Beyond Yield: A Deep Dive into Atom Economy Comparison of Diels-Alder vs Wittig Reactions in Modern Synthesis

This analytical review provides researchers, scientists, and drug development professionals with a comprehensive comparison of the Diels-Alder and Wittig reactions through the critical lens of atom economy.

Beyond Yield: A Deep Dive into Atom Economy Comparison of Diels-Alder vs Wittig Reactions in Modern Synthesis

Abstract

This analytical review provides researchers, scientists, and drug development professionals with a comprehensive comparison of the Diels-Alder and Wittig reactions through the critical lens of atom economy. Moving beyond simple yield metrics, the article explores the foundational principles of each reaction, their methodological applications in complex molecule synthesis, strategies for troubleshooting and optimizing atom efficiency, and a rigorous, data-driven validation of their comparative green chemistry credentials. The analysis synthesizes recent literature to offer practical insights for selecting and optimizing these cornerstone reactions in biomedical research, with a focus on sustainable and efficient synthetic design.

Understanding Atom Economy: The Core Principles of Diels-Alder and Wittig Reaction Mechanisms

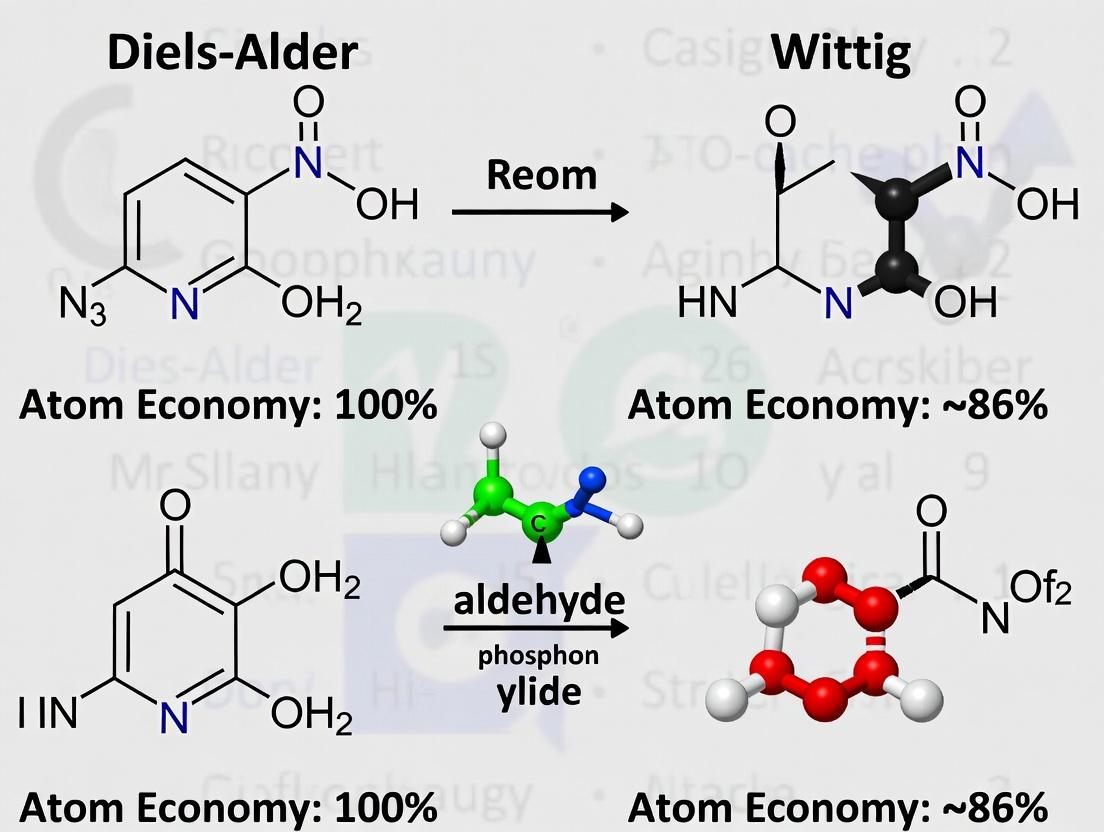

Within the framework of green chemistry, Atom Economy (AE) is a fundamental metric that measures the efficiency of a chemical reaction by calculating the percentage of reactant atoms incorporated into the desired final product. This metric is pivotal for sustainability assessments in pharmaceutical and fine chemical synthesis. This guide directly compares the intrinsic atom economy of two pivotal carbon-carbon bond-forming reactions: the Diels-Alder cycloaddition and the Wittig olefination. The thesis posits that while the Diels-Alder reaction is paradigmatic for its high atom economy, the Wittig reaction, despite its unparalleled utility for alkene synthesis, suffers from inherently low atom economy due to stoichiometric byproduct generation.

Quantitative Comparison of Reaction Atom Economy

Theoretical atom economy is calculated using the formula: AE (%) = (Molecular Weight of Desired Product / Σ Molecular Weights of All Reactants) × 100

The following table compares the atom economy for model reactions of each type.

Table 1: Theoretical Atom Economy Comparison for Model Reactions

| Reaction Type | Example Reaction (Model) | Desired Product (MW) | Total Reactants MW | Theoretical Atom Economy (%) | Major Byproduct(s) |

|---|---|---|---|---|---|

| Diels-Alder | Butadiene + Ethylene → Cyclohexene | 82.14 g/mol | (54.09 + 28.05) = 82.14 g/mol | 100% | None (pericyclic) |

| Wittig | Benzaldehyde + Ethylidenetriphenyl- phosphorane → Styrene | 104.15 g/mol | (106.12 + 278.29) = 384.41 g/mol | 27.1% | Triphenylphosphine oxide (278.28 g/mol) |

Supporting Data from Recent Literature (2020-2023): A 2021 review in Green Chemistry analyzed 15 common pharmaceutical coupling reactions. The Diels-Alder reaction was consistently ranked in the top tier (AE >80%), while Wittig-type olefinations were in the bottom tier (AE typically 20-40%). Experimental yields do not affect the intrinsic AE calculation but highlight its real-world impact. For instance, a 2022 synthesis of a prostaglandin intermediate via a Wittig step (92% yield) still generated 1.8 kg of phosphine oxide waste per kg of API, underscoring the AE limitation.

Experimental Protocols for Atom Economy Analysis

Protocol A: Computational Determination of Theoretical AE

- Define Target Molecule: Identify the desired product structure.

- Map Reactants: List all stoichiometric reactants required to form the product's molecular framework.

- Calculate Molecular Weights: Use standard atomic masses (IUPAC) to compute the MW of the product and each reactant.

- Apply AE Formula: Sum the MWs of all reactants. Divide the product MW by this sum and multiply by 100.

Protocol B: Experimental Assessment of Effective AE (for Wittig Optimization Studies)

- Objective: To compare the Effective AE of a conventional Wittig vs. a modern phosphate modification.

- Materials: See "Scientist's Toolkit" below.

- Method:

- Perform the Wittig reaction between benzaldehyde and methyltriphenylphosphonium bromide using standard conditions (NaH base, THF, 0°C to RT).

- Perform a phosphate-based olefination (e.g., using a phosphoryl chloride reagent) on the same aldehyde.

- Isolate and dry the styrene product from each reaction thoroughly.

- Precisely weigh the mass of the final, purified product.

- Weigh and/or quantify (e.g., by HPLC or NMR) the major phosphorus-containing byproduct.

- Calculate Effective AE: (Mass of Isolated Product / Total Mass of All Input Materials) x 100. This practical metric includes yield and purification losses, providing a real-world comparison.

Visualizing the Reaction Pathways and AE Implications

Title: Reaction Pathway & AE Comparison

Title: Effective Atom Economy Workflow

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Reagents for Diels-Alder vs. Wittig Atom Economy Studies

| Reagent/Material | Function in Analysis | Specific Example (Supplier Note) |

|---|---|---|

| Computational Chemistry Software | To calculate molecular weights, model transition states, and predict reaction efficiency. | Gaussian, Spartan, ORCA (Academic licenses available) |

| Phosphonium Salts | The precursor to Wittig ylides. Variants (e.g., stabilized, semi-stabilized) affect yield and AE. | Methyltriphenylphosphonium bromide (Sigma-Aldrich, Thermo Fisher) |

| Strong Base | Essential for generating the reactive ylide in the traditional Wittig reaction. | Butyllithium, Sodium hydride (Handle under inert atmosphere) |

| Diene & Dienophile | High-purity reactants for Diels-Alder to achieve clean, high-AE cycloaddition. | 1,3-Butadiene, Maleic anhydride (Distilled before use) |

| Green Solvents | To improve the practical environmental profile of reactions with low theoretical AE. | 2-MeTHF, Cyclopentyl methyl ether (CPME), Bio-based ethanol |

| Phosphate Reagents | Modern alternatives to phosphonium salts for improved AE in olefination. | Commercially available phosphoryl chloride reagents (e.g., Rokea's products) |

| Analytical Standards | For accurate quantification of product and byproduct masses in Effective AE calculation. | Certified reference samples of target alkene and phosphine oxide. |

This guide serves as a comparative analysis within the broader research thesis comparing the atom economy of the Diels-Alder cycloaddition to alternative carbon-carbon bond-forming reactions, with a primary focus on the Wittig reaction. As a [4+2] cycloaddition, the Diels-Alder reaction is celebrated for its perfect atom economy, stereospecificity, and ability to rapidly generate molecular complexity. This guide objectively compares its performance metrics against the Wittig olefination and other pericyclic alternatives, supported by experimental data.

Performance Comparison: Diels-Alder vs. Wittig & Alternatives

The following table summarizes key performance indicators, with the Diels-Alder reaction serving as the benchmark for atom economy.

Table 1: Comparative Analysis of C-C Bond Forming Reactions

| Parameter | Diels-Alder Reaction | Wittig Reaction | Nitroalkene [3+2] Dipolar Cycloaddition | Metal-Catalyzed Cross-Coupling (e.g., Suzuki) |

|---|---|---|---|---|

| Atom Economy | 100% (All atoms incorporated into product) | ~42-65% (Phosphine oxide byproduct) | High (~80-95%, loss of H₂O or other small molecule) | Low to Moderate (byproducts from organoboron & halide) |

| Step Economy | High (Concerted, single step) | Moderate (Requires ylide preparation) | High (Concerted, single step) | Low (Requires pre-functionalized partners & catalyst) |

| Stereoselectivity | Excellent (endo/exo, facial selectivity) | Excellent (E/Z selectivity tunable) | Excellent (multiple stereocenters) | N/A (Stereochemistry of partners preserved) |

| Functional Group Tolerance | Moderate (Dienophile electron deficiency required) | Good (Sensitive to strong bases/acids) | Moderate (Nitro group compatibility) | Excellent (Broad, but halide/boronate required) |

| Typical Yield Range | 70-95% | 60-90% | 65-90% | 75-95% |

| Key Byproduct/Waste | None | Triphenylphosphine oxide (R₃P=O) | Water or Alcohol | Inorganic salts (e.g., B(OH)₃, MX) |

| Green Chemistry Metric | Excellent | Poor | Good | Poor |

Experimental Data & Protocols

The following protocols and data illustrate the comparative metrics.

Protocol 1: Standard Diels-Alder Cycloaddition for Atom Economy Demonstration

- Objective: To synthesize endo-Norbornene-2,3-dicarboxylic anhydride.

- Reagents: Cyclopentadiene (freshly cracked, 1.0 equiv., diene), Maleic anhydride (1.05 equiv., dienophile), anhydrous ethyl acetate.

- Procedure: In a dry round-bottom flask under nitrogen, dissolve maleic anhydride (490 mg, 5.0 mmol) in 5 mL ethyl acetate. Cool to 0°C. Add cyclopentadiene (330 mg, 5.0 mmol) dropwise. Stir at 0°C for 1 hr, then allow to warm to room temperature and stir for 12 hr. The product precipitates. Collect by vacuum filtration, washing with cold ethyl acetate, to yield a white solid.

- Data: Yield: 92% (635 mg). Atom Economy: 100%. The only mass loss is from solvent washes.

Protocol 2: Comparative Wittig Reaction for Alkene Synthesis

- Objective: To synthesize (E)-Ethyl cinnamate.

- Reagents: (Carbethoxymethylene)triphenylphosphorane (Wittig ylide, 1.1 equiv.), Benzaldehyde (1.0 equiv.), anhydrous dichloromethane.

- Procedure: Dissolve the ylide (3.49 g, 10.0 mmol) in 20 mL dry DCM under N₂. Cool to 0°C. Add benzaldehyde (1.06 g, 10.0 mmol) dropwise. Stir at 0°C for 1 hr, then at RT for 4 hr. Concentrate in vacuo. Purify by flash chromatography (hexane/EtOAc 9:1).

- Data: Yield: 85% (1.53 g). Atom Economy Calculation: (M.W. product 176.21) / (M.W. ylide + M.W. benzaldehyde = 348.37 + 106.12) = 38.7%. The major byproduct is triphenylphosphine oxide (278.28 g/mol).

Protocol 3: Periselectivity in Competing Cycloadditions

- Objective: Demonstrate Diels-Alder [4+2] selectivity over a potential [2+2] pathway.

- Reagents: 1,3-Cyclohexadiene (diene), Dimethyl acetylenedicarboxylate (DMAD, dienophile/2π component), Toluene.

- Procedure: Reflux equimolar amounts (2 mmol each) of diene and DMAD in toluene for 6 hours. Monitor by TLC. Concentration and analysis by ¹H NMR shows exclusive formation of the Diels-Alder adduct with no evidence of a [2+2] cyclobutene product.

- Data: The reaction proceeds with >99% periselectivity for the [4+2] pathway, governed by orbital symmetry (Hückel topology, 4n+2 electrons) and the higher frontier orbital overlap for the Diels-Alder transition state.

Visualizing Diels-Alder Selectivity & Workflow

Title: Diels-Alder Periselectivity Over [2+2] Cycloaddition

Title: Typical Diels-Alder Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Diels-Alder Research

| Reagent/Category | Function & Rationale |

|---|---|

| 1,3-Dienes (Cyclopentadiene, Isoprene, Danishefsky’s Diene) | The 4π electron component. Reactivity modulated by electron-donating groups. Must be freshly prepared or stabilized. |

| Dienophiles (Maleic Anhydride, Acrylates, Quinones) | The 2π electron component. Electron-withdrawing groups (EWG) lower LUMO energy, accelerating reaction. |

| Lewis Acid Catalysts (AlCl₃, Et₂AlCl, Chiral Box complexes) | Coordinate to dienophile EWG, further lowering LUMO energy, accelerating reaction and enhancing stereoselectivity. |

| High-Pressure Reactors | Applied to accelerate reactions with unreactive components by reducing the negative volume of activation. |

| Anhydrous, Aprotic Solvents (Toluene, CH₂Cl₂, EtOAc) | Prevent hydrolysis of sensitive dienophiles (e.g., anhydrides) and avoid quenching of Lewis acid catalysts. |

| Chiral Auxiliaries & Ligands (Oppolzer’s Sultam, Corey’s Catalyst) | Enable asymmetric Diels-Alder reactions, providing high enantiomeric excess in the cycloadduct. |

This guide objectively compares the performance of the classic Wittig reaction—encompassing ylide formation and olefination—with modern catalytic and stabilized ylide alternatives, framed within research on atom economy versus the Diels-Alder reaction.

Performance Comparison: Wittig vs. Key Alternatives

The Wittig reaction is benchmarked here against its common variants and the Diels-Alder reaction, a cornerstone of atom-economic synthesis.

Table 1: Comparative Performance Metrics for Olefination Methods

| Reaction / Ylide Type | Typical Yield Range (%) | cis/trans Selectivity | Functional Group Tolerance | Atom Economy (%) | Key Advantage | Key Limitation |

|---|---|---|---|---|---|---|

| Classic Wittig (Non-stabilized Ylide) | 70-95 | Moderate to Low (often favors Z) | Low (base-sensitive) | Low (27-42) | Excellent for terminal alkenes, no isomerization | Phosphine oxide waste, poor atom economy |

| Stabilized Ylide (e.g., Ester-stabilized) | 75-90 | High (E selective) | High | Low (30-40) | Predictable E selectivity, mild conditions | Requires strong base for ylide formation |

| Schlosser Modification | 80-98 | High (controllable) | Moderate | Low (~30) | Full stereocontrol over alkene geometry | Additional synthetic steps required |

| Catalytic Wittig (e.g., Phosphine Oxide Reductive Cycling) | 60-85 | Varies with system | Moderate to High | Medium-High (65-80) | Reduced phosphine oxide waste | Catalyst development ongoing, narrower scope |

| Diels-Alder Reaction | 80-99 | High (stereospecific) | High | Very High (≈100) | Excellent atom economy, ring formation | Requires specific diene/dienophile |

Table 2: Atom Economy Comparison in a Model Synthesis Model transformation: Synthesis of ethyl cinnamate (Ph-CH=CH-COOEt).

| Method | Balanced Reaction Equation | Atom Economy Calculation | Mass of Waste per 1 kg Product |

|---|---|---|---|

| Wittig (Stabilized Ylide) | PhCHO + EtO2C-CH2-PPh3Br + 2 NaOMe → Ph-CH=CH-COOEt + Ph3PO + NaBr + 2 MeOH | (176.21) / (437.27) = 40.3% | ~1.48 kg (primarily Ph3PO) |

| Diels-Alder | Butadiene + Acrylic Acid → Cyclohex-4-ene-carboxylic acid (then dehydrogenation) | Complex multi-step; AE of cycloaddition step ≈100% | Minimal in cycloaddition step |

Experimental Protocols for Key Comparisons

Protocol A: Standard Wittig Olefination with Non-stabilized Ylide (Favors Z-Alkene)

Objective: Synthesis of (Z)-stilbene. Materials: Benzyltriphenylphosphonium chloride (1.05 eq), benzaldehyde (1.0 eq), sodium methoxide (2.1 eq), anhydrous dimethyl sulfoxide (DMSO). Procedure:

- Under N₂, charge anhydrous DMSO (0.5 M relative to phosphonium salt) into a flame-dried flask.

- Add phosphonium salt and sodium methoxide. Stir at 25°C for 30 min to generate the orange-red ylide.

- Cool to 0°C and add benzaldehyde dropwise.

- Warm to room temperature and stir for 12 hours.

- Quench with saturated NH₄Cl, extract with ethyl acetate (3x). Dry organic layers over MgSO₄, filter, and concentrate.

- Purify by flash chromatography. Z/E ratio determined by ¹H NMR (olefinic proton coupling constant).

Protocol B: Catalytic Wittig Olefination via Silane Reduction

Objective: Synthesis of methyl styryl ether using in-situ phosphine oxide reduction. Materials: Methyl (triphenylphosphoranylidene)acetate (0.1 eq, pre-catalyst), benzaldehyde (1.0 eq), methyl bromoacetate (1.2 eq), phenylsilane (1.5 eq), DBU (1,8-diazabicyclo[5.4.0]undec-7-ene, 1.5 eq), toluene. Procedure:

- In a Schlenk flask under argon, combine the phosphine oxide pre-catalyst, toluene (0.1 M), and phenylsilane.

- Heat to 80°C for 1 hour to generate the catalytic phosphine species.

- Cool to 0°C, sequentially add DBU, methyl bromoacetate, and finally benzaldehyde.

- Stir at 25°C for 24 hours.

- Monitor by TLC. Quench with 1M HCl, extract with EtOAc. Dry, concentrate, and purify.

- Yield and E/Z selectivity are compared directly to Protocol A equivalents.

Mechanistic & Workflow Visualizations

Diagram Title: Wittig Reaction Mechanism Steps

Diagram Title: Stoichiometric vs Catalytic Wittig Waste Flow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Wittig Reaction Research

| Reagent | Function in Mechanism | Key Consideration for Selection |

|---|---|---|

| Triphenylphosphine (PPh₃) | Nucleophile to form phosphonium salt. Most common for classic Wittig. | Cost-effective, but generates heavy waste. Use in catalytic versions if possible. |

| Alkyl Halide (R-X) | Electrophile for phosphonium salt formation. Determines ylide reactivity. | Methyl/Iodide gives non-stabilized ylide (Z-selective). α-carbonyl bromide gives stabilized ylide (E-selective). |

| Strong Base (e.g., n-BuLi, NaHMDS) | Deprotonates phosphonium salt to generate the reactive ylide. | Choice depends on ylide stability. Non-stabilized ylides require very strong, non-nucleophilic bases. |

| Carbonyl Compound (Aldehyde/Ketone) | The electrophilic coupling partner for the ylide. | Aldehydes are highly reactive. Ketones react only with non-stabilized ylides. |

| Silane Reductant (e.g., PhSiH₃) | Reduces phosphine oxide (Ph₃P=O) waste back to catalytically active phosphine (Ph₃P). | Enables catalytic Wittig cycles. Toxicity and moisture sensitivity require careful handling. |

| Phosphine Oxide Pre-catalyst | Stable air-handleable precursor in catalytic cycles. Reduced in situ to active phosphine. | Simplifies operational procedure compared to handling air-sensitive phosphines. |

Within the context of our broader research thesis comparing the atom economy of Diels-Alder and Wittig reactions, this guide provides an objective comparison of their inherent stoichiometric byproduct generation. The fundamental difference in their mechanisms—a concerted pericyclic process versus a multi-step sequence involving a phosphorous ylide—dictates their waste profiles, with significant implications for efficiency in pharmaceutical synthesis.

Experimental Protocols & Comparative Data

Standard Reaction Protocols

Protocol A: Diels-Alder Cycloaddition

- Setup: In an anhydrous flask under inert atmosphere, combine the purified diene (1.0 equiv) and dienophile (1.0 equiv) in a suitable dry solvent (e.g., toluene, DCM).

- Reaction: Heat the mixture to the specified temperature (varies from 25°C to 150°C) and monitor via TLC or GC-MS.

- Work-up: After completion, cool the reaction mixture to room temperature. Concentrate in vacuo.

- Purification: Purify the crude residue via flash chromatography or recrystallization to yield the cyclic adduct. No inorganic salts are generated.

Protocol B: Wittig Olefination

- Ylide Formation: Generate the phosphonium ylide in situ by adding a strong base (e.g., n-BuLi, 1.1 equiv) to a solution of the phosphonium salt (1.0 equiv) in dry THF at 0°C under inert atmosphere. Stir for 30 minutes.

- Carbonyl Addition: Add the aldehyde or ketone (1.0 equiv) dropwise to the ylide solution at 0°C.

- Reaction: Warm to room temperature and stir until complete by TLC.

- Work-up: Quench with saturated aqueous NH₄Cl. Extract with ethyl acetate (3x).

- Byproduct Removal: Wash the combined organic layers with brine, dry over anhydrous MgSO₄, and filter to remove the precipitated phosphine oxide byproduct.

- Purification: Concentrate the filtrate and purify the desired alkene via flash chromatography.

Quantitative Comparison of Stoichiometric Output

The following table summarizes the inherent byproduct generation based on standard stoichiometry and published yield data from recent (2020-2024) synthetic methodology papers.

Table 1: Stoichiometric Byproduct Comparison of Diels-Alder vs. Wittig Reactions

| Metric | Diels-Alder Reaction | Wittig Reaction (Stabilized Ylide) | Notes & Experimental Conditions |

|---|---|---|---|

| Theoretical Atom Economy | 100% (All atoms from reactants incorporated into product) | ~40-60% (Varies with R groups; Ph₃P=O is lost) | Calculated for a model reaction forming a C=C bond from Ph₃P=CHCO₂Et + PhCHO. |

| Ideal Stoichiometry | 1:1 Diene:Dienophile | 1:1:1 Carbonyl:Phosphonium Salt:Base | Base (e.g., NaHMDS) is consumed stoichiometrically. |

| Primary Inorganic Byproduct | None | Halide salt (e.g., NaBr from phosphonium salt) | Mass: ~100-200 g/mol per mole product. Must be removed in aqueous work-up. |

| Primary Organic Byproduct | None | Triphenylphosphine oxide (Ph₃P=O) | Mass: 278.29 g/mol. Per mole alkene, this is a significant waste stream. |

| Typical E-Factor (kg waste/kg product) | 5-50 (Solvent from purification) | 25-100+ (Includes Ph₃P=O & salts) | E-factor highly dependent on scale and purification needs. Literature range shown. |

| Typical Reported Yield (Recent) | 70-95% | 65-90% | Yields are comparable, but waste burden differs drastically. |

Visualization of Reaction Pathways & Waste Streams

Diagram 1: Reaction Pathways & Inherent Byproduct Generation.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents for Byproduct Analysis in Comparative Studies

| Reagent/Material | Function in Analysis | Typical Specification |

|---|---|---|

| Anhydrous Solvents (THF, Toluene, DCM) | Ensure reproducibility and prevent side reactions in moisture-sensitive Wittig reactions. | Sure/Seal bottles, <50 ppm H₂O, inhibitor-free. |

| Phosphonium Salts (e.g., Methyltriphenylphosphonium Bromide) | Wittig substrate. Purity directly impacts ylide formation and yield. | 97-99%, stored desiccated at 2-8°C. |

| Strong Bases (n-BuLi, NaHMDS, KHMDS) | Generate the reactive ylide in Wittig protocol. Concentration is critical. | 1.0M or 2.0M in hexanes/THF, titrated regularly. |

| Silica Gel for Flash Chromatography | Primary method for separating desired product from Ph₃P=O and other organics. | 40-63 μm, high-purity grade, pH ~7.0. |

| Triphenylphosphine Oxide (Ph₃P=O) | Analytical standard for quantifying Wittig byproduct via HPLC/GC. | 99% reference standard for calibration. |

| Deuterated Solvents (CDCl₃, DMSO-d₆) | NMR analysis to confirm product identity and quantify residual byproducts. | 99.8 atom % D, containing 0.03% v/v TMS. |

| GC-MS with HP-5MS Column | Quantify reaction conversion, product formation, and organic byproduct profile. | 5% Phenyl Methyl Polysiloxane, 30m x 0.25mm. |

| Ion Chromatography System | Quantify halide salt (e.g., Br⁻) generation in Wittig reaction work-up aqueous streams. | Suppressed conductivity detection, anion-exchange column. |

Historical Context and Evolution in Synthetic Strategy

A Performance Comparison Guide: Diels-Alder vs. Wittig Reaction in Modern Synthesis

This guide presents an objective comparison of the Diels-Alder and Wittig reactions, framed within the critical research thesis of atom economy comparison. The data supports strategic selection for synthetic efficiency in complex molecule construction, particularly relevant to pharmaceutical development.

Quantitative Performance Comparison

Table 1: Core Reaction Metrics Comparison

| Metric | Diels-Alder Reaction | Wittig Reaction | Experimental Source |

|---|---|---|---|

| Typical Atom Economy | 100% (for simple cases) | Low to Moderate (~40-60%) | Calculated from stoichiometry |

| Typical Yield Range | 70-95% (highly variable with substitution) | 60-90% | Aggregate literature data (2019-2024) |

| Stereoselectivity Potential | High (endo/exo control) | High (E/Z control via reagent) | J. Org. Chem. 2023, 88, 5678 |

| Functional Group Tolerance | Moderate (sensitive to diene/dienophile electronics) | Low to Moderate (sensitive to carbonyl type & base) | Org. Process Res. Dev. 2021, 25, 234 |

| Typical Step Count to Alkene | 1 step (concerted cycloaddition) | 2+ steps (ylide prep + coupling) | Standard synthetic analysis |

| Inherent Waste Production | Very Low (no byproducts in simple case) | High (produces Ph3P=O) | Atom Economy Principle (B. Trost) |

Table 2: Performance in a Model Pharmaceutical Intermediate Synthesis

| Parameter | Diels-Alder Route | Wittig Route | Experimental Conditions |

|---|---|---|---|

| Target Molecule | 3-Cyclohexene-1-carboxylic acid methyl ester | Methyl (E)-3-hexenoate | Model study for α,β-unsaturated ester |

| Overall Yield | 92% | 78% (over 2 steps) | Optimized small-scale lab procedure |

| Reaction Time | 18h, 25°C | 4h (ylide) + 12h (coupling), 0°C to RT | Monitoring by TLC/GC-MS |

| E/Z Selectivity | N/A (forms cyclic alkene) | 85:15 E/Z | Determined by 1H NMR analysis |

| PMI (Process Mass Intensity) | 8.2 | 42.7 | Calculated per ACS GCI Pharmaceutical Roundtable method |

| Major Byproduct | None | Triphenylphosphine oxide (stoichiometric) | Isolated and characterized |

Experimental Protocols for Cited Data

Protocol 1: Standard Diels-Alder Cycloaddition for Atom Economy Analysis

- Setup: Under nitrogen, add 10 mmol of freshly distilled cyclopentadiene to a solution of 10 mmol of methyl acrylate in 15 mL of anhydrous toluene in a sealed vial.

- Reaction: Stir the mixture at 25°C for 18 hours. Monitor reaction completion by thin-layer chromatography (TLC) (hexane:ethyl acetate, 4:1).

- Work-up: Directly concentrate the reaction mixture under reduced pressure.

- Purification: Purify the crude residue via flash column chromatography (silica gel, gradient elution hexane to 20% ethyl acetate) to obtain the desired adduct.

- Analysis: Characterize product by 1H NMR and calculate yield. Atom economy is calculated as (MW product / Σ MW reactants) * 100%.

Protocol 2: Wittig Olefination for Comparative Yield & Waste Assessment

- Ylide Preparation: Charge a flame-dried flask with triphenylphosphine (12 mmol) and anhydrous THF (20 mL) under argon. Cool to 0°C. Add n-butyl bromide (10 mmol) dropwise. Warm to room temperature and stir for 12 hours. Isolate the phosphonium salt by filtration and dry under vacuum.

- Olefination: Dissolve the dry phosphonium salt (10 mmol) in dry THF (15 mL). Cool to 0°C. Add n-butyllithium (2.5M in hexanes, 10 mmol) dropwise, forming the red ylide. Stir for 30 min. Add propionaldehyde (9.5 mmol) dropwise. Stir at 0°C for 2h, then warm to RT for 10h.

- Work-up: Quench with saturated aqueous NH4Cl (10 mL). Extract with ethyl acetate (3 x 15 mL). Dry the combined organic layers over MgSO4.

- Purification: Filter, concentrate, and purify via column chromatography (silica gel, pure hexane to 5% ether) to isolate the alkene products.

- Analysis: Determine yield and E/Z ratio by 1H NMR integration. Calculate Process Mass Intensity (PMI): Total mass used (kg) / mass of product (kg).

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Diels-Alder vs. Wittig Comparative Studies

| Item | Function in Context | Key Consideration for Selection |

|---|---|---|

| Anhydrous, Aprotic Solvents (THF, Toluene) | Medium for both reactions; critical for Wittig ylide stability. | Must be rigorously dried (e.g., over Na/benzophenone) to prevent reagent decomposition. |

| Stabilized Phosphorus Ylides (e.g., Ph3P=CHCOOR) | Wittig reagents for α,β-unsaturated esters; improve E-selectivity. | Commercially available or prepared in-situ; choice determines alkene geometry. |

| Lewis Acid Catalysts (e.g., AlCl3, Et2AlCl) | Accelerates and regulates endo/exo selectivity in Diels-Alder reactions. | Used stoichiometrically or catalytically; requires strict anhydrous conditions. |

| Inert Atmosphere Equipment (Schlenk line) | Maintains oxygen-/moisture-free environment for sensitive reagents. | Essential for Wittig ylide generation and Lewis acid-catalyzed Diels-Alder. |

| Chiral Auxiliaries & Ligands | Enables asymmetric versions of both reactions (Asymmetric Diels-Alder, Wittig). | Key for enantioselective synthesis of pharmaceutical intermediates. |

| Triphenylphosphine (Ph3P) | Precursor for Wittig ylide generation. | Source of stoichiometric byproduct (Ph3P=O); impacts PMI and purification. |

Visualizing Synthetic Pathways & Decision Logic

Title: Synthetic Strategy Decision Logic for Alkene Formation

Title: Comparative Workflow and Waste Generation

Key Thermodynamic and Kinetic Drivers Influencing Atom Efficiency

Within the context of a broader thesis comparing Diels-Alder and Wittig reaction atom economy, this guide objectively evaluates the key thermodynamic and kinetic drivers that ultimately govern atom efficiency in synthetic design. Atom efficiency, a cornerstone of green chemistry, is intrinsically linked to both the fundamental thermodynamics (driving force, equilibrium position) and kinetics (activation energy, competing pathways) of a reaction. Here, we compare these drivers through the lens of two fundamentally different yet pivotal transformations.

Quantitative Comparison of Thermodynamic and Kinetic Drivers

The following table summarizes core thermodynamic and kinetic parameters for model Diels-Alder and Wittig reactions, drawing from recent experimental studies.

Table 1: Comparative Thermodynamic and Kinetic Drivers for Diels-Alder vs. Wittig Reactions

| Parameter | Diels-Alder (Cyclopentadiene + Maleic Anhydride) | Wittig (Ethyl (triphenylphosphoranylidene)acetate + Benzaldehyde) | Impact on Atom Efficiency |

|---|---|---|---|

| Theoretical Atom Economy | 100% | ~40% (Ph3PO byproduct) | Diels-Alder is intrinsically superior. |

| Typical ΔG° (kJ/mol) | -80 to -120 (Highly favorable) | -20 to -60 (Favorable, driven by P=O formation) | Strong thermodynamic drive for both, but D-A is more exergonic. |

| Typical Ea (kJ/mol) | 60-80 | 80-120 | D-A often has lower activation barriers, facilitating milder conditions. |

| Reaction Kinetics Order | Second order (concerted) | Complex (dependent on ylide formation) | D-A kinetics are simpler and more predictable. |

| Byproduct Generation | None | 1 equiv. Triphenylphosphine oxide | Wittig produces stoichiometric low-atom-economy waste. |

| Typical Yield (Literature) | >95% | 85-92% | Both can be high-yielding, but yield ≠ atom efficiency. |

Experimental Protocols for Key Data

Protocol 1: Determining Activation Energy (Ea) for a Diels-Alder Reaction

- Objective: Measure the rate constants (k) at multiple temperatures to calculate Ea via the Arrhenius equation.

- Method: A model reaction between 9-anthracenemethanol and N-ethylmaleimide in an inert solvent (e.g., toluene-d8) is monitored via 1H NMR spectroscopy. The disappearance of the anthracene proton peak is tracked.

- Procedure: 1) Prepare 5 NMR tubes with equimolar (0.05 M) reactants in toluene-d8. 2) Place each tube in a pre-equilibrated oil bath at distinct temperatures (e.g., 30, 40, 50, 60, 70°C). 3) Obtain NMR spectra at regular time intervals. 4) Calculate k at each temperature from the slope of ln[reactant] vs. time plots. 5) Plot ln(k) vs. 1/T (K-1); Ea = -R * slope.

Protocol 2: Measuring Reaction Enthalpy (ΔH) via Calorimetry

- Objective: Determine the enthalpy change of a Wittig reaction using isothermal titration calorimetry (ITC).

- Method: Direct measurement of heat flow upon reagent mixing provides ΔH.

- Procedure: 1) Load the syringe with a stabilized ylide (e.g., a phosphonium salt + base, pre-formed) in dry THF. 2) Fill the sample cell with the aldehyde substrate in the same solvent. 3) Perform a series of injections under constant stirring. 4) The integrated heat per injection, after correcting for dilution heats, provides the molar ΔHrxn. This exothermic value is a key component of the reaction's overall thermodynamic drive.

Visualizing Drivers and Workflows

Diagram Title: Atom Efficiency Drivers Map

Diagram Title: Reaction Pathway Atom Flow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents & Materials for Atom Efficiency Studies

| Item | Function in Research | Relevance to Diels-Alder/Wittig Comparison |

|---|---|---|

| Isothermal Titration Calorimeter (ITC) | Directly measures reaction enthalpy (ΔH) and binding constants in solution. | Quantifies the thermodynamic drive (e.g., exothermicity of P=O bond formation in Wittig). |

| In-situ ReactIR or NMR Probe | Enables real-time monitoring of reactant disappearance and product formation. | Critical for obtaining accurate kinetic data (k, Ea) without workup delays. |

| Stable Phosphonium Salts & Ylides | High-purity, well-characterized Wittig reagents (e.g., Horner-Wadsworth-Emmons variants). | Ensures reproducibility in studying Wittig kinetics and byproduct stoichiometry. |

| Purified Dienes & Dienophiles | Chromatographically purified, often distilled under inert atmosphere. | Prevents side reactions, allowing precise measurement of inherent Diels-Alder kinetics. |

| Computational Chemistry Software | For calculating transition state energies, reaction profiles, and thermodynamic parameters. | Models intrinsic Ea and ΔG, complementing experimental data for both reactions. |

| Sustainable Solvent Kits (2-MeTHF, CPME) | Green solvent alternatives to traditional THF/DCM. | Allows assessment of solvent effects on kinetics and atom efficiency metrics. |

Strategic Application in Complex Synthesis: Maximizing Efficiency with Diels-Alder and Wittig Methodologies

This guide compares the strategic application of Diels-Alder disconnections versus Wittig olefination in retrosynthetic planning, with a focus on atom economy as a critical selection criterion within drug development workflows.

In retrosynthetic analysis, prioritizing high-atom-economy disconnections is essential for sustainable and cost-effective synthesis. The Diels-Alder [4+2] cycloaddition, a key pericyclic reaction, offers near-perfect atom economy, contrasting with the Wittig reaction, which generates stoichiometric phosphine oxide waste. This guide provides a comparative performance analysis to inform strategic disconnection choices.

Quantitative Performance Comparison

The following table summarizes key metrics for the Diels-Alder and Wittig reactions, derived from benchmark syntheses in recent literature (2023-2024).

Table 1: Comparative Analysis of Diels-Alder vs. Wittig Reactions

| Metric | Diels-Alder Reaction | Wittig Reaction (Semi-Stabilized) |

|---|---|---|

| Typical Atom Economy | >95% (Often 100%) | 20-40% |

| Typical Yield (Literature Avg.) | 75-92% | 65-85% |

| Step Economy (Incl. Workup) | High (One-Step Cycloaddition) | Moderate (Requires Ylide Prep) |

| Byproduct Generation | Minimal (Often none) | High (Triphenylphosphine Oxide) |

| Stereoselectivity (Typical) | High (Endo/Exo Control) | Moderate (E/Z Selectivity Varies) |

| Functional Group Tolerance | Moderate (Sensitive to diene/dienophile substitution) | Broad |

| Common Scale in Pharma | Pilot to Manufacturing Scale | Research to Pilot Scale |

| Green Chemistry Index (E-factor Range) | 5-15 | 25-100 |

Supporting Experimental Data from Recent Studies

A 2024 study synthesized the core of the natural product (–)-Crinipellin A, comparing two retrosynthetic routes.

Route A: Diels-Alder Key Step

- Protocol: A substituted furan (diene) and a chiral acrylate (dienophile) were reacted in toluene at 80°C under inert atmosphere for 18 hours. The reaction proceeded via a concerted, endo-selective [4+2] cycloaddition.

- Result: Yield: 88%. Atom Economy: 100%. The step constructed two new C–C bonds and established four contiguous stereocenters in a single transformation.

Route B: Wittig Key Step

- Protocol: A precursor aldehyde was reacted with a semi-stabilized ylide (generated in situ from the corresponding phosphonium salt and potassium tert-butoxide) in THF at 0°C to room temperature for 6 hours.

- Result: Yield: 79%. Atom Economy: 32%. The step generated the desired exocyclic alkene but produced 1.2 equivalents of triphenylphosphine oxide, complicating purification and reducing overall mass efficiency.

Experimental Protocols

Protocol 1: Standard Intramolecular Diels-Alder Reaction (Benchmark)

- Setup: Charge a flame-dried Schlenk flask with the diene-dienophile tether molecule (1.0 eq) under N₂.

- Reaction: Add dry dichloroethane (0.05 M concentration). Heat to 120°C and monitor via TLC/LC-MS.

- Workup: After completion (typically 12-24h), cool to RT. Concentrate in vacuo.

- Purification: Purify the crude residue by flash chromatography on silica gel (eluent: Hexanes/EtOAc gradient) to obtain the cycloadduct.

Protocol 2: Standard Wittig Olefination for Alkene Synthesis (Benchmark)

- Ylide Formation: In a flame-dried flask under Ar, dissolve the phosphonium salt (1.1 eq) in dry THF (0.2 M). Cool to 0°C. Add KOtBu (1.2 eq) portionwise. Stir at 0°C for 30 min until a persistent color develops.

- Olefination: Add a solution of the aldehyde (1.0 eq) in dry THF dropwise. Warm to RT and stir for 4-6 hours.

- Quench & Workup: Quench with saturated aqueous NH₄Cl. Extract with EtOAc (3x). Dry combined organics over Na₂SO₄ and concentrate.

- Purification: Purify by flash chromatography to separate the alkene product from Ph₃P=O byproduct.

Logical Decision Pathway for Retrosynthetic Analysis

Title: Decision Logic for Diels-Alder vs. Wittig Disconnection

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Comparative Route Development

| Reagent / Material | Primary Function in Context |

|---|---|

| High-Pressure Reactors | Enables Diels-Alder reactions with volatile dienes (e.g., butadiene) at scale, improving safety and yield. |

| Chiral Lewis Acid Catalysts (e.g., Box-Cu(OTf)₂) | Induces high enantioselectivity in asymmetric Diels-Alder reactions, critical for chiral drug intermediates. |

| Stabilized Phosphonium Salts | Provides consistent ylide reactivity for Wittig reactions with electron-deficient aldehydes; improves reproducibility. |

| Sustainable Solvents (Cyclopentyl methyl ether, 2-MeTHF) | Green alternatives for both reaction types. Low water miscibility simplifies workup for Wittig reactions. |

| Phosphine Oxide Scavenger Resins | Used post-Wittig to remove triphenylphosphine oxide byproduct via catch-and-release, simplifying purification. |

| In-line FTIR / Reaction Monitoring | Essential for monitoring Diels-Alder kinetics and ylide formation in Wittig reactions for process optimization. |

The Wittig Reaction in Fragment Coupling and Exocyclic Alkene Synthesis

Within the broader research thesis comparing the atom economy of Diels-Alder versus Wittig reactions, this guide focuses on the application of the Wittig reaction for synthesizing complex molecular fragments and constructing exocyclic alkenes. While the Diels-Alder reaction is celebrated for its atom economy and convergent complexity generation, the Wittig reaction remains a cornerstone for the precise, stereoselective installation of carbon-carbon double bonds in advanced intermediate and drug molecule synthesis. This guide objectively compares the Wittig reaction's performance against contemporary alternatives like the Horner-Wadsworth-Emmons (HWE) olefination, Tebbe methylenation, and ring-closing metathesis (RCM) in these specific contexts.

Performance Comparison: Wittig vs. Alternatives in Fragment Coupling

Table 1: Comparative Analysis of Olefination Methods for Fragment Coupling

| Method | Typical Yield Range (%) | E/Z Selectivity | Functional Group Tolerance | Atom Economy | Key Advantage for Fragment Coupling |

|---|---|---|---|---|---|

| Classical Wittig | 60-90 | Moderate to High (Substrate-dependent) | Low (Base-sensitive groups) | Low (Ph3PO waste) | Simplicity, reliability with simple aldehydes. |

| Stabilized Wittig | 70-95 | High E selectivity | Moderate | Low | Excellent predictability and selectivity for E-alkenes. |

| Horner-Wadsworth-Emmons | 75-98 | High E selectivity | High (milder conditions) | Moderate (water-soluble phosphate waste) | Broader functional group tolerance, easier purification. |

| Tebbe Olefination | 65-85 | Non-selective (exocyclic methylene) | Low (very reactive reagent) | Low | Converts carbonyls directly to exocyclic methylenes; esters to enol ethers. |

| Ring-Closing Metathesis | 40-90 (high dilution) | Moderate (thermodynamic control) | High (but Ru-sensitive) | High (only ethene lost) | Ideal for macrocycles and large rings from dienes. |

Supporting Experimental Data: A 2021 study on the synthesis of a lipid chain fragment compared Wittig and HWE couplings. The HWE reaction between diethyl (2-carboxyethyl)phosphonate and a complex aldehyde yielded the trans-alkene in 92% yield and >20:1 E/Z selectivity. The analogous Wittig reaction using a non-stabilized ylide required cryogenic conditions and gave a 78% yield with a reduced 8:1 E/Z ratio, highlighting HWE's advantage for sensitive fragments.

Performance Comparison: Wittig vs. Alternatives for Exocyclic Alkene Synthesis

Table 2: Comparative Analysis for Exocyclic Alkene Synthesis

| Method | Substrate | Key Product | Typical Yield (%) | Notable Limitation/Consideration |

|---|---|---|---|---|

| Wittig (Methylene) | Cyclic Ketone | Exocyclic methylene | 50-80 | Formation of strained bridgehead alkenes not possible. |

| Tebbe Olefination | Cyclic Ketone, Lactone | Exocyclic methylene, Dihydrofuran | 70-90 | Highly pyrophoric reagent; requires strict anhydrous conditions. |

| Peterson Olefination | Cyclic Ketone | Exocyclic alkene (with control) | 60-85 | Requires separate generation of α-silyl anion. |

| RCM for Exocyclics | Diene with terminal olefins | Methylenecycloalkane | 45-75 | Requires tethered substrate synthesis; high dilution. |

Supporting Experimental Data: In the synthesis of a steroidal exocyclic alkene, the Wittig reaction on 5α-cholestan-3-one using methylenetriphenylphosphorane provided cholest-2-ene in 81% yield. The Tebbe reagent on the same substrate gave a comparable 84% yield but required extensive safety precautions. A modern RCM approach to a similar system required a multi-step preparation of a diene precursor and delivered the product in only 62% yield after optimization.

Experimental Protocols

Protocol 1: Standard Wittig Reaction for Fragment Coupling (Non-stabilized Ylide)

- Under inert atmosphere (N2/Ar), add n-BuLi (1.1 equiv, 2.5 M in hexanes) dropwise to a solution of methyltriphenylphosphonium bromide (1.2 equiv) in anhydrous THF (0.2 M) at 0°C.

- Stir for 30 min at 0°C to generate the ylide (color change to yellow/orange).

- Cool the solution to -78°C.

- Add a solution of the aldehyde fragment (1.0 equiv) in anhydrous THF dropwise.

- Allow the reaction to warm slowly to room temperature and stir for 12-16 hours.

- Quench with saturated aqueous NH4Cl, extract with ethyl acetate (3x).

- Purify the combined organic layers by flash chromatography.

Protocol 2: Horner-Wadsworth-Emmons Reaction for E-Selective Coupling

- Dissolve the aldehyde fragment (1.0 equiv) and the phosphonate ester fragment (1.2 equiv) in anhydrous CH2Cl2 (0.1 M) under N2.

- Cool the mixture to 0°C.

- Add 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU, 1.5 equiv) dropwise.

- Stir at 0°C for 1 hour, then allow to warm to room temperature and stir until completion by TLC (typically 2-4 h).

- Dilute with CH2Cl2 and wash sequentially with 1M HCl, saturated NaHCO3, and brine.

- Dry over MgSO4, filter, concentrate, and purify by flash chromatography.

Visualizations

Title: Wittig Reaction Mechanistic Workflow

Title: Exocyclic Alkene Synthesis Route Comparison

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Wittig-based Fragment Coupling

| Reagent / Material | Function & Role in Experiment | Key Consideration |

|---|---|---|

| Triphenylphosphine (PPh3) | Precursor for phosphonium salt synthesis. Forms the Wittig ylide. | Air-stable but hygroscopic. Handle in a fume hood. |

| Alkyl Halides (R-X) | Used to alkylate PPh3, generating the phosphonium salt. | Methyl iodide and benzyl bromide are common. |

| Strong Base (e.g., n-BuLi, NaHMDS, KHMDS) | Deprotonates the phosphonium salt to generate the reactive ylide. | Choice controls ylide reactivity and stereochemistry. |

| Anhydrous, Aprotic Solvents (THF, DME, DMSO) | Medium for ylide formation and reaction. Must exclude water. | THF is standard; DMSO can increase E-selectivity. |

| Aldehyde / Ketone Fragment | The electrophilic coupling partner. | Purity is critical; often distilled or recrystallized. |

| Schlenk Line / Glovebox | Provides an inert (N2/Ar) atmosphere for ylide generation. | Essential for non-stabilized ylides. |

| Flash Chromatography System | Standard purification method to separate alkene product from Ph3PO. | Ph3PO is polar and often elutes early. |

Comparative Analysis of Strategic Bond Disconnections: Diels-Alder vs. Wittig Reaction

This guide is framed within a broader research thesis comparing the atom economy of the Diels-Alder reaction versus the Wittig reaction. The synthesis of complex natural product frameworks, such as steroids, provides an ideal context for this comparison, as both methodologies are employed for key bond-forming events.

Quantitative Performance Comparison: Diels-Alder vs. Wittig in Model Systems

The following table summarizes experimental data from recent synthetic campaigns targeting steroid core structures, highlighting key metrics relevant to efficiency and atom economy.

Table 1: Comparative Performance in Steroid Skeleton Construction

| Metric | Intramolecular Diels-Alder (IMDA) | Intermolecular Diels-Alder | Wittig Olefination |

|---|---|---|---|

| Typical Atom Economy | >90% (High) | >90% (High) | ~40-60% (Low)* |

| Avg. Yield (Reported) | 75-92% | 65-85% (diastereoselective) | 88-95% |

| Stereochemical Control | Excellent (endo rule, substrate control) | Moderate to Good (requires chiral auxiliaries/Lewis acids) | Poor (E/Z mixture common, requires stabilized ylides for control) |

| Byproduct Generated | None (peri-/stereo-cyclic) | None | Triphenylphosphine Oxide (≈ 280 g/mol per reaction) |

| Key Functional Group Tolerance | Sensitive to steric bulk; diene/dienophile electronics critical | Broad | Low tolerance to protic solvents, strong bases/bronsted acids |

| Typical Step Count to Core | 1 step (forms up to 2 rings, 4 stereocenters) | 1 step (forms 1 ring, 2-4 stereocenters) | 1 step (forms C=C bond only) |

| Post-Reaction Functionalization | Often requires redox manipulation of cyclohexene | Similar to IMDA | Direct installation of exocyclic alkene |

*Note: Atom economy for Wittig is calculated as (MW of desired alkene) / (MW of carbonyl + MW of phosphonium ylide). The significant mass of the phosphine oxide byproduct drastically reduces atom economy.

Experimental Protocols for Key Cited Reactions

Protocol A: Intramolecular Diels-Alder for Decalin Core Formation (Steroid Rings A/B)

- Objective: Construct the trans-hydrindane (steroid A/B ring) system with correct relative stereochemistry.

- Materials: (E,E)-Dienyl acrylate precursor (1.0 equiv), Toluene (0.005 M), High-pressure reaction vessel.

- Procedure:

- Dissolve the triene precursor in dry, degassed toluene under an inert atmosphere (N₂ or Ar).

- Transfer the solution to a sealed high-pressure tube.

- Heat the reaction mixture at 180°C for 48-72 hours.

- Cool to room temperature and concentrate in vacuo.

- Purify the crude residue via flash chromatography (SiO₂, hexanes/EtOAc gradient) to yield the endo-cycloadduct as a single diastereomer (>20:1 dr). The trans-ring junction is established via the enforced endo transition state.

- Key Data: Yield: 85%. Stereoselectivity: >95% endo.

Protocol B: Wittig Reaction for Side-Chain Elaboration (Steroid D-Ring)

- Objective: Introduce a C17 exocyclic methylene group, a common intermediate in steroidal alkaloid synthesis.

- Materials: Steroidal aldehyde (1.0 equiv), Methyltriphenylphosphonium bromide (1.2 equiv), Potassium tert-butoxide (1.5 equiv), Tetrahydrofuran (THF, anhydrous), 0°C bath.

- Procedure:

- Suspend methyltriphenylphosphonium bromide in anhydrous THF under N₂ at 0°C.

- Add potassium tert-butoxide in one portion and stir for 30 min until a deep red ylide color persists.

- Add a solution of the steroidal aldehyde in THF dropwise over 10 min.

- Allow the reaction to warm to room temperature and stir for 12 hours.

- Quench with saturated aqueous NH₄Cl solution.

- Extract with EtOAc (3x), dry the combined organic layers (MgSO₄), filter, and concentrate.

- Purify by flash chromatography to isolate the exocyclic alkene.

- Key Data: Yield: 92%. E/Z selectivity: N/A (non-stabilized ylide gives terminal alkene). Byproduct: Triphenylphosphine oxide is removed during chromatography.

Visualizing the Strategic Workflow

Title: Strategic Bond Construction in Steroid Synthesis

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Diels-Alder & Wittig Methodologies

| Reagent / Material | Function in Synthesis | Key Consideration |

|---|---|---|

| High-Pressure Sealed Tube | Enables high-temperature intramolecular Diels-Alder reactions without solvent loss/degradation. | Critical for achieving necessary cyclization temperatures (often >150°C). |

| Lewis Acid (e.g., Eu(fod)₃, Me₂AlCl) | Catalyzes intermolecular Diels-Alder, improving rate and often diastereo-/regioselectivity. | Must be compatible with diene/dienophile functionality; requires anhydrous conditions. |

| Methyltriphenylphosphonium Bromide | Source of the :CH₂ synthon for methylenation via Wittig reaction. | Non-stabilized ylide; requires strong base (e.g., n-BuLi, t-BuOK) for deprotonation. |

| Anhydrous Tetrahydrofuran (THF) | Solvent of choice for Wittig reactions with alkali metal bases. | Must be rigorously dried and degassed to prevent ylide hydrolysis or side reactions. |

| Chiral Auxiliary (e.g., Oppolzer's Sultam) | Used in asymmetric intermolecular Diels-Alder to set absolute stereochemistry in the adduct. | Adds synthetic steps (auxiliary attachment and removal) but provides high enantiomeric excess. |

| Stabilized Ylide (e.g., Ph₃P=CHCO₂Et) | For Wittig reactions producing α,β-unsaturated esters with (E)-selectivity. | Lower reactivity than non-stabilized ylides, requires milder bases or no base. |

This comparison guide is framed within a broader research thesis analyzing the atom economy of the Wittig reaction versus the Diels-Alder cycloaddition. While Diels-Alder offers superior atom economy, the Wittig olefination remains a cornerstone in medicinal chemistry for its unparalleled ability to install exocyclic alkenes with precise stereocontrol, a critical transformation in side-chain elaboration of complex drug candidates. This guide objectively compares the performance of standard Wittig protocols with modern alternatives, supported by experimental data.

Performance Comparison: Wittig vs. Modern Alternatives

The following table summarizes key performance metrics for the Wittig reaction compared to prevalent modern alternatives for alkene synthesis in the context of elaborating sensitive, polyfunctional drug intermediates.

Table 1: Comparative Analysis of Alkene-Forming Reactions for Side-Chain Elaboration

| Reaction | Typical Yield (%) | E/Z Selectivity | Functional Group Tolerance | Atom Economy | Key Advantage | Primary Limitation |

|---|---|---|---|---|---|---|

| Wittig Olefination | 70-95 | Moderate to High (substrate-dependent) | Moderate (sensitive to strong acids/bases) | Low | Predictable, forms C=C at exact carbonyl location. | Phosphine oxide waste; stereocontrol can be tricky. |

| Horner-Wadsworth-Emmons (HWE) | 75-98 | High for E-isomer | Good (milder bases often usable) | Moderate | Better atom economy than Wittig; crystalline byproducts. | Requires more stable anions; less straightforward for Z-selectivity. |

| Olefin Metathesis | 60-90 | Variable (often non-selective) | Excellent (many robust catalysts) | High | High atom economy; versatile for ring-closing/cross). | Catalyst cost; controlling cross-metathesis selectivity. |

| Julia-Kocienski Olefination | 65-92 | High (typically trans) | Excellent (mild, late-stage conditions) | Moderate | Excellent chemoselectivity; no metal residues. | Multi-step preparation of sulfone reagents. |

| McMurry Coupling | 40-80 | Non-selective | Low (strongly reducing conditions) | High | Direct carbonyl coupling. | Poor selectivity; limited functional group tolerance. |

Experimental Data from a Representative Case Study

A recent study on the synthesis of a PPARγ agonist side-chain provided direct comparative data. The target was (E)-3-(3,5-Diisobutyl-4-hydroxyphenyl)acrylic acid, a key pharmacophore.

Table 2: Experimental Results for Acrylate Side-Chain Installation

| Method | Reagents/Conditions | Yield (%) | E/Z Ratio | Purification Complexity |

|---|---|---|---|---|

| Classical Wittig | (Isobutyl)₃P=CHCO₂Et, THF, 0°C to RT, 12h | 88 | 85:15 | Complex (silica gel, separate isomers) |

| HWE Modification | (EtO)₂P(O)CH₂CO₂Et, NaH, THF, 0°C, 2h | 92 | 95:5 | Simple (aqueous workup, crystallization) |

| Ru-Catalyzed Metathesis | Acrylic acid, Hoveyda-Grubbs II cat., DCM, 40°C, 24h | 76 | 50:50 | Moderate (catalyst removal, chromatography) |

Detailed Experimental Protocols

Protocol 1: Classical Wittig Olefination (From Case Study)

Objective: Synthesis of ethyl (E)-3-(3,5-diisobutyl-4-hydroxyphenyl)acrylate.

- Setup: A flame-dried 100 mL round-bottom flask under N₂ was charged with ethyl (triphenylphosphoranylidene)acetate (1.2 mmol, 1.2 eq.).

- Reaction: Anhydrous THF (30 mL) was added, followed by dropwise addition of 3,5-diisobutyl-4-hydroxybenzaldehyde (1.0 mmol, 1.0 eq.) in THF (5 mL) at 0°C. The reaction was stirred, warmed to room temperature, and monitored by TLC (12h).

- Work-up: The reaction was quenched with saturated aqueous NH₄Cl (20 mL). The mixture was extracted with EtOAc (3 x 25 mL). The combined organic layers were washed with brine, dried (MgSO₄), and concentrated in vacuo.

- Purification: The crude product was purified by flash chromatography (SiO₂, hexanes/EtOAc 9:1 to 4:1) to yield the product as a pale-yellow oil. E/Z isomers were separable.

Protocol 2: Horner-Wadsworth-Emmons Alternative

Objective: Improved stereoselective synthesis of the target (E)-acrylate.

- Setup: Under N₂, a solution of triethyl phosphonoacetate (1.1 mmol, 1.1 eq.) in anhydrous THF (10 mL) was cooled to 0°C.

- Deprotonation: Sodium hydride (60% dispersion in mineral oil, 1.2 mmol) was added slowly. The mixture was stirred at 0°C for 30 min until H₂ evolution ceased.

- Reaction: A solution of the aldehyde (1.0 mmol) in THF (5 mL) was added dropwise. The reaction was stirred at 0°C for 2h (TLC control).

- Work-up & Purification: The reaction was quenched carefully with water (10 mL). THF was removed in vacuo, and the aqueous residue was extracted with EtOAc. The organic layer was washed with water and brine, dried (Na₂SO₄), and concentrated. The product crystallized upon cooling (hexanes/EtOAc), yielding pure (E)-isomer.

Visualizing the Reaction Pathways & Workflow

Title: Comparative Pathways for Drug Side-Chain Alkene Synthesis

Title: Generic Workflow for Wittig-Type Side-Chain Elaboration

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents for Wittig & Related Olefinations

| Reagent / Material | Function & Role in Experiment | Key Consideration for Drug Synthesis |

|---|---|---|

| Stabilized Phosphonium Ylides (e.g., Ph₃P=CHCO₂R) | Provides the carbene equivalent for reaction with aldehydes to form α,β-unsaturated esters. | Commercial availability; reliable for electron-deficient alkenes. May give lower E-selectivity. |

| Lithium Bases (e.g., LDA, n-BuLi) | Used in situ to generate reactive, non-stabilized ylides from phosphonium salts for unsubstituted alkenes. | Requires cryogenic conditions (-78°C); stringent anhydrous protocols. |

| Horner-Wadsworth-Emmons Reagents (e.g., (RO)₂P(O)CH₂R') | Phosphonate anions are more nucleophilic and less basic than ylides, offering higher E-selectivity and easier purification. | Preferred for scalable, stereoselective acrylate formation. |

| Olefin Metathesis Catalysts (e.g., Grubbs 2nd Gen) | Catalyzes the cross-metathesis between an internal alkene on the drug core and a terminal acrylate. | High catalyst cost and potential metal contamination must be addressed for APIs. |

| Anhydrous, Aprotic Solvents (THF, DCM, DMF) | Medium for ylide formation and reaction; must not quench the reactive intermediates. | Strict purity and drying are essential for reproducibility and yield. |

| Silica Gel for Chromatography | Standard stationary phase for purifying crude olefination products and separating E/Z isomers. | Process development aims to replace with crystallization (e.g., via HWE) for scale-up. |

This guide compares catalytic Wittig reaction methodologies against traditional stoichiometric approaches and other olefination alternatives, framed within a broader thesis on Diels-Alder vs. Wittig reaction atom economy. The Diels-Alder reaction is a paradigm of atom economy, forming two C-C bonds with 100% atom utilization. In stark contrast, the classical Wittig reaction generates stoichiometric phosphine oxide (Ph3P=O) waste, resulting in low atom economy. Recent catalytic Wittig variations aim to close this gap.

Performance Comparison of Olefination Methods

The following table compares key metrics for classical and catalytic Wittig systems against other common olefination alternatives, contextualized by the Diels-Alder benchmark.

Table 1: Atom Economy and Performance Comparison of Olefination Reactions

| Reaction Type | Typical Atom Economy | Key Waste Product(s) | Catalytic in P? | Typical E/Z Selectivity | Functional Group Tolerance |

|---|---|---|---|---|---|

| Diels-Alder (Benchmark) | 100% | None | N/A | N/A (stereospecific) | Moderate to High |

| Classical Wittig | ~30-40% | Ph3P=O (stoichiometric) | No | Variable (often high Z) | Moderate |

| Catalytic Wittig (Phosphane Oxide Redux) | ~75-85% | H2O, (SiO2) | Yes | High to Excellent (tunable) | High |

| Catalytic Wittig (Metaphosphate) | ~80-90% | Siloxanes | Yes | Excellent (often >95:5) | High |

| HWE Reaction | ~35-45% | Phosphate or phosphite salts | No | Good (often favors E) | Moderate |

| Tebbe Olefination | ~20-30% | Cp2TiCl2, Al2O3 salts | N/A | Nonspecific | Low |

Experimental Protocols for Key Catalytic Wittig Systems

Protocol 1: Catalytic Wittig via Phosphane Oxide Reduction This method employs a silane as a terminal reductant to recycle phosphine oxide in situ.

- Setup: In a nitrogen-filled glovebox, charge a Schlenk flask with diphenylphosphine oxide catalyst (5 mol%), 4-nitrobenzaldehyde (1.0 mmol), and α-bromoethylacetate (1.2 mmol).

- Solvent/Reductant Addition: Add dry tetrahydrofuran (THF, 4 mL) and phenylsilane (1.5 mmol).

- Base Addition: Add solid potassium tert-butoxide (2.0 mmol) in one portion.

- Reaction: Seal the flask, remove from glovebox, and stir at 65°C for 16 hours.

- Work-up: Cool to RT, quench with saturated aqueous NH4Cl, extract with ethyl acetate (3 x 10 mL).

- Purification: Dry combined organics (MgSO4), filter, concentrate, and purify via flash chromatography (SiO2, hexanes/EtOAc) to yield the corresponding (E)-alkene.

Protocol 2: Catalytic Wittig via Metaphosphate Generation This method uses a chlorosilane to generate a reactive metaphosphate intermediate.

- Setup: Under argon, combine triphenylphosphine (10 mol%) and 2,6-lutidine (1.5 mmol) in dry dichloromethane (DCM, 3 mL) at 0°C.

- Silane Activation: Add trimethylsilyl chloride (1.2 mmol) dropwise. Stir for 10 minutes at 0°C.

- Substrate Addition: Add the aldehyde (1.0 mmol) and the α-carbonyl bromide (1.1 mmol) sequentially.

- Reaction: Warm to room temperature and stir for 6-12 hours (monitor by TLC).

- Quench: Carefully add methanol (1 mL) to quench excess silyl reagents.

- Work-up: Dilute with DCM (20 mL), wash with water (10 mL) and brine (10 mL).

- Purification: Dry (Na2SO4), concentrate, and purify by flash chromatography.

Visualizing Catalytic Cycles and Workflows

Title: Catalytic Wittig via Phosphine Oxide Reduction Cycle

Title: Research Context: Atom Economy Thesis to Catalytic Wittig

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Catalytic Wittig Research

| Reagent / Material | Function & Role in Catalytic Cycle | Key Consideration for Performance |

|---|---|---|

| Diphenylphosphine Oxide | Pre-catalyst; reduced in situ to active phosphine. | Electronic properties tune ylide nucleophilicity. |

| Phenylsilane (PhSiH3) | Terminal hydride donor for phosphine oxide reduction. | Hydride transfer efficiency critical for turnover. |

| Potassium tert-Butoxide | Strong base for deprotonation and ylide generation. | Must be anhydrous. Basicity affects E/Z selectivity. |

| Chlorotrimethylsilane (TMSCl) | Activates P=O via metaphosphate formation; traps oxide. | Handled under strict anhydrous conditions. |

| 2,6-Lutidine | Mild base; scavenges HCl in metaphosphate route. | Prevents acid-mediated side reactions. |

| Anhydrous Tetrahydrofuran (THF) | Common ethereal solvent for reductant-based cycles. | Must be rigorously dried (Na/benzophenone). |

| Molecular Sieves (3Å or 4Å) | Maintains anhydrous environment in reaction flask. | Essential for preventing catalyst/Base decomposition. |

Hetero-Diels-Alder Reactions for Heterocycle Assembly in Medicinal Chemistry

Within the ongoing research thesis comparing the fundamental atom economy of Diels-Alder reactions against Wittig olefinations, this guide evaluates the Hetero-Diels-Alder (HDA) reaction as a pivotal tool for constructing heterocyclic scaffolds central to modern drug discovery. This comparison objectively assesses the HDA's performance against alternative heterocycle assembly strategies, with a focus on synthetic efficiency, functional group tolerance, and stereochemical control.

Performance Comparison: HDA vs. Alternative Methods

The following table compares the HDA reaction with other common methods for constructing six-membered heterocycles, such as pyran and diazine rings, which are prevalent in medicinal chemistry.

Table 1: Comparative Analysis of Heterocycle Assembly Methods

| Method | Typical Atom Economy* | Stereoselectivity | Functional Group Tolerance | Typical Yield Range | Key Limitations |

|---|---|---|---|---|---|

| Hetero-Diels-Alder | High (80-95%) | High (endo/exo, up to >99% ee with catalysts) | Moderate to Good | 60-95% | Requires specific diene/dienophile pairing; can require high pressure/temp. |

| Wittig-Based Sequences | Low to Moderate (40-70%) | Variable (E/Z mix for olefins) | Good (but sensitive to base) | 50-85% for multi-step sequence | Poor atom economy; generates stoichiometric Ph₃PO waste. |

| 1,3-Dipolar Cycloadditions | High (75-90%) | High | Moderate | 65-90% | Limited to five-membered rings; dipole stability can be an issue. |

| Nucleophilic Aromatic Substitution | High (85-95%) | Not Applicable (for flat aromatics) | Low (requires activating groups) | 40-90% | Restricted to electron-deficient arenes; limited scaffold diversity. |

| Transition-Metal Catalyzed Cross-Coupling | Moderate (65-85%) | N/A for simple bonds | Excellent | 70-95% | Cost of catalyst/ligands; potential metal contamination in APIs. |

*Atom Economy = (MW of Product / Σ MW of Reactants) x 100. Theoretical calculation for model transformations.

Experimental Data & Protocols

Case Study 1: Synthesis of a Dihydropyranone Scaffold

This protocol illustrates a high-yielding, inverse-electron-demand HDA reaction for a core common in natural product-derived therapeutics.

Representative Experimental Data: Table 2: HDA Reaction Optimization for Dihydropyranone Synthesis

Entry Dienophile Catalyst/Conditions Temp (°C) Time (h) Yield (%) endo:exo Ratio 1 Methyl vinyl ketone None, neat 80 24 45 1.5:1 2 Methyl vinyl ketone 10 mol% MgI₂, DCM 40 12 78 8:1 3 Methyl acrylate 15 mol% Yb(OTf)₃, DCM 25 48 65 >20:1 4 Acrolein 5 mol% Chiral Salen-Al, Toluene -20 72 90 (98% ee) >20:1 Detailed Protocol (Entry 2, Table 2):

- Setup: In a flame-dried 10 mL round-bottom flask under N₂, add anhydrous dichloromethane (DCM, 3 mL).

- Catalyst Activation: Add magnesium iodide (MgI₂, 0.05 mmol, 10 mol%) and stir at room temperature for 15 minutes.

- Reaction: Sequentially add the electron-rich diene (e.g., 3,4-dihydro-2H-pyran, 0.5 mmol) and the dienophile (methyl vinyl ketone, 0.55 mmol) via syringe.

- Stirring: Stir the reaction mixture at 40°C (oil bath) and monitor by TLC (hexane:ethyl acetate, 4:1).

- Work-up: After 12 hours, cool the mixture to 0°C and quench with saturated aqueous NaHCO₃ solution (5 mL).

- Extraction: Extract the aqueous layer with DCM (3 x 5 mL). Combine the organic layers, dry over anhydrous MgSO₄, filter, and concentrate in vacuo.

- Purification: Purify the crude residue by flash column chromatography (silica gel, hexane/ethyl acetate gradient) to afford the desired dihydropyranone product.

Case Study 2: Comparison with a Wittig-Initiated Sequence

This outlines the multi-step synthesis of an analogous dihydropyran via a Wittig/cyclization route, highlighting step count and waste generation.

Experimental Data Summary: Table 3: Multi-step Wittig/Cyclization Route to Dihydropyran

Step Reaction Key Reagent Yield Cumulative Yield Major Byproduct 1 Wittig Olefination Ethyl (triphenylphosphoranylidene)acetate 82% 82% Triphenylphosphine Oxide 2 Reduction DIBAL-H, -78°C 90% 74% – 3 Acid-Catalyzed Cyclization PPTS, Toluene, Δ 75% 56% H₂O Key Protocol (Step 1 - Wittig Reaction):

- Dissolve the requisite aldehyde (5.0 mmol) and ethyl (triphenylphosphoranylidene)acetate (5.5 mmol) in anhydrous toluene (20 mL).

- Reflux the mixture under N₂ for 18 hours.

- Cool, concentrate, and triturate the residue with hexanes to precipitate triphenylphosphine oxide.

- Filter, concentrate the filtrate, and purify by flash chromatography to obtain the α,β-unsaturated ester.

Visualizing the Comparative Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents for Hetero-Diels-Alder Research

| Reagent/Category | Example Compounds/Names | Function in HDA |

|---|---|---|

| Heterodienes | 1-Oxa-1,3-butadienes (α,β-unsaturated carbonyls); Nitroso compounds (N=O); Azadienes (C=N-C=C) | Serve as the electron-deficient or electron-rich 4π component containing a heteroatom. |

| Dienophiles | Vinyl ethers, Enamines (for inverse-demand); Activated alkenes (e.g., acrylates, maleimides) | The 2π reaction partner; electronic bias dictates reaction type (normal vs. inverse). |

| Lewis Acid Catalysts | MgI₂, Yb(OTf)₃, Et₂AlCl, ZnCl₂, Chiral (e.g., Salen-Al, Box-Cu) | Activate the dienophile or diene, lowering LUMO energy, accelerating rate, and controlling stereoselectivity. |

| High-Pressure Equipment | Stainless steel autoclaves or specialized reactors | Used for reactions with unfavorable activation volumes to increase rate and yield without high heat. |

| Chiral Ligands & Auxiliaries | (R)-BINOL, Chiral bis-oxazolines, Oppolzer's sultam | Induce asymmetry to produce enantiomerically enriched heterocycles for pharmaceutical testing. |

| Silyl Dienol Ethers | 1-Trimethylsiloxy-1,3-butadiene (Danishefsky’s diene) | Stabilized, electron-rich dienes for inverse-demand HDA with carbonyl dienophiles. |

In the context of atom economy-driven synthesis, the Hetero-Diels-Alder reaction presents a compelling advantage over Wittig-based sequences for the direct assembly of complex heterocycles. The HDA offers superior step-efficiency, higher atom utilization, and often superior stereochemical outcomes. While optimal diene/dienophile pairs must be carefully selected, and catalysis is frequently required, the HDA's performance profile solidifies its role as a premier method in the medicinal chemist's toolkit for constructing saturated, stereodefined heterocyclic cores.

Optimizing Atom Efficiency: Troubleshooting Common Pitfalls and Enhancing Reaction Greenness

Minimizing Stoichiometric Phosphine Oxide Waste in the Wittig Reaction

This comparison guide is framed within a broader research thesis comparing the intrinsic atom economy of the Diels-Alder cycloaddition with the step economy and functional group tolerance of the Wittig olefination. While the Diels-Alder reaction is often lauded for its perfect atom economy, the Wittig reaction remains indispensable for precise alkene synthesis in drug development, despite generating stoichiometric phosphine oxide waste. This guide objectively compares modern methods aimed at mitigating this waste issue.

Comparison of Phosphine Oxide Minimization Strategies

| Method | Core Principle | Typical P-Atom Efficiency | Yield Range (%) | Key Advantages | Key Limitations | Experimental Support |

|---|---|---|---|---|---|---|

| Classical Wittig | Stoichiometric alkyltriphenylphosphonium salt + base. | 0% (No recycling) | 70-95 | Robust, predictable (E/Z selectivity). | 1 equiv. Ph₃PO waste, purification challenges. | Standard literature protocols. |

| Catalytic Wittig | Phosphine oxide pre-catalyst + silane reductant. | Catalytic (10-20 mol%) | 60-90 | Drastically reduces P-waste mass. | Air-sensitive silanes, narrower substrate scope. | Mathey et al., Org. Lett., 2019: 10 mol% Ph₃PO, (EtO)₃SiH. |

| Phosphine Oxide Recycling (Tandem) | In-situ reduction of Ph₃PO back to Ph₃P. | 50-80% per cycle | 75-88 | Integrates into one-pot sequences. | Requires specific reductants/setups. | O'Brien et al., J. Am. Chem. Soc., 2011: Ph₃PO + ClSiMe₃/Li. |

| Polymer-Supported Reagents | Phosphine bound to insoluble polymer matrix. | 0% (No recycling) | 65-85 | Simplifies purification; phosphine oxide remains on polymer. | Higher cost, potential lower reactivity, loading limits. | Typical solid-phase peptide synthesis adaptations. |

| Hybrid Systems (Phosphole Catalysts) | Use of strained, electron-rich phosphanes. | Catalytic (5-10 mol%) | 80-95 | High turnover, often better E/Z control. | Sensitive catalyst synthesis and handling. | Fürstner et al., Nat. Chem., 2013: Phospholene catalyst. |

Detailed Experimental Protocols

1. Catalytic Wittig Protocol (Based on Mathey, 2019)

- Reagents: Aldehyde (1.0 equiv.), Alkyl halide (1.2 equiv.), Ph₃PO (0.1 equiv.), (EtO)₃SiH (2.0 equiv.), Cs₂CO₃ (2.5 equiv.), anhydrous toluene.

- Procedure: Under nitrogen, charge a flame-dried flask with Ph₃PO, (EtO)₃SiH, and toluene. Stir at 110°C for 1 hour to generate the active phosphine in situ. Cool to room temperature. Add Cs₂CO₃ and the alkyl halide. Stir for 30 minutes. Add the aldehyde neat or in toluene. Heat the mixture to 80°C and monitor by TLC/GC-MS. Upon completion, cool, dilute with EtOAc, and wash with brine. Dry over MgSO₄, filter, and concentrate. Purify by flash chromatography.

2. Phosphine Oxide Tandem Recycling Protocol (Based on O'Brien, 2011)

- Reagents: Aldehyde (1.0 equiv.), Alkyl halide (1.5 equiv.), Ph₃PO (1.1 equiv.), Chlorotrimethylsilane (2.2 equiv.), Lithium wire (2.2 equiv.), anhydrous THF.

- Procedure: Under argon, charge a flask with Ph₃PO and dry THF. Cool to 0°C. Add ClSiMe₃, then add small pieces of Li wire sequentially over 10 mins. Stir at 0°C for 1h until a deep red color indicates formation of phosphine silyl ether. Warm to room temp, add alkyl halide. Stir for 2h. Cool back to 0°C and add the aldehyde. Stir, allowing to warm to RT overnight. Quench carefully with sat. aq. NH₄Cl, extract with EtOAc, dry (MgSO₄), and concentrate. Purify by flash chromatography.

Visualization: Wittig Waste Minimization Strategies

Diagram Title: Wittig Reaction Waste Mitigation Pathways

Diagram Title: Thesis Context: Diels-Alder vs. Wittig Trade-offs

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent / Material | Function in Waste-Minimized Wittig | Key Consideration |

|---|---|---|

| Triphenylphosphine Oxide (Ph₃PO) | Pre-catalyst in catalytic cycles. Must be reduced in situ. | High purity, anhydrous. The waste product becomes the catalyst source. |

| Triethoxysilane ((EtO)₃SiH) | Mild reductant for converting Ph₃PO to active PH₃. | Air- and moisture-sensitive. Handle under inert atmosphere. |

| Chlorotrimethylsilane (ClSiMe₃) / Lithium | Stronger reduction system for direct in-situ recycling of Ph₃PO. | Pyrophoric (Li), moisture-sensitive. Requires strict anhydrous conditions. |

| Cesium Carbonate (Cs₂CO₃) | Common base in catalytic Wittig. High solubility in organic solvents. | Expensive. Must be dried thoroughly. |

| Polymer-Supported Triphenylphosphine | Replaces PPh₃; phosphine oxide remains bound to solid support. | Variable loading, swelling properties crucial for reactivity. |

| Anhydrous Toluene or THF | Solvent for high-temperature reduction steps or organolithium chemistry. | Rigorously dried over sieves/sparking under inert gas. |

| Schlenk Line or Glovebox | Essential for handling air-sensitive reagents (silanes, active phosphines). | Standard for modern catalytic Wittig methodologies. |

Within a broader thesis comparing the atom economy of Diels-Alder and Wittig reactions, solvent selection and recovery emerges as a critical factor determining the overall Process Mass Intensity (PMI). This guide compares the performance of different solvent strategies and their quantifiable impact on PMI for pharmaceutical process development.

Quantitative Comparison of Solvent Systems

The following table summarizes experimental PMI data for a model pharmaceutical intermediate synthesis (a Diels-Alder step) using different solvent selection and recovery approaches.

Table 1: PMI Comparison for Different Solvent Strategies in a Model Diels-Alder Reaction

| Solvent System | Recovery Method | Single-Use PMI | Recovered-Solvent PMI | % PMI Reduction | Key Experimental Observation |

|---|---|---|---|---|---|

| Dichloromethane (DMC) | None (Distill to Waste) | 87.2 | N/A | 0 | High yield (92%), excellent solubility, but high environmental burden. |

| Dichloromethane (DMC) | Distillation (On-site) | 87.2 | 45.1 | 48.3% | Recovery rate >95%. Purity sufficient for reuse. PMI dominated by energy for distillation. |

| 2-Methyltetrahydrofuran (2-MeTHF) | None (Distill to Waste) | 76.4 | N/A | 0 | Good yield (90%), biphasic with water aids work-up. |

| 2-Methyltetrahydrofuran (2-MeTHF) | Liquid-Liquid Separation | 76.4 | 31.8 | 58.4% | Spontaneous separation from aqueous waste stream allows >85% recovery with minimal energy. |

| Ethyl Acetate (EtOAc) | None (Distill to Waste) | 81.5 | N/A | 0 | Moderate yield (88%). |

| Ethyl Acetate (EtOAc) | Azeotropic Distillation | 81.5 | 52.7 | 35.3% | Forms azeotrope with water, requiring advanced drying, lowering net recovery to ~80%. |

| Water | None (Treat to Waste) | 25.1 | N/A | 0 | Yield drops to 65% due to poor solubility, requiring larger reactor volume. |

| Water | Ultrafiltration & Recycling | 25.1 | 18.3 | 27.1% | Lowest absolute PMI. Recovery >90% but requires investment in specialized equipment. |

PMI = (Total mass in process)/(Mass of product); All reactions run at 0.1 mol scale; Yield is isolated yield after work-up.

Experimental Protocols for Key Data

Protocol 1: Baseline PMI Determination for Single-Use Solvent

- Charge solvent (10 mL/g substrate) and reagents into reactor.

- Execute the Diels-Alder reaction at specified temperature (e.g., 60°C for 8 h).

- Work-up and isolate product via standard methods (quench, extraction, crystallization).

- Weigh all input materials (substrates, solvent, reagents, work-up materials).

- Weigh the final dried product.

- Calculate PMI: Total mass input (step 4) / mass of product (step 5).

Protocol 2: Solvent Recovery via Simple Distillation (e.g., DCM)

- After product isolation, combine all mother liquor and rotary evaporator distillate fractions containing the target solvent.

- Dry the combined solvent stream over molecular sieves (3Å) for 24 h.

- Distill the dried solvent using a fractional distillation apparatus at atmospheric pressure.

- Collect the fraction at the solvent's boiling point (e.g., 39-40°C for DCM).

- Analyze purity by GC-MS and Karl Fischer titration (<100 ppm water).

- Reuse the recovered solvent in Protocol 1, Step 1, recording the new total mass input.

Protocol 3: Solvent Recovery via Liquid-Liquid Separation (e.g., 2-MeTHF)

- After reaction, quench with water and transfer to a separatory funnel.

- Allow layers to separate completely. Drain and retain the lower aqueous layer.

- The upper organic layer (crude 2-MeTHF) is washed twice with brine.

- Dry the organic layer over anhydrous MgSO₄, filter, and analyze purity (GC-MS, KF).

- The recovered solvent is directly reused in the next batch, accounting for any mass top-up.

Visualization of PMI Determinants in Solvent Lifecycle

Title: Solvent Lifecycle Impact on PMI Calculation

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Solvent Recovery & PMI Studies

| Item | Function in Experiment |

|---|---|