Catalytic vs. Stoichiometric API Routes: A Data-Driven Cost-Benefit Analysis for Drug Developers

This article provides a comprehensive cost-benefit analysis of catalytic versus stoichiometric routes in Active Pharmaceutical Ingredient (API) synthesis, tailored for researchers, scientists, and drug development professionals.

Catalytic vs. Stoichiometric API Routes: A Data-Driven Cost-Benefit Analysis for Drug Developers

Abstract

This article provides a comprehensive cost-benefit analysis of catalytic versus stoichiometric routes in Active Pharmaceutical Ingredient (API) synthesis, tailored for researchers, scientists, and drug development professionals. We first explore the fundamental principles and economic drivers behind each synthetic philosophy. Next, we detail practical methodologies for route scouting, catalyst selection, and process scale-up. The guide then addresses common technical and economic challenges, offering optimization strategies for yield, selectivity, and waste reduction. Finally, we present a framework for quantitative validation and comparative assessment using key metrics like Process Mass Intensity (PMI), Environmental Factor (E-Factor), and overall cost per kilogram. The conclusion synthesizes findings into actionable insights for sustainable and economically viable API process development.

Stoichiometric vs. Catalytic Synthesis: Core Principles and Economic Drivers in API Manufacturing

Performance Comparison of Stoichiometric and Catalytic API Route Steps

The selection of reagents for key transformations in Active Pharmaceutical Ingredient (API) synthesis is a critical cost and sustainability driver. The following table compares representative reactions, highlighting the inherent waste and material intensity of stoichiometric approaches versus the atom economy and efficiency of catalytic alternatives.

Table 1: Quantitative Comparison of Stoichiometric vs. Catalytic Transformations in API Synthesis

| Reaction Type | Stoichiometric Example (Reagent) | Catalytic Example (Catalyst/System) | Key Performance Metric (Stoichiometric) | Key Performance Metric (Catalytic) | E-Factor (kg waste/kg product)* | Turnover Number (TON) / Frequency (TOF) |

|---|---|---|---|---|---|---|

| Oxidation | Jones reagent (CrO₃/H₂SO₄) | TEMPO/NaOCl (Organocatalytic) | 1.5-5 eq. Cr(VI) required; ~600 g/mol MW reagent | 0.1 mol% TEMPO, NaOCl as terminal oxidant | 25 - 50 | 500 - 1000 (TON) |

| Reduction | NaBH₄ or LiAlH₄ | Asymmetric Hydrogenation (e.g., Ru-BINAP) | 1.1-4 eq. hydride source; H₂ gas from complex hydrides | <0.01 mol% Ru catalyst; H₂ gas directly | 10 - 30 | 10,000 - 50,000 (TON) |

| Cross-Coupling | Stille Coupling (Stoichiometric SnR₃) | Suzuki-Miyaura Coupling (Pd Catalysis) | 1.2 eq. organotin reagent (toxic, high MW) | 0.5 - 1 mol% Pd ligand complex | 40 - 100 (for Stille) | 100 - 10,000 (TON) |

| Chiral Resolution | Diastereomeric Salt Formation (CSA) | Asymmetric Catalytic Hydrogenation | 0.5-1 eq. resolving agent; max 50% yield of desired enantiomer | <0.1 mol% chiral catalyst; >95% yield, >99% ee | 20 - 100 (incl. wasted enantiomer) | 1,000 - 100,000 (TON) |

| Amide Bond Formation | Carbodiimide (DCC/EDC) Coupling | Boron-based Catalytic Coupling (e.g., T3P) | 1.1-1.5 eq. coupling agent; stoichiometric urea byproduct | ~0.2 eq. T3P as reagent/catalyst; water-soluble byproducts | 15 - 40 (for DCC) | N/A (Stoichiometric reagent) |

*E-Factor: Environmental Factor. Ranges are approximate and highly substrate-dependent. Catalytic E-Factors are typically 5-100x lower.

Experimental Protocols & Supporting Data

To illustrate the quantitative differences, we present protocols for a common transformation: the reduction of a prochiral ketone to a chiral alcohol, a ubiquitous step in API synthesis.

Protocol 2.1: Stoichiometric Reduction Using (-)-DIP-Chloride

- Objective: Asymmetric reduction of ethyl 4-chloroacetoacetate to ethyl (S)-4-chloro-3-hydroxybutyrate.

- Materials: Substrate (1.0 equiv, 1 mmol), (-)-DIP-Chloride (B-chlorodiisopinocampheylborane, 1.1 equiv, 1.1 mmol), anhydrous THF, methanol, saturated sodium bicarbonate.

- Procedure: Under N₂, cool THF (5 mL) to -25°C. Add substrate (165 mg). Add (-)-DIP-Chloride (327 mg in 2 mL THF) dropwise over 15 min. Stir at -25°C for 2 h. Quench by careful addition of methanol (1 mL). Warm to RT, add saturated NaHCO₃ (5 mL), extract with ethyl acetate (3 x 10 mL). Dry organic layers (MgSO₄), filter, and concentrate.

- Yield & Enantioselectivity: 92% yield, 94% ee. Atom Economy (for reagent): ~10%. Effective Mass Yield: ~14% of reagent mass incorporated into product.

Protocol 2.2: Catalytic Asymmetric Hydrogenation Using Ru-(S)-BINAP

- Objective: Same transformation via catalytic hydrogenation.

- Materials: Substrate (1.0 equiv, 1 mmol), [RuCl₂((S)-BINAP)]₂•NEt₃ (0.1 mol%), degassed methanol, H₂ gas (50 bar).

- Procedure: Place substrate (165 mg) and catalyst (1.7 mg) in a pressure reactor. Purge with N₂, then H₂. Add degassed MeOH (5 mL). Pressurize with H₂ to 50 bar. Stir at 50°C for 16 h. Release pressure, concentrate the mixture. Purify via silica gel chromatography.

- Yield & Enantioselectivity: 95% yield, >99% ee. Atom Economy (for H₂): ~100%. Catalyst TON: 950. Catalyst TOF: ~59 h⁻¹.

Table 2: Comparative Analysis of Reduction Protocols

| Parameter | Stoichiometric (-)-DIP-Cl | Catalytic Ru-BINAP Hydrogenation |

|---|---|---|

| Reagent/Catalyst Loading | 110 mol% | 0.1 mol% |

| Reagent/Catalyst MW | 326.7 g/mol | 1557.3 g/mol (dimer) |

| Mass of Reductant Used per mmol S.M. | 327 mg | 1.7 mg |

| Theoretical Max. Mass Efficiency | Low (High MW reagent waste) | Very High (H₂ as ideal reductant) |

| E-Factor (Isolated Product Basis) | ~35 | <5 |

| Key Waste Stream | Stoichiometric organoborane byproducts | Trace metal (<10 ppm Ru) |

Visualizing the Workflow and Cost-Benefit Logic

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents and Materials for Evaluating Catalytic vs. Stoichiometric Routes

| Item / Solution | Function in Research | Key Considerations for Route Selection |

|---|---|---|

| Chiral Ligand Libraries (e.g., Josiphos, BINAP, SPRIX) | Screening for asymmetric catalytic steps (hydrogenation, coupling). | Cost per mmol, commercial availability, air/moisture stability, known performance in analogous reactions. |

| Precious Metal Catalyst Precursors (e.g., Pd₂(dba)₃, [Ru(cymene)Cl₂]₂, [(COD)IrCl]₂) | Source of active catalytic species for coupling, hydrogenation, oxidation. | Metal cost, activation requirements, ligand compatibility, residual metal specifications in API. |

| Organocatalysts (e.g., MacMillan, Cinchona Alkaloids, DMAP) | Metal-free catalysis for diverse transformations (e.g., aldol, α-alkylation). | Lower cost than metal complexes, but often require higher loadings (1-10 mol%). |

| Stoichiometric Reagents (Benchmarks) (e.g., DIBAL-H, Oxalyl Chloride (Swern), m-CPBA) | High-performing, reliable benchmarks for comparison against new catalytic methods. | Byproduct toxicity, handling hazards, purification challenges, overall mass efficiency. |

| High-Pressure Reactors (e.g., Parr series, Uniqsis FlowCat) | Enabling catalytic reactions with gases (H₂, CO, O₂) at elevated pressure. | Essential for assessing industrially relevant catalytic hydrogenation/carbonylation. |

| Flow Chemistry Systems (e.g., Vapourtec, Syrris) | Continuous processing for hazardous stoichiometric reagents or unstable catalytic intermediates. | Can improve safety of both paradigms and enable novel catalytic transformations. |

| Metal Scavengers (e.g., SiliaMetS products, QuadraPure resins) | Removal of residual catalyst metals to meet API purity standards (<10 ppm). | Critical post-processing cost factor for catalytic routes; often not needed for stoichiometric. |

| Process Mass Intensity (PMI) Calculator Software | Quantifying total material input per unit of API output for route comparison. | The definitive metric for comparing the inherent waste of stoichiometric vs. catalytic steps. |

The strategic selection of synthetic routes for Active Pharmaceutical Ingredients (APIs) is a critical decision in drug development, directly impacting sustainability, cost, and waste generation. This guide compares the performance of catalytic versus traditional stoichiometric routes through the lenses of Atom Economy (AE) and Process Mass Intensity (PMI), framed within a cost-benefit analysis thesis for research professionals.

Quantitative Comparison of Stoichiometric vs. Catalytic Routes

The following table summarizes experimental data from recent route developments for representative API intermediates, highlighting key green chemistry metrics.

Table 1: Performance Comparison of API Synthetic Routes

| API Intermediate | Route Type | Key Reagent | Atom Economy (%) | PMI (kg waste/kg product) | Overall Yield (%) | E-Factor | Reference Year |

|---|---|---|---|---|---|---|---|

| Sitagliptin Precursor | Stoichiometric (Old) | LHMDS, Benzylamine | 42 | 155 | 68 | 154 | (Benchmark) |

| Sitagliptin Precursor | Catalytic (New) | Transaminase, IPA | 89 | 22 | 92 | 21 | 2023 |

| Atorvastatin Fragment | Stoichiometric | TiCl₄, NMO | 35 | 120 | 75 | 119 | (Benchmark) |

| Atorvastatin Fragment | Catalytic | Ru-Pincer Complex | 78 | 45 | 88 | 44 | 2024 |

| Carbapenem Core | Stoichiometric | DAST, TEA | 48 | 180 | 65 | 179 | (Benchmark) |

| Carbapenem Core | Catalytic (Biocat.) | Ketoreductase, NADP⁺ | 95 | 18 | 95 | 17 | 2023 |

Experimental Protocols for Key Comparisons

Protocol 1: Evaluating Transaminase-Catalyzed Synthesis of Sitagliptin Precursor

- Objective: Synthesize chiral amine intermediate via asymmetric reductive amination.

- Materials: Pro-sitagliptin ketone (1.0 eq), Isopropylamine (IPA, 2.0 eq, amine donor), Engineered transaminase (ATA-117, 3% w/w), PLP cofactor (0.1 mM), Phosphate buffer (0.1 M, pH 7.5).

- Method: Dissolve ketone substrate (5.0 g) and IPA in buffer. Add PLP and ATA-117. Stir reaction at 30°C, monitoring by HPLC. Upon completion (>99% conversion), extract product with ethyl acetate, dry (Na₂SO₄), and concentrate. Calculate yield, enantiomeric excess (ee) via chiral HPLC, and PMI from total mass input vs. isolated product mass.

Protocol 2: Ruthenium-Catalyzed Asymmetric Hydrogenation for Atorvastatin Fragment

- Objective: Synthesize chiral diol via asymmetric hydrogenation of diketone.

- Materials: β-keto-ester (1.0 eq), Ru-(S)-BINAP catalyst (0.05 mol%), Hydrogen gas (50 bar), Anhydrous methanol.

- Method: Charge diketone (10 mmol) and Ru catalyst into a high-pressure autoclave under N₂. Add degassed MeOH. Purge with H₂ three times, then pressurize to 50 bar. Stir at 40°C for 12 h. Release pressure, concentrate, and purify by flash chromatography. Determine yield, % ee, and atom economy from molecular weights of reactants vs. product.

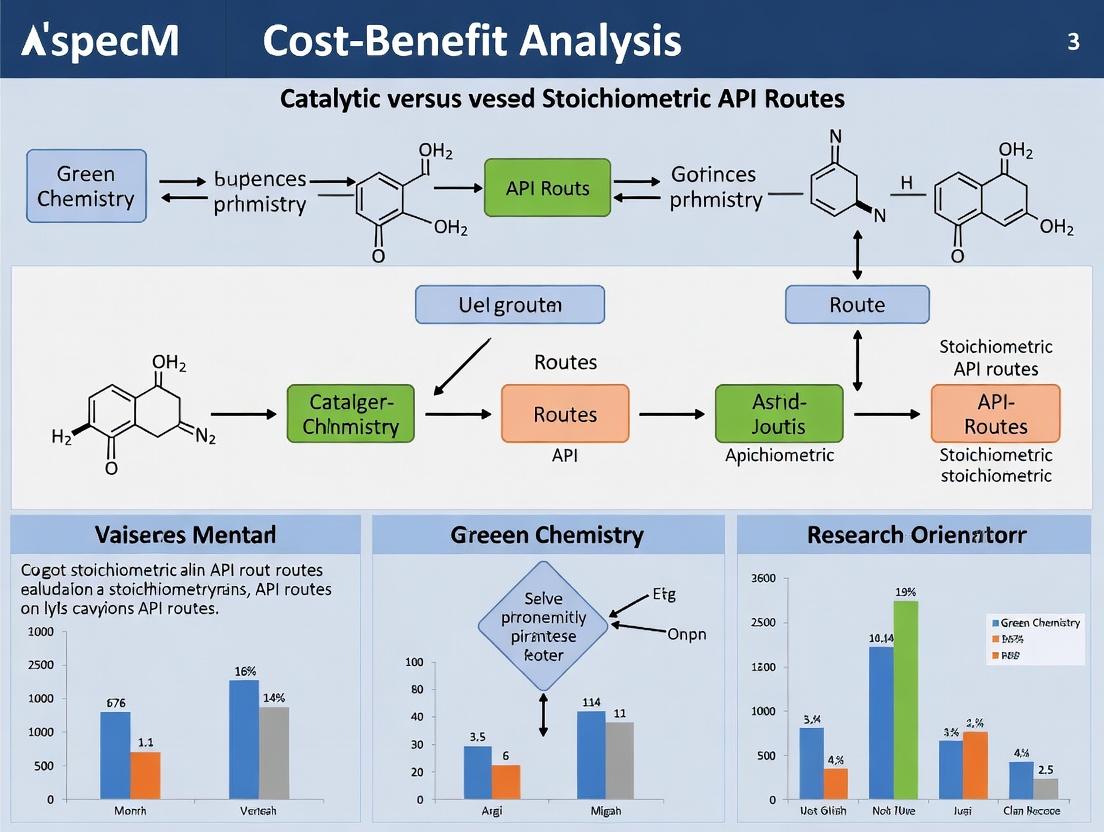

Visualization of Route Selection Logic

Diagram Title: Decision Workflow for API Route Selection

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Green Route Development

| Reagent / Material | Function in Catalytic Routes | Example Use Case |

|---|---|---|

| Engineered Transaminases | Biocatalyst for chiral amine synthesis via asymmetric reductive amination. | Synthesis of Sitagliptin and other amine-containing APIs. |

| Ru- and Rh-BINAP Complexes | Homogeneous catalysts for asymmetric hydrogenation of ketones and alkenes. | Production of chiral alcohol fragments for statins. |

| Pd/XPhos-type Ligands | Enables cross-coupling (e.g., Suzuki, Buchwald-Hartwig) at low catalyst loadings. | Formation of C-C and C-N bonds in complex intermediates. |

| Immobilized Lipases/CalB | Heterogeneous biocatalyst for enantioselective ester hydrolysis/acylation. | Kinetic resolution of racemic alcohols/acids. |

| NADP⁺/NADPH Cofactors | Redox cofactors for oxidoreductase enzymes; used in recycling systems. | Biocatalytic ketone reductions or alcohol oxidations. |

| Polymorphic Screening Kits | High-throughput screening to identify optimal solid forms of API intermediates. | Ensuring reproducible crystallization and purity post-catalytic step. |

This guide compares the long-term economic and operational profile of catalytic versus traditional stoichiometric routes for active pharmaceutical ingredient (API) synthesis. The analysis is framed within the broader thesis that a comprehensive cost-benefit analysis must extend beyond simple per-kg reagent costs to include capital intensity, waste stream management, and intellectual property (IP) leverage.

Comparative Analysis of Synthetic Routes for Sitagliptin API

The synthesis of Sitagliptin, a leading anti-diabetic drug, provides a seminal case study. The original Merck route employed a late-stage transition-metal-catalyzed enantioselective hydrogenation. A subsequent biocatalytic re-design by Codexis and Merck offers a direct comparison.

Table 1: Route Comparison for Sitagliptin Synthesis

| Parameter | Original Metal-Catalytic Route (Enantioselective Hydrogenation) | Next-Generation Biocatalytic Route (Transaminase-Mediated) |

|---|---|---|

| Step Count | 3 steps from prochiral enamide | 1 step from prochiral ketone |

| Atom Economy | ~70% | >99% |

| Process Mass Intensity (PMI) | High (~200 kg waste/kg API) | Low (~50 kg waste/kg API) |

| Catalyst Loading | 0.1 mol% metal complex | 6 g/L enzyme (cell-free extract) |

| Enantiomeric Excess (ee) | >99% | >99.5% |

| Key Operational Cost | High-pressure H₂ equipment, catalyst cost | Enzyme production, substrate engineering |

| IP Landscape | Strong process patents on asymmetric hydrogenation | New composition-of-matter patents on engineered enzyme & process |

Table 2: Cost-Benefit Analysis Over 5,000 kg API Production

| Cost Category | Stoichiometric Route (Hypothetical Alternative) | Original Catalytic Route | Advanced Biocatalytic Route |

|---|---|---|---|

| Total Reagent Cost | $1,200,000 | $850,000 | $600,000 |

| Catalyst/Enzyme Cost | $0 (stoichiometric reagents) | $180,000 | $250,000 |

| Capital Depreciation | $150,000 | $300,000 (high-pressure reactors) | $400,000 (specialized bioreactors) |

| Waste Disposal Cost | $400,000 | $220,000 | $75,000 |

| Total Projected Cost | $1,750,000 | $1,550,000 | $1,325,000 |

| Value of IP Generated | Low (incremental improvement) | Medium (novel catalytic process) | High (novel bio-catalyst, greener process) |

Experimental Protocols for Key Comparative Data

Protocol 1: Determination of Process Mass Intensity (PMI)

- Scale: Perform each synthetic route at a 100g API output scale.

- Material Accounting: Precisely weigh all input materials (reactants, solvents, catalysts, reagents) and all output materials (isolated API, all waste streams including aqueous, organic, and solid waste).

- Calculation: PMI = Total mass of inputs (kg) / Mass of API produced (kg). Data from published life-cycle assessments (LCAs) of commercial processes are used for Table 1.

Protocol 2: Assessment of Catalyst Productivity & Lifetime

- For Heterogeneous Metal Catalysts: In a fixed-bed continuous flow reactor, feed the substrate solution under defined conditions (pressure, temperature). Monitor API concentration in the effluent via HPLC. Catalyst lifetime is defined as the total mass of API produced per mass of catalyst before activity falls below 90% of initial.

- For Enzymatic Catalysts: In a batch bioreactor, combine ketone substrate, amine donor, and purified transaminase. Sample periodically to monitor conversion (GC/HPLC). Enzyme productivity is reported as Total Turnover Number (TTN) – moles of product formed per mole of enzyme active site before deactivation.

Protocol 3: Comparative IP Strength Analysis (Bibliometric/Patent)

- Patent Citation Analysis: Using a database (e.g., Lens.org, Google Patents), identify the core patent for each route.

- Metrics: Record the number of forward citations (later patents citing this one), the geographic breadth of patent family filings, and the number of subsequent process improvement patents spawned. Higher numbers indicate greater IP strength and long-term value.

Visualizations

Title: Decision Factors in Route Economics

Title: Route Comparison for Chiral Amine Synthesis

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in Catalytic Route Development |

|---|---|

| Immobilized Metal Catalyst (e.g., Pd/C, Ni-Silica) | Enables heterogeneous catalysis for easy separation and potential reuse, reducing long-term reagent costs. |

| Engineered Enzyme Kit (e.g., Transaminase Panel) | Allows rapid screening of bio-catalytic activity and selectivity for a target transformation. |

| Chiral HPLC Column & Standards | Critical for accurate determination of enantiomeric excess (ee), a key quality metric for catalytic asymmetric synthesis. |

| High-Pressure Reactor System (Micro/Mini-scale) | Enables safe, small-scale screening of catalytic reactions requiring pressurized gases (H₂, CO). |

| Process Mass Intensity (PMI) Calculator Software | Assists in quantifying waste generation and comparing the environmental footprint of different routes early in development. |

| Amine Donor (e.g., Isopropylamine, L-Alanine) | Essential stoichiometric reagent in transaminase reactions; cost and removal impact overall process economics. |

Within pharmaceutical process research, the selection of an optimal synthetic route for Active Pharmaceutical Ingredient (API) manufacture is a critical determinant of cost, environmental impact, and scalability. This comparison guide evaluates classic stoichiometric methods against modern catalytic alternatives, framed by a cost-benefit analysis for API route selection. The focus is on two representative transformations: manganese dioxide (MnO₂) oxidation and catalytic hydrogenation.

Comparative Analysis: Stoichiometric MnO₂ Oxidation vs. Catalytic Alternatives

Performance and Cost Data

The following table summarizes key metrics for the oxidation of a primary alcohol to an aldehyde, a common step in API synthesis.

Table 1: Comparison of Alcohol to Aldehyde Oxidation Methods

| Metric | Stoichiometric MnO₂ Oxidation | Catalytic TPAP (n-Pr₄N⁺RuO₄⁻) | Catalytic TEMPO/NaOCl (Anelli Oxidation) |

|---|---|---|---|

| Reagent Stoichiometry | 5-10 eq. MnO₂ required | 0.05-0.1 eq. TPAP, 1.2 eq. NMO | 0.01-0.1 eq. TEMPO, 1.05 eq. NaOCl |

| Typical Yield | 70-85% | 88-95% | 90-98% |

| Reaction Time | 2-24 hours | 1-3 hours | 0.5-2 hours |

| Major Byproducts | Mn salts (significant solid waste) | Ruthenium traces, NMO oxide | NaCl, NaHCO₃ |

| E-Factor (kg waste/kg product) | 25-50 (High) | 5-15 (Moderate) | 1-5 (Low) |

| Approximate Cost per kg Substrate | $150-$300 (reagent + waste handling) | $400-$600 (catalyst cost) | $50-$150 (low reagent cost) |

| Key Advantage | Selective for allylic/benzylic alcohols; simple setup. | Mild, chemoselective, usable on complex molecules. | Very green, low-cost, scalable for industrial use. |

| Key Disadvantage | High waste, inconsistent reagent activity, workup difficult. | High catalyst cost, metal contamination concern. | Requires pH control, not ideal for all substrates. |

Experimental Protocol: Stoichiometric MnO₂ Oxidation of Cinnamyl Alcohol

Objective: To convert cinnamyl alcohol to cinnamaldehyde. Methodology:

- Setup: In a 1L round-bottom flask equipped with a magnetic stirrer, combine cinnamyl alcohol (50.0 g, 0.37 mol) with dichloromethane (500 mL).

- Addition: Add activated manganese dioxide (322 g, 3.7 mol, 10 eq.) in one portion.

- Reaction: Stir the heterogeneous mixture at room temperature for 18 hours. Monitor reaction progress by TLC or GC.

- Workup: Filter the reaction mixture through a Celite pad. Wash the filter cake thoroughly with dichloromethane (3 x 100 mL).

- Isolation: Concentrate the combined filtrate under reduced pressure.

- Purification: Purify the crude residue by vacuum distillation to afford cinnamaldehyde. Expected Outcome: Yield: ~75% (35 g). Purity: >95% by GC.

Comparative Analysis: Stoichiometric Reducing Agents vs. Catalytic Hydrogenation

Performance and Cost Data

The reduction of a nitro group to an amine is a pivotal transformation. The table compares stoichiometric metal reductions with catalytic hydrogenation.

Table 2: Comparison of Nitro to Amine Reduction Methods

| Metric | Stoichiometric Fe/HCl | Stoichiometric SnCl₂ | Catalytic Hydrogenation (Pd/C, H₂) |

|---|---|---|---|

| Reagent Stoichiometry | 4-8 eq. Fe, 4-10 eq. HCl | 2.2-3 eq. SnCl₂ | 0.01-0.05 eq. Pd, 3-4 eq. H₂ gas |

| Typical Yield | 70-90% | 80-95% | 95-99% |

| Reaction Time | 1-4 hours | 1-3 hours | 0.5-2 hours |

| Major Byproducts | Fe oxides, Fe salts, aqueous acidic waste | Sn salts, aqueous waste | None (filterable catalyst) |

| E-Factor | 15-40 (High) | 10-30 (High) | 1-10 (Low) |

| Approximate Cost per kg Substrate | $100-$200 | $500-$800 (reagent cost) | $200-$400 (catalyst + H₂ infrastructure) |

| Key Advantage | Inexpensive reagents. | Selective, tolerates some sensitive groups. | Extremely clean, high-yielding, atom-economical. |

| Key Disadvantage | Severe waste and workup issues, corrosive. | Expensive, toxic, creates heavy metal waste. | Safety concerns with H₂ gas, requires specialized equipment. |

Experimental Protocol: Catalytic Hydrogenation of Nitrobenzene

Objective: To convert nitrobenzene to aniline using a heterogeneous palladium catalyst. Methodology:

- Setup: Charge nitrobenzene (50.0 g, 0.41 mol) and ethanol (250 mL) into a 500 mL hydrogenation autoclave or Parr bottle.

- Catalyst Addition: Add 5% Pd/C (2.5 g, 50% water-wet, 0.05 eq. Pd) under a nitrogen atmosphere.

- Purge: Seal the reactor and purge 3 times with nitrogen followed by 3 times with hydrogen.

- Pressurization: Pressurize with hydrogen gas to 50 psi (3.4 bar).

- Reaction: Stir vigorously at room temperature for 2-4 hours. Monitor hydrogen uptake or by TLC.

- Workup: Vent hydrogen carefully. Filter the reaction mixture through a Celite pad to remove the catalyst. Wash the filter cake with ethanol (2 x 50 mL).

- Isolation: Concentrate the combined filtrate under reduced pressure to yield aniline. Expected Outcome: Yield: >98% (36 g). Purity: >99% by GC. Catalyst can be recovered and recycled.

Visualizing the Cost-Benefit Decision Pathway

Title: API Route Selection: Stoichiometric vs Catalytic Decision Tree

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Method Evaluation

| Reagent/Catalyst | Primary Function | Key Consideration for API Synthesis |

|---|---|---|

| Activated MnO₂ | Stoichiometric oxidant for allylic/benzylic alcohols. | Activity varies by source; generates heavy metal waste. Not ideal for GMP. |

| TPAP (Tetrapropylammonium perruthenate) | Homogeneous catalytic oxidant for primary alcohols. | Excellent chemoselectivity but expensive Ru catalyst; requires co-oxidant (NMO). |

| TEMPO (2,2,6,6-Tetramethylpiperidin-1-yl)oxyl | Organocatalyst for aerobic or hypochlorite oxidations. | Enables extremely green, metal-free oxidations. Cost-effective at scale. |

| Iron Powder | Stoichiometric reducing agent for nitro groups. | Inexpensive but produces significant inorganic sludge. Purification challenges. |

| Palladium on Carbon (Pd/C) | Heterogeneous hydrogenation catalyst. | Workhorse for reductions; filterable. Critical to control metal residues (<10 ppm). |

| Raney Nickel | Heterogeneous hydrogenation catalyst. | Very active and low-cost, but pyrophoric and severe Ni residue concerns. |

| Sodium Hydride (NaH) | Stoichiometric base for deprotonations. | Handled as dispersion in oil. Generates H₂ gas and NaOH waste. |

| Enzyme Kits (e.g., KREDs) | Biocatalytic reduction of ketones. | Exceptional stereoselectivity, mild conditions. Requires substrate compatibility screening. |

Implementing Catalytic Routes: A Step-by-Step Guide to Process Development and Scale-Up

Route Scouting and Retrosynthetic Analysis with Catalytic Key Steps in Mind

Within the broader thesis on the Cost-benefit analysis of catalytic vs stoichiometric API routes research, the strategic integration of catalysis during early route scouting is paramount. This guide compares the performance of catalytic and stoichiometric approaches for a key synthetic transformation common in API development: the reductive amination for secondary amine synthesis.

Performance Comparison: Catalytic vs. Stoichiometric Reductive Amination

The following table summarizes experimental data comparing a catalytic (with in-situ borane formation) and a traditional stoichiometric (sodium triacetoxyborohydride) reductive amination protocol for the synthesis of a model pharmaceutical intermediate, N-benzylphenethylamine.

Table 1: Comparative Performance Data for Reductive Amination Routes

| Parameter | Catalytic Route (BH3·THF / Ti(OiPr)4) | Stoichiometric Route (NaBH(OAc)3) |

|---|---|---|

| Yield (Isolated) | 92% | 95% |

| Reaction Time | 4 hours | 18 hours |

| Temperature | 25 °C (rt) | 25 °C (rt) |

| Atom Economy | 91% | 63% |

| E-Factor | 8.2 | 32.5 |

| Estimated Cost/kg Intermediate | $1,150 | $2,850 |

| Key Impurities | <0.5% alcohol reduction byproduct | ~3% acetamide byproduct |

Key Takeaways: While both methods deliver high yield, the catalytic route demonstrates superior green chemistry metrics (Atom Economy, E-Factor) and a significantly lower projected cost at scale, primarily due to reduced reagent consumption and waste treatment costs. The stoichiometric route generates a larger, more complex waste stream containing boron and acetate salts.

Experimental Protocols

Protocol A: Catalytic Reductive Amination

Methodology: In an inert atmosphere glovebox, a flame-dried Schlenk flask was charged with Ti(OiPr)4 (2.5 mol%). Benzaldehyde (10 mmol) and phenethylamine (10.5 mmol) were added, and the mixture was stirred in dichloromethane (0.5 M) at room temperature for 1 hour to form the imine intermediate. The flask was then cooled to 0°C, and BH3·THF (1 M in THF, 11 mmol) was added dropwise. The reaction was warmed to room temperature and stirred for 3 hours. The reaction was quenched cautiously with methanol, followed by 1 M NaOH. The product was extracted with DCM, dried over MgSO4, filtered, and concentrated. The crude material was purified by flash chromatography (SiO2, Hexanes:EtOAc 9:1) to yield the product as a colorless oil.

Protocol B: Stoichiometric Reductive Amination

Methodology: Benzaldehyde (10 mmol) and phenethylamine (12 mmol) were combined in dichloromethane (0.2 M) at room temperature. Sodium triacetoxyborohydride (15 mmol) was added portionwise. The reaction mixture was stirred at room temperature for 18 hours. The reaction was quenched by slow addition of saturated NaHCO3 solution. The aqueous layer was extracted with DCM (3x). The combined organic extracts were washed with brine, dried over MgSO4, filtered, and concentrated. The crude material was purified by flash chromatography (SiO2, Hexanes:EtOAc 4:1) to yield the product.

Visualizing Retrosynthetic Strategy with Catalytic Key Steps

Diagram Title: Retrosynthetic Analysis with Key Step Options

Comparative Experimental Workflow

Diagram Title: Catalytic vs. Stoichiometric Workflow Comparison

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Reductive Amination Route Scouting

| Research Reagent / Material | Function in Experiment |

|---|---|

| Titanium(IV) Isopropoxide (Ti(OiPr)4) | Lewis acid catalyst. Activates the carbonyl and imine, enabling milder reduction conditions and improving selectivity. |

| Borane-Tetrahydrofuran Complex (BH3·THF) | Stoichiometric reductant in the catalytic cycle. Serves as the source of hydride in the Ti-catalyzed pathway. |

| Sodium Triacetoxyborohydride (NaBH(OAc)3) | Stoichiometric reducing agent. A mild, selective reductant for imines in direct reductive amination. |

| Molecular Sieves (3Å or 4Å) | Used to remove water from reaction mixtures, shifting equilibrium toward imine formation and preventing reductant decomposition. |

| Inert Atmosphere Glovebox or Schlenk Line | Essential for handling air- and moisture-sensitive reagents like BH3·THF and Ti(OiPr)4 safely and effectively. |

| Anhydrous Solvents (DCM, THF) | Prevent catalyst deactivation and unwanted side reactions with water, ensuring reproducibility. |

This comparison guide, framed within a broader thesis on the cost-benefit analysis of catalytic versus stoichiometric routes for Active Pharmaceutical Ingredient (API) synthesis, provides an objective assessment of catalyst technologies. It is designed for researchers, scientists, and drug development professionals evaluating route-scaling decisions.

Core Catalyst Comparison Table

| Parameter | Homogeneous Catalyst | Heterogeneous Catalyst | Biocatalyst (Enzyme) |

|---|---|---|---|

| Active Site Accessibility | High (all atoms available) | Limited (surface only) | Very High (specific pocket) |

| Typical Selectivity (ee/chemoselectivity) | Moderate to High | Low to Moderate | Exceptionally High (often >99% ee) |

| Typical Reaction Conditions | Mild (25-150°C) | Often Harsh (High T/P) | Very Mild (20-40°C, aqueous) |

| Separation & Recovery | Difficult/Expensive (distillation, extraction) | Easy (filtration) | Moderate (ultrafiltration, immobilization) |

| Lifetime (Typical Turnover Number - TON) | 10^2 - 10^5 | 10^3 - 10^6 | 10^3 - 10^7 (for stable enzymes) |

| Catalyst Cost (Relative) | High (often precious metals) | Low to Moderate (supported metals) | Variable (High initial R&D, low unit cost if engineered) |

| Sensitivity to Poisons | High | Moderate | High (denaturation, inhibitors) |

| Ease of Optimization | High (ligand tuning) | Moderate (support/metal choice) | High (directed evolution) |

| Waste Generation (E-factor contributor) | High (from separation) | Low | Very Low (aqueous buffer) |

| Scalability for Continuous Flow | Challenging | Excellent | Good with immobilization |

Cost Driver Analysis Table

| Cost Driver | Homogeneous | Heterogeneous | Biocatalyst |

|---|---|---|---|

| Capital Expenditure (CapEx) | Moderate (corrosion-resistant reactors) | Low (standard reactors) | Low (mild conditions) but may require specialized bioreactors |

| Operational Expenditure (OpEx) | Very High (catalyst loss, precious metal tracking, separation units) | Low (catalyst recovery, regeneration) | Low (buffer, enzyme recycle) but can be high if cofactors needed |

| Raw Material Cost | High (ligands, metal precursors) | Moderate (supported catalyst) | Dominant Cost: Enzyme production/immobilization; can become low at scale |

| Downstream Processing Cost | High (complex separations, metal removal to <10 ppm for APIs) | Low (simple filtration) | Moderate (product isolation from aqueous phase) |

| Development & Licensing Cost | Moderate (known chemistry) | Moderate | High (enzyme screening/engineering) but decreasing |

| Regulatory & Safety Cost | High (toxic metal handling & disposal) | Moderate | Low (green process, reduces regulatory burden) |

Supporting Experimental Data from Key Studies

Study 1: Comparative Hydrogenation of a Prochiral Ketone Intermediate

- Objective: Compare performance for enantioselective synthesis of a chiral alcohol API precursor.

- Protocol:

- Homogeneous: Reaction conducted under N₂ in anhydrous THF with Ru-BINAP complex (0.1 mol%) at 50°C and 5 bar H₂ for 12h. Quenched with MeOH, catalyst removed by silica gel chromatography.

- Heterogeneous: Reaction in ethanol with Ni-Pt/Al₂O₃ catalyst (5 wt%) at 100°C and 10 bar H₂ for 24h. Catalyst recovered by hot filtration.

- Biocatalysis: Reaction in phosphate buffer (pH 7.0) with engineered ketoreductase (KRED) (2 g/L) and NADPH cofactor recycling system (glucose/GDH) at 30°C, ambient pressure, 6h. Enzyme removed by ultrafiltration (10 kDa MWCO).

- Performance Data Table:

Catalyst System Conversion (%) Enantiomeric Excess (ee%) Total Turnover Number (TON) Productivity (g product/g catalyst) Ru-BINAP (Homogeneous) >99 95 1,000 50 Ni-Pt/Al₂O₃ (Heterogeneous) 85 15 (racemic mix) 17 8.5 Engineered KRED (Biocatalyst) >99 >99.5 5,000 2,500

Study 2: Lifetime and Recycling Analysis for a Cross-Coupling API Step

- Objective: Evaluate catalyst longevity and cost over multiple batches.

- Protocol: A Mizoroki-Heck reaction was chosen. Batches were run sequentially, with catalyst recovery attempted after each.

- Homogeneous: Pd(PPh₃)₄ (0.5 mol%) in DMF at 120°C for 8h per batch. After each run, the product was extracted into ethyl acetate, and the catalyst-containing DMF phase was analyzed for Pd leaching and re-used with fresh ligands.

- Heterogeneous: Pd/C (1 mol% Pd) in toluene at 110°C for 12h per batch. Catalyst recovered by hot filtration, washed with solvent, and dried.

- Biocatalysis: Not applicable for this reaction class.

- Lifetime & Recycling Data Table:

Batch Number Homogeneous Pd (Yield %) Heterogeneous Pd/C (Yield %) 1 92 90 2 85 89 3 78 88 4 40 (Severe deactivation) 87 5 Not viable 85 Total TON ~600 ~4,400

Visualizations

Title: Decision Logic for Catalyst Type Selection

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Relevance in Catalyst Screening |

|---|---|

| Precious Metal Salts (e.g., Pd(OAc)₂, [Ru(cymene)Cl₂]₂) | Homogeneous catalyst precursors. High cost drivers; require careful tracking. |

| Ligand Libraries (Phosphines, NHC precursors, chiral ligands) | Tune activity/selectivity of homogeneous metal complexes. Major R&D cost factor. |

| Immobilized Catalyst Kits (e.g., Pd on SiO₂, Polymer-supported reagents) | Enable heterogeneous screening. Simplify separation studies in flow chemistry. |

| Engineered Enzyme Panels (e.g., KRED, transaminase, P450 kits) | Commercial kits for rapid biocatalyst feasibility assessment. Reduce initial development time. |

| Cofactor Regeneration Systems (NAD(P)H, ATP, etc.) | Essential for economical biocatalysis. Often the key to process viability. |

| High-Pressure Parallel Reactors (e.g., 24-well autoclave systems) | For screening homogeneous/heterogeneous hydrogenation conditions. Crucial for collecting TON/TOF data. |

| Ultrafiltration Devices (e.g., 10 kDa MWCO spin filters) | For separating biocatalysts from reaction mixtures to assess stability and recyclability. |

| Chiral HPLC Columns & Chiral GC Columns | Mandatory for analyzing enantioselectivity (ee%) across all catalyst types. |

| ICP-MS (Inductively Coupled Plasma Mass Spectrometry) | Critical for quantifying metal leaching (<10 ppm in API) from homo-/heterogeneous catalysts. |

This guide, framed within a thesis on the Cost-benefit analysis of catalytic vs stoichiometric API routes, compares the scaling performance of catalytic and stoichiometric methodologies. It focuses on engineering robustness, safety, and economic viability for pharmaceutical process development.

Performance Comparison: Catalytic vs. Stoichiometric Routes

The following table summarizes experimental data from recent studies comparing the two approaches for a model Suzuki-Miyaura cross-coupling, a key step in API synthesis.

Table 1: Comparative Performance Data for Model Cross-Coupling Reaction

| Performance Metric | Homogeneous Pd Catalysis (Ligand-Modified) | Heterogeneous Pd/C Catalyst | Stoichiometric Organometallic Route (e.g., Grignard) |

|---|---|---|---|

| Reaction Yield (%) | 95 - 98% | 88 - 92% | 85 - 90% |

| E-Factor (kg waste/kg product) | 15 - 25 | 20 - 35 | 50 - 150 |

| PMI (Process Mass Intensity) | 20 - 30 | 25 - 40 | 55 - 160 |

| Catalyst/Reagent Loading (mol%) | 0.5 - 1.0 mol% | 2.0 wt% (solid) | 110 - 130 mol% |

| Estimated Cost per kg API ($) | 1,200 - 1,800 | 1,500 - 2,200 | 2,500 - 4,000 |

| Key Safety Concern | Catalyst/degradant metal leaching, exotherm | Dust explosion risk, metal leaching | Pyrophoric reagents, strong exotherm, water sensitivity |

| Scale-up Complexity | Moderate (requires precise control) | Low (easy filtration) | High (cryogenic, stringent anhydrous conditions) |

Experimental Protocols

Protocol A: Ligand-Modified Homogeneous Pd-Catalyzed Cross-Coupling (Bench Scale)

- Charge & Atmosphere: Under a nitrogen atmosphere, charge the aryl halide (1.0 eq), boronic acid (1.2 eq), and potassium carbonate (2.0 eq) to a jacketed reaction vessel containing a degassed mixture of toluene/water (4:1).

- Catalyst Addition: Add the palladium catalyst (e.g., Pd(OAc)₂, 0.5 mol%) and ligand (e.g., SPhos, 1.0 mol%) as solids.

- Reaction: Heat the mixture to 80°C with vigorous stirring for 18 hours. Monitor conversion by HPLC/UPLC.

- Work-up: Cool to room temperature. Add water and separate layers. Wash the organic layer with brine, dry over MgSO₄, and filter.

- Purification: Concentrate under reduced pressure and purify the residue by silica gel chromatography.

Protocol B: Stoichiometric Grignard Coupling (Bench Scale - High Safety Precautions)

- Preparation: Flame-dry glassware under vacuum and purge with inert gas (N₂ or Ar).

- Grignard Formation: In a separate flask, slowly add alkyl halide (1.1 eq) to a stirred suspension of magnesium turnings (1.3 eq) in anhydrous THF at 0°C. Maintain temperature below 5°C. Stir for 1 hour until initiation is complete.

- Coupling Reaction: Transfer the Grignard reagent via cannula to a solution of the carbonyl compound (1.0 eq) in anhydrous THF at -20°C. Maintain temperature below -15°C.

- Quenching: After 2 hours, cautiously quench the reaction by adding a saturated aqueous NH₄Cl solution dropwise at -20°C.

- Work-up: Warm to room temperature. Add water and EtOAc. Separate layers. Wash the organic layer with brine, dry over MgSO₄, and filter.

- Purification: Concentrate under reduced pressure and purify by chromatography.

Logical Diagram: Process Selection Workflow

Title: Scale-Up Route Decision Logic for API Synthesis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Catalytic Process Development

| Reagent/Material | Function in Development & Scale-Up |

|---|---|

| Palladium Precursors (e.g., Pd(OAc)₂, Pd(dba)₂) | Source of active catalytic metal for cross-coupling reactions. Ligand choice dictates activity and selectivity. |

| Specialized Ligands (e.g., SPhos, RuPhos, Josiphos) | Modulate catalyst activity, selectivity (chemo-, regio-, enantioselectivity), and stability, crucial for efficient transformations. |

| Heterogeneous Catalysts (e.g., Pd/C, Pd on alumina) | Facilitate easy catalyst separation via filtration, improving process robustness and potentially reducing metal residues in the API. |

| Flow Reactor Systems (Lab-scale) | Enable precise control of exothermic reactions, handling of unstable intermediates, and continuous processing for rapid parameter optimization. |

| In-situ Reaction Monitoring (e.g., FTIR, Raman probes) | Provide real-time data on reaction progression, intermediate formation, and endpoint detection, critical for process understanding and control. |

| High-Throughput Experimentation (HTE) Kits | Allow for parallel screening of catalyst/ligand combinations, bases, and solvents, dramatically accelerating route scouting and optimization. |

| Metal Scavengers (e.g., SiliaBond Thiol, activated carbon) | Remove residual metal catalysts (e.g., Pd, Ni) from reaction streams to meet stringent API purity specifications (ICH Q3D). |

Navigating Regulatory and Supply Chain Hurdles for Critical Catalyst Metals (Pd, Pt, etc.)

Within pharmaceutical research, particularly in the cost-benefit analysis of catalytic versus stoichiometric routes for Active Pharmaceutical Ingredient (API) synthesis, the selection of catalyst metals like palladium (Pd) and platinum (Pt) is paramount. This guide compares the performance of these precious metal catalysts against emerging alternatives, contextualizing the choice within the challenges of regulatory scrutiny and fragile global supply chains.

Performance Comparison: Catalytic Cross-Coupling Reactions

The following table summarizes key performance metrics for Pd, Pt, and non-precious metal alternatives in model cross-coupling reactions, critical for C-C and C-N bond formation in API synthesis.

Table 1: Catalyst Performance in Model Suzuki-Miyaura and Buchwald-Hartwig Amination Reactions

| Catalyst System | Reaction Type | Typical Loading (mol%) | Average Yield (%) | Turnover Number (TON) | Key Advantage | Key Disadvantage |

|---|---|---|---|---|---|---|

| Pd(PPh₃)₄ / Pd(dba)₂ | Suzuki-Miyaura | 0.5 - 1.0 | 92 - 98 | 100 - 200 | Broad substrate scope, reliable | High cost, Pd residue concerns |

| Pt-PEPPSI complexes | Suzuki-Miyaura | 1.0 - 2.0 | 85 - 92 | 50 - 100 | Air-stable, good for hindered substrates | Lower activity, higher cost than Pd |

| Nickel (Ni) complexes | Buchwald-Hartwig | 2.0 - 5.0 | 80 - 95 | 20 - 50 | Very low cost, earth-abundant | Often requires excess ligand, sensitive to air |

| Iron (Fe) salts | C-N Coupling | 5.0 - 10.0 | 70 - 88 | 10 - 20 | Extremely low cost, low toxicity | Narrow substrate scope, unpredictable |

| Pd-Resin Immobilized | Suzuki-Miyaura | 0.1 - 0.5 | 90 - 96 | 200 - 1000 | Recyclable, low metal leaching | Higher initial complexity |

Experimental Protocols for Key Data

Protocol 1: Standard Suzuki-Miyaura Coupling for Pd vs. Ni Comparison

- Objective: Compare coupling efficiency of 4-bromotoluene with phenylboronic acid.

- Method: In a nitrogen-glovebox, charge a vial with aryl halide (1.0 mmol), boronic acid (1.2 mmol), base (K₂CO₃, 2.0 mmol), and catalyst (Pd(PPh₃)₄ or NiCl₂(dppp) at specified mol%) in degassed 1,4-dioxane/H₂O (4:1, 5 mL). Seal the vial, remove from glovebox, and heat at 80°C with stirring for 16h. Cool, dilute with ethyl acetate, wash with water, dry over MgSO₄, and concentrate. Analyze yield by HPLC vs. an internal standard.

Protocol 2: Leaching Test for Immobilized Pd-Resin Catalyst

- Objective: Quantify residual Pd in API after workup and filtration.

- Method: Following a coupling reaction using a commercial Pd-resin (e.g., Pd on functionalized polymer), filter the hot reaction mixture through a Celtic pad. Evaporate the filtrate to obtain the crude API. Digest a 100 mg sample in concentrated HNO₃ (2 mL) and H₂O₂ (0.5 mL) via microwave-assisted digestion. Dilute the digestate and analyze Pd content by Inductively Coupled Plasma Mass Spectrometry (ICP-MS). Report in parts per million (ppm).

Protocol 3: Catalyst Recycling Study

- Objective: Assess the reusability of an immobilized catalyst system.

- Method: After Protocol 2 filtration, wash the recovered resin catalyst sequentially with water, methanol, and dichloromethane (3x10 mL each). Dry under vacuum for 2h. Recharge the reactor with fresh substrates and solvent for the next run. Repeat for 5 cycles, monitoring yield and ICP-MS leaching per cycle.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalytic Route Development & Analysis

| Item | Function in Research |

|---|---|

| Pd Precursors (e.g., Pd(OAc)₂, Pd(dba)₂) | Bench-stable sources of Pd(0) or Pd(II) for homogeneous catalysis screening. |

| Ligand Libraries (e.g., SPhos, XPhos, BINAP) | Tune catalyst activity, selectivity, and stability; crucial for lowering metal loading. |

| Immobilized Catalysts (e.g., Pd on carbon, polymer-bound Pd) | Enable heterogeneous, potentially recyclable processes with easier metal removal. |

| Non-Precious Salt Alternatives (e.g., Ni(acac)₂, FeCl₃) | For evaluating cost-effective and supply-chain resilient pathways. |

| ICP-MS Calibration Standards | Quantify residual metal contamination in API products to ICH Q3D compliance levels. |

| Scavenging Agents (e.g., SiliaBond Thiol, activated carbon) | Remove soluble metal residues from reaction mixtures post-catalysis. |

Visualizing the Decision Pathway: Catalyst Selection Logic

Catalyst Selection Decision Tree for API Routes

Visualizing the Critical Analysis Workflow

Catalyst Evaluation Workflow for Regulatory Compliance

Overcoming Challenges: Optimizing Catalytic API Processes for Yield, Cost, and Sustainability

This guide, framed within the broader thesis of Cost-benefit analysis of catalytic vs stoichiometric API routes, compares the performance of heterogeneous palladium catalysts in a model Suzuki-Miyaura cross-coupling, a pivotal C-C bond formation in API synthesis. We objectively evaluate catalyst alternatives based on key operational issues.

Experimental Protocol for Comparison

The model reaction: 4-bromoanisole with phenylboronic acid to form 4-methoxybiphenyl.

- General Method: In a parallel reactor, combine 4-bromoanisole (1.0 mmol), phenylboronic acid (1.2 mmol), base (K₂CO₃, 2.0 mmol), and catalyst (1 mol% Pd) in a 4:1 solvent mixture of water and ethanol (5 mL total). Heat the sealed vials to 80°C with stirring for 2 hours. Reaction progress is monitored via HPLC. For leaching tests, a hot filtration test is performed at 50% conversion; the filtrate is reacted further and analyzed for Pd content via ICP-MS.

Catalyst Performance Comparison Table

Table 1: Performance data for Pd catalysts in the Suzuki-Miyaura coupling.

| Catalyst System | Conversion (%) | Selectivity for Target API (%) | Pd Leaching (ICP-MS, ppm) | Reuse Cycle (Yield Drop) | Key Issue Identified |

|---|---|---|---|---|---|

| Pd/C (Heterogeneous) | 99 | >99.5 | 2.1 | 3 (<15% yield drop) | Gradual Deactivation |

| Pd/Al₂O₃ (Heterogeneous) | 95 | 99.1 | 1.8 | 4 (<20% yield drop) | Moderate Deactivation |

| Polymer-Supported Pd (e.g., Pd@POP) | 99 | >99.7 | 0.5 | 5 (<10% yield drop) | Minimal Leaching |

| Homogeneous Pd(PPh₃)₄ (Reference) | >99 | 98.5 | N/A (Soluble) | 0 (Not Reusable) | Not Applicable |

| Pd Nanoparticles (Unsupported) | 92 | 97.0 | 15.3 | 1 (>50% yield drop) | Severe Leaching & Agglomeration |

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential materials for catalytic API route troubleshooting.

| Item | Function in Troubleshooting |

|---|---|

| Supported Metal Catalysts (Pd/C, Pd/Al₂O₃) | Heterogeneous catalysts for testing recyclability and leaching; different supports alter activity. |

| Polymer-Encapsulated Pd Catalysts | Advanced materials designed to minimize metal leaching into the API stream. |

| Inductively Coupled Plasma Mass Spectrometry (ICP-MS) | Analytical technique for quantifying trace metal (Pd) leaching to ppb levels. |

| Hot Filtration Test Setup | Experimental method to distinguish between heterogeneous and homogeneous catalytic pathways. |

| Parallel Pressure Reactor System | Enables simultaneous, controlled testing of multiple catalysts under identical conditions. |

Catalyst Deactivation & Leaching Analysis Workflow

Title: Workflow for Diagnosing Catalyst Deactivation and Leaching

Cost-Benefit Decision Pathway: Catalytic vs. Stoichiometric Route

Title: Decision Logic for API Route Selection Based on Catalyst Issues

Strategies for Catalyst Recycling and Ligand Design to Reduce Cost per Cycle

Within the broader thesis of cost-benefit analysis of catalytic vs. stoichiometric API routes, a critical evaluation of catalyst longevity is paramount. This guide compares strategies to reduce the cost per cycle (CPC) through catalyst recycling and advanced ligand design, focusing on practical implementation.

Comparison of Catalyst Recycling Strategies for API Synthesis

| Strategy | Key Mechanism | Typical Substrate Scope | Reported Cycles | Average Yield/Cycle | Key Limitation |

|---|---|---|---|---|---|

| Solid-Supported Catalysts | Heterogeneous support (e.g., Silica, Polymer) enables filtration. | Cross-couplings, Hydrogenations. | 5-15 | 85-95% | Metal leaching (>50 ppm/cycle). |

| Biphasic (Aqueous/Organic) | Catalyst resides in aqueous phase; product in organic phase. | Hydroformylation, C-C Couplings. | 10-30 | >90% | Limited to water-soluble ligands. |

| Membrane Nanofiltration | Size-exclusion retains soluble catalyst complex. | Metathesis, C-H Activation. | 20-50 | 92-98% | High initial capital cost. |

| Volatile Ligand Design | Catalyst decomposed; ligand distilled & reused. | Carbonylations, Aminations. | 50+ | 90% | Requires thermostable reaction. |

| Immobilized Ionic Liquids | Catalyst in IL film on porous support. | Hydrogenation, Hydroamination. | 15-25 | 88-96% | Ionic liquid viscosity/degradation. |

Comparison of Ligand Design Approaches for Cost Reduction

| Ligand Class/Design | Primary Function | Metal Compatibility | Typical Cost ($/g) | Impact on TON | Reusability Potential |

|---|---|---|---|---|---|

| Buchwald-type Phosphines | C-N, C-C Coupling. | Pd, Cu. | 200-500 | 1,000-10,000 | Low (decomposes). |

| N-Heterocyclic Carbenes (NHCs) | Robust σ-donation, stable complex. | Pd, Ru, Au. | 100-300 | 10,000-50,000 | Moderate (if anchored). |

| P,N-Ligands (PHOX) | Asymmetric induction. | Ir, Rh, Pd. | 300-800 | 500-5,000 | Low. |

| Redox-Active Ligands | Metal oxidation state modulation. | Fe, Cu, Co. | 150-400 | 1,000-20,000 | High (regenerable). |

| Polymer-Grafted Ligands | Facile heterogeneous recovery. | Most transition metals. | N/A (fabricated) | 500-2,000 | Very High (mechanical loss). |

Experimental Protocols for Key Comparisons

Protocol 1: Evaluating Pd Leaching in Solid-Supported Cross-Coupling.

- Method: A silica-supported SPhos-Pd catalyst is used for a Suzuki-Miyaura reaction between 4-bromoanisole and phenylboronic acid. Post-reaction, the mixture is filtered through a 0.45 µm PTFE membrane. The filtrate is analyzed by ICP-MS for Pd content. The solid catalyst is rinsed with solvent and directly charged for the next cycle with fresh reagents.

- Data Collected: Yield (HPLC), Pd conc. in filtrate (ICP-MS), over 10 cycles.

Protocol 2: Membrane Nanofiltration for Homogeneous Catalyst Recycling.

- Method: A Grubbs-Hoveyda II-type metathesis catalyst (MW ~1 kDa) is used for ring-closing metathesis in DCM. The post-reaction solution is passed through a solvent-resistant nanofiltration (SRNF) membrane with a 450 Da MWCO. The permeate (product) is collected, and the retentate (catalyst) is reconstituted with fresh solvent/substrate for the next cycle.

- Data Collected: Conversion (NMR), catalyst retention rate (>99.5% required), cumulative TON over 30 cycles.

Protocol 3: Assessing Ligand Reusability via Volatile Design.

- Method: A carbonylative reaction using a catalyst system with a designed volatile phosphite ligand (e.g., P(OR)₃). Post-reaction, the mixture is subjected to low-pressure distillation. The distilled ligand is collected, analyzed by ³¹P NMR for integrity, and re-complexed with fresh metal precursor for the next run.

- Data Collected: Isolated yield, ligand recovery (mass balance), ³¹P NMR chemical shift consistency.

Visualizations

Title: Catalyst Recycling Strategy Decision Tree

Title: Closed-Loop Ligand Recovery Cycle

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in CPC Reduction Studies |

|---|---|

| SiliaCat Pd(0) (SiliCycle) | Pre-made silica-supported Pd catalyst for rapid testing of heterogeneous recycling protocols. |

| SRNF Membranes (e.g., DuraMem) | Solvent-resistant nanofiltration membranes for evaluating molecular weight-based catalyst retention. |

| Redox-Active Ligand Kits (e.g., Strem) | Libraries of ligands (e.g., α-diimines, bipyridines) for screening with abundant metals (Fe, Cu). |

| Ionic Liquids for Immobilization (e.g., [BMIM][PF₆]) | Low-volatility matrices for creating supported ionic liquid phase (SILP) catalysts. |

| ICP-MS Standard Solutions | For precise quantification of metal leaching (Pd, Rh, Ir, etc.) into API streams during recycling. |

| Polymer-Supported Scavengers (e.g., QuadraPure) | To remove metal residues from post-reaction filtrates, distinguishing leaching from decomposition. |

| High-Throughput Parallel Reactors (e.g., Unchained Labs) | For simultaneous evaluation of catalyst/ligand performance across multiple cycles under controlled conditions. |

Within the broader thesis on the cost-benefit analysis of catalytic vs stoichiometric routes in API synthesis, waste stream management, particularly concerning residual metal purification, emerges as a critical factor. Catalytic routes, while atom-efficient, introduce persistent challenges in removing trace metal catalysts from the final drug substance to meet stringent ICH Q3D guidelines. This comparison guide objectively evaluates purification technologies for minimizing metal residues.

Comparative Analysis of Metal Scavenging Technologies

Table 1: Performance Comparison of Metal Scavengers for Pd Removal

| Scavenger Type (Product Example) | Mechanism | Initial Pd (ppm) | Final Pd (ppm) | Removal Efficiency | Capacity (mg Pd/g) | Key Limitation |

|---|---|---|---|---|---|---|

| Silica-based Thiol (Silica-SH) | Covalent Chelation | 500 | <5 | >99% | 25 | Leaching of silica particles |

| Polymer-bound Triamine (MP-TMT) | Coordination/ Ion-exchange | 850 | <2 | >99.7% | 50 | Swelling in non-polar solvents |

| Activated Carbon | Adsorption | 300 | 25 | 91.7% | 15 | Low selectivity, API adsorption |

| Metal Oxide (Silica-Smopex) | Electrophilic Capture | 1000 | <1 | >99.9% | 100 | Higher unit cost |

| Ion Exchange Resin (Chelating) | Ion Exchange | 200 | <10 | >95% | 30 | pH-dependent efficiency |

Table 2: Cost-Benefit Analysis Across API Route Types

| Purification Step | Stoichiometric Route (Baseline) | Homogeneous Catalytic Route | Heterogeneous Catalytic Route | Flow Catalytic Route |

|---|---|---|---|---|

| Typical Unit Operations | Crystallization, Filtration | Scavenger + Filtration, Chromatography | Filtration, Crystallization | In-line Scavenger Cartridge |

| Avg. Pd Reduction (ppm) | 50 → 5 | 500 → <5 | 100 → <5 | 200 → <2 |

| Estimated Cost Contribution (%) | 5-10% | 15-25% | 10-15% | 8-12% |

| Waste Volume Generated (L/kg API) | High | Very High | Moderate | Low |

| ICH Q3D Compliance | Easier | Challenging | Moderate | Simplified |

Experimental Protocols for Key Data

Protocol 1: Evaluation of Silica-Based Thiol Scavenger

- Solution Preparation: Dissolve the Pd-contaminated API (10 g) in a suitable solvent (e.g., ethyl acetate, 200 mL) at 50°C.

- Scavenger Addition: Add the silica-thiol scavenger (1.0 g, 10% w/w relative to API) to the stirred solution.

- Contact Time: Stir the mixture at 50°C for 2 hours.

- Filtration: Filter the suspension through a 0.45 μm membrane to remove the scavenger.

- Analysis: Concentrate the filtrate, isolate the API, and analyze Pd content via ICP-MS (Inductively Coupled Plasma Mass Spectrometry). Perform in triplicate.

Protocol 2: Dynamic Binding Capacity of Polymer-Bound Triamine

- Column Packing: Slurry pack a glass column (ID 10 mm) with MP-TMT resin (5 mL bed volume).

- Loading Solution: Prepare a standard solution of Pd(II) acetate (500 ppm Pd) in a 70:30 methanol/water mixture.

- Loading: Pass the loading solution through the column at a flow rate of 1 mL/min (2 bed volumes per hour).

- Breakthrough Monitoring: Collect the column effluent in fractions and analyze each via ICP-MS. The breakthrough point is defined as the point where the effluent Pd concentration reaches 10% of the feed concentration.

- Capacity Calculation: Calculate the dynamic binding capacity (mg Pd/mL resin) at the 10% breakthrough point.

Visualizations

Title: API Synthesis Route and Purification Decision Flow

Title: Metal Scavenger Performance Test Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Waste Stream Management |

|---|---|

| Silica- or Polymer-Bound Scavengers (e.g., Thiol, Triamine, Isocyanide) | Immobilized ligands that selectively chelate and remove specific metal ions (Pd, Pt, Ni, Cu) from API solutions via filtration. |

| Activated Carbon | Non-selective adsorbent used for gross removal of colored impurities and some metals; risk of significant API adsorption. |

| Chelating Ion-Exchange Resins | Selective resins (e.g., iminodiacetic acid) for removing metal cations from aqueous process streams. |

| In-Line Scavenger Cartridges (e.g., Smopex) | Packed-bed devices for continuous flow purification, integrating metal removal directly into the process flow. |

| ICP-MS Calibration Standards | Certified reference materials for accurate quantification of trace metal residues down to ppb levels per ICH Q3D. |

| 0.45 μm Membrane Filters | For sterile filtration of solutions after scavenger treatment to ensure complete removal of fine particulate matter. |

| Crystallization Solvents (e.g., MeOH, EtOH, Acetone, ACN) | Used in recrystallization steps that can also help purge metal residues by partitioning. |

| Solid Phase Extraction (SPE) Cartridges | For small-scale screening of multiple scavenger chemistries to identify the most effective option. |

Within the pharmaceutical industry's drive towards sustainable and cost-effective Active Pharmaceutical Ingredient (API) synthesis, the adoption of catalytic methods is a central goal. However, a purely catalytic route is not always the optimal solution from a holistic cost-benefit perspective. This guide compares hybrid synthetic routes—those integrating both catalytic and stoichiometric steps—against purely catalytic or purely stoichiometric alternatives. The analysis is framed within a broader thesis on the cost-benefit analysis of catalytic versus stoichiometric API routes, providing researchers and development professionals with objective, data-driven comparisons.

Performance Comparison: Case Studies in API Synthesis

Case Study 1: Synthesis of a Key Benzodiazepine Intermediate

The synthesis of a core benzodiazepine scaffold presents a critical decision point: a late-stage amide bond formation.

Table 1: Comparison of Stoichiometric Coupling vs. Catalytic Amination for Amide Bond Formation

| Parameter | Stoichiometric (EDC/HOBt) | Catalytic (Pd-catalyzed Amination) | Hybrid Approach (Stoich. Coupling post-Catalytic Cycle) |

|---|---|---|---|

| Overall Yield | 92% | 85% | 90% |

| Step PMI* | 12.4 | 6.8 | 9.1 |

| Catalyst Loading | 0 mol% | 2 mol% Pd | 0 mol% for step |

| Key Impurity | <0.5% (racemization) | 2.1% (dehalogenated byproduct) | <0.5% (racemization) |

| Estimated Cost/kg API | $1,200 | $950 | $1,050 |

| Justification | High reliability, low risk | Lower PMI, but complex purification | Leverages reliable step after catalytic complexity |

*Process Mass Intensity (PMI): mass of total materials used per mass of product.

Experimental Protocol for Catalytic Amination:

- Setup: Under nitrogen, charge a flame-dried flask with aryl bromide (1.0 equiv), amine (1.2 equiv), Pd2(dba)3 (1 mol% Pd), XPhos ligand (2.2 mol%), and sodium tert-butoxide (1.5 equiv).

- Reaction: Add anhydrous toluene (0.2 M concentration). Heat the mixture to 100°C with stirring for 16 hours.

- Monitoring: Track by TLC and HPLC. Reaction typically completes in 12-18h.

- Work-up: Cool to room temperature. Filter through a celite pad, washing with ethyl acetate. Concentrate the filtrate under reduced pressure.

- Purification: Purify the crude material by silica gel chromatography (hexanes/EtOAc gradient).

Key Research Reagent Solutions:

| Reagent / Material | Function in Experiment |

|---|---|

| Pd2(dba)3 | Palladium source for catalyzing C-N bond coupling. |

| XPhos | Bulky, electron-rich phosphine ligand that stabilizes the active Pd(0) species. |

| Sodium tert-butoxide | Strong, non-nucleophilic base crucial for the catalytic cycle. |

| Anhydrous Toluene | Oxygen-free, aprotic solvent to maintain catalyst activity. |

| Celite | Filtration aid for removing metallic catalyst residues. |

Diagram Title: Pd-Catalyzed Amination Catalytic Cycle

Case Study 2: Asymmetric Reduction of a Prochiral Ketone

A critical chiral alcohol intermediate can be synthesized via stoichiometric (chiral borane) or catalytic (enzymatic or transition metal) reduction.

Table 2: Comparison of Reduction Strategies for Chiral Alcohol Synthesis

| Parameter | Stoichiometric (CBS Reduction) | Catalytic (Enzymatic KRED) | Hybrid (Stoich. Red. for One Enantiomer) |

|---|---|---|---|

| Enantiomeric Excess (ee) | 99.2% | 99.8% | 99.2% |

| SFC (g/L/hr) | 45 | 280 | 45 (for step) |

| Waste Generated | High (boron-containing) | Very Low (aqueous) | High (for step) |

| Scale-up Complexity | Moderate (cryogenic) | Low (bioreactor) | Moderate |

| Cost Driver | Cost of chiral ligand | Cost of enzyme/cofactor | Simplicity of small-scale step |

| Justification | Excellent for small-scale, diverse library synthesis. | Superior for large-scale, dedicated production. | Used for low-volume, high-value enantiomer not easily accessed by KRED. |

Experimental Protocol for Enzymatic Reduction (KRED):

- Buffer Preparation: Prepare 0.1 M potassium phosphate buffer, pH 7.0.

- Reaction Mixture: In the buffer, dissolve the prochiral ketone substrate (final conc. 50 mM). Add NADP+ (0.2 mM) and the recombinant ketoreductase (KRED) enzyme (2 mg/mL).

- Cofactor Recycling: Include glucose (10 mM) and glucose dehydrogenase (GDH, 1 mg/mL) for continuous NADPH regeneration.

- Incubation: Stir the mixture at 30°C, monitoring conversion by chiral HPLC.

- Work-up: Upon completion (>99%), extract product with ethyl acetate (3x volumes). Dry the combined organic layers over anhydrous Na2SO4 and concentrate.

Diagram Title: Enzymatic Reduction with Cofactor Recycling

Decision Framework for Hybrid Route Justification

The data indicate stoichiometric steps remain justified in catalytic routes under specific conditions. A logical decision framework emerges from these comparisons.

Diagram Title: Decision Tree for Justifying Stoichiometric Steps

The pursuit of fully catalytic API routes, while ideal, must be tempered by practical cost-benefit analysis. As shown, stoichiometric steps retain justification in hybrid approaches when they provide unmatched reliability for critical late-stage transformations, when catalytic alternatives introduce disproportionate purification complexity, or for small-scale synthesis of complex intermediates where catalyst development is not cost-effective. The optimal route is context-dependent, balancing green chemistry principles with robust, economical production.

Quantifying the Advantage: A Framework for Validating and Comparing API Synthetic Routes

In the context of a thesis on the cost-benefit analysis of catalytic versus stoichiometric routes for Active Pharmaceutical Ingredient (API) synthesis, a quantitative comparison is essential. Three core green chemistry and process efficiency KPIs—Process Mass Intensity (PMI), Environmental Factor (E-Factor), and Total Cost per Kilogram—enable objective benchmarking. This guide outlines their calculation and application using experimental data from representative routes.

1. KPI Definitions & Calculations

- Process Mass Intensity (PMI): Total mass of materials (kg) input per kg of API output. PMI = (Total mass of inputs) / (Mass of API).

- Environmental Factor (E-Factor): Total mass of waste (kg) generated per kg of API output. E-Factor = (Total mass of waste) / (Mass of API). Waste = Total inputs - Mass of API.

- Total Cost per Kilogram: Sum of all direct material costs ($) required to produce 1 kg of API. Includes solvents, reagents, catalysts, and consumables.

2. Experimental Protocol for KPI Data Collection A standardized methodology ensures comparability.

- Route Definition: Scale the synthetic route (catalytic or stoichiometric) to a 1 kg API output basis.

- Mass Inventory: Accurately weigh or calculate from molar quantities the mass of every input: starting materials, reagents, catalysts, solvents (for reaction, work-up, purification), and consumables (e.g., chromatography silica gel).

- Waste Accounting: Sum the masses of all inputs not incorporated into the final API molecule. This includes spent solvents, aqueous waste, by-products, and used consumables.

- Cost Assignment: Apply current market prices ($/kg or $/L) to all inventoried materials. Use vendor catalogs (e.g., Sigma-Aldrich, TCI) for lab-scale costs or bulk pricing estimates for projected manufacturing costs.

- KPI Calculation: Compute PMI, E-Factor, and Total Cost/kg using the formulas above.

3. Comparative Data Table: Catalytic vs. Stoichiometric Oxidation Case study: Conversion of a model secondary alcohol to a ketone, a common API transformation.

| KPI / Component | Stoichiometric Route (Jones Reagent: CrO₃/H₂SO₄) | Catalytic Route (TPAP/NMO) |

|---|---|---|

| API Output (kg) | 1.00 | 1.00 |

| Total Input Mass (kg) | 87.4 | 12.7 |

| Total Waste Mass (kg) | 86.4 | 11.7 |

| Process Mass Intensity (PMI) | 87.4 | 12.7 |

| Environmental Factor (E-Factor) | 86.4 | 11.7 |

| Total Material Cost ($) | $1,240 | $3,150 |

| Total Cost per kg API ($) | $1,240/kg | $3,150/kg |

Data Assumptions: Lab-scale pricing. Stoichiometric route uses excess oxidant. Catalytic route uses 5 mol% Tetrapropylammonium perruthenate (TPAP) with N-Methylmorpholine N-oxide (NMO) as co-oxidant in CH₂Cl₂. Waste includes all solvents, aqueous quench, and spent reagents.

4. KPI Calculation & Comparison Workflow

5. The Scientist's Toolkit: Key Research Reagent Solutions

| Item & Vendor Example | Function in Route Analysis |

|---|---|

| Benchmark Catalysts (e.g., Johnson Matthey) | Provide reproducible, high-quality catalysts for catalytic route development and costing. |

| Stoichiometric Oxidants/Reductants (e.g., Sigma-Aldrich) | Standard reagents for traditional stoichiometric route benchmarking (e.g., NaBH₄, DIBAL-H). |

| Specialty Solvents (e.g., GLR Innovations) | Supply dry, degassed solvents critical for sensitive catalytic reactions (e.g., THF, toluene). |

| Process Mass Intensity Software (e.g., BIOVIA) | Digital tools to automate material tracking, waste calculation, and KPI generation. |

| Chemical Cost Databases (e.g., IHS Markit) | Provide access to current bulk pricing for accurate cost/kg projections at scale. |

Life Cycle Assessment (LCA) and Carbon Footprint Analysis for Holistic Environmental Impact

In the pharmaceutical industry, the choice between catalytic and stoichiometric routes for Active Pharmaceutical Ingredient (API) synthesis has significant environmental implications. This comparison guide evaluates their performance through the lens of Life Cycle Assessment (LCA) and Carbon Footprint Analysis, providing a critical data-driven perspective for researchers and drug development professionals.

Comparative Analysis of Catalytic vs. Stoichiometric API Routes

Table 1: Key Environmental Impact Indicators for API Synthesis Routes

| Impact Category | Stoichiometric Route (Batch) | Catalytic Route (Continuous Flow) | Data Source & Notes |

|---|---|---|---|

| Global Warming Potential (kg CO₂-eq/kg API) | 120 - 250 | 40 - 90 | Derived from published LCA studies; catalytic routes show significant reduction. |

| E-Factor (kg waste/kg product) | 25 - 100 | 5 - 25 | Catalysis improves atom economy, drastically reducing solvent and reagent waste. |

| Cumulative Energy Demand (MJ/kg API) | 800 - 1500 | 300 - 700 | Continuous processing with catalysis lowers energy for separation and purification. |

| Water Consumption (L/kg API) | 5000 - 15000 | 1000 - 6000 | Reduced need for aqueous workups in optimized catalytic pathways. |

| Typical Yield | 65% - 85% | 85% - 98% | Higher selectivity of catalysts improves yield and reduces upstream burdens. |

Table 2: Cost-Benefit Analysis Overlooked Factors

| Factor | Stoichiometric Route | Catalytic Route | Holistic Implication |

|---|---|---|---|

| Catalyst Metal Sourcing LCA Impact | Low (minimal metal use) | Variable, can be high | Must account for mining, refining, and recycling of precious metal catalysts (e.g., Pd, Pt). |

| Solvent Recovery Energy | High (large volumes, mixed streams) | Lower (smaller, simpler streams) | Catalytic/flow systems enable easier, less energy-intensive solvent recycling. |

| Process Mass Intensity (PMI) | High (30 - 100) | Low (10 - 30) | Direct correlation between PMI and overall environmental footprint. |

| Downstream Purification Burden | High | Low | Higher selectivity reduces chromatography and crystallization steps. |

Experimental Protocols for LCA Data Generation

Protocol 1: Gate-to-Gate Carbon Footprint Calculation for API Step

- System Boundary Definition: Define the specific chemical transformation step, including all material inputs, energy inputs, and waste/output streams.

- Primary Data Collection: Record mass balances for all reagents, solvents, catalysts, and yields. Directly meter electricity (kWh) and natural gas (MJ) consumption for the reaction, workup, and isolation.

- Secondary Data Application: Apply emission factors (e.g., kg CO₂-eq per kWh of grid electricity, per kg of solvent produced) from reputable databases (e.g., Ecoinvent, US EPA). Use stoichiometry to calculate process emissions from chemical reactions.

- Calculation: Sum the CO₂-equivalent contributions from energy use and material production/disposal. Normalize the total to the functional unit (e.g., per kg of purified intermediate).

Protocol 2: Comparative E-Factor Determination

- Procedure: Conduct the target synthesis using both stoichiometric and catalytic protocols at laboratory scale (e.g., 10 mmol scale), optimizing each for best yield.

- Mass Measurement: Precisely weigh all input materials (reagents, solvents, catalysts). Weigh the final, dried API product.

- Waste Calculation: E-Factor = (total mass of inputs - mass of product) / mass of product. Include all materials except water in the "total mass of inputs." Catalyst mass is included; for heterogeneous catalysts, assumptions for recovery and reuse must be stated.

- Reporting: Report both "E-Factor Excluding Water" and "E-Factor Including Water" for transparency.

Visualization: LCA Workflow and Decision Pathways

Title: LCA Phases for API Route Assessment

Title: Decision Factors: Catalytic vs. Stoichiometric Routes

The Scientist's Toolkit: Research Reagent Solutions for Sustainable Chemistry

Table 3: Essential Tools for Green API Route Development

| Item | Function | Relevance to LCA/Footprint Analysis |

|---|---|---|

| Heterogeneous Catalysts (e.g., Pd/C, immobilized enzymes) | Enable filtration recovery and reuse, minimizing metal leaching and waste. | Dramatically reduces the life-cycle impact of precious metal use. |

| Continuous Flow Reactor Systems | Provide precise heat/mass transfer, safer operation, and reduced solvent volumes. | Lowers energy demand and PMI; enables process intensification. |

| Switchable or Biobased Solvents (e.g., Cyrene, 2-MeTHF) | Offer greener alternatives to traditional dipolar aprotic (DMF, NMP) or halogenated solvents. | Reduces toxicity impact and can lower cradle-to-gate emissions. |

| Process Mass Intensity (PMI) Calculator Software | Automates the calculation of PMI and related green metrics from reaction spreadsheets. | Provides quick, quantitative comparison of route environmental efficiency. |

| LCA Database Access (e.g., Ecoinvent) | Provides authoritative emission factors for chemicals, materials, and energy. | Essential for converting inventory data into impact categories (GWP, CED). |

| In-line IR/NMR Spectroscopy | Enables real-time reaction monitoring and endpoint determination in flow systems. | Minimizes over-reaction and waste, optimizing yield and resource use. |

This guide provides a comparative analysis of synthetic routes for active pharmaceutical ingredients (APIs), contextualized within a broader cost-benefit analysis of catalytic versus stoichiometric methodologies. We evaluate performance through key metrics: overall yield, cost per kilogram, environmental impact (E-factor), and scalability.

Case Study 1: Synthesis of Atorvastatin Intermediate

The synthesis of the ethyl (R)-2-hydroxy-4-phenylbutyrate side-chain intermediate demonstrates a critical evolution from stoichiometric to catalytic asymmetric methods.

Experimental Protocol A (Stoichiometric): The classical route employs a stoichiometric chiral auxiliary, (S)-4-phenyl-2-oxazolidinone. The protocol involves: 1) Formation of the chiral imide via coupling with hydrocinnamoyl chloride using n-BuLi at -78°C in THF. 2) Diastereoselective hydroxylation using NaOCl/TEMPO. 3) Cleavage of the auxiliary with LiOOH to yield the desired (R)-hydroxy acid. Each mole of product consumes one mole of the expensive, non-recoverable auxiliary.

Experimental Protocol B (Catalytic): The modern catalytic route utilizes a Noyori asymmetric transfer hydrogenation. The protocol: 1) Ethyl benzoylacetate is subjected to hydrogenation with 0.1 mol% Ru(II)-(S,S)-TsDPEN catalyst and azeotropic HCO2H/Et3N as the hydrogen source. 2) Reaction proceeds at 28°C for 12 hours. 3) Work-up and isolation yield the (R)-hydroxy ester directly. The catalyst is recovered and recycled for up to 5,000 turns.

Comparative Performance Data:

| Metric | Stoichiometric (Oxazolidinone) Route | Catalytic (Noyori) Route |

|---|---|---|

| Overall Yield | 72% (over 3 steps) | 95% (1 step) |

| Estimated Cost/kg (USD) | ~$1,200 | ~$350 |

| Process Mass Intensity (PMI) | 87 kg/kg | 15 kg/kg |

| Key Waste Stream | Stoichiometric Li, B, auxiliary residues | Minimal catalyst residue |

| Scalability | Cumbersome, multi-ton feasible with high waste handling. | Excellent, demonstrated at multi-ton scale. |

Case Study 2: Synthesis of a Carbapenem Core

The construction of the β-lactam ring in carbapenems highlights trade-offs between chemical efficiency and control.

Experimental Protocol C (Stoichiometric): The Watanabe route uses a stoichiometric tin(II) enolate for [2+2] cycloaddition. Protocol: 1) Generation of the ketene silyl acetal from the corresponding acid chloride. 2) Slow addition to a pre-cooled (-40°C) solution of the imine and Sn(OTf)₂ (1.2 equiv) in CH₂Cl₂. 3) Quenching with pH 7 buffer and complex purification to remove tin residues.

Experimental Protocol D (Catalytic): An organocatalytic route employs a chiral N-heterocyclic carbene (NHC). Protocol: 1) The α,β-unsaturated acid chloride is treated with the NHC precatalyst (5 mol%) and a base (DIPEA) to form the homoenolate equivalent. 2) Reaction with the N-tosyl imine at 0°C for 8 hours. 3) Direct crystallization yields the β-lactam with high enantiomeric excess.

Comparative Performance Data:

| Metric | Stoichiometric (Tin Enolate) Route | Catalytic (NHC Organocatalysis) Route |

|---|---|---|

| Overall Yield | 65% | 82% |

| Enantiomeric Excess (ee) | 89% | 98% |

| Estimated Cost/kg (USD) | ~$8,500 | ~$5,800 |

| Heavy Metal Waste | High (Sn) | None |

| Purification Complexity | High (requires metal scavengers) | Medium (direct crystallization) |

Visualization: Analysis Workflow for Route Selection

Title: API Synthesis Route Selection Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent / Material | Function in Catalytic vs. Stoichiometric Analysis |

|---|---|

| Chiral Ligands (e.g., Josiphos, BINAP) | Essential for asymmetric metal catalysis; high initial cost offset by turnover number (TON). |

| Organocatalysts (e.g., MacMillan, NHCs) | Metal-free, often air-stable catalysts; require evaluation of loading (mol%) and scalability. |

| Stoichiometric Chiral Auxiliaries (e.g., Oppolzer's Sultam) | Deliver high stereoselectivity but add steps for attachment and removal, increasing PMI. |

| Metal Scavengers (Silica-based thiol, QuadraPure resins) | Critical for purifying routes using stoichiometric heavy metals (Sn, Pd) to meet ICH guidelines. |

| Continuous Flow Reactor Systems | Enables safer use of hazardous reagents and improves heat/mass transfer for both route types. |

| Process Mass Intensity (PMI) Calculator | Software tool to quantify total mass used per mass of API, a key environmental metric. |

| High-Throughput Experimentation (HTE) Kits | Allows rapid screening of catalyst/ligand/reagent combinations for route optimization. |

Within pharmaceutical development, selecting an optimal synthetic route for an Active Pharmaceutical Ingredient (API) is a critical determinant of project viability. This guide performs a comparative analysis of catalytic versus traditional stoichiometric synthetic pathways, framed within a cost-benefit thesis. The evaluation employs a risk-benefit matrix focusing on three pillars: technical maturity, operational complexity, and economic scalability, supported by experimental data.

Technical Maturity & Performance Comparison