A Practical Guide to AGREE: Mastering Green Analytical Chemistry Metric Software

This guide provides researchers, scientists, and drug development professionals with a comprehensive resource for the AGREE (Analytical GREEnness) metric software.

A Practical Guide to AGREE: Mastering Green Analytical Chemistry Metric Software

Abstract

This guide provides researchers, scientists, and drug development professionals with a comprehensive resource for the AGREE (Analytical GREEnness) metric software. It covers foundational principles, from understanding the 12 SIGNIFICANCE criteria of Green Analytical Chemistry (GAC) to downloading and installing the open-source tool. The article delivers a step-by-step methodological walkthrough for calculating and interpreting a method's greenness score, supported by real-world examples from analytical chemistry and pharmaceutical development. Readers will also learn advanced troubleshooting for common assessment challenges, strategies to optimize their analytical methods' environmental footprint, and how to validate their findings by comparing AGREE with other established metric systems like NEMI and Analytical Eco-Scale.

Understanding AGREE: The Foundation of Modern Green Analytical Chemistry

The Emergence of Green Analytical Chemistry

Green Analytical Chemistry (GAC) has emerged as a critical subfield of green chemistry, specifically focused on minimizing the environmental footprint of analytical activities while maintaining the quality and reliability of results [1]. The core mission of GAC is to mitigate the adverse effects of analytical procedures on human health, safety, and the environment [2]. This paradigm shift encourages the use of energy-saving instruments, substantial reduction or elimination of toxic reagents and solvents, and minimization of waste generation during analytical processes [3]. The principles of GAC serve as a catalyst for advancing analytical chemistry by balancing the reduction of environmental impacts with the improvement of analytical results quality [2].

The transition from traditional analytical practices to greener approaches represents a fundamental change in how chemists approach methodological development. Traditional methods often prioritize performance parameters like sensitivity and precision, sometimes at significant environmental cost. In contrast, GAC promotes a holistic view that integrates environmental responsibility as a core component of methodological robustness [1]. This evolution reflects a growing recognition within the scientific community that analytical chemistry's success in determining the composition and quantity of matter must be aligned with broader sustainability goals [1].

The Critical Need for Greenness Assessment Metrics

While the theoretical principles of GAC provide valuable guidance, their practical implementation requires standardized assessment tools. Without objective metrics, claims of "greenness" remain subjective and difficult to validate or compare. Greenness metrics transform abstract principles into measurable, comparable parameters, enabling chemists to make informed decisions when developing or selecting analytical methods [3] [2].

The development of these metrics addresses a significant gap in traditional analytical chemistry assessment. Standard method validation typically focuses on performance merits such as limit of detection (LOD), recovery, precision, and linear range, while historically overlooking environmental impacts [3]. Green metrics provide the necessary framework to evaluate the environmental sustainability of analytical procedures systematically, ensuring that ecological considerations become an integral part of methodological optimization [4].

The Evolution from Green to White Analytical Chemistry

A significant recent development in sustainable analytical chemistry is the emergence of White Analytical Chemistry (WAC), which represents the next iteration beyond GAC [5]. While GAC has largely concentrated on reducing negative environmental externalities, WAC follows a more holistic framework that integrates three equally important components, color-coded following the Red-Green-Blue (RGB) model:

- The Green Component: Incorporates traditional GAC metrics focused on environmental sustainability [5] [4].

- The Red Component: Adds assessment of analytical performance, ensuring method functionality isn't compromised for sustainability [5].

- The Blue Component: Considers economic and practical aspects, including cost and usability [5].

This triadic model reinforces that a truly sustainable method must balance environmental responsibility with analytical efficacy and practical implementation. The evolution from GAC to WAC highlights the increasing sophistication of sustainability assessment in analytical science.

The growing recognition of GAC principles has stimulated the development of numerous metric tools to evaluate the greenness of analytical procedures. These tools vary in complexity, scope, and application, providing options for different analytical contexts and user needs.

Table 1: Key Green Analytical Chemistry Metrics and Their Characteristics

| Metric Name | Type of Output | Key Assessment Criteria | Primary Applications | Strengths | Limitations |

|---|---|---|---|---|---|

| NEMI [3] [2] [4] | Qualitative | PBT chemicals, hazardous wastes, pH, waste amount | General analytical methods | Simple, visual pictogram | Binary assessment; limited scope |

| Analytical Eco-Scale [3] [2] [4] | Semi-quantitative | Reagent toxicity, waste, energy consumption | Method comparison | Penalty point system enables scoring | Subjective penalty assignments |

| GAPI [3] [4] | Semi-quantitative | Entire analytical process from sampling to detection | Comprehensive method evaluation | Visual, covers entire workflow | No overall score; somewhat subjective |

| AGREE [3] [4] | Quantitative (0-1 score) | 12 principles of GAC | Holistic method assessment | Comprehensive; user-friendly pictogram | Subjective weighting of criteria |

| AGREEprep [3] [2] | Quantitative | Sample preparation-specific parameters | Sample preparation methods | First dedicated sample prep tool | Must be used with broader tools |

| ComplexGAPI [3] [4] | Semi-quantitative | Includes preliminary synthesis steps | Methods involving material synthesis | Broader scope including pre-analysis | Complex pictogram; no cumulative score |

| RGB Model [5] | Quantitative | Environmental, functional, practical aspects | Holistic sustainability assessment | Balanced sustainability view | More complex implementation |

| BAGI [2] | Quantitative | Applicability, practicality | Method practicality assessment | Focuses on practical implementation | Narrow focus |

Detailed Examination of Selected Metrics

National Environmental Methods Index (NEMI) was one of the earliest GAC metrics, introduced in 2002 [2]. Its pictogram is a circle divided into four quarters, with each section colored green if specific criteria are met: (1) no PBT (persistent, bioaccumulative, toxic) chemicals are used; (2) no hazardous solvents from D, F, P, or U lists are employed; (3) pH between 2 and 12; and (4) waste generated is less than 50 g [2]. While appreciated for its simplicity, NEMI's binary (yes/no) assessment provides limited differentiation between methods [4].

Analytical Eco-Scale offers a semi-quantitative approach by assigning penalty points to non-green aspects of an analytical method [2] [4]. Starting from a base score of 100 for an "ideal green analysis," points are deducted for hazardous reagents, energy consumption exceeding 0.1 kWh per sample, and waste generation [2]. The resulting score allows direct comparison between methods, with higher scores indicating greener methods [4].

Green Analytical Procedure Index (GAPI) uses a five-part color-coded pictogram to assess the entire analytical process from sample collection through preparation to final detection and interpretation [4]. Each section is colored green, yellow, or red based on the environmental impact of that step, providing immediate visual identification of areas for improvement [4].

Analytical Greenness (AGREE) represents a significant advancement by incorporating all 12 principles of GAC into a unified assessment tool [4]. It provides both a pictogram and a numerical score between 0 and 1, offering a comprehensive and easily interpretable evaluation [3] [4]. The tool evaluates multiple criteria including reagent toxicity, waste production, energy consumption, and operator safety [3].

AGREE Metric: Detailed Protocol for Implementation

The AGREE (Analytical Greenness Calculator) metric has gained significant traction due to its comprehensive coverage of GAC principles and user-friendly output. Below is a detailed protocol for implementing AGREE in methodological assessment.

Experimental Protocol for AGREE Application

Purpose: To evaluate the greenness profile of analytical methods using the AGREE metric, which assesses compliance with the 12 principles of Green Analytical Chemistry.

Principles: AGREE operates by evaluating an analytical method against 12 criteria derived from the foundational principles of GAC. Each criterion is scored, and the results are integrated into a comprehensive pictogram with an overall score between 0 and 1, where higher scores indicate greener methods [3] [4].

Table 2: Research Reagent Solutions for AGREE Implementation

| Item Name | Function/Application | Specification Guidelines |

|---|---|---|

| AGREE Software | Calculates greenness score based on input parameters | Freeware available online; inputs based on 12 GAC principles |

| Method Documentation | Complete procedural details for assessment | Must include all steps from sample collection to final analysis |

| Safety Data Sheets (SDS) | Chemical hazard assessment | Required for all reagents, solvents, and standards used |

| Energy Consumption Data | Power usage quantification | Instrument power ratings, operational time measurements |

| Waste Inventory | Tracking of generated waste | Mass/volume of all waste streams, disposal methods |

Procedure:

- Method Deconstruction: Break down the analytical method into discrete steps including sample collection, preservation, transportation, storage, preparation, instrumentation, and data analysis.

- Data Collection: For each step, gather quantitative and qualitative data including:

- Reagent types, quantities, and hazard classifications

- Solvent volumes and environmental impact

- Energy consumption of equipment

- Waste generation amounts and treatment

- Operator safety considerations

- Throughput and analysis time

- Input Parameter Scoring: Rate the method against each of the 12 GAC principles using the AGREE software interface, assigning scores based on predefined criteria.

- Calculation: Execute the AGREE algorithm which applies weighting factors to each principle and computes the overall score.

- Interpretation: Analyze the resulting pictogram and numerical output to identify environmental hotspots and opportunities for methodological improvement.

Notes:

- The assessment requires transparent documentation of all methodological parameters.

- Comparative assessments should maintain consistent scoring criteria across methods.

- The tool accommodates both laboratory-based and on-site analytical methods.

Visualizing Metric Relationships and Applications

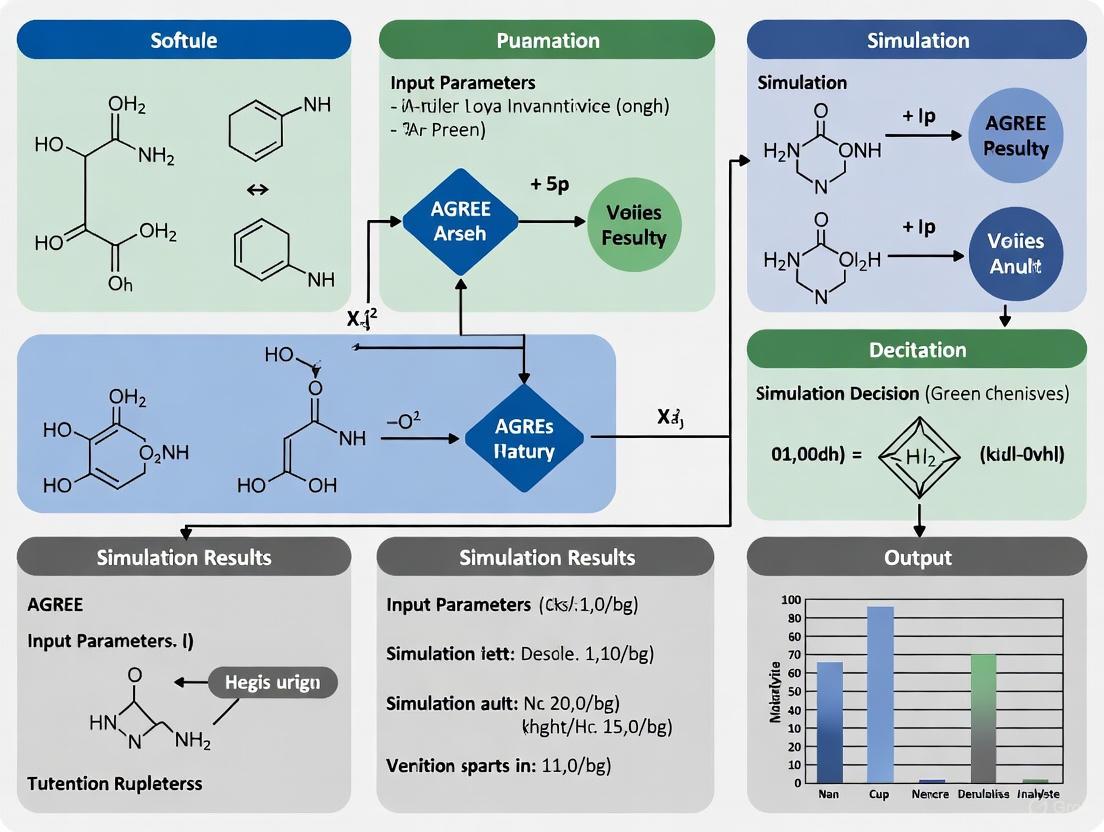

The following diagram illustrates the evolutionary relationships between major GAC metrics and their positioning within the broader White Analytical Chemistry framework:

GAC Metrics Evolution and WAC Framework

The workflow below demonstrates the practical application of GAC metrics in methodological development and assessment:

GAC Assessment Workflow

Current Challenges and Future Perspectives

Despite significant advances in GAC metrics, several challenges remain in their widespread implementation. Coordination failure within the field presents a substantial barrier, as transitioning to greener analytical practices requires collaboration among manufacturers, researchers, routine laboratories, and policymakers [1]. The traditional and conservative nature of analytical chemistry has limited cooperation between key players like industry and academia, hindering the adoption of circular processes [1].

Another significant challenge is the rebound effect in green analytical chemistry, where efforts to reduce environmental impact lead to unintended consequences that offset or negate the intended benefits [1]. For example, a novel, low-cost microextraction method that uses minimal solvents might lead laboratories to perform significantly more extractions than before, increasing the total volume of chemicals used and waste generated [1]. Similarly, automation can lead to over-testing, where analyses are performed more frequently than necessary simply because the technology allows it [1].

The evaluation of standard methods reveals substantial room for improvement. A recent assessment of 174 standard methods and their 332 sub-method variations from CEN, ISO, and Pharmacopoeias using the AGREEprep metric revealed poor greenness performance: 67% of the methods scored below 0.2 on the AGREEprep scale (where 1 represents the highest possible score) [1]. These findings demonstrate that many official methods still rely on resource-intensive and outdated techniques, highlighting the urgent need to update standard methods by including contemporary and mature analytical approaches [1].

Future developments in GAC metrics will likely address these challenges through several avenues:

- Integration of lifecycle assessment principles to account for the full environmental impact of analytical methods [4]

- Development of specialized metrics for emerging analytical technologies and application areas

- Standardization of weighting systems to reduce subjectivity in assessments

- Implementation of green financing models specifically designed to promote innovations aligned with GAC and WAC goals [5]

- Enhanced education and training to build entrepreneurial mindset among researchers and facilitate commercialization of green innovations [1]

As regulatory agencies increasingly recognize the importance of environmental sustainability, the role of GAC metrics in method validation and approval processes is expected to grow, ultimately contributing to reduced ecological footprints of analytical activities worldwide [1].

Green Analytical Chemistry (GAC) is a dedicated framework aimed at making analytical procedures more environmentally benign and safer for humans. It encompasses a broad set of criteria for evaluation, including the amounts and toxicity of reagents used, the quantity of waste generated, energy requirements, and the number of procedural steps, with considerations for miniaturization and automation [6]. The AGREE (Analytical GREEnness) calculator is a comprehensive, flexible, and straightforward software tool designed to perform a standardized assessment of an analytical method's environmental impact [6].

Developed by Pena-Pereira, Wojnowski, and Tobiszewski, this open-source software translates the 12 principles of Green Analytical Chemistry (often referred to as the SIGNIFICANCE principles) into a unified, easily interpretable score. The tool provides a pictogram that visually summarizes the performance of an analytical procedure across all criteria, offering a clear and informative result that aids researchers, scientists, and drug development professionals in evaluating and improving their methods [6].

The AGREE Methodology: Scoring and Assessment Criteria

The core of the AGREE approach is its transformation of the 12 principles of GAC into a transparent scoring system. The software calculates a final score on a scale from 0 to 1, offering a balanced overview of the method's greenness. The calculation is based on the 12 SIGNIFICANCE principles, which serve as the assessment criteria [6].

The 12 SIGNIFICANCE Principles of Green Analytical Chemistry

The AGREE software evaluates analytical methods against the following 12 principles, which are presented in the table below alongside a brief description of their focus areas [6].

Table 1: The 12 Principles of Green Analytical Chemistry (SIGNIFICANCE) as Implemented in AGREE

| Principle Number | Principle Focus Area | Description |

|---|---|---|

| 1 | Toxicity of Reagents/Solvents | Evaluates the safety and environmental impact of chemicals used. |

| 2 | Amounts of Reagents/Solvents Used | Assesses the minimization of material consumption. |

| 3 | Energy Consumption | Measures the total energy requirements of the procedure. |

| 4 | Waste Generation | Quantifies the amount of waste produced. |

| 5 | Number of Procedural Steps | Considers the simplicity and directness of the method. |

| 6 | Miniaturation/Integration/Automation | Evaluates the use of advanced, efficient technologies. |

| 7 | Analytical Performance | Ensures the method maintains accuracy, sensitivity, etc. |

| 8 | Operator's Safety | Assesses the risk and exposure to hazardous conditions. |

| 9 | Throughput of the Method | Measures the efficiency and speed of analysis. |

| 10 | Cost of Equipment/Operation | Considers the economic viability of the method. |

| 11 | Source of the Method's Greenness | Identifies which specific aspects contribute to greenness. |

| 12 | Additional Negative Impacts/Remarks | Accounts for any other environmental or safety concerns. |

A key feature of the AGREE software is its flexibility. The tool allows users to assign weights to each of the 12 criteria based on their specific priorities or the requirements of a particular analysis. This means that if certain principles, such as waste generation or energy consumption, are of paramount importance for a given application, they can be given more significance in the final score calculation [6].

The final output is an intuitive pictogram that displays not only the overall greenness score but also the method's performance on each individual criterion. This visual representation allows for a rapid and comprehensive understanding of the method's environmental strengths and weaknesses [6].

AGREEprep: A Specialized Tool for Sample Preparation

Building upon the foundation of AGREE, a related tool called AGREEprep has been developed specifically for evaluating the greenness of sample preparation methods. Sample preparation is a critical step in many analytical procedures and can be a significant contributor to the overall environmental footprint [7].

AGREEprep conducts its assessment based on 10 steps that correspond to the 10 principles of green sample preparation. Like its predecessor, it uses user-friendly, open-source software to calculate and visualize the results. However, the tutorial on AGREEprep notes that some steps can be challenging to evaluate, either because essential data is not readily available or because some criteria are not well-defined in standard methodological reports [7]. This highlights the importance of thorough data collection and reporting when aiming to conduct a complete greenness assessment.

Practical Application: A Protocol for Using AGREE Software

The following section provides a detailed, step-by-step protocol for researchers to effectively utilize the AGREE software for assessing an analytical method.

Phase 1: Software Setup and Data Collection

- Software Acquisition: Download the open-source AGREE software from the official website: https://mostwiedzy.pl/AGREE [6].

- Method Definition: Clearly define the scope and all steps of the analytical procedure to be assessed.

- Data Gathering: Compile all necessary quantitative and qualitative data for the method. This includes, but is not limited to:

- Types and quantities of all reagents and solvents used.

- Total energy consumption (e.g., from heating, cooling, instrumentation runtime).

- Total mass of waste generated, categorized if possible by hazard.

- Number of discrete manual or automated steps (e.g., extraction, dilution, derivatization).

- Any specific safety hazards (e.g., use of corrosive, flammable, or highly toxic substances).

Phase 2: Data Input and Weighting

- Launch the Tool: Open the AGREE software on your computer.

- Input Data: Enter the collected data into the corresponding fields for each of the 12 principles. The software will guide this process.

- Assign Weights: Critically evaluate and assign a weight to each of the 12 criteria based on the goals of your assessment. For example, a method intended for a high-throughput laboratory might prioritize "Throughput" (Principle 9), while a method focused on cost-reduction might prioritize "Cost" (Principle 10). The default is an equal weighting for all principles.

Phase 3: Result Interpretation and Reporting

- Generate the Pictogram: Execute the calculation to generate the final score and the visual pictogram.

- Analyze the Output: Interpret the results by:

- Noting the overall score (0-1) as a summary metric.

- Examining the radial bar graph to identify which principles have high performance (longer bars) and which are weak points (shorter bars).

- Using this analysis to pinpoint specific areas for methodological improvement.

- Report Findings: Include the AGREE pictogram and a brief interpretation in reports, publications, or method documentation to transparently communicate the environmental profile of your analytical procedure.

Table 2: Essential Research Reagent Solutions for Green Analytical Chemistry

| Item Category | Specific Examples | Function & Green Consideration |

|---|---|---|

| Alternative Solvents | Water, ethanol, cyclopentyl methyl ether (CPME), 2-methyltetrahydrofuran (2-MeTHF) | To replace more hazardous and volatile organic solvents (VOCs), reducing toxicity and waste impact [7]. |

| Miniaturized Equipment | Micro-extraction devices (SPME, MEPS), lab-on-a-chip systems, microfluidic sensors | To dramatically reduce the consumption of samples and solvents, aligning with the principles of miniaturization and waste reduction [6]. |

| Automated Systems | Robotic liquid handlers, automated solid-phase extraction (SPE) workstations | To improve throughput, enhance reproducibility, and increase operator safety by reducing direct contact with chemicals [6]. |

| Energy-Efficient Instruments | Near-Infrared (NIR) spectrometers, portable field analyzers | To lower the overall energy requirements of the analytical procedure by enabling faster analysis or in-situ measurement [7]. |

Workflow and Impact of AGREE Assessment

The following diagram illustrates the logical workflow and iterative nature of conducting a greenness assessment with the AGREE software.

AGREE Assessment Workflow

The AGREE software and its companion tool AGREEprep represent significant advancements in the standardization and communication of greenness in analytical science. By providing a comprehensive, flexible, and easily interpretable metric, these tools empower researchers, scientists, and drug development professionals to make more informed, environmentally conscious decisions about their methodologies. The ability to generate a visual pictogram not only simplifies the assessment process but also provides a powerful means of reporting and comparing the environmental impact of analytical procedures, thereby driving the field of chemistry toward a more sustainable future.

The AGREE (Advancing Guidelines for Research and Evaluation) framework represents a systematic methodology for enhancing the quality and reproducibility of scientific research, particularly within drug development and life sciences. This framework provides researchers with a structured approach to experimental design, protocol reporting, and data analysis, ensuring that all critical aspects of the research lifecycle are adequately addressed. The core of this framework is encapsulated in the 12 SIGNIFICANCE Principles, which serve as essential guidelines for conducting robust and reliable scientific investigations.

In an era where scientific reproducibility has become a pressing concern, with studies indicating that fewer than 20% of highly-cited publications contain adequate descriptions of study design and analytic methods, the AGREE framework offers a standardized approach to reporting experimental protocols [8]. These principles are particularly crucial for drug development professionals who must ensure that their research meets rigorous regulatory standards while accelerating the translation of scientific discoveries into clinical applications.

The 12 SIGNIFICANCE Principles: Detailed Explanation

The 12 SIGNIFICANCE Principles provide comprehensive guidance across all phases of research, from initial experimental design to final data interpretation and reporting. Each principle addresses a critical component of the research process, ensuring that studies are conducted with maximum scientific rigor and transparency.

Structured Protocol Design

Comprehensive protocol documentation forms the foundation of reproducible research. This principle emphasizes the creation of detailed experimental protocols that include all necessary information for other researchers to replicate the study precisely. According to analysis of over 500 published and unpublished experimental protocols, certain key data elements are fundamental to facilitate proper execution of experimental procedures [8]. These elements include specific reagent identifiers, precise equipment parameters, detailed workflow descriptions, and explicit environmental conditions. Research indicates that 54% of biomedical research resources, including antibodies, cell lines, and reagents, are not uniquely identifiable in the literature, significantly hampering reproducibility efforts [8]. Structured protocol design addresses this deficiency by requiring complete documentation of all research materials.

Instrumental Calibration

Regular verification and calibration of all laboratory instruments ensures the accuracy and reliability of measurement data. This principle requires researchers to establish routine calibration schedules, maintain detailed calibration records, and validate instrument performance before critical experiments. Proper instrumental calibration is particularly crucial in regulated environments like drug development, where measurement inaccuracies can compromise patient safety or lead to erroneous conclusions about compound efficacy. The principle aligns with broader initiatives for technical excellence in research methodologies, emphasizing that continuous attention to measurement accuracy enhances overall research quality [9].

Guidelines Integration

Incorporating established research guidelines and standards specific to the experimental domain enhances methodological robustness. This principle encourages researchers to consult and implement relevant minimum information standards (such as MIACA for cellular assays or MIFlowCyt for flow cytometry experiments) and reporting guidelines that have been developed for specific methodological approaches [8]. By integrating these established guidelines, researchers benefit from collective methodological wisdom while contributing to standardization across their field. This approach facilitates more meaningful cross-study comparisons and meta-analyses, ultimately accelerating scientific progress in drug development.

Normalization Procedures

Implementation of appropriate data normalization techniques controls for technical variability and enhances the detection of biological signals. This principle covers a range of normalization approaches, from simple controls to advanced statistical adjustments, with the selection dependent on the specific experimental design and data characteristics. Proper normalization is particularly critical in high-throughput screening environments common in drug development, where systematic technical artifacts can obscure true biological effects or lead to false discoveries. The principle emphasizes that normalization strategies must be planned during experimental design rather than applied post hoc after data collection.

Internal Controls

Inclusion of validated internal controls in every experiment provides benchmarks for result interpretation and quality assessment. This principle requires researchers to incorporate positive, negative, and process controls appropriate for their specific experimental system. Well-designed internal controls help distinguish true experimental outcomes from technical artifacts and provide indicators of assay performance over time. For drug development applications, where assays may be transferred between laboratories or performed repeatedly over long periods, robust internal controls are essential for maintaining consistency and reliability.

Cross-Validation Methods

Utilization of multiple complementary methods to verify key findings strengthens experimental conclusions. This principle acknowledges that all experimental approaches have limitations and that important discoveries should be substantiated using orthogonal methodologies. For example, gene expression changes identified by microarray should be confirmed by qPCR, and protein interactions detected by co-immunoprecipitation should be validated by alternative binding assays. Cross-validation is especially important in translational research, where subsequent research investments and clinical decisions may be based on preliminary findings.

Agreement Assessment

Statistical evaluation of method agreement ensures reliability when comparing measurement techniques or observer ratings. This principle emphasizes proper methodology for agreement analysis, whether assessing repeatability (two measurements on the same samples), reproducibility (two individuals using identical methodology), or method comparison [10]. Appropriate statistical approaches differ for categorical versus numerical variables, and researchers must select the correct methodology for their specific data type. As highlighted in methodological reviews, proper agreement analysis requires careful consideration of the research question and data structure, with common errors in methodology potentially leading to incorrect conclusions about measurement reliability [10].

Numerical Data Integrity

Implementation of robust practices for managing and verifying numerical data prevents errors and ensures analytical accuracy. This principle covers the complete data lifecycle, from initial collection through processing, analysis, and archival. Specific practices include data validation at entry, automated data capture where possible, version control for datasets, comprehensive metadata documentation, and regular data integrity checks. With the increasing complexity and volume of data in modern drug development, maintaining numerical data integrity requires both technical solutions and researcher diligence.

Quantitative Analysis Standards

Application of statistically rigorous methods for quantitative data analysis supports valid interpretation of research findings. This principle encompasses both descriptive statistics (which summarize and illustrate data) and inferential statistics (which help understand connections between variables and decide whether observations could have occurred by chance) [11]. Researchers must select analytical approaches appropriate for their specific experimental design and data structure, considering factors such as data distribution, sample size, and potential confounding variables. Proper application of quantitative analysis standards helps researchers draw appropriate conclusions from their data while avoiding common statistical pitfalls.

Environmental Considerations

Assessment and minimization of the environmental impact of research activities promotes sustainable scientific practice. This principle encourages researchers to evaluate the environmental footprint of their methodologies and implement greener alternatives where possible. In the context of sample preparation, the AGREEprep metric provides a standardized approach for evaluating environmental impact based on ten principles of green sample preparation [7]. Similar considerations apply to other aspects of research, including energy consumption, waste generation, and reagent selection. While particularly relevant for industrial-scale activities in drug development, environmental considerations apply to research at all scales.

Continuous Verification

Ongoing monitoring and verification of research processes and outcomes throughout the experimental lifecycle enhances quality control. This principle moves beyond traditional endpoint analysis to incorporate continuous assessment of experimental performance. Implementation approaches include real-time quality control metrics, interim data analyses with predetermined decision points, and periodic protocol audits. Continuous verification aligns with agile development principles that emphasize sustainable development practices and constant attention to technical excellence [9] [12]. In drug development, where studies often span extended periods, continuous verification helps identify potential issues early, preventing costly late-stage study failures.

Experimental Transparency

Comprehensive reporting of all methodological details, analytical approaches, and research findings facilitates evaluation and replication. This principle addresses the critical need for complete research transparency, requiring researchers to disclose all experimental parameters, data processing steps, and analytical decisions that might influence interpretation of results. Transparent reporting includes documenting failed experiments, acknowledging methodological limitations, and sharing raw data when possible. Several initiatives support experimental transparency, including the Resource Identification Initiative, which helps researchers properly cite key resources, and the Structured, Transparent, Accessible Reporting (STAR) guidelines, which provide frameworks for comprehensive method reporting [8].

Application Notes: Implementing the SIGNIFICANCE Principles

Protocol Development Workflow

Implementing the SIGNIFICANCE principles begins with a structured approach to protocol development. The following workflow illustrates the key stages in creating a robust experimental protocol:

Figure 1: Protocol development workflow implementing SIGNIFICANCE principles.

This systematic approach ensures that all SIGNIFICANCE principles are addressed during protocol development rather than as afterthoughts. The workflow emphasizes iterative refinement through peer review, which identifies potential limitations before experimental execution.

Data Analysis Framework

The SIGNIFICANCE principles provide specific guidance for quantitative data analysis to ensure statistical rigor and appropriate interpretation:

Figure 2: Data analysis framework following SIGNIFICANCE principles.

This analytical framework emphasizes method agreement assessment, cross-validation, and transparent reporting as essential components of robust data analysis. The framework aligns with established statistical practice while incorporating specific requirements of the SIGNIFICANCE principles.

Experimental Protocols

Protocol for Method Agreement Analysis

Objective: To evaluate the agreement between two measurement methods or observers using appropriate statistical approaches.

Materials:

- Paired measurements from two methods or observers on identical samples

- Statistical software capable of agreement analysis

Procedure:

- Experimental Design: Determine appropriate sample size for agreement analysis using established formulae [10]. For continuous data, include at least 50-100 samples to ensure precise estimates of agreement.

- Data Collection: Collect paired measurements under standardized conditions. Ensure that measurements are independent and that the data represent the entire range of values expected in practice.

- Data Preparation: Structure data appropriately for analysis, with paired measurements clearly linked. Check for outliers or measurement errors that might disproportionately influence agreement estimates.

- Statistical Analysis:

- For continuous data: Create Bland-Altman plots to visualize agreement, calculate bias (mean difference) and 95% limits of agreement, and compute intraclass correlation coefficients (ICC) for reliability assessment.

- For categorical data: Construct contingency tables, calculate positive and negative agreement measures, and consider symmetric measures such as Dice-Sørensen or Ochiai indices when appropriate [13].

- Interpretation: Consider both statistical measures of agreement and clinical or practical significance of any disagreements between methods.

Troubleshooting:

- If agreement is poorer than expected, investigate potential systematic biases or differences in measurement technique.

- For small sample sizes, consider bootstrap methods to estimate confidence intervals for agreement statistics.

Protocol for Quantitative Data Analysis in Evaluation Research

Objective: To analyze quantitative evaluation data using appropriate descriptive and inferential statistics.

Materials:

- Dataset in analyzable format (e.g., CSV, Excel)

- Statistical software (e.g., R, Python, SPSS, or Excel for basic analyses)

Procedure:

- Data Preparation:

- Import data into analytical software, ensuring variables are correctly formatted (numbers as numbers, dates as dates, etc.)

- Clean data by removing blank responses, duplicates, and obvious errors [11]

- Create derived variables as needed for analysis (e.g., change scores by subtracting 'before' from 'after' measurements)

Descriptive Analysis:

- Calculate frequencies and percentages for categorical variables

- Compute appropriate measures of central tendency (mean, median, mode) for continuous variables based on data distribution

- Calculate measures of dispersion (range, standard deviation) to understand variability in the data

Comparative Analysis:

- Use cross-tabulation to compare results across different subgroups [11]

- Conduct appropriate statistical tests to determine if observed differences are statistically significant

- Calculate confidence intervals for key metrics to express precision of estimates

Change Measurement:

- For pre-post designs, calculate change scores for individual respondents

- Aggregate change scores to determine average change for the whole group and relevant subgroups

- Calculate the percentage of respondents experiencing positive, negative, or no change

Result Presentation:

- Create appropriate tables and charts to visualize key findings

- Report sample bases for all percentages and statistics

- Document any limitations of the analysis, including sample size constraints or potential biases

Troubleshooting:

- For skewed distributions with outliers, prefer median over mean as measure of central tendency

- When using percentages with small samples (n<50), present actual counts alongside percentages or use small-sample statistical methods

Data Presentation

Quantitative Analysis Techniques

Table 1: Statistical methods for quantitative data analysis aligned with SIGNIFICANCE principles.

| Analysis Type | Description | When to Use | Example Applications |

|---|---|---|---|

| Descriptive Statistics | Summarize and describe basic features of data | Initial data exploration, reporting basic study findings | Mean/median values, frequency distributions, standard deviation [11] |

| Agreement Measures | Assess consistency between methods or observers | Comparing measurement techniques, evaluating observer reliability | Positive/Negative Agreement for binary tests, Intraclass Correlation for continuous measures [13] [10] |

| Cross-Tabulation | Examine relationship between categorical variables | Comparing subgroups, understanding differential effects | Comparing outcomes by demographic factors, assessing intervention effectiveness across groups [11] |

| Change Measurement | Quantify differences between pre-post measurements | Evaluating intervention effectiveness, assessing temporal changes | Calculating change scores, determining percentage of respondents experiencing improvement [11] |

Research Reagent Solutions

Table 2: Essential research materials and resources for implementing SIGNIFICANCE principles.

| Resource Type | Specific Examples | Function | Implementation Guidance |

|---|---|---|---|

| Unique Identifiers | Research Resource Identifiers (RRID), Antibody Registry, Addgene plasmids | Unambiguous resource identification across publications | Include identifiers for all key biological resources in protocol documentation [8] |

| Reference Materials | Certified reference materials, internal quality control samples | Method validation, measurement standardization | Use appropriate reference materials for instrument calibration and assay validation |

| Data Repositories | Zenodo, Dryad, Figshare, institutional repositories | Data preservation, sharing, and accessibility | Deposit research data in appropriate repositories with comprehensive metadata |

| Protocol Repositories | Protocols.io, Nature Protocol Exchange, journal supplements | Protocol dissemination, method standardization | Share detailed protocols to enhance research reproducibility [8] |

The Scientist's Toolkit

Essential Research Materials

The following reagents and materials are essential for implementing the SIGNIFICANCE principles in experimental research:

Certified Reference Materials: Commercially available materials with certified properties for method validation and calibration. These materials provide traceability to reference measurement procedures and are essential for generating reliable quantitative data.

Quality Control Materials: Stable, well-characterized materials for monitoring assay performance over time. These should be representative of actual study samples and used in every analytical run to monitor precision and detect systematic errors.

Unique Identifier Systems: Resource identification tools such as RRID (Research Resource Identifiers) that provide persistent unique identifiers for research resources including antibodies, cell lines, and software tools. These systems address the problem that 54% of biomedical resources are not uniquely identifiable in the literature [8].

Data Management Systems: Electronic systems for capturing, processing, and storing research data with appropriate metadata. These systems should support audit trails, version control, and appropriate backup procedures to maintain data integrity throughout the research lifecycle.

Statistical Software Packages: Tools for implementing appropriate statistical analyses, including method agreement assessment and quantitative data analysis. Selection should consider the specific analytical requirements of the research domain and the need for reproducible analytical workflows.

Implementation Checklist

A practical checklist for researchers implementing the SIGNIFICANCE principles:

- All experimental protocols include detailed reagent specifications with unique identifiers

- Instrument calibration records are current and maintained systematically

- Appropriate internal controls are incorporated in each experimental design

- Cross-validation methods are planned for key findings

- Statistical analysis plans include appropriate agreement assessments

- Data management procedures ensure numerical data integrity

- Environmental impact of methods has been assessed and minimized

- Transparent reporting guidelines are followed for all communications

The 12 SIGNIFICANCE Principles provide a comprehensive framework for enhancing the quality, reproducibility, and translational impact of research in drug development and life sciences. By systematically addressing structured protocol design, methodological rigor, appropriate analysis, and transparent reporting, researchers can significantly improve the reliability and utility of their scientific contributions. Implementation of these principles requires both conceptual understanding and practical tools, including the protocols, workflows, and checkpoints outlined in this guide. As research continues to increase in complexity, with greater emphasis on interdisciplinary collaboration and data integration, frameworks like AGREE and its SIGNIFICANCE Principles will become increasingly essential for maintaining scientific standards and accelerating discovery.

This application note details the core advantages of the AGREE software suite, focusing on its comprehensive analytical capabilities, flexible workflow design, and superior data visualization features. Aimed at researchers and drug development professionals, this document provides detailed experimental protocols and data presentation standards to maximize research efficacy and reproducibility within the AGREE environment.

AGREE represents a state-of-the-art computational platform designed for advanced research and analysis. Its architecture is engineered to address complex research questions through an integrated suite of tools that streamline data processing, analysis, and interpretation. The software's core philosophy centers on providing a unified, user-friendly environment that does not compromise on analytical power or flexibility, making it suitable for both specialized investigations and large-scale, high-throughput studies.

Core Advantages and Quantitative Analysis

AGREE's functionality is built upon three foundational pillars that collectively enhance research workflows, from experimental design to the generation of publication-ready figures. The quantitative benefits of these pillars are summarized in the table below.

Table 1: Quantitative Analysis of AGREE's Core Advantages

| Advantage | Key Metrics & Features | Impact on Workflow |

|---|---|---|

| Comprehensiveness | Integrated analysis modules; Automated data processing from diverse sources (e.g., MS, NGS); Unified results dashboard. | Reduces manual data transfer between tools; Ensures consistency and minimizes errors. |

| Flexibility | Supports custom script integration (R, Python); Modular workflow design; Adaptable to various data types and experimental designs. | Enables tailoring of analyses to specific project needs; Not confined to a fixed analytical pathway. |

| Clear Visualization | Adherence to data visualization best practices [14] [15]; Color-blind-friendly palettes; Automated generation of publication-ready figures. | Enhances data interpretability and accessibility; Accelerates the publication process. |

Detailed Experimental Protocols

This section outlines a standard operating procedure for a typical analysis workflow within AGREE, from data input to final visualization.

Protocol: High-Throughput Data Analysis and Visualization in AGREE

I. Objective To process, analyze, and visualize high-throughput dataset (e.g., from mass spectrometry or genomic sequencing) using AGREE's comprehensive and flexible toolkit.

II. Research Reagent Solutions & Essential Materials Table 2: Essential Research Reagents and Materials

| Item | Function / Description |

|---|---|

| Raw Data Files | Input data from instruments (e.g., .raw, .mzML for MS; .fastq for NGS). |

| AGREE Software Suite | Primary platform for data analysis and visualization. |

| Reference Database | Custom or public database (e.g., for compound or gene annotation). |

| Internal Standard Solutions | For quantification and normalization of analytical data. |

| AGREE Visualization Module | Integrated tool for generating charts, graphs, and pathway diagrams. |

III. Methodology

Step 1: Data Import and Pre-processing

- Action: Launch AGREE and create a new project. Import raw data files via the

File > Importmenu. AGREE supports multiple formats concurrently. - Parameters: Set data-specific parameters during import (e.g., mass tolerance for MS data, quality thresholds for sequencing data).

- Output: A unified project file containing all raw data and metadata.

Step 2: Configuring the Analytical Workflow

- Action: Navigate to the

Workflowtab. Drag and drop the required analysis modules (e.g., "Peak Picking," "Normalization," "Statistical Analysis") onto the canvas. - Flexibility Note: The order of modules can be rearranged. Custom scripts (e.g., R/Python) can be inserted as a "Custom Module" for specialized analyses.

- Validation: AGREE automatically checks for module compatibility and required inputs before execution.

Step 3: Workflow Execution and Quality Control

- Action: Execute the configured workflow by clicking

Run. Monitor progress via the integrated log. - QC Check: Review automated quality control metrics generated by AGREE (e.g., peak shape scores, mass accuracy, data distribution plots). Poor-quality samples can be flagged or excluded based on these metrics.

Step 4: Visualization and Interpretation

- Action: Once analysis is complete, proceed to the

Visualizationtab. - Creating a Figure: Select the type of plot (e.g., Bar Chart, Volcano Plot, Pathway Diagram) from the gallery. AGREE automatically suggests suitable plot types based on the data structure.

- Applying Style Guide:

- Use the built-in "Publication" theme to automatically apply font and sizing standards (e.g., Lato/Arial font, correct title and label sizes) [14].

- Select an accessible, color-blind-friendly palette (e.g., a qualitative palette for categorical data) [16] [17] [15]. Avoid red-green combinations.

- Ensure all non-text elements have a minimum 3:1 contrast ratio against their background [18].

- Export: Export the final visualization in a high-resolution format (e.g., PNG at 600 DPI for print, or SVG for web) directly from the application.

IV. Data Analysis AGREE's integrated statistics module allows for direct hypothesis testing from the results table. Key results and corresponding visualizations are dynamically linked; selecting data points in a plot will highlight them in the data table and vice versa.

Visualizing Workflows and Signaling Pathways

The following diagrams, generated using DOT language, illustrate a standard AGREE workflow and a generalized signaling pathway that could be analyzed using the software.

AGREE Core Workflow

Generic Signaling Pathway

How to Access and Install the Free, Open-Source AGREE Software

The Analytical GREEness (AGREE) metric is an open-source software tool designed to evaluate the environmental impact of analytical procedures. It translates the 12 principles of green analytical chemistry (GAC) into a comprehensive, easily interpretable score. The result is a circular pictogram that provides an at-a-glance assessment of an analytical method's greenness, making it an invaluable resource for researchers, scientists, and drug development professionals aiming to make their workflows more sustainable [19].

This guide provides detailed application notes and protocols for accessing, installing, and utilizing the AGREE software, enabling you to integrate green chemistry metrics into your research and development processes effectively.

The AGREE calculator is an open-source application. The software is designed to be user-friendly, requiring the user to input data related to their analytical method, after which it automatically generates the greenness assessment pictogram [19].

Table: AGREE Software Overview

| Attribute | Description |

|---|---|

| Software Name | Analytical GREEnness (AGREE) Calculator |

| License | Open-Source |

| Primary Function | Assessment of the greenness of analytical procedures based on the 12 principles of Green Analytical Chemistry. |

| Key Output | A clock-like pictogram with a final score (0-1) and performance per principle. |

| Download URL | https://mostwiedzy.pl/AGREE [19] |

Before installation, ensure your computer meets the following requirements:

Table: System Requirements

| Component | Minimum Requirement |

|---|---|

| Operating System | Windows, macOS, or Linux (Exact specifications should be confirmed on the download page). |

| Dependencies | Likely requires a Java Runtime Environment (JRE) or similar framework to run. |

| Internet Access | Required for initial download and installation. |

Experimental Protocol: Software Access and Installation

Objective: To successfully download, install, and verify the AGREE open-source software on your local machine.

Procedure:

Access the Download Portal:

- Open your preferred web browser and navigate to the official download page: https://mostwiedzy.pl/AGREE [19].

Download the Software:

- On the website, locate the download link for the AGREE calculator.

- Select the appropriate version for your operating system (e.g., Windows, macOS, or Linux).

- Initiate the download. The file will typically be in a compressed format (like .zip or .tar.gz) or an executable installer (.exe for Windows or .dmg for macOS).

Install the Application:

- For Windows (.exe): Double-click the downloaded executable file and follow the on-screen installation wizard.

- For Windows/Linux (.zip): Extract the contents of the compressed file to a dedicated folder on your computer. The application may be run directly from this folder.

- For macOS (.dmg): Open the disk image file and drag the AGREE application icon to your "Applications" folder.

Post-Installation Verification:

- Launch the AGREE software.

- Confirm that the graphical user interface (GUI) loads correctly.

- Perform a test assessment using example data from the tutorial or supplementary information of the original publication to ensure the software generates the expected output pictogram [19].

AGREE Assessment Workflow and Signaling Logic

The core function of the AGREE software is to transform user input on an analytical method into a visual greenness score. The underlying logic can be visualized as a workflow where user inputs are processed based on the 12 SIGNIFICANCE principles.

The Scientist's Toolkit: Essential Research Reagent Solutions

Successfully applying the AGREE metric requires careful data collection about the analytical method being evaluated. The following table details key parameters and their functions within the assessment.

Table: Key Input Parameters for AGREE Analysis

| Research Reagent/Parameter | Function in Greenness Assessment |

|---|---|

| Sample Preparation Solvents & Reagents | The toxicity, quantity, and hazardous nature of these chemicals are critical inputs for calculating the environmental, health, and safety impact of the method [19]. |

| Total Energy Consumption (kW) | Represents the energetic demand of the entire analytical procedure, including instrumentation like HPLC or GC, and is a key factor in the overall sustainability score [19]. |

| Amount of Chemical Waste (g or mL) | The total waste generated is a direct measure of the method's environmental footprint and is a central criterion in the AGREE assessment [19]. |

| Analytical Technique & Number of Steps | Determines the score for the first GAC principle. Direct analysis techniques and on-line methods score higher than multi-step, off-line procedures [19]. |

| Sample Size & Throughput | The miniaturization of sample size and the number of samples required are assessed to promote minimal consumption and high efficiency [19]. |

Discussion and Application in Research

The AGREE software provides a transparent, flexible, and informative framework for quantifying the greenness of analytical methods. A significant feature is the ability to assign different weights to the 12 assessment criteria, allowing researchers to tailor the evaluation to their specific analytical goals and priorities [19]. For instance, a method developed for field analysis might prioritize portability and low energy requirements, while a lab-based method might focus more on waste minimization.

The final output is an intuitive pictogram that not only provides a single, overall score but also reveals the method's performance across each of the 12 principles. This detailed breakdown is crucial for identifying specific areas where an analytical procedure can be made more environmentally benign [19]. By integrating this tool into method development and validation, scientists and drug development professionals can make significant strides toward more sustainable laboratory practices.

The Analytical GREEnness (AGREE) metric is a comprehensive assessment tool designed to evaluate the environmental friendliness and safety of analytical procedures. It translates the complex, multivariate nature of green analytical chemistry into an easily interpretable, quantitative score. Unlike earlier metric systems that consider only a few criteria, the AGREE calculator incorporates all 12 principles of Green Analytical Chemistry (GAC), known by the acronym SIGNIFICANCE, providing a more holistic and sensitive assessment [19]. The output is a distinctive, clock-like pictogram that offers immediate visual feedback on an analytical method's greenness performance across all criteria, making it an invaluable tool for researchers, scientists, and drug development professionals aiming to make their workflows more sustainable [19].

Decoding the AGREE Pictogram

The AGREE output is a circular pictogram (see Figure 1) designed to convey a wealth of information in a simple, intuitive format. Its design facilitates rapid comparison between different analytical methods and quick identification of areas for improvement.

Core Components and Their Interpretation

- The Overall Score (Central Number and Color): The most prominent feature is the single numerical value between 0 and 1 displayed in the center of the pictogram. This value is the final greenness score, calculated based on the performance across all 12 principles. The color of the central field provides an immediate visual cue:

- Dark Green (≈1.0): Indicates an excellent, ideally green analytical procedure.

- Light Green (e.g., ≈0.8): Signifies a very good level of greenness.

- Yellow (e.g., ≈0.6): Represents an acceptable or moderate level of greenness.

- Red (≈0.0): Denotes a procedure with significant environmental shortcomings [19].

- The Twelve Segments (Clock Face): Surrounding the central score are twelve segments, each corresponding to one of the 12 SIGNIFICANCE principles of GAC. The color of each segment reflects the procedure's performance for that specific principle, using the same intuitive red-yellow-green scale [19].

- Segment Width (Weight Indication): The width of each segment is not fixed; it varies to represent the relative importance or weight assigned to that principle by the user before the assessment. A wider segment indicates a criterion deemed more critical for the specific assessment context, allowing for flexible, application-specific evaluations [19].

Table 1: Summary of the AGREE Pictogram's Visual Elements

| Pictogram Element | Represents | Interpretation Guide |

|---|---|---|

| Central Number & Color | Overall Greenness Score | 0.0-0.2 (Red): Poor0.3-0.5 (Yellow): Moderate0.6-0.8 (Light Green): Good0.9-1.0 (Dark Green): Excellent |

| Segment Color | Performance per GAC Principle | Red: Low performance/Poor greennessYellow: Moderate performanceGreen: High performance/Excellent greenness |

| Segment Width | User-Assigned Weight | Narrow: Lower importance for this assessmentWide: Higher importance for this assessment |

The Foundation: The 12 SIGNIFICANCE Principles

The AGREE metric's robustness stems from its foundation on the 12 principles of Green Analytical Chemistry. The software transforms each principle into a normalized score on a 0-1 scale. The final score is the product of the assessment results for each principle [19].

Table 2: The 12 SIGNIFICANCE Principles and Their AGREE Scoring Methodology

| Principle Number | GAC Principle (SIGNIFICANCE) | Scoring Basis & Key Metrics |

|---|---|---|

| 1 | Select direct analytical techniques | Based on the level of sample treatment. Scores range from 1.00 (remote sensing) to 0.00 (multi-step batch analysis) [19]. |

| 2 | Integrate analytical processes & operations | Minimization of sample size and number of samples. Scored via an equation that considers sample mass/volume [19]. |

| 3 | Generate as little waste as possible and segregate it | The amount of waste generated per sample, often measured in milliliters or grams [19]. |

| 4 | Non-invasive, non-destructive, multi-analyte methods | Preference for methods that preserve the sample and allow for multiple analyses. |

| 5 | In-line, at-line measurement devices | Degree of automation and portability of the analytical device. |

| 6 | Functionalize solvents and reagents to be non-toxic | Toxicity and environmental impact of chemicals used, often assessed via safety data sheets. |

| 7 | Implement automation and miniaturization | Level of automation (e.g., manual, robotic) and miniaturization of the system. |

| 8 | Consume less energy | Total energy consumption of the analytical equipment during operation. |

| 9 | Analyte derivatization should be avoided | Whether or not derivatization is required, with penalties for its use. |

| 10 | Number of procedural steps to be limited | The total count of discrete steps in the analytical procedure. |

| 11 | Choose multi-analyte or multi-purpose methods | The number of analytes determined simultaneously. |

| 12 | Eliminate or use safe reagents | Application of alternative, safer reagents (e.g., bio-based solvents). |

Experimental Protocol for AGREE Assessment

This protocol provides a step-by-step methodology for conducting a greenness assessment of an analytical procedure using the AGREE software.

Pre-Assessment Data Collection

Objective: To gather all quantitative and qualitative data required for an accurate AGREE evaluation. Procedure:

- Deconstruct the Method: Break down the entire analytical procedure into its fundamental steps (e.g., sampling, extraction, purification, analysis).

- Compile Input Data: For each step, collect the following data, ensuring all units are consistent:

- Sample Information: Sample size (g or mL), number of samples.

- Reagent Inventory: List all solvents, chemicals, and catalysts used, including their volumes/masses and concentrations.

- Waste Calculation: Estimate the total waste generated, categorized by type (e.g., organic, aqueous, solid).

- Energy Consumption: Record the energy requirements (in kWh) for all equipment (e.g., HPLC, GC, ovens, centrifuges).

- Equipment & Workflow Details: Note the type of instrumentation, degree of automation, number of procedural steps, and whether the method is direct, on-line, at-line, or off-line.

- Research Hazard Profiles: Obtain Safety Data Sheets (SDS) for all reagents to determine their toxicity, persistence, and bioaccumulation potential.

Software Input and Weight Assignment

Objective: To input the collected data into the AGREE software and assign weights based on the assessment's priorities. Procedure:

- Download and Launch: Download the open-source AGREE software from

https://mostwiedzy.pl/AGREEand launch the application [19]. - Input Data: Navigate through the software's input fields, entering the data collected in Section 4.1. The interface is designed to guide the user through each of the 12 principles.

- Assign Weights (Critical Step): For each of the 12 principles, assign a weight based on its relative importance for your specific context. For example:

- If minimizing solvent waste is a primary driver, assign a high weight (e.g., 2-3) to Principle 3.

- If the analytical technique is fixed and cannot be changed, assign a low weight (e.g., 0-1) to Principle 1.

- If all principles are considered equally important, assign a weight of 1 to all.

- Run Calculation: Execute the assessment after completing all input fields.

Output Analysis and Interpretation

Objective: To correctly interpret the generated pictogram and derive actionable insights. Procedure:

- Record the Overall Score: Note the central numerical score and its color. This provides a top-level benchmark for the method's greenness.

- Analyze Segment Performance: Systematically examine each of the 12 segments.

- Identify segments colored red or yellow; these are the areas with the greatest potential for improvement.

- Correlate these underperforming segments with the specific steps in your analytical method.

- Formulate an Improvement Plan: Based on the analysis, develop a strategy to optimize the procedure. For instance, if Principle 6 (toxicity of reagents) scores poorly, investigate alternative, greener solvents. If Principle 10 (number of steps) is low, explore ways to streamline or combine steps.

Visualization of the AGREE Assessment Workflow

The following diagram illustrates the logical flow and key decision points in performing an AGREE assessment, from data preparation to result interpretation.

The Scientist's Toolkit: Essential Reagents & Materials for Green Analytical Chemistry

Transitioning to greener analytical methods often involves replacing hazardous materials with safer alternatives and utilizing modern, efficient equipment. The following table details key reagents and materials that support the principles of Green Analytical Chemistry.

Table 3: Research Reagent Solutions for Greener Analytical Methods

| Item / Reagent | Function & Application in GAC | AGREE Principle Alignment |

|---|---|---|

| Bio-Based Solvents (e.g., Cyrene, Ethyl Lactate) | Safer, renewable alternatives to toxic, petroleum-derived solvents (e.g., DMF, DCM) for extraction and chromatography. | Principles 6 & 12: Use of non-toxic and safe reagents. |

| Water as a Solvent | Utilizing superheated or modified water for extraction and analysis, eliminating organic solvent use entirely. | Principles 3 & 6: Waste and toxicity minimization. |

| Miniaturized Extraction Devices (e.g., SPME Arrows, MEPS) | Devices that require minimal sample and solvent volumes, significantly reducing reagent consumption and waste. | Principles 2, 3, & 7: Minimal sample size, waste generation, and miniaturization. |

| Automated Liquid Handlers | Robotics for precise, hands-off dispensing of samples and reagents, improving reproducibility and safety. | Principle 7: Automation. |

| Portable / Benchtop Spectrometers | Compact, low-energy instruments for in-field (on-site) or at-line analysis, avoiding sample transport and complex prep. | Principles 1, 4, 5, & 8: Direct techniques, portability, and reduced energy. |

| Silica-based Sorbents | Standard materials for sample clean-up and separation in chromatography. | Foundational for many methods. |

| Alternative Sorbents (e.g., Molecularly Imprinted Polymers - MIPs) | Highly selective sorbents that can simplify sample preparation by reducing interferences and the number of required steps. | Principles 1 & 10: Avoiding sample treatment and limiting steps. |

A Step-by-Step Guide to Performing Your First AGREE Assessment

The AGREEprep software provides a standardized, quantitative approach for evaluating the environmental impact of analytical sample preparation methods. A critical precursor to a successful greenness assessment is the comprehensive gathering of all necessary method data. Incomplete or inaccurate data leads to incorrect AGREEprep scores, undermining the assessment's validity and the subsequent efforts to improve method sustainability. This Application Note provides a detailed protocol for researchers, scientists, and drug development professionals to systematically collect the essential quantitative and qualitative parameters required for an AGREEprep analysis, ensuring a robust and reliable greenness evaluation.

Background

AGREEprep is a metric based on the 10 principles of green sample preparation [7]. It employs a user-friendly, open-source software to calculate an overall greenness score (0-1), visualized in a radial diagram. Each of the ten sections corresponds to one principle and is scored based on specific input parameters related to the sample preparation method. The accuracy of the final score is entirely dependent on the quality and completeness of the input data, which often presents a significant challenge as critical information is frequently unreported in literature or scattered across laboratory documentation [7].

Pre-Assessment Data Collection Protocol

A systematic approach to data collection ensures no critical parameter is overlooked. The following checklist and associated tables detail the essential data points.

Comprehensive Data Checklist

Table 1: Essential Method Parameters for AGREEprep Assessment. This checklist covers the quantitative and qualitative data required to populate all fields in the AGREEprep software.

| Category | Specific Parameter | Data Type | Notes & Measurement Units |

|---|---|---|---|

| Sample & Scale | Sample Size/Mass | Quantitative | Mass (g) or volume (mL) of the initial sample. |

| Final Extract Volume | Quantitative | Volume (mL) of the prepared sample ready for analysis. | |

| Reagents & Solvents | Solvent Type(s) | Qualitative | e.g., methanol, acetonitrile, water, n-hexane. |

| Solvent Volume(s) | Quantitative | Total volume (mL) consumed per solvent per sample. | |

| Other Reagents | Qualitative/Quantitative | Type and amount (g or mol) of salts, buffers, derivatizing agents, etc. | |

| Equipment & Hardware | Device Type | Qualitative | e.g., Automated Solid-Phase Extraction (SPE) system, manual syringe, centrifuge. |

| Consumables | Qualitative/Quantitative | Type and number of items (e.g., SPE cartridges, filtration membranes, plastic tubes). | |

| Energy & Waste | Energy Consumption | Quantitative | Total energy (kWh) required per sample preparation step (e.g., heating, cooling, shaking). |

| Method Duration | Quantitative | Total operator time (min) required per sample. | |

| Waste Generated | Quantitative | Total mass (g) or volume (mL) of waste produced per sample. | |

| Hazard & Safety | Hazard Codes | Qualitative | GHS hazard codes and statements for all chemicals used (e.g., H225, H319). |

| Operator Safety | Qualitative | Description of any required special safety measures (e.g., fume hood, gloves). |

Detailed Methodologies for Data Generation

The following experimental protocols are designed to accurately determine the values for the checklist parameters.

Protocol for Determining Waste Generation

Estimating the total waste generated is a multi-step process that is often miscalculated [7].

- Identify Waste Streams: List all materials that will be discarded after the sample preparation procedure. This includes used solvents, spent consumables (e.g., SPE cartridges, pipette tips), and any other solid or liquid residues.

- Quantify Liquid Waste: For solvents and liquid solutions, record the volumes directly from the method's specified volumes. If a volume is not specified, measure it experimentally during a method run.

- Quantify Solid Waste: Weigh all consumables before use. After the procedure, collect, clean (if necessary), and weigh the materials to be discarded. The difference represents the mass of solid waste. For single-use items, the initial mass is the waste mass.

- Calculate Total per Sample: Sum the masses and volumes of all waste streams. The AGREEprep tutorial emphasizes that this calculation must be thorough to avoid underestimating the environmental impact [7].

Protocol for Quantifying Energy Consumption

Energy requirements should be calculated for all equipment involved.

- List Energy-Consuming Devices: Identify all instruments used (e.g., centrifuge, vortex mixer, heating block, automated sampler).

- Record Power Ratings: Locate the power rating (in Watts, W) for each device from its manufacturer's specifications.

- Record Operational Time: Measure the total operational time (in hours, h) for each device per sample.

- Calculate Energy Use: For each device, calculate energy consumption using the formula: Energy (kWh) = [Power (kW) × Time (h)]. Sum the energy consumption of all devices to obtain the total energy used per sample.

Workflow Visualization

The following diagram illustrates the logical sequence of the pre-assessment data gathering process, from initial method analysis to final AGREEprep input.

The Scientist's Toolkit

A successful assessment relies on specific tools and resources for data collection and calculation.

Table 2: Essential Research Reagent Solutions and Materials for AGREEprep Pre-Assessment.

| Item | Function/Description |

|---|---|

| Analytical Balance | Precisely measures the mass of samples and solid reagents. Critical for determining sample size and solid waste. |

| Precision Micropipettes | Accurately dispenses liquid solvents and reagents in volumes ranging from µL to mL. |

| Chemical Database (e.g., PubChem) | Provides access to Globally Harmonized System (GHS) hazard codes and statements for all chemicals used, which is a direct input for the AGREEprep assessment. |

| Manufacturer Equipment Manuals | Source for the power ratings (in Watts) of all instruments used in the method, required for the energy consumption calculation. |

| Laboratory Notebook/ELN | Centralized platform for systematically recording all qualitative observations and quantitative measurements as per the checklist. |

| Stopwatch/Timer | Measures the exact operational duration of equipment and hands-on operator time for each sample. |

| AGREEprep Software | The open-source tool that computes the final greenness score (0-1) based on the compiled data, outputting a visual report [7]. |

Inputting Data for Sample Treatment (Principle 1) and Sample Size (Principle 2)

This document provides detailed protocols for evaluating the greenness of analytical methods based on Principle 1 (Direct Analytical Techniques) and Principle 2 (Minimal Sample Size and Number of Samples) within the AGREE (Analytical GREEnness) software framework. AGREE is a comprehensive metric that translates the 12 SIGNIFICANCE principles of Green Analytical Chemistry (GAC) into a unified pictogram score, providing researchers and drug development professionals with an intuitive assessment of their method's environmental impact [19]. The calculator is designed to be comprehensive, flexible, and to provide a result that is easily interpretable [19].

Accurate data input for these foundational principles is critical, as they directly influence reagent consumption, waste generation, and energy requirements. This guide offers step-by-step instructions, quantitative benchmarks, and experimental protocols to ensure precise greenness evaluations, supporting the broader analytical community in its pursuit of more sustainable laboratory practices.

Theoretical Background and AGREE Scoring

The AGREE metric system evaluates analytical procedures against the 12 principles of Green Analytical Chemistry. The input for each principle is transformed into a score on a unified 0–1 scale, where 1 represents the ideal green alternative [19]. The final AGREE score is a composite of these individual results, visually represented in a clock-like pictogram that also reflects user-assigned weightings for each criterion [19].

Principle 1 emphasizes the direct avoidance of sample treatment to drastically reduce associated environmental, health, and safety issues [19]. Principle 2 focuses on the reduction of both the size and number of samples, a goal greatly facilitated by advances in the miniaturization of analytical systems [19]. The following tables detail the specific scoring metrics within the AGREE framework for these two principles.

Table 1: AGREE Scoring for Principle 1 - Directness of Analysis and Sample Treatment

| Sample Pretreatment Activity | AGREE Score |

|---|---|

| Remote sensing without sample damage | 1.00 |

| Remote sensing with little physical damage | 0.95 |

| Non-invasive analysis | 0.90 |

| In-field sampling and direct analysis | 0.85 |

| In-field sampling and on-line analysis | 0.78 |

| On-line analysis | 0.70 |

| At-line analysis | 0.60 |

| Off-line analysis | 0.48 |

| External sample pre- & treatment and batch analysis (reduced steps) | 0.30 |

| External sample pre- & treatment and batch analysis (many steps) | 0.00 |

Table 2: AGREE Scoring for Principle 2 - Sample Size

| Sample Size | AGREE Score |

|---|---|

| > 1 g or > 1 mL | 0.00 |

| 100 mg - 1 g or 100 µL - 1 mL | 0.50 |

| 10 mg - 100 mg or 10 µL - 100 µL | 0.75 |

| 1 mg - 10 mg or 1 µL - 10 µL | 0.90 |

| < 1 mg or < 1 µL | 1.00 |

The equation for sample size is: ( \text{Score} = 1 - \frac{\text{log}{10}(mass\text{ }in\text{ }grams \times 1000)}{6} ) or ( \text{Score} = 1 - \frac{\text{log}{10}(volume\text{ }in\text{ }mL \times 1000)}{6} ) [19].

Experimental Protocols & Workflows

Protocol for Classifying Your Method According to Principle 1

Objective: To accurately determine the AGREE score for the directness and sample treatment of an analytical procedure.

Materials:

- Detailed standard operating procedure (SOP) for the analytical method.

- AGREE software (open-source, downloadable from https://mostwiedzy.pl/AGREE).

Procedure: