systematic approach for an initial assessment of ethanol-based mobile phases.

- Objective: To rapidly evaluate whether ethanol can achieve a comparable separation to a reference ACN method for a given mixture of analytes.

- Materials & Equipment:

- HPLC/UHPLC System: Standard system with UV detector.

- Columns: C18 column (e.g., 150 mm x 4.6 mm, 5 µm) or a suitable UHPLC column (e.g., 100 mm x 2.1 mm, sub-2 µm).

- Chemicals: HPLC-grade ethanol, water, phosphoric acid/ammonium phosphate, or other pH buffers as needed.

- Samples: Standard solution of target analytes.

- Procedure:

- System Preparation: Prepare a water-rich mobile phase (e.g., 95:5 Water:Ethanol) and an ethanol-rich mobile phase (e.g., 5:95 Water:Ethanol). For isocratic screening, prepare 3-5 intermediate compositions.

- Method Transfer:

- Start with a linear gradient method that covers a wide range from 5% to 95% of the organic modifier.

- Use a flow rate and gradient time scaled appropriately for the column dimensions.

- Maintain the same column temperature and detection wavelength as the original ACN method, if applicable.

- Execution:

- Inject the standard mixture and run the gradient method.

- Observe retention times, peak shapes (asymmetry factor), and resolution between critical pairs.

- Data Analysis:

- Compare the chromatogram with the one obtained using the ACN method.

- Calculate key performance indicators: plate count, resolution, and retention factor.

- Note the backpressure and baseline stability, particularly at low wavelengths.

- Troubleshooting:

- High Backpressure: Due to higher viscosity of ethanol-water mixes. Consider reducing flow rate, using a shorter column, or increasing column temperature slightly.

- Poor Peak Shape: May indicate need for pH adjustment or a different buffer. The selectivity of ethanol is similar to methanol, so methods originally developed with methanol may transfer more easily.

Protocol 2: Method Development with Partially Miscible Solvents (e.g., Carbonate Esters)

This protocol addresses the unique challenges of using solvents like dimethyl carbonate (DMC) which are not fully miscible with water in all proportions [29].

- Objective: To develop a robust HPLC method using a carbonate ester as the primary organic modifier.

- Materials & Equipment:

- HPLC System, Columns (as in Protocol 1).

- Chemicals: Dimethyl carbonate (HPLC grade), co-solvent (Methanol or ACN), water, additives.

- Special Consideration: Ternary Phase Diagrams for the water/co-solvent/carbonate ester system are essential to identify stable, single-phase mobile phase compositions [29].

- Procedure:

- Phase Behavior Study:

- Consult or create a ternary phase diagram for Water/MeOH/DMC.

- Identify a composition zone that remains a single phase across the entire range of your intended gradient. For example, a minimum of 5-10% MeOH might be required to keep DMC miscible in aqueous phases.

- Method Design:

- Design a gradient method where the DMC percentage varies, but the co-solvent percentage is kept constant at a level that ensures miscibility (e.g., 5% MeOH held isocratically, while DMC is ramped from 10% to 60%).

- Ensure the starting and ending mobile phase compositions are within the single-phase region of the ternary diagram.

- Chromatographic Evaluation:

- Run the method and evaluate separation performance.

- Pay close attention to baseline noise and drift due to the higher UV cut-off of DMC. Adjusting the detection wavelength above 240 nm may be necessary.

- Phase Behavior Study:

- Troubleshooting:

- Pressure Fluctuations or Cloudy Eluents: Indicates phase separation. Revisit the ternary diagram and increase the percentage of the co-solvent.

- Low Sensitivity: Caused by high UV cut-off. Try switching to a longer wavelength or using a different detection technique (e.g., Charged Aerosol Detection) if available.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Green HPLC Solvent Substitution

| Item | Function/Description | Example & Notes |

|---|---|---|

| Green Solvents | Primary replacement for acetonitrile in the mobile phase. | Ethanol (96% or absolute, HPLC grade), Dimethyl Carbonate (HPLC grade), Propylene Carbonate (HPLC grade). |

| Co-solvents | Ensure miscibility of green solvents with aqueous phases. | Methanol (HPLC grade), Acetonitrile (HPLC grade, used minimally). |

| Stationary Phases | The analytical column for separation. | C18, C8, or phenyl-based columns, including those designed for low-dispersion UHPLC (e.g., 1.7-2.6 µm particles). |

| Buffer Salts & Additives | Control mobile phase pH and ionic strength to optimize peak shape and retention. | Ammonium formate, ammonium acetate, phosphoric acid, trifluoroacetic acid (TFA). |

| Greenness Assessment Software | Quantify and report the environmental benefits of the new method. | AGREE calculator (open access), other software supporting GAPI, AGREEprep. |

Advanced Strategy: Instrumental and Operational Enhancements

Beyond solvent substitution, further significant reductions in environmental impact can be achieved through instrumental advances and operational changes.

Adoption of UHPLC and SPP Technology: Ultra-High-Performance Liquid Chromatography (UHPLC) using columns packed with sub-2-µm fully porous or superficially porous particles (SPP) provides higher efficiency per unit time [29] [31]. This allows the use of shorter columns, which directly translates to reduced solvent consumption and faster analysis times, thereby lowering waste generation and energy use per analysis [29] [31]. The van Deemter equation explains the superior efficiency of smaller particles, enabling high-resolution separations at higher flow rates without significant loss of efficiency [29].

Miniaturization of Column Dimensions: A highly effective strategy is to transfer methods from traditional columns (e.g., 4.6 mm internal diameter) to columns with smaller internal diameters (e.g., 2.1 mm or 1.0 mm). The reduction in solvent flow rate is proportional to the square of the reduction in internal diameter, potentially leading to 75-90% reduction in solvent consumption for the same method timeline [28].

Alternative Chromatographic Modes:

- Micellar Liquid Chromatography (MLC): Uses aqueous solutions of surfactants above their critical micellar concentration as mobile phases, potentially eliminating or drastically reducing the need for organic solvents [26].

- Supercritical Fluid Chromatography (SFC): Utilizes supercritical CO2 as the primary mobile phase. CO2 is non-toxic, non-flammable, and can be easily recycled, making SFC an exceptionally green technique for suitable analytes [25] [28].

The integration of these strategies creates a comprehensive workflow for developing sustainable analytical methods, as summarized below.

Regulatory and Practical Considerations in Pharmaceuticals

Transitioning to greener methods in a regulated environment requires careful planning.

- Method Validation: Any change in the mobile phase composition for a pharmacopeial or validated quality control method is considered a major modification, requiring a full re-validation to demonstrate that the new method is equivalent or superior to the original in terms of accuracy, precision, specificity, linearity, and robustness [28].

- Method Transfer and Documentation: The transfer of an established method to a greener version should be managed through a formal Method Transfer Protocol. Documentation should include the rationale for the change (e.g., GAC principles, operator safety, cost reduction), all development data, and a comparative greenness assessment using tools like AGREE or Analytical Eco-Scale [30].

- Balancing Greenness and Practicality: A pure greenness metric score must be balanced with practical requirements (Blue Applicability Grade Index - BAGI) and analytical performance (Red) in what is known as the White Analytical Chemistry (WAC) concept [30]. The ideal "white" method finds a harmonious balance between environmental sustainability, practical feasibility, and excellent analytical performance.

The evolution of sample preparation strategies has been marked by a significant shift from conventional, large-scale techniques towards miniaturized and micro-scale approaches. This transition is a cornerstone of Green Analytical Chemistry (GAC), which aims to develop analytical methods that minimize environmental impact while maintaining robust analytical performance [32]. The drive for sustainability in pharmaceutical analysis has positioned miniaturization as a smart strategy, directly addressing key environmental concerns such as hazardous solvent consumption, waste generation, and operator safety [1].

Traditional sample preparation methods, particularly in pharmaceutical High-Performance Liquid Chromatography (HPLC), often involve substantial volumes of organic solvents, generate large quantities of hazardous waste, and pose risks to analysts [1]. In contrast, miniaturized extraction techniques have been developed not only to enhance analytical performance but also to improve safety and reduce the ecological footprint of analytical operations [32]. The greenness of these modern methods can be systematically evaluated using metric tools such as AGREEprep, which provides a comprehensive assessment of environmental impact [32].

This document provides detailed application notes and protocols for implementing miniaturized sample preparation strategies within pharmaceutical research and development. By adopting these approaches, scientists and drug development professionals can significantly advance the implementation of GAC principles in their laboratories.

Quantitative Comparison: Conventional vs. Miniaturized Methods

The environmental and practical advantages of miniaturized methods become clear through direct quantitative comparison with conventional approaches. The following tables summarize key performance and environmental metrics.

Table 1: Environmental and Operational Comparison of Sample Preparation Techniques

| Parameter | Conventional Liquid-Liquid Extraction (LLE) | Miniaturized Techniques (e.g., SULLME) |

|---|---|---|

| Typical Solvent Volume | 50 - 150 mL per sample [1] | < 10 mL per sample [30] |

| Waste Generation | High (> 50 mL/sample) [1] | Significantly Reduced (< 10 mL/sample) [30] |

| Analytical Eco-Scale Score | Lower (Higher Penalty Points) [30] | Higher (Approximately 56-60 in case studies) [30] |

| Hazardous Reagent Use | Common | Reduced, with a shift toward safer alternatives [30] |

| Operator Safety | Lower (Exposure to larger solvent volumes) | Enhanced (Smaller volumes, enclosed systems) [32] |

| Throughput | Often lower due to longer steps | Potential for higher throughput (e.g., 2 samples/hour in a SULLME case study) [30] |

Table 2: Greenness Assessment Scores of a Miniaturized Method (SULLME) Using Different Metrics Data derived from a case study on sugaring-out liquid-liquid microextraction [30]

| Greenness Metric Tool | Score | Key Strengths | Key Weaknesses |

|---|---|---|---|

| Modified GAPI (MoGAPI) | 60 / 100 | Use of green solvents; microextraction scale | Waste >10 mL; moderately toxic substances; specific storage needs |

| AGREE | 56 / 100 | Miniaturization; semiautomation; small sample volume (1 mL) | Use of toxic/flammable solvents; moderate waste; low throughput (2 samples/hour) |

| Analytical Green Star (AGSA) | 58.33 / 100 | Semi-miniaturization; no derivatization | Manual handling; multiple pretreatment steps; hazardous reagents |

| Carbon Footprint (CaFRI) | 60 / 100 | Low energy consumption (0.1–1.5 kWh/sample) | No renewable energy; no CO2 tracking; long transport distances |

Detailed Experimental Protocols

Protocol 1: Sugaring-Out Induced Homogeneous Liquid-Liquid Microextraction (SULLME)

Principle: This technique utilizes a water-miscible solvent and a sugar-based agent to induce phase separation, concentrating analytes into a small organic solvent layer [30].

1. Reagents and Solutions

- Sample Solution: Aqueous solution containing the target pharmaceutical analytes.

- Extraction Solvent: A water-miscible organic solvent (e.g., acetonitrile, acetone).

- Sugaring-Out Agent: Anhydrous glucose or fructose.

2. Equipment

- 10-15 mL conical centrifuge tubes

- Micropipettes (100 - 1000 µL)

- Vortex mixer

- Centrifuge

- Analytical instrument for detection (e.g., HPLC-MS)

3. Step-by-Step Procedure

- Sample Introduction: Transfer a 1.0 mL aqueous sample aliquot into a 15 mL centrifuge tube [30].

- Solvent Addition: Add 500 µL of a selected water-miscible organic solvent (e.g., acetonitrile) to the sample. Cap the tube and vortex for 30-60 seconds to form a homogeneous solution.

- Phase Separation Induction: Add a predetermined amount of sugaring-out agent (e.g., 1.0 g of anhydrous glucose). Cap the tube and vortex vigorously for 60 seconds. A cloudy solution with fine droplets of the separated organic phase will form.

- Centrifugation: Centrifuge the mixture at 4000 rpm for 5 minutes to complete phase separation and consolidate the organic extract at the top of the tube.

- Collection: Carefully collect the upper organic layer (typically 200-400 µL) using a micro-syringe or pipette.

- Analysis: Transfer the extract to a vial for direct analysis or perform a solvent exchange if required by the detection system.

4. Method Notes

- The volumes of sample, solvent, and mass of the sugaring-out agent should be optimized for specific analytes.

- This method is considered semi-miniaturized and avoids derivatization, contributing to its greenness profile [30].

Protocol 2: General Framework for Micro-Sampling in Sample Preparation

Principle: Minimize all scales of an analytical method, including sample size, solvent consumption, and waste generation, through direct miniaturization of classical techniques.

1. Reagents and Solutions

- Sample: Liquid or dissolved solid sample.

- Miniaturized Extraction Solvent: A small volume of an organic solvent appropriate for the extraction (e.g., ethyl acetate for SDME, a polymeric coating for SPME).

2. Equipment

- Low-volume vials (1-2 mL) or 96-well plates

- Micro-syringes (10 - 250 µL)