Applying AGREE Metric to HPLC Methods: A Practical Guide for Sustainable Pharmaceutical Analysis

This comprehensive guide explores the application of the Analytical Greenness (AGREE) metric to High-Performance Liquid Chromatography (HPLC) methods, providing researchers and pharmaceutical professionals with practical frameworks for assessing and improving...

Applying AGREE Metric to HPLC Methods: A Practical Guide for Sustainable Pharmaceutical Analysis

Abstract

This comprehensive guide explores the application of the Analytical Greenness (AGREE) metric to High-Performance Liquid Chromatography (HPLC) methods, providing researchers and pharmaceutical professionals with practical frameworks for assessing and improving environmental sustainability. Covering foundational principles to advanced implementation strategies, the article details how AGREE evaluates HPLC methods across twelve green chemistry principles, offering a quantitative approach to environmental impact assessment. Through methodological guidance, troubleshooting insights, and comparative validation frameworks, this resource enables the development of robust, regulatory-compliant analytical methods that align with global sustainability initiatives while maintaining analytical performance. The integration of AGREE with Quality by Design (QbD) approaches and other green assessment tools provides a holistic strategy for advancing sustainable practices in pharmaceutical analysis and biomedical research.

Understanding AGREE: The Foundation of Green HPLC Assessment

The Evolution of Green Analytical Chemistry and AGREE's Role

The field of analytical chemistry has undergone a significant paradigm shift with the emergence of Green Analytical Chemistry (GAC), which aims to minimize the environmental impact of analytical processes while maintaining high standards of accuracy and precision [1]. This transformative approach addresses the paradox that analytical methods, often used for environmental monitoring, can themselves contribute to environmental degradation through the use of hazardous solvents, energy-intensive equipment, and waste generation [2]. The concept has further evolved with the introduction of White Analytical Chemistry (WAC), which integrates environmental sustainability with analytical performance (red) and practical/economic aspects (blue) in a holistic RGB model [3] [4]. This review traces the evolution of greenness assessment tools, with particular focus on the Analytical GREEnness (AGREE) metric and its pivotal role in advancing sustainable HPLC method development within pharmaceutical research and drug development.

The Evolution of Greenness Assessment Metrics

The development of tools to evaluate the environmental impact of analytical methods has progressed from basic checklists to sophisticated, quantitative frameworks that provide comprehensive sustainability assessments.

Table 1: Evolution of Major Greenness Assessment Tools

| Tool Name | Year Introduced | Assessment Scope | Output Type | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| NEMI | Early 2000s | Basic environmental criteria | Binary pictogram | Simple, user-friendly | Lacks granularity; doesn't assess full workflow [3] |

| Analytical Eco-Scale (AES) | 2012 | Hazardous reagent use, energy demand | Numerical score (0-100) | Enables direct method comparison | Relies on expert judgment; no visual component [3] |

| GAPI | 2018 | Entire analytical process | Color-coded pictogram | Comprehensive; visual identification of high-impact stages | No overall score; somewhat subjective [3] |

| AGREE | 2020 | 12 principles of GAC | Pictogram + numerical score (0-1) | Comprehensive; user-friendly; facilitates comparisons | Limited pre-analytical process assessment [3] |

| AGREEprep | 2023 | Sample preparation only | Pictogram + numerical score | Addresses crucial, often overlooked step | Must be used with broader tools for full method evaluation [3] |

| AGSA | 2025 | Multiple green criteria | Star-shaped diagram + score | Intuitive visualization; multi-criteria assessment | Newer, less established tool [3] |

This evolution reflects a continuous effort to balance comprehensiveness with usability, with later tools addressing specific gaps in their predecessors. The transition from simple yes/no evaluations to nuanced scoring systems has enabled researchers to make more informed decisions regarding method sustainability [2] [3]. The progression also demonstrates a shift from focusing solely on environmental aspects to incorporating practical and economic considerations through frameworks like White Analytical Chemistry [4].

The AGREE Metric: Principles and Framework

The Analytical GREEnness (AGREE) metric represents a significant advancement in green assessment tools by directly incorporating the 12 principles of Green Analytical Chemistry into a unified evaluation framework [3]. This tool provides both a circular pictogram and a numerical score between 0 and 1, offering immediate visual and quantitative feedback on a method's environmental performance [3] [5].

The AGREE assessment considers multiple aspects of the analytical process, including:

- Energy consumption and the use of alternative energy sources [1]

- Amount of waste generated and waste management strategies [3]

- Toxicity of reagents and solvents used [1] [3]

- Miniaturization and automation of processes [3]

- Sample preparation requirements and derivatization steps [3]

- Operator safety considerations [3]

The strength of AGREE lies in its ability to provide a holistic assessment of the entire analytical workflow while remaining accessible to researchers [3]. Unlike earlier tools that focused on isolated aspects, AGREE integrates multiple sustainability dimensions into a single, interpretable output, making it particularly valuable for comparing method modifications and guiding development toward greener alternatives [2] [5].

Application Notes: AGREE in HPLC Method Development

Case Study 1: Simultaneous Determination of Resveratrol and Vitamin E

An HPLC method for simultaneously determining resveratrol and vitamin E in dietary supplements was assessed using AGREE, achieving a score of 0.61, confirming the method's greenness [6]. The method employed a simple sample preparation with gradient elution using acetonitrile and water, completing analysis in just 7 minutes [6]. The main green advantages included minimal sample preparation, reduced analysis time, and appropriate sensitivity, though the use of acetonitrile rather than greener alternatives presented an opportunity for further improvement.

Case Study 2: Eco-Friendly Determination of Letrozole

A green HPLC method for quantifying Letrozole in tablets utilized ethanol-water (50:50) as the mobile phase, completely replacing toxic solvents [7]. The method featured an extremely short analysis time of 3 minutes and was comprehensively validated per ICH guidelines [7]. AGREE evaluation demonstrated excellent environmental performance, complemented by additional assessments using GAPI and ChlorTox Scale, highlighting the value of using multiple complementary metrics for a comprehensive sustainability profile [7].

Case Study 3: Analysis of Cephalosporin Antibiotics

Implementation of an AQbD approach for developing an HPLC method to determine four cephalosporin antibiotics resulted in an AGREE score of 0.75, significantly higher than many conventional methods [5]. The optimized method used acetonitrile and 0.04 M phosphate buffer at pH 6 in a 7:93 ratio, successfully separating the four drugs in under 6 minutes [5]. This case demonstrates how method optimization directly enhances environmental performance while maintaining analytical effectiveness.

Table 2: AGREE Scores and Green Features in HPLC Method Applications

| Analytical Application | AGREE Score | Key Green Features | Analysis Time | Mobile Phase |

|---|---|---|---|---|

| Resveratrol & Vitamin E | 0.61 | Simple sample preparation, rapid analysis | 7 minutes | Acetonitrile-water (gradient) [6] |

| Letrozole quantification | Not specified | Ethanol-water mobile phase, no toxic solvents | 3 minutes | Ethanol-water (50:50) [7] |

| Cephalosporin antibiotics | 0.75 | Optimized solvent ratio, fast separation | <6 minutes | Acetonitrile-phosphate buffer (7:93) [5] |

| Iron chelating drugs | Evaluated | Ethanol-acidic water, green solvents | Not specified | Ethanol-acidic water pH 3.0 (70:30) [8] |

Implementation Workflow

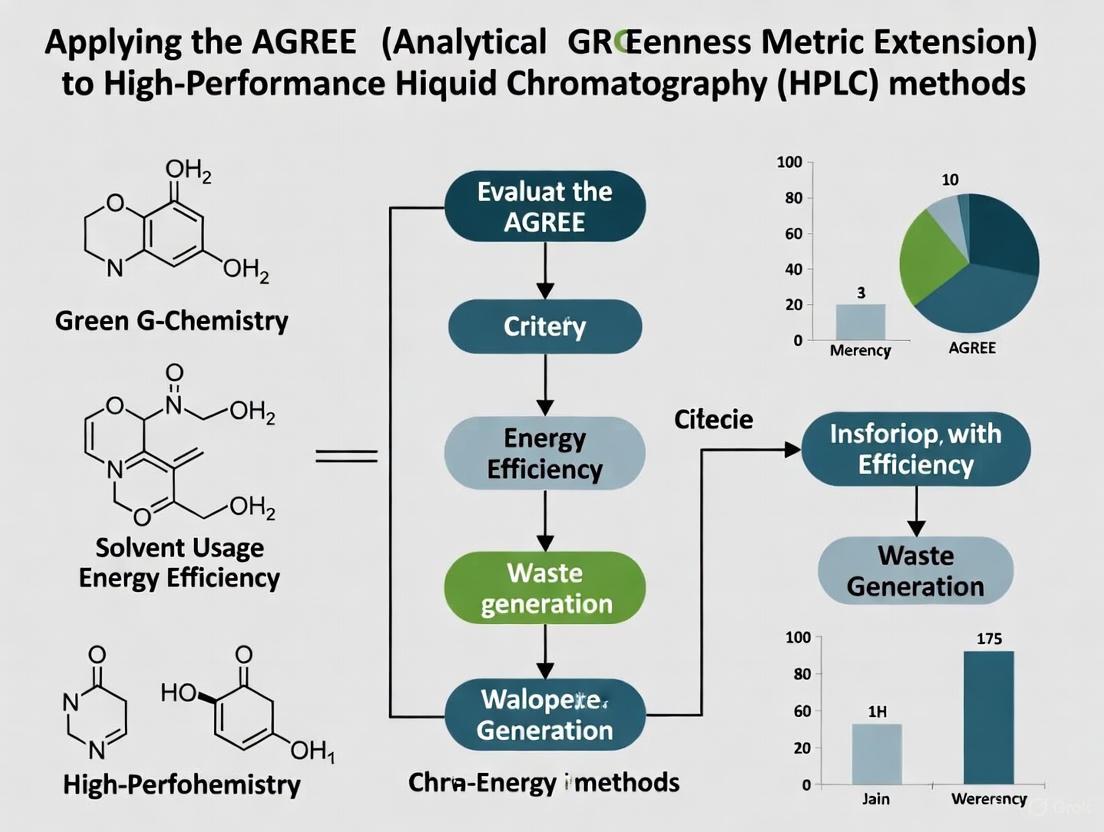

The diagram below illustrates the systematic workflow for developing green HPLC methods using AGREE for sustainability assessment:

Experimental Protocols

Protocol 1: AGREE Assessment of HPLC Methods

Purpose: To evaluate the environmental sustainability of HPLC methods using the AGREE metric.

Materials and Software:

- AGREE calculator software

- Complete method details including sample preparation, reagents, instrumentation, and waste management data

Procedure:

- Compile Method Information: Gather complete details on all method components including sample volume, solvent types and volumes, energy consumption, waste generation, and safety considerations [3].

- Input Parameters into AGREE: Enter the collected data into the AGREE software, addressing all 12 principles of Green Analytical Chemistry [3].

- Interpret Results: Analyze the resulting pictogram and numerical score. Scores closer to 1 indicate superior greenness [3] [5].

- Identify Improvement Areas: Use the sector-specific scores in the pictogram to pinpoint aspects of the method with the greatest environmental impact [3].

- Implement Modifications: Apply green chemistry principles to address identified weaknesses, such as solvent substitution or waste reduction strategies [1] [3].

- Reassess Method: Repeat AGREE evaluation after modifications to quantify improvement [3].

Protocol 2: Development of Green HPLC Methods Using AQbD

Purpose: To systematically develop environmentally sustainable HPLC methods through Analytical Quality by Design principles.

Materials:

- HPLC system with column heater and variable wavelength detector

- Columns of different chemistries

- Green solvents (ethanol, water, acetone, ethyl acetate)

- Software for experimental design

Procedure:

- Define Analytical Target Profile: Identify critical method requirements including separation, sensitivity, and sustainability goals [8] [5].

- Risk Assessment: Use Ishikawa fishbone diagram to identify factors potentially impacting method performance and environmental footprint [5].

- Initial Scouting: Screen different column chemistries and mobile phases focusing on green solvents like ethanol-water mixtures [7] [8].

- Experimental Design: Implement design of experiments to optimize critical parameters while minimizing experimental runs [8] [5].

- Method Optimization and Validation: Establish optimal conditions and validate according to ICH guidelines [6] [7] [5].

- Greenness Assessment: Evaluate the final method using AGREE and complementary tools like GAPI or AES [6] [7] [5].

Research Reagent Solutions for Green HPLC

Table 3: Essential Materials for Green HPLC Method Development

| Reagent/ Material | Function | Green Alternatives | Environmental Benefit |

|---|---|---|---|

| Acetonitrile | Organic modifier in mobile phase | Ethanol, methanol | Less toxic, biodegradable [7] [8] |

| Methanol | Organic solvent | Ethanol | Less toxic, renewable source [8] |

| n-Hexane | Non-polar solvent | Ethyl acetate, acetone | Reduced toxicity [1] |

| Phosphate buffers | Mobile phase additive | Formic acid, other volatile acids | Better biodegradability [5] |

| C18 columns | Stationary phase | Various chemistries | Method efficiency, reduced run times [5] |

| Supercritical CO2 | Extraction, chromatography | Replacement for organic solvents | Non-toxic, recyclable [1] |

Integration with Complementary Assessment Frameworks

While AGREE provides a comprehensive greenness evaluation, its integration with other assessment frameworks offers a more complete picture of method sustainability and practicality.

White Analytical Chemistry (WAC)

The RGB model of White Analytical Chemistry expands beyond environmental considerations to include:

- Red component: Analytical performance including accuracy, sensitivity, and robustness [4]

- Green component: Environmental impact assessed by tools like AGREE [4]

- Blue component: Practical and economic aspects such as cost, time, and operational simplicity [4]

This holistic framework ensures that green methods maintain analytical effectiveness and practical applicability, addressing the criticism that early GAC approaches sometimes sacrificed performance for sustainability [4].

Complementary Green Assessment Tools

Using AGREE alongside other green metrics provides multidimensional insights:

- GAPI and Modified GAPI: Offer more detailed visual assessment of specific method stages [3]

- Analytical Eco-Scale: Provides penalty-based scoring that complements AGREE's principle-based approach [6] [3]

- ComplexGAPI: Extends assessment to include pre-analytical processes like reagent synthesis [3]

- Carbon Footprint Reduction Index (CaFRI): Focuses specifically on climate impact through carbon emissions [3]

The diagram below shows the relationship between these assessment frameworks and their respective focuses:

The evolution of Green Analytical Chemistry has transformed how researchers approach method development, with the AGREE metric representing a significant advancement in sustainability assessment tools. By providing a user-friendly, comprehensive, and quantitative evaluation based on the 12 principles of GAC, AGREE enables systematic improvement of HPLC methods' environmental profiles [3] [5]. The integration of AGREE with Analytical Quality by Design approaches creates a powerful framework for developing methods that are both environmentally sustainable and analytically sound [8] [5] [9]. Furthermore, the incorporation of AGREE into the broader context of White Analytical Chemistry ensures that green methods maintain high performance standards and practical applicability [4]. As analytical chemistry continues to evolve toward greater sustainability, AGREE and complementary assessment tools will play an increasingly vital role in guiding researchers toward greener practices while maintaining the scientific rigor required for pharmaceutical research and drug development.

The Analytical GREEnness (AGREE) metric is a comprehensive, quantitative tool designed to evaluate the environmental impact and sustainability of analytical methods, including High-Performance Liquid Chromatography (HPLC). Aligning with the 12 core principles of Green Analytical Chemistry (GAC), AGREE provides a unified scoring system from 0 to 1, where higher scores indicate greener, more sustainable analytical procedures [10]. The transition towards sustainable analytical practices is a paradigm shift from traditional approaches that prioritize performance alone, moving to a framework that balances analytical efficiency with environmental, safety, and economic considerations [11].

In pharmaceutical development and other industries reliant on HPLC, the AGREE metric helps researchers and drug development professionals systematically assess and minimize the negative impacts of their methods. This includes reducing hazardous solvent consumption, minimizing waste generation, and lowering energy demands, all while maintaining the integrity and reliability of analytical results [12] [13]. The adoption of AGREE supports the broader objectives of Green Analytical Chemistry (GAC) and the emerging concept of White Analytical Chemistry (WAC), which seeks to harmonize analytical efficiency (red), environmental sustainability (green), and practical/economic effectiveness (blue) [12] [14].

The 12 Principles of Green Analytical Chemistry and AGREE Scoring

The AGREE metric algorithm translates each of the 12 SIGNIFICANCE principles of GAC into a standardized score on a 0-1 scale. The final AGREE score is the product of these 12 individual assessments, visually represented in an intuitive clock-like pictogram [10]. The table below details each principle, its core objective, and its specific interpretation in the context of HPLC method development.

Table 1: The 12 Principles of Green Analytical Chemistry and Their Application in AGREE for HPLC

| Principle Number | Core Principle (SIGNIFICANCE) | Key Focus Area in HPLC | Typical HPLC Assessment Criteria |

|---|---|---|---|

| 1 | Direct analysis | Sample treatment | Preference for on-line/in-line analysis; penalty for multi-step, off-line sample preparation [10]. |

| 2 | Minimal sample size | Sample consumption | Smaller sample volumes or masses are scored higher [10]. |

| 3 | In-situ measurements | Sample location & transport | In-field analysis is ideal; transport to lab scores lower [10]. |

| 4 | Integration & automation | Method streamlining | Automated, hyphenated systems are favored [10]. |

| 5 | Derivatization avoidance | Reagent use & toxicity | Methods avoiding derivatization reagents score highest [10]. |

| 6 | Energy minimization | Instrument energy demand | Lower energy consumption per sample yields higher scores [13]. |

| 7 | Use of safe reagents | Reagent & solvent toxicity | Replacement of hazardous solvents (e.g., acetonitrile) with greener alternatives (e.g., ethanol) improves score [12] [15]. |

| 8 | Multi-analyte determination | Sample throughput & efficiency | Methods analyzing multiple compounds simultaneously are preferred [13]. |

| 9 | Waste minimization | Solvent waste generation | Reduced mobile phase volumes, lower flow rates, and waste recycling increase score [15] [13]. |

| 10 | Choice of detection method | Detector energy & resource use | Simpler, less energy-intensive detectors (e.g., UV vs. MS) can be favored from a green perspective [10]. |

| 11 | Renewable & recycled reagents | Solvent sourcing & lifecycle | Use of bio-based or recycled solvents improves score [13]. |

| 12 | Accident & operator safety | Hazard prevention | Toxicity, flammability, and corrosivity of chemicals used are assessed [10]. |

A key feature of the AGREE calculator is its flexibility. It allows users to assign different weights to each of the 12 principles based on their specific analytical priorities or regulatory constraints. This weighted assessment is visually reflected in the width of the segments in the final output pictogram, providing an immediate overview of both the performance and the prioritized aspects of the method's greenness [10].

AGREE Assessment Workflow for HPLC Methods

Implementing the AGREE metric involves a systematic process from data collection to result interpretation. The following diagram illustrates the core workflow for evaluating an HPLC method.

Diagram 1: AGREE HPLC Assessment Workflow

Experimental Protocol for Data Collection

To perform an AGREE assessment, the following protocol outlines the necessary data collection steps for a typical HPLC method.

Protocol 1: Data Collection for AGREE Input

Sample Preparation:

- Record all steps, including weighing, extraction, dilution, filtration, and derivatization.

- Quantify the number of discrete procedural steps.

- Note the types and volumes (in mL) of all solvents and reagents used in preparation.

- Identify any hazardous chemicals used (e.g., strong acids/bases).

HPLC Instrumental Parameters:

- Mobile Phase: Document the exact composition (e.g., Water:Ethanol, 70:30 v/v) and the use of any additives (e.g., 0.1% formic acid). Note the pH if applicable.

- Flow Rate: Record the flow rate in mL/min.

- Run Time: Document the analytical run time per sample in minutes.

- Column: Specify the column dimensions (length, internal diameter, particle size).

- Column Oven: Record the temperature (°C).

- Detection: Note the detection technique (e.g., UV-Vis, MS).

Waste and Throughput:

- Calculate the total volume of mobile phase (and other solvents) used per sample, including equilibration time.

- Calculate the volume of waste generated per sample.

- Determine the sample throughput (number of samples analyzed per hour or day).

AGREE Software Calculation Protocol

Once the data is collected, the AGREE score is calculated using dedicated, open-source software.

Protocol 2: AGREE Score Calculation

- Software Access: Download the AGREE software from the official repository at

https://mostwiedzy.pl/AGREE[10]. - Data Input: Enter the collected data from Protocol 1 into the corresponding fields in the software interface. The software translates the qualitative and quantitative data into scores for each of the 12 principles.

- Weight Assignment (Optional): Assign relative weights (from 0 to 1) to each of the 12 principles if certain aspects of greenness are more critical to your assessment than others.

- Output Generation: The software automatically generates a pictogram, which includes:

- A final AGREE score (0-1) in the center.

- Twelve colored sections representing each GAC principle, with green indicating high performance, yellow moderate, and red poor performance.

- Section widths that reflect the assigned weights.

Case Studies and Applications in Pharmaceutical Analysis

The AGREE metric has been successfully applied to evaluate and improve the sustainability of various HPLC methods in pharmaceutical analysis. The following case studies demonstrate its practical utility and quantitative output.

Table 2: AGREE Scores from Recent Pharmaceutical HPLC Method Developments

| Analyzed Drug(s) | Key Green Features of the HPLC Method | Reported AGREE Score | Reference & Context |

|---|---|---|---|

| Tafamidis Meglumine | Simple solvent system without buffers; use of methanol and acetonitrile with 0.1% ortho-phosphoric acid. | 0.83 | A QbD-based stability-indicating method, highlighting a strong alignment with GAC principles [16]. |

| Cinnarizine | Mobile phase of methanol and 0.1% ortho-phosphoric acid (95:5); low flow rate of 0.5 mL/min. | Method optimized for greenness, scored higher than previously published methods using AGREE and other metrics [14]. | |

| Nebivolol, Telmisartan, Valsartan, Amlodipine | Mobile phase of 0.1% formic acid in water and ethanol; replacement of traditional hazardous solvents. | Method assessed and confirmed its alignment with sustainable practices using AGREE [12]. |

Detailed Case Study: Tafamidis Meglumine Analysis

A stability-indicating RP-HPLC method for Tafamidis Meglumine showcases how analytical quality and sustainability can be achieved simultaneously. The method was developed using a Quality-by-Design (QbD) approach, optimizing critical parameters like mobile phase composition, column temperature, and flow rate [16].

Key Green Attributes:

- Solvent System: The method uses a mixture of methanol and acetonitrile with 0.1% ortho-phosphoric acid, deliberately avoiding more hazardous buffers and reagents [16].

- Performance: The method was rigorously validated per ICH guidelines and demonstrated excellent linearity, accuracy, and precision, proving that green methods do not compromise analytical quality [16].

- AGREE Validation: The method achieved a high AGREE score of 0.83, providing a quantitative and authoritative confirmation of its environmental sustainability [16].

Advanced Concepts and Complementary Tools

The Research Scientist's Toolkit for Green HPLC

Beyond AGREE, several other tools and concepts are essential for developing and evaluating sustainable HPLC methods.

Table 3: Essential Toolkit for Developing Green HPLC Methods

| Tool or Concept | Primary Function | Application Example in HPLC |

|---|---|---|

| AGREEprep | Specifically evaluates the greenness of sample preparation steps, based on 10 assessment criteria [11] [13]. | Assessing the environmental impact of solid-phase extraction (SPE) or liquid-liquid extraction (LLE) used prior to HPLC injection. |

| White Analytical Chemistry (WAC) | A multicriteria framework balancing Analytical efficiency (Red), Ecological impact (Green), and Practical/economic efficiency (Blue) [12] [14]. | Ensuring a method is not only green but also analytically sound and cost-effective to implement in a routine lab. |

| Blue Applicability Grade Index (BAGI) | Evaluates the practical viability and applicability of an analytical method based on 10 parameters, such as cost, throughput, and operational simplicity [13]. | Determining how easily a new green HPLC method can be adopted in a quality control laboratory for daily use. |

| Analytical Eco-Scale | A semi-quantitative tool that assigns penalty points for hazardous practices; the remaining score (from 100) indicates greenness [13] [14]. | Providing an alternative rapid assessment of a method's environmental friendliness. |

| Green Solvent Selection Tool (GSST) | A free online tool that provides a composite sustainability score (G) for solvents, helping in mobile phase selection [12]. | Comparing the sustainability of ethanol versus acetonitrile for a new method development. |

Strategies for Improving AGREE Scores in HPLC

Based on the principles assessed by AGREE, the following strategies can directly enhance the sustainability score of an HPLC method:

- Solvent Replacement: Substitute toxic solvents like acetonitrile with greener alternatives such as ethanol or methanol [12] [15]. For example, a method for peptide analysis can replace environmentally persistent trifluoroacetic acid (TFA) with more biodegradable methanesulfonic acid (MSA) [15].

- Miniaturization and Volume Reduction: Utilize columns with smaller internal diameters, reduce flow rates, and employ micro-HPLC systems to significantly cut mobile phase consumption and waste generation [13].

- Method Optimization and Automation: Apply Quality-by-Design (QbD) and Design of Experiments (DoE) to develop robust methods that minimize reagent use and analysis time while maximizing throughput [12] [16]. Automate sample preparation to reduce solvent use and improve safety [11].

- System Operation: Implement on/off LC-MS mechanisms instead of continuous flow to save solvents and energy during idle periods [15].

The principles of Green Analytical Chemistry (GAC) have revolutionized how researchers evaluate the environmental impact of analytical methods, particularly in high-performance liquid chromatography (HPLC). As the scientific community strives to align with sustainability goals, several assessment tools have emerged to quantify and compare the "greenness" of analytical procedures [3]. Among these, the Analytical GREEnness (AGREE) metric has gained significant prominence alongside established tools like the National Environmental Methods Index (NEMI), Green Analytical Procedure Index (GAPI), and Analytical Eco-Scale [17]. Each tool offers distinct approaches—from simple pictograms to comprehensive scoring systems—enabling researchers to make informed decisions that balance analytical performance with environmental responsibility [18]. Understanding the strengths, limitations, and appropriate applications of these metrics is crucial for advancing sustainable practices in pharmaceutical analysis and drug development. This assessment is particularly relevant within the broader context of White Analytical Chemistry (WAC), which seeks to harmonize analytical performance (red), environmental impact (green), and practical applicability (blue) [18] [19]. The following sections provide a detailed comparison of these four key metrics, supported by experimental protocols and practical implementation guidelines for HPLC method development.

Comparative Analysis of Green Assessment Metrics

The table below summarizes the fundamental characteristics, scoring mechanisms, and key differentiators of the four green assessment metrics.

Table 1: Fundamental Characteristics of Green Assessment Metrics

| Metric | Year Introduced | Assessment Scope | Scoring System | Visual Output | Primary Advantages | Main Limitations |

|---|---|---|---|---|---|---|

| NEMI | Early 2000s [3] | Basic environmental criteria [3] | Binary (pass/fail) for 4 criteria [3] | Simple quadrant pictogram [3] | User-friendly, rapid assessment [3] | Lacks granularity, limited scope [3] |

| Analytical Eco-Scale | 2012 [3] | Reagents, energy, waste [3] | Penalty points subtracted from 100 [3] | Numerical score only [3] | Quantitative results, method comparison [3] | Subjective penalty assignments [3] |

| GAPI | 2018 [3] | Comprehensive workflow from sampling to detection [3] | Qualitative (green/yellow/red) for multiple parameters [3] | Multi-section pictogram [3] | Detailed process evaluation [3] | No overall score, some subjectivity [3] |

| AGREE | 2020 [18] | 12 principles of GAC [18] | 0-1 scale with weighting options [18] | Circular diagram with score [18] | Comprehensive, aligns with GAC principles [18] | Subjective weighting, limited pre-analytical coverage [3] |

Quantitative Scoring Comparison

The following table compares how each metric scores different aspects of an analytical method, using examples from published HPLC applications.

Table 2: Scoring Characteristics and Application Examples of Green Metrics

| Metric | Score Range | Ideal Score | Score Interpretation | Applied to HPLC Example | Reported Score |

|---|---|---|---|---|---|

| NEMI | 0-4 criteria met [3] | 4 green quadrants [3] | Binary assessment of basic environmental criteria [3] | Melatonin analysis [20] | 3/4 criteria met [20] |

| Analytical Eco-Scale | 0-100 [3] | 100 [3] | Higher score indicates greener method [3] | Pantoprazole/Domperidone analysis [19] | 83 [19] |

| GAPI | 5-color levels per parameter [3] | All green sections [3] | Visual identification of environmental hotspots [3] | Lobeglitazone/Glimepiride analysis [21] | 10 green sections [21] |

| AGREE | 0-1 [18] | 1 [18] | Higher score indicates better alignment with GAC principles [18] | Melatonin analysis [20] | 0.81 [20] |

Experimental Protocols for Greenness Assessment

Protocol for AGREE Metric Application

Principle: The AGREE metric evaluates analytical methods against the 12 principles of Green Analytical Chemistry, providing both a quantitative score (0-1) and an intuitive visual output [18].

Procedure:

- Access the AGREE calculator (available as open-access software) [18].

- Input methodological data across 12 categories corresponding to GAC principles:

- Direct analysis techniques and minimal sample preparation

- Reduced sample size and miniaturization

- In-line, on-line, or at-line measurements

- Elimination or simplification of sample preparation steps

- Integration of analytical operations and automation

- Reduced energy consumption and operator safety

- Avoidance of derivatization reagents

- Selection of renewable and biodegradable reagents

- Reduction of waste generation and proper management

- Multi-analyte determinations for high throughput

- Elimination of toxic reagents wherever possible

- Enhancement of operator safety [18]

- Assign weighting factors (0-1) to each principle based on application context and priorities. Use equal weighting (1.0) for standard assessment.

- Generate the output: The software produces a circular pictogram with colored sections and an overall score.

- Interpret results: Sections approaching green indicate better compliance; the numerical score facilitates method comparison [18].

Application Note: In an HPLC method for melatonin analysis, AGREE highlighted advantages of ethanol-water mobile phases but identified waste management as an improvement area [20].

Protocol for Multi-Metric Assessment

Principle: A comprehensive greenness profile requires complementary metrics to address different environmental aspects [3].

Procedure:

- Perform NEMI assessment:

- Identify all chemicals used in the method

- Check if any are Persistent, Bioaccumulative, and Toxic (PBT)

- Determine if any are hazardous (D-list chemicals)

- Calculate total waste generated per analysis

- Mark applicable quadrants in the pictogram [3]

Calculate Analytical Eco-Scale score:

- Start with base score of 100

- Subtract penalty points for:

- Hazardous reagents (1-20 points based on toxicity)

- Waste amount (1-5 points based on volume)

- Energy consumption (0-5 points for >0.1 kWh/sample)

- Operator hazard (1-5 points for safety risks) [3]

- Classify results: >75 excellent, >50 acceptable, <50 inadequate greenness [3]

Construct GAPI pictogram:

- Complete the five-part template evaluating:

- Sample collection, preservation, and transport

- Sample preparation type and scale

- Reagents and chemicals used

- Instrumentation and device type

- Method type and throughput [3]

- Assign green, yellow, or red to each subsection based on environmental impact

- Complete the five-part template evaluating:

Compare results: Identify consistent strengths and weaknesses across all metrics for a comprehensive assessment [3].

Application Note: A micellar HPLC method for metformin and bisoprolol analysis demonstrated superior greenness across multiple metrics (AGREE, BAGI, CaFRI) due to reduced organic solvent consumption [22].

Assessment Workflow and Relationships

The following diagram illustrates the decision-making process for selecting and applying green assessment metrics in analytical method development:

The Scientist's Toolkit: Essential Reagents and Materials for Green HPLC

Research Reagent Solutions

The following table presents key reagents and materials that enhance the greenness profile of HPLC methods while maintaining analytical performance.

Table 3: Essential Reagents and Materials for Green HPLC Methods

| Reagent/Material | Function in HPLC | Green Alternative | Environmental Benefit | Application Example |

|---|---|---|---|---|

| Ethanol | Mobile phase organic modifier [20] [19] | Replace acetonitrile or methanol [20] [19] | Biodegradable, renewable, less toxic [20] [19] | Melatonin analysis [20] |

| Water | Mobile phase aqueous component [20] | Solvent for hydrophilic compounds | Non-toxic, readily available | Pantoprazole/Domperidone analysis [19] |

| Sodium Dodecyl Sulfate (SDS) | Surfactant for micellar chromatography [22] | Enable water-based separations | Reduces organic solvent consumption | Metformin/Bisoprolol analysis [22] |

| Potassium Phosphate Buffer | Mobile phase pH control [19] | Replace volatile buffer salts | Reduced toxicity, better waste profile | Pantoprazole/Domperidone analysis [19] |

| Bio-based Reagents | Various analytical applications | Replace petroleum-derived chemicals | Renewable sourcing, biodegradability | SULLME method [3] |

The comprehensive comparison of AGREE, NEMI, GAPI, and Analytical Eco-Scale reveals that each metric offers unique value for different assessment scenarios in HPLC method development. AGREE provides the most holistic evaluation against the 12 principles of GAC with its combined numerical and visual output, while NEMI offers rapid preliminary screening. The Analytical Eco-Scale enables quantitative comparison through its penalty-point system, and GAPI delivers detailed process-level assessment across the entire analytical workflow. For researchers developing sustainable HPLC methods, a multi-metric approach is recommended to leverage the complementary strengths of these tools. This strategy aligns with the White Analytical Chemistry framework, balancing environmental responsibility with analytical performance and practical applicability to advance greener pharmaceutical analysis.

The Twelve Principles of Green Analytical Chemistry in AGREE Scoring

The paradigm of Green Analytical Chemistry (GAC) has emerged as a transformative framework aimed at minimizing the environmental impact of analytical procedures while maintaining analytical performance [23]. The field has evolved from basic waste reduction concepts to a sophisticated discipline with clearly defined principles and assessment tools [3]. Among these tools, the Analytical GREEnness (AGREE) metric represents a significant advancement by offering a comprehensive, quantitative evaluation system based directly on the twelve principles of GAC [10]. The AGREE calculator translates these principles into a unified scoring system that generates an easily interpretable pictogram, providing researchers with both a overall score and detailed performance analysis across each GAC principle [10]. This approach has become particularly valuable in High-Performance Liquid Chromatography (HPLC) method development, where traditional practices often involve substantial consumption of hazardous solvents, energy-intensive operations, and significant waste generation [24].

The AGREE metric addresses a critical need in analytical chemistry for a standardized, transparent tool that evaluates environmental performance throughout the entire analytical workflow [10]. Unlike earlier assessment tools that focused on limited criteria, AGREE incorporates all twelve GAC principles while allowing flexibility for users to assign weights based on their specific analytical requirements and priorities [10]. This comprehensive nature makes AGREE especially valuable for pharmaceutical research and drug development, where regulatory compliance, method robustness, and sustainability are increasingly important considerations [25] [9].

The Twelve Principles of Green Analytical Chemistry: Operationalization in AGREE

The AGREE metric system operationalizes each of the twelve GAC principles through specific, measurable criteria transformed into scores on a 0-1 scale [10]. The following table summarizes how each principle is translated into assessment parameters within the AGREE framework.

Table 1: The Twelve Principles of Green Analytical Chemistry and Their Implementation in AGREE Scoring

| Principle Number | GAC Principle | AGREE Assessment Parameters | Score Calculation Basis |

|---|---|---|---|

| 1 | Direct analytical techniques | Sample treatment requirements and procedural steps [10] | Remote sensing (1.00) to multi-step batch analysis (0.00) [10] |

| 2 | Minimal sample size and number | Sample volume and number of samples [10] | Sample mass/volume with logarithmic transformation [10] |

| 3 | In-situ measurements | Analysis location relative to sample source [10] | On-site (higher) to off-site (lower) scoring [10] |

| 4 | Integration of analytical processes & automation | Method automation and workflow integration [10] | Number of operators and manual steps required [10] |

| 5 | Minimized energy consumption | Energy demand of equipment [10] | Power requirements and analysis time [10] |

| 6 | Avoid derivatization | Use of chemical derivatization [10] | Binary assessment: derivatization required or not [10] |

| 7 | Use of safer solvents & reagents | Toxicity, flammability, environmental impact [10] | GHS hazard pictograms and safety data [10] |

| 8 | Improved resource management & waste reduction | Generated waste volume and management [10] | Waste amount with logarithmic transformation [10] |

| 9 | Prioritization of multi-analyte methods | Analytical throughput and multi-analyte capability [10] | Number of analytes determined simultaneously [10] |

| 10 | Renewable source utilization | Chemical origin (bio-based vs petroleum) [10] | Percentage of reagents from renewable sources [10] |

| 11 | Waste elimination after use | Degradability and treatment of waste [10] | Waste treatment requirements and biodegradability [10] |

| 12 | Operator safety enhancement | Occupational hazards and exposure risks [10] | Hazard statements and safety precautions needed [10] |

The AGREE software combines these individual assessments into a unified score presented in a circular pictogram, with the overall greenness score (0-1) displayed in the center and segment colors indicating performance for each principle [10]. The tool also allows for weighting of different principles based on their importance in specific analytical scenarios, with the segment width in the pictogram reflecting these assigned weights [10].

Figure 1: AGREE Assessment Workflow. The diagram illustrates the sequential evaluation of the twelve GAC principles within the AGREE metric system, culminating in the generation of a comprehensive pictogram score.

Experimental Protocol: Implementing AGREE for HPLC Method Evaluation

Materials and Software Requirements

Table 2: Essential Research Reagents and Software for AGREE-Based HPLC Method Development

| Item | Function/Application | Green Considerations |

|---|---|---|

| AGREE Software | Greenness assessment calculator | Free, open-source tool available online [10] |

| Ethanol | Alternative reverse-phase mobile phase | Bio-based, less toxic replacement for acetonitrile [24] [9] |

| Methanol | Organic modifier in mobile phase | Preferable to acetonitrile when alternative not feasible [26] |

| Water | Aqueous mobile phase component | Solvent choice with minimal environmental impact [27] |

| Formic Acid | Mobile phase pH modifier | Lower toxicity compared to phosphate buffers [9] |

| C18 Column | Stationary phase for separation | Standard HPLC column available in various dimensions [25] |

Step-by-Step AGREE Assessment Protocol for HPLC Methods

Phase 1: Method Documentation and Data Collection

- Document the complete analytical procedure from sample preparation to final analysis, including all reagents, solvents, and consumables [10].

- Record exact volumes and masses of all chemicals used per analysis, noting sample size and number of samples required [10].

- Identify energy consumption of all equipment, including analysis time, temperature requirements, and instrument power specifications [10].

- Compile safety data for all chemicals, including GHS hazard classifications, safety precautions, and disposal requirements [10].

Phase 2: AGREE Software Input and Calculation

- Access the AGREE calculator through the official website or open-source platform [10].

- Input data for each of the twelve principles using the standardized scoring criteria provided in the software documentation [10].

- Assign weightings to principles based on methodological priorities (e.g., higher weight to waste minimization for high-throughput methods) [10].

- Generate the AGREE pictogram and record the overall score (0-1) and individual principle performances [10].

Phase 3: Interpretation and Method Optimization

- Analyze the AGREE output to identify methodological steps with the lowest greenness scores [10].

- Implement optimization strategies targeting low-scoring areas, such as solvent substitution, miniaturization, or automation [24].

- Reassess the optimized method using AGREE to quantify greenness improvements [10].

- Document the final method with the AGREE score for reporting and comparison purposes [25].

Applications in HPLC Method Development: Case Studies and Data Analysis

Pharmaceutical Analysis Case Studies

Recent applications of AGREE scoring in HPLC method development demonstrate its utility across various pharmaceutical analysis contexts:

Case Study 1: Panobinostat Degradation Product Analysis A validated HPLC method for analyzing Panobinostat and its degradation products achieved comprehensive greenness assessment using AGREE alongside other metrics [25]. The method employed a Waters Xbridge C18 column with a mobile phase of 10 mM ammonium formate buffer (pH 3.0) and ethanol, specifically selecting ethanol as a green alternative to traditional solvents [25]. The AGREE evaluation provided a quantitative measure of the method's environmental performance, complementing validation parameters according to ICH guidelines [25].

Case Study 2: Simultaneous Determination of Antihypertensive Drugs Researchers developed a green HPLC method for simultaneous quantification of Nebivolol hydrochloride, Telmisartan, Valsartan, and Amlodipine besylate using a mobile phase of 0.1% formic acid in water and ethanol [9]. The method specifically replaced conventional hazardous organic solvents with environmentally friendly alternatives, with the AGREE metric confirming its alignment with sustainable practices [9]. Additional assessment using the Analytical Method Greenness Score (AMGS) and White Analytical Chemistry (WAC) approaches provided complementary validation of the method's environmental credentials [9].

Case Study 3: Flavokawain A Quantification A recent RP-HPLC method for estimating Flavokawain A in bulk and tablet dosage forms used methanol-water (85:15 v/v) mobile phase and achieved an AGREE score of 0.79, indicating good greenness performance [27]. The method demonstrated that appropriate solvent selection and method optimization can yield environmentally sustainable approaches without compromising analytical validity, with recovery studies showing values between 99.2% to 101.3% [27].

Case Study 4: COVID-19 Antiviral Drug Analysis A multi-analyte HPLC method for simultaneous determination of five COVID-19 antivirals (favipiravir, molnupiravir, nirmatrelvir, remdesivir, and ritonavir) was comprehensively evaluated using multiple greenness assessment tools [26]. The method used a water-methanol mobile phase and achieved an AGREE score of 0.70, alongside favorable scores on AGREEprep (0.59) and other metrics, demonstrating its comprehensive greenness profile for pharmaceutical quality control [26].

Table 3: Comparative AGREE Scores for Pharmaceutical HPLC Applications

| Analytical Application | Mobile Phase Composition | AGREE Score | Key Green Features |

|---|---|---|---|

| Flavokawain A quantification [27] | Methanol:Water (85:15 v/v) | 0.79 | Simple mobile phase, minimal sample preparation |

| COVID-19 antiviral analysis [26] | Water:Methanol (30:70 v/v) | 0.70 | Multi-analyte determination, isocratic elution |

| Antihypertensive combination [9] | 0.1% Formic acid:Ethanol | Not specified* | Ethanol substitution, green solvent selection |

| Panobinostat degradation [25] | Ammonium formate:Ethanol | Not specified* | Ethanol use, direct analysis technique |

| SULLME antiviral method [3] | Not specified | 0.56 | Miniaturization, reduced solvent consumption |

Note: Specific AGREE scores not provided in source publications, but greenness was confirmed using the metric.

Advanced Assessment Frameworks

The evaluation of analytical method sustainability has evolved beyond single-metric approaches. The White Analytical Chemistry (WAC) framework employs an RGB model to balance three critical aspects: red (analytical performance), green (environmental impact), and blue (practicality and productivity) [24]. This comprehensive approach ensures that greenness improvements do not compromise analytical validity or practical implementation [24].

Complementary tools like AGREEprep specifically evaluate sample preparation steps, which often account for significant environmental impact in analytical workflows [24] [3]. For HPLC methods, this is particularly relevant as sample extraction, clean-up, and pre-concentration steps can involve substantial solvent consumption and waste generation [3].

Figure 2: Comprehensive Evaluation Framework for Sustainable HPLC Methods. The White Analytical Chemistry (WAC) model balances environmental sustainability (Green) with analytical performance (Red) and practical implementation (Blue) requirements.

Discussion: Strategic Implementation and Future Directions

Optimization Strategies for Enhanced AGREE Scores

Based on successful applications in pharmaceutical analysis, several strategic approaches can significantly improve AGREE scores for HPLC methods:

Solvent Substitution and Reduction: Replacing traditional hazardous solvents like acetonitrile with green alternatives such as ethanol or methanol represents the most impactful optimization strategy [24] [9]. Method miniaturization, including reduced column dimensions and lower flow rates, further decreases solvent consumption and waste generation [24].

Energy Efficiency Improvements: Implementing room temperature separations rather than heated column compartments reduces energy consumption [24]. Additionally, developing rapid analysis methods with shorter run times decreases overall energy requirements per sample [26].

Multi-analyte Methods: Developing comprehensive multi-analyte approaches that quantify multiple compounds in a single run significantly enhances analytical throughput and resource efficiency [26]. This approach directly addresses Principle 9 of GAC while providing practical benefits for routine analysis [10].

Sample Preparation Simplification: Implementing direct analysis techniques that eliminate or minimize sample preparation steps substantially improves greenness scores [10] [3]. When sample preparation is necessary, miniaturized techniques such as microextraction approaches reduce reagent consumption and waste generation [3].

Complementary Assessment Tools

While AGREE provides comprehensive greenness evaluation, researchers are increasingly employing complementary metrics to gain multidimensional sustainability assessments:

AGREEprep: Specifically evaluates sample preparation steps, which often account for significant environmental impact in analytical workflows [24].

Modified GAPI (MoGAPI): Offers a complementary pictogram-based approach with cumulative scoring for improved comparability between methods [3].

Blue Applicability Grade Index (BAGI): Assesses practical method applicability, including cost, time, and operational factors, ensuring that greenness improvements do not compromise practical implementation [24].

Carbon Footprint Reduction Index (CaFRI): Focuses specifically on climate impact by estimating carbon emissions associated with analytical procedures [3].

Regulatory Implications and Future Trends

The integration of greenness assessment into analytical method development aligns with broader regulatory trends toward sustainable practices [11]. Recent evaluations of standard methods from pharmacopeias and standardization organizations have revealed generally poor greenness performance, highlighting the need for updating established methods with more sustainable approaches [11]. Regulatory agencies are increasingly recognizing the importance of environmental considerations, with potential future requirements for greenness metrics in method validation and approval processes [11].

The concept of Circular Analytical Chemistry (CAC) represents an emerging framework that extends beyond greenness to incorporate principles of waste valorization, resource recovery, and full lifecycle assessment [11]. This approach aligns analytical chemistry with broader circular economy objectives, potentially shaping future method development practices and sustainability assessments [11].

The AGREE metric provides a sophisticated, principle-based framework for quantifying the environmental performance of HPLC methods in pharmaceutical research and drug development. By translating the twelve principles of Green Analytical Chemistry into a comprehensive scoring system, AGREE enables researchers to make informed decisions, optimize methodological greenness, and demonstrate commitment to sustainable practices. The case studies presented illustrate how strategic implementation of green principles—particularly solvent substitution, method miniaturization, and multi-analyte approaches—can yield significant environmental benefits without compromising analytical validity. As the field continues to evolve, the integration of AGREE with complementary assessment tools and emerging frameworks like Circular Analytical Chemistry will further advance the sustainability of pharmaceutical analysis, aligning scientific practice with environmental responsibility.

The Analytical GREEnness (AGREE) metric is a sophisticated software-based tool designed to evaluate the environmental impact of analytical methods. Developed in 2020, it provides a comprehensive assessment framework that directly incorporates all 12 principles of Green Analytical Chemistry (GAC) into a unified algorithm [28] [24]. Unlike earlier green assessment tools that focused on limited aspects of method environmental impact, AGREE offers a holistic evaluation through a standardized scoring system and intuitive visual output [24]. This tool has gained significant traction in analytical chemistry, particularly in high-performance liquid chromatography (HPLC) method development, where it helps researchers and pharmaceutical professionals quantify and improve the sustainability of their analytical procedures [24].

The fundamental innovation of AGREE lies in its ability to transform complex environmental considerations into a simple, interpretable output consisting of a numerical score from 0 to 1 and a corresponding color-coded pictogram [28] [24]. This output enables rapid comparison between different analytical methods and identifies specific areas for environmental improvement. As regulatory focus on sustainability intensifies and the analytical community increasingly adopts green chemistry principles, understanding how to properly interpret AGREE results has become essential for researchers developing HPLC methods in pharmaceutical applications [24].

The AGREE Assessment Framework

The Twelve Principles of Green Analytical Chemistry

AGREE's assessment framework is built upon the 12 foundational principles of Green Analytical Chemistry, with each principle assigned a specific weight in the overall calculation [24]. These principles encompass the entire analytical procedure and provide a comprehensive structure for evaluating environmental impact. The principles address key aspects including reagent toxicity, energy consumption, waste generation, operator safety, and analytical efficiency [24]. By incorporating all these dimensions, AGREE ensures that no single environmental aspect disproportionately influences the overall assessment, while still allowing critical factors to receive appropriate emphasis through the weighting system.

The 12 principles evaluated by AGREE include: (1) direct analytical techniques to minimize sample preparation; (2) reduced sample size and number; (3) in-situ measurements; (4) waste minimization; (5) safer solvents/reagents; (6) avoidance of derivatization; (7) energy efficiency; (8) miniaturization and reagent-free approaches; (9) automation and integration; (10) multi-analyte methods; (11) real-time analysis; and (12) application of greenness metrics [24]. Each principle contributes differently to the final score based on its relative importance in the overall environmental impact, creating a balanced assessment that reflects both immediate and lifecycle environmental considerations.

AGREE Software and Calculation

AGREE utilizes dedicated open-source software to perform its calculations and generate its distinctive circular pictogram [24]. Users input data related to their analytical method across the 12 GAC principles, and the software automatically computes the scores and produces the visual output. The algorithm behind AGREE incorporates predefined weighting factors that assign different levels of importance to each principle, though these weightings can sometimes be adjusted based on specific assessment needs [28]. This software-based approach standardizes the evaluation process, reducing subjectivity and improving the reproducibility of greenness assessments across different methods and laboratories [28].

The calculation process translates method characteristics into principle-specific scores that are then aggregated into the final result. The software architecture ensures that all relevant environmental aspects are considered proportionally, while the visual representation makes complex multi-criteria assessment results immediately accessible to researchers, quality control managers, and regulatory professionals [24]. This combination of computational rigor and visual clarity has positioned AGREE as one of the most comprehensive and user-friendly greenness assessment tools available for HPLC method evaluation [24].

Interpreting AGREE Scores and Color Codes

The AGREE Pictogram Structure

The AGREE pictogram presents assessment results through a circular diagram divided into 12 sections, each corresponding to one principle of GAC [24]. This clock-like visualization provides immediate visual feedback on method performance across all environmental dimensions. Each section displays a color ranging from red (poor performance) through yellow (moderate performance) to green (excellent performance), creating an intuitive at-a-glance assessment of method greenness [28] [24]. The center of the pictogram displays the overall numerical score, offering a quantitative measure of environmental performance that complements the qualitative color information.

The strategic use of color coding in the AGREE pictogram follows universal conventions where red signals environmental concerns and green indicates alignment with sustainability goals. This visual system allows researchers to quickly identify which specific aspects of their HPLC method require improvement – if a section appears red, the corresponding GAC principle is not being adequately addressed [24]. The combination of sector-specific coloring and the overarching numerical score provides both detailed and summary evaluations, supporting both method optimization efforts and comparative assessments between different analytical procedures.

Quantitative Score Interpretation

The AGREE metric generates an overall numerical score ranging from 0 to 1, which serves as a quantitative measure of method greenness [24]. This single-value output simplifies comparison between methods and provides a clear benchmark for improvement. The interpretation of these scores follows a standardized approach:

- Scores below 0.5 indicate methods with significant environmental concerns that require substantial modification to align with green chemistry principles [29].

- Scores between 0.5-0.75 represent methods with moderate environmental performance that partially address green chemistry principles but have room for improvement [29].

- Scores above 0.75 signify methods with excellent greenness credentials that comprehensively incorporate GAC principles [29].

Table 1: Interpretation of AGREE Scores in HPLC Method Development

| Score Range | Color Code | Greenness Level | Recommended Action |

|---|---|---|---|

| 0.0 - 0.50 | Predominantly Red | Unsatisfactory | Major method modification required |

| 0.51 - 0.75 | Mixed Yellow/Green | Acceptable | Targeted improvements recommended |

| 0.76 - 1.0 | Predominantly Green | Excellent | Maintain and validate current approach |

In practical applications, HPLC methods with AGREE scores above 0.7 are generally considered environmentally favorable. For example, a recently developed RP-HPLC method for simultaneous determination of five COVID-19 antiviral drugs achieved an AGREE score of 0.70, indicating good environmental performance [29]. Similarly, a stability-indicating RP-HPLC method for lobeglitazone sulphate and glimepiride in tablets demonstrated satisfactory greenness through its AGREE assessment [21]. These examples illustrate how the numerical score provides a standardized benchmark for evaluating HPLC methods in pharmaceutical analysis.

Case Study: AGREE Assessment of an HPLC Method for Antiviral Drugs

A recent development of an RP-HPLC method for simultaneous determination of five COVID-19 antiviral drugs (favipiravir, molnupiravir, nirmatrelvir, remdesivir, and ritonavir) provides a practical example of AGREE interpretation in pharmaceutical analysis [29]. The method utilized an isocratic mobile phase of water and methanol (30:70 v/v) at a flow rate of 1 mL/min with UV detection at 230 nm [29]. The AGREE assessment yielded a score of 0.70, placing it in the acceptable to good environmental performance range [29].

Analysis of the individual section scores revealed that the method performed well in areas such as energy efficiency (due to moderate analysis time and ambient temperature operation), waste reduction (through reasonable solvent consumption), and use of direct detection (avoiding derivatization) [29]. The pictogram likely showed green sections for these principles. However, the assessment also identified limitations in solvent greenness (methanol use rather than more environmentally benign alternatives) and sample preparation requirements, which would appear as yellow or possibly red sections on the pictogram [29]. This case demonstrates how the AGREE output guides researchers toward specific improvements while providing an overall measure of environmental performance suitable for regulatory and publication purposes.

AGREE in Context: Complementary Assessment Tools

Relationship to Other Greenness Assessment Metrics

AGREE exists within a broader ecosystem of greenness assessment tools, each with distinct characteristics and applications. Understanding how AGREE complements these other metrics provides valuable context for interpreting its results. The Analytical Eco-Scale offers a simpler penalty-point-based system that quantifies deviation from ideal green methods based on solvent toxicity, energy consumption, waste generation, and occupational hazards [24]. The Green Analytical Procedure Index (GAPI) provides a visual, semi-quantitative evaluation considering the entire analytical workflow through a color-coded pictogram, though unlike AGREE it does not generate a single composite score [28] [24].

Table 2: Comparison of Major Greenness Assessment Tools for HPLC Methods

| Tool Name | Graphical Output | Output Type | Key Focus Areas | Notable Features |

|---|---|---|---|---|

| AGREE | Circular diagram (0-1) | Quantitative score + color codes | All 12 GAC principles | Holistic single-score metric with software support |

| GAPI | Color-coded pictogram | Semi-quantitative | Entire analytical workflow | Easy visualization, no total score |

| Analytical Eco-Scale | Numerical score | Semi-quantitative | Solvent toxicity, energy, waste, hazards | Simple penalty-point system |

| AGREEprep | Pictogram + score | Quantitative | Sample preparation only | First dedicated sample prep metric |

More recently, AGREEprep was developed as a specialized tool focusing specifically on sample preparation techniques, addressing this particularly resource-intensive analytical stage through ten assessment criteria [28] [24]. While each tool has merits, AGREE's combination of comprehensive principle coverage, quantitative output, and visual clarity has made it particularly valuable for HPLC method assessment in regulated pharmaceutical environments where documentation and comparability are essential [24].

The White Analytical Chemistry Framework: Integrating Red, Green, and Blue Dimensions

AGREE finds its full potential when integrated within the broader framework of White Analytical Chemistry (WAC), which balances environmental sustainability with analytical quality and practical applicability [30]. In this model, greenness represents just one of three critical dimensions, complemented by redness (analytical performance) and blueness (practical applicability) [30]. This holistic approach ensures that environmental improvements do not come at the expense of analytical reliability or practical implementation.

The Blue Applicability Grade Index (BAGI) has emerged as AGREE's natural complement for assessing practical method characteristics [30]. BAGI evaluates ten key practicality attributes including analysis type, throughput, reagent availability, automation, and sample preparation, generating a score from 25-100 alongside a visual pictogram [24] [30]. Similarly, the recently introduced Red Analytical Performance Index (RAPI) provides standardized assessment of analytical performance criteria [30]. When used together, AGREE, BAGI, and RAPI provide a comprehensive RGB evaluation that supports balanced method development decisions, preventing the overemphasis of any single dimension at the expense of others [30].

Diagram 1: The White Analytical Chemistry Framework. AGREE (green) is one of three complementary assessment tools that together provide a balanced evaluation of analytical methods.

Experimental Protocol: Conducting AGREE Assessment for HPLC Methods

Sample Preparation and Data Collection

The first step in AGREE assessment involves comprehensive documentation of all method parameters and their alignment with the 12 GAC principles [29]. For HPLC methods, this requires careful recording of:

- Solvent consumption: Total volume of mobile phase and other solvents used per analysis, including preparation steps [29]

- Energy requirements: Analysis time, column temperature, detector energy consumption, and other power-intensive components [31]

- Waste generation: All waste streams including used mobile phase, sample preparation materials, and cleaning solvents [29]

- Reagent toxicity: Classification of all chemicals according to safety data sheets, with preference for less hazardous alternatives [24]

- Sample throughput: Number of samples processed per unit time, affecting overall resource efficiency [24]

Researchers should gather safety data sheets for all reagents, calculate cumulative energy consumption based on instrument specifications and run times, and quantify waste streams accurately [29]. This data collection phase is critical as it forms the foundation for the entire assessment. In the case of pharmaceutical HPLC methods, this documentation also supports regulatory submissions and quality control protocols [29].

AGREE Software Implementation

After comprehensive data collection, researchers utilize the AGREE software to input method parameters and generate the assessment output [24]. The implementation process involves:

- Software access: Download the open-source AGREE software from authorized repositories [24]

- Data input: Enter method characteristics corresponding to each of the 12 GAC principles through the user interface [24]

- Weighting adjustment: Apply any necessary custom weighting to specific principles based on methodological priorities (if supported by the software version) [28]

- Score calculation: Execute the software algorithm to generate the overall score between 0-1 and the color-coded pictogram [24]

- Result interpretation: Analyze the output to identify methodological strengths and weaknesses across the 12 principles [29]

The software automatically translates the input parameters into principle-specific scores, applies the predefined weighting scheme, and generates the visual output that represents the method's environmental profile [24]. This process standardizes greenness assessment across different methods and laboratories, enabling meaningful comparisons and collaborative improvement efforts [28].

Results Interpretation and Method Optimization

The final phase involves interpreting AGREE outputs to guide method improvements and documentation. Researchers should:

- Identify weak areas: Principles with red or yellow coloring indicate aspects requiring modification [29]

- Prioritize modifications: Focus on changes that will most significantly improve the overall score [24]

- Implement improvements: Common HPLC optimizations include solvent substitution (replacing acetonitrile with methanol), method miniaturization, reducing analysis time, and temperature optimization [24] [29]

- Reassess: Conduct follow-up AGREE evaluations to quantify improvement after modifications [29]

For example, in the RP-HPLC method for antiviral analysis, the AGREE score of 0.70 provided specific guidance for potential improvements, such as exploring alternative solvent systems or reducing sample preparation requirements [29]. This iterative assessment-optimization cycle enables continuous environmental improvement while maintaining analytical validity, ultimately leading to HPLC methods that better align with pharmaceutical industry sustainability goals [24] [29].

Essential Research Reagent Solutions for AGREE Assessment

Table 3: Key Research Reagents and Materials for AGREE Implementation in HPLC Studies

| Item | Function in AGREE Assessment | Application Example |

|---|---|---|

| AGREE Software | Open-source tool for calculating scores and generating pictograms | Automated assessment of method compliance with 12 GAC principles [24] |

| Solvent Safety Data Sheets | Documentation of reagent toxicity for principle-specific scoring | Evaluating environmental and safety impacts of mobile phase components [29] |

| HPLC Method Documentation | Complete procedural details for accurate parameter input | Providing data on solvent consumption, energy use, and waste generation [29] |

| Alternative Solvent Databases | Resources for identifying greener chemical substitutes | Method optimization to replace hazardous solvents with safer alternatives [24] |

| Energy Monitoring Equipment | Quantification of instrument power consumption | Precise measurement of principle #7 (energy efficiency) compliance [24] |

The AGREE metric represents a significant advancement in standardized environmental assessment for analytical methods, particularly in pharmaceutical HPLC applications. Its comprehensive 12-principle framework, quantitative scoring system, and intuitive visual output provide researchers with a powerful tool for developing more sustainable analytical practices. Proper interpretation of AGREE results – understanding both the significance of the 0-1 score and the color-coded principle assessment – enables targeted method improvements that reduce environmental impact without compromising analytical quality.

When integrated within the broader White Analytical Chemistry framework alongside complementary tools like BAGI and RAPI, AGREE supports the development of balanced analytical methods that excel across all critical dimensions: environmental sustainability, practical applicability, and analytical performance. As regulatory expectations evolve and the scientific community places greater emphasis on green chemistry principles, mastery of AGREE interpretation will become increasingly essential for researchers, quality control professionals, and drug development scientists working with HPLC methodologies in pharmaceutical applications.

Practical Implementation: Applying AGREE to HPLC Method Development and Analysis

Step-by-Step AGREE Assessment for HPLC Methods

The Analytical GREEnness (AGREE) metric is a comprehensive, open-source assessment tool that evaluates the environmental impact of analytical methods based on the 12 core principles of Green Analytical Chemistry (GAC) [10]. This tool transforms the complex, multivariate concept of greenness into a straightforward, easily interpretable pictogram score ranging from 0 to 1, with higher scores indicating greener methods [10]. The AGREE calculator has become instrumental for analytical chemists, particularly in pharmaceutical analysis, where High-Performance Liquid Chromatography (HPLC) is a cornerstone technique but often involves significant solvent consumption and waste generation [27] [32] [33].

For researchers framing their work within a broader thesis on sustainable analytical practices, incorporating the AGREE assessment provides a scientifically robust and standardized way to demonstrate a method's environmental credentials. Unlike earlier metrics, AGREE offers a nuanced evaluation structured around all 12 GAC principles, allowing for a balanced assessment that considers factors such as energy consumption, waste generation, reagent toxicity, and operator safety [34] [10]. Its output is an informative, clock-shaped pictogram that not only displays a final score but also visually represents the method's performance across each principle, offering immediate insight into areas of strength and opportunities for improvement [10].

Principles of Green Analytical Chemistry and the AGREE Workflow

The AGREE metric is built upon the 12 SIGNIFICANCE principles of Green Analytical Chemistry. The assessment process involves evaluating an analytical method against these principles, which are converted into a unified scoring system [10]. The following diagram illustrates the logical workflow for conducting an AGREE assessment.

Step-by-Step AGREE Assessment Protocol

This section provides a detailed, practical protocol for applying the AGREE metric to an HPLC method, as required for rigorous thesis research.

Step 1: Gathering Method Parameters

The first step involves the systematic collection of all relevant data pertaining to the HPLC method. This data forms the foundation for the subsequent scoring in the AGREE software [10].

Experimental Protocol for Data Collection:

- Sample Preparation: Record the number of sample preparation steps (e.g., extraction, filtration, dilution), the exact volumes of all solvents used, and the masses of all reagents. Note if any derivatization is performed [10].

- HPLC Instrumental Conditions: Document the mobile phase composition (including pH modifiers), flow rate (mL/min), column dimensions and temperature, total run time, and detection method (e.g., UV, MS) [27] [29] [33].

- Energy & Throughput: Record the instrument's power consumption (if known) or the total analysis time per sample. Note the number of samples that can be analyzed in a single sequence [10].

- Waste & Safety: Calculate the total volume of waste generated per sample (including from preparation and the HPLC run itself). Consult Safety Data Sheets (SDS) to identify hazards associated with all chemicals used [32] [10].

Step 2: Scoring Against the 12 GAC Principles

Using the data from Step 1, assign a score for each of the 12 principles. The AGREE software uses a pre-defined scale (typically 0 to 1) for each principle. The table below summarizes key scoring considerations for an HPLC context, derived from the AGREE foundation paper and application studies [10].

Table 1: AGREE Scoring Guide for HPLC Methods

| GAC Principle | High Score (Green) Example | Low Score (Red) Example |

|---|---|---|

| 1: Direct Analysis | Minimal or no sample preparation (e.g., direct injection of a filtered solution) [10] | Multi-step sample pre-treatment (e.g., liquid-liquid extraction, solid-phase extraction) [10] |

| 2: Sample Size | Small sample volumes (< 1 mL) or masses [10] | Large sample volumes or masses [10] |

| 3: In-situ Measurement | On-line or at-line analysis [10] | Off-line analysis in a centralized lab [10] |

| 4: Method Integration | A single, integrated analytical technique [10] | Multiple, separate techniques required for analysis [10] |

| 5: Derivatization | No derivatization agents used [27] [29] | Use of hazardous derivatization reagents [10] |

| 6: Energy Consumption | Low-energy instrumentation or short run times [32] | High-power instruments with long run times [10] |

| 7: Reagent Toxicity | Use of green solvents (e.g., ethanol, water) [27] | Use of persistent, bioaccumulative, or toxic (PBT) solvents (e.g., acetonitrile, halogenated solvents) [32] [10] |

| 8: Operator Safety | Automated systems minimizing exposure; use of non-toxic chemicals [10] | Manual handling of highly toxic, carcinogenic, or mutagenic substances [10] |

| 9: Waste Generation | Minimal waste (< 10 mL per analysis); waste properly recycled or treated [32] | Large waste volumes (> 50 mL per analysis) with no treatment [10] |

| 10: Multi-analyte | Simultaneous determination of multiple analytes [29] | Method limited to a single analyte [10] |

| 11: Throughput & Speed | High-throughput, fast analysis (e.g., < 5 min run time) [32] | Slow, low-throughput analysis [10] |

| 12: Miniaturization | Use of micro-flow or UHPLC systems [35] | Use of conventional HPLC with standard columns and flow rates [10] |

Step 3: Inputting Data into the AGREE Software

With the parameters scored, the next step is to use the dedicated software to calculate the final metric.

Experimental Protocol for Software Use:

- Access the Software: Download the open-source AGREE calculator from the official website:

https://mostwiedzy.pl/AGREE[10]. - Input Scores: Enter the scores for each of the 12 principles into the corresponding fields in the software interface. The software documentation provides guidance on the scaling for each input [10].

- Assign Weights (Optional): A key feature of AGREE is the ability to assign a relative weight (from 0 to 1) to each principle based on its importance in your specific context. For instance, in a lab focused on operator safety, Principle 8 could be assigned a higher weight [10].

- Generate the Pictogram: The software automatically calculates the overall score and generates the characteristic circular pictogram. The final score (0-1) appears in the center, while the colored segments show the performance for each principle. The width of each segment reflects the assigned weight [10].

Case Studies: AGREE in HPLC Method Evaluation

The following case studies from recent literature demonstrate the practical application of the AGREE metric in validating the greenness of HPLC methods for pharmaceutical analysis.

Table 2: AGREE Scores from Recent HPLC Method Applications

| Analytical Method (Analyte) | Key Greenness Features | Reported AGREE Score | Reference |

|---|---|---|---|

| RP-HPLC (Flavokawain A) | Methanol:water mobile phase; isocratic elution; no toxic solvents. | 0.79 | [27] |