A Beginner's Guide to Comparing Green Chemistry Metrics: NEMI, AES, and AGREE

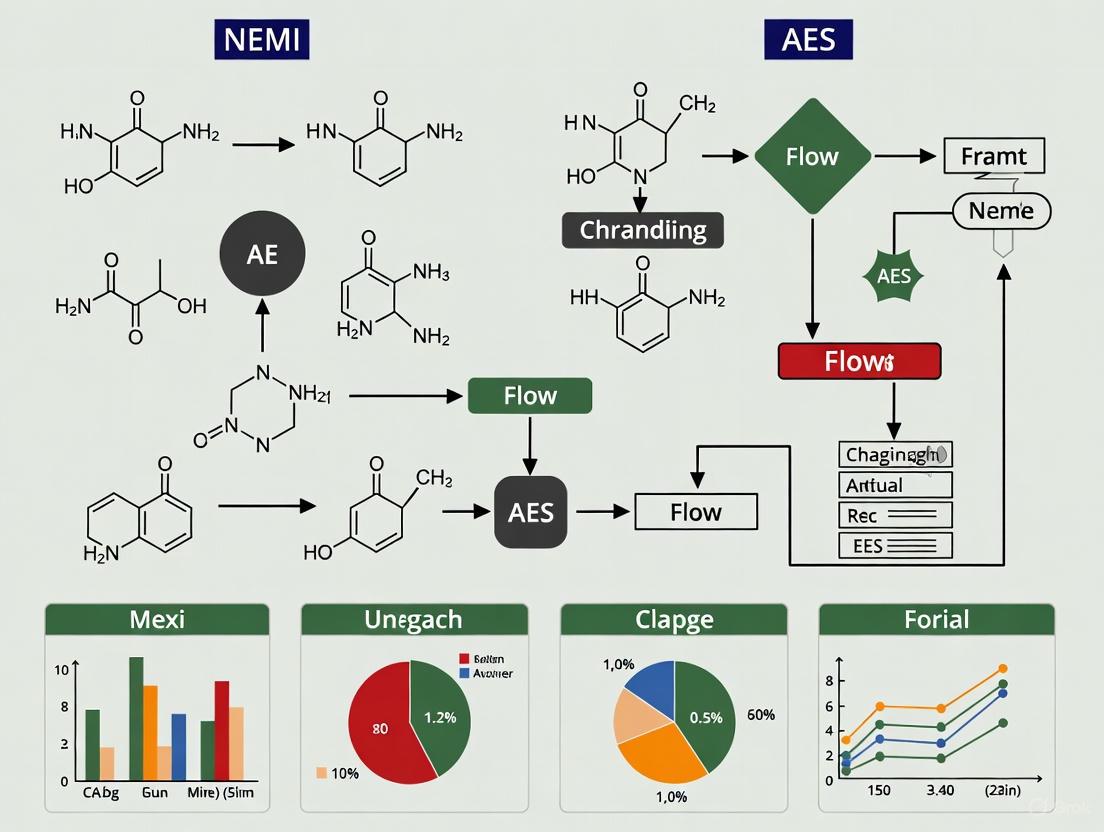

This article provides a foundational guide for researchers, scientists, and drug development professionals on three pivotal green chemistry assessment tools: the National Environmental Method Index (NEMI), Analytical Eco-Scale (AES), and...

A Beginner's Guide to Comparing Green Chemistry Metrics: NEMI, AES, and AGREE

Abstract

This article provides a foundational guide for researchers, scientists, and drug development professionals on three pivotal green chemistry assessment tools: the National Environmental Method Index (NEMI), Analytical Eco-Scale (AES), and Analytical GREEnness (AGREE). It covers the core principles, practical application, and comparative strengths and weaknesses of each metric. Designed for beginners, the content explores how to interpret results, troubleshoot common issues, and strategically select the right tool to validate and improve the environmental sustainability of analytical methods, particularly in pharmaceutical analysis.

Green Chemistry Metrics 101: Understanding NEMI, AES, and AGREE

Green Analytical Chemistry (GAC) is an environmentally conscious methodology within analytical chemistry that aims to mitigate the detrimental effects of analytical techniques on the natural environment and human health [1]. It emerged as an extension of green chemistry, specifically applied to analytical chemistry techniques and procedures [2]. The primary challenge of GAC is to balance the reduction of the adverse effects of analytical procedures on the environment with the improvement of the quality of analysis results [3].

GAC focuses on decreasing or eliminating dangerous solvents, reagents, and other materials while providing rapid and energy-saving methodologies that maintain proper validation parameters [2]. This represents a shift in how analytical difficulties are approached while striving for environmental benignity, addressing health, safety, and environmental issues during analysis [2].

The Principles and Framework of GAC

The 12 Principles of Green Analytical Chemistry

The foundation of GAC is built upon 12 principles that serve as crucial guidelines for implementing greener practices in analytical procedures. These principles were formulated by revising the original 12 principles of green chemistry, selecting four from the original set and incorporating eight additional principles specifically relevant to analytical chemistry [3]. These principles cover various aspects of analytical methods and provide clear guidance for greening laboratory operations [4].

The Triadic Model: From Green to White Analytical Chemistry

The evaluation of analytical methods has evolved into a broader framework known as White Analytical Chemistry (WAC), which integrates three color-coded dimensions [2]:

- Green component: Focuses on environmental sustainability

- Blue component: Assesses methodological practicality

- Red component: Evaluates analytical performance and functionality

This holistic perspective balances environmental impact with functionality, avoiding an unconditional increase in greenness at the expense of analytical performance [1].

The Critical Role of Metrics in GAC

The assessment of a method's greenness is crucial to ensure adherence to sustainability goals and environmental precautions [2]. Traditional green chemistry metrics like E-Factor or Atom Economy are inadequate for assessing the greenness of analytical chemistry, as they don't fully address the unique requirements of analytical processes [2].

Proper GAC tools are essential for [3]:

- Evaluating whether an analytical procedure can be considered "green"

- Providing objective assessment of environmental impact

- Facilitating comparison between different analytical methods

- Identifying areas for improvement in analytical procedures

- Guiding the development of new, more sustainable methods

Without standardized metrics, claims about environmental sustainability remain subjective and difficult to verify, hindering progress in making analytical chemistry more sustainable.

National Environmental Methods Index (NEMI)

NEMI, developed in 2002, is one of the oldest GAC metrics [3]. Its pictogram is a circle divided into four quarters, with each representing a different criterion [3]:

NEMI uses a simple four-quadrant pictogram for greenness assessment. Each quadrant turns green when specific environmental criteria are met [3].

Analytical Eco-Scale (AES)

The Analytical Eco-Scale is a semi-quantitative assessment tool that operates on the principle of assigning a total score of 100 points for an ideal green analysis [3]. Penalty points are subtracted based on [3]:

- Amounts of solvents or reagents used

- Energy consumption

- Hazards of chemicals used

- Quantity of waste produced

To be considered an "ideal green analysis," an analytical method must meet three conditions [3]:

- Solvents or reagents used should not pose any health, environmental, or physical hazards

- Energy consumed for each sample should be less than 0.1 kWh

- No waste should be produced during analytical procedures

Analytical Greenness (AGREE) Metric

AGREE is a comprehensive assessment tool based on the 12 principles of GAC [2]. It provides both a unified circular pictogram and a numerical score between 0 and 1, enhancing interpretability and facilitating direct comparisons between methods [2]. The tool's strength lies in its comprehensive coverage and user-friendly interface, though it doesn't sufficiently account for pre-analytical processes [2].

Evolution of GAC metrics from basic binary assessment to comprehensive evaluation frameworks that cover multiple aspects of environmental impact [3] [2].

Comparative Analysis of NEMI, AES, and AGREE

Quantitative Comparison of Key Metrics

Table 1: Comprehensive Comparison of Three Primary GAC Assessment Tools

| Feature | NEMI | Analytical Eco-Scale | AGREE |

|---|---|---|---|

| Year Developed | 2002 [3] | 2012 [3] | More recent advancement [2] |

| Assessment Type | Qualitative binary [3] | Semi-quantitative [3] | Quantitative (0-1 score) [2] |

| Visual Output | 4-quadrant pictogram [3] | Numerical score only [2] | Circular pictogram with score [2] |

| Key Criteria | PBT chemicals, hazardous waste, pH, waste amount [3] | Reagent toxicity, energy use, waste generation [3] | All 12 GAC principles [2] |

| Scoring System | Pass/Fail for each criterion [3] | Penalty points from ideal 100 [3] | 0-1 scale with weighting [2] |

| Strengths | Simple, immediate visual assessment [3] | Facilitates method comparison, quantitative [3] | Comprehensive, user-friendly, covers full workflow [2] |

| Limitations | General information only, time-consuming search, not quantitative [3] | Relies on expert judgment, no visual component [2] | Subjective weighting, limited pre-analytical coverage [2] |

| Best Use Case | Preliminary screening, basic compliance checking [3] | Educational contexts, direct method comparison [2] | Comprehensive evaluation, research applications [2] |

Detailed Methodologies and Experimental Protocols

Implementing NEMI Assessment

The NEMI assessment protocol involves four specific checkpoints [3]:

- PBT Assessment: Verify that chemicals used are not on the Persistent, Bioaccumulative, and Toxic chemicals (PBT) list

- Hazardous Waste Check: Confirm no solvents are present on D, F, P, or U hazardous wastes lists

- pH Verification: Ensure sample pH remains between 2 and 12 throughout the procedure

- Waste Quantification: Calculate total waste produced is no more than 50 g

Each criterion is represented by one quadrant in the NEMI pictogram, which turns green when the requirement is met or remains blank if not [3].

Applying the Analytical Eco-Scale

The Analytical Eco-Scale methodology follows these steps [3]:

- Start with a base score of 100 points representing an ideal green analysis

- Subtract penalty points for each parameter:

- Reagent hazards: 1-20 points based on toxicity and amount

- Waste amount: 0-5 points based on quantity generated

- Energy consumption: 0-10 points based on kWh per sample

- Other occupational hazards: 0-15 points

- Interpret the final score:

- >75: Excellent green analysis

- 50-75: Acceptable green analysis

- <50: Insufficient green character

The penalty points are assigned based on detailed tables that specify point deductions for various levels of hazardous materials and energy consumption [3].

Executing AGREE Evaluation

The AGREE assessment protocol incorporates [2]:

- Input Collection: Gather data on all 12 GAC principles including sample preparation, reagent use, energy consumption, and waste management

- Weighting Assignment: Apply subjective weighting to different criteria based on their relative importance

- Score Calculation: The tool calculates a final score between 0 and 1, with higher scores indicating better greenness

- Pictogram Generation: The output includes a circular visual representation with colored segments indicating performance in different areas

AGREE provides the most comprehensive evaluation but requires more detailed data collection than the other methods [2].

Advanced and Specialized GAC Metrics

Recent Developments in GAC Assessment

The field of GAC metrics continues to evolve with several advanced tools recently developed [3] [2]:

AGREEprep: The first tool dedicated exclusively to evaluating the environmental impact of sample preparation, addressing a crucial but often overlooked part of the analytical workflow [2]

ComplexGAPI: Extends GAPI assessment to explicitly incorporate preliminary steps, making it especially relevant for material-based testing [2]

Carbon Footprint Reduction Index (CaFRI): Estimates and encourages reduction of carbon emissions associated with analytical procedures, aligning with climate-focused sustainability goals [2]

Analytical Green Star Analysis (AGSA): Uses a star-shaped diagram to represent performance across multiple green criteria including reagent toxicity, waste generation, energy use, and solvent consumption [2]

The Researcher's Toolkit for GAC Implementation

Table 2: Essential Research Reagent Solutions and Materials for Green Analytical Chemistry

| Item Category | Specific Examples | Function in GAC | Green Alternatives |

|---|---|---|---|

| Extraction Techniques | Liquid-Liquid Extraction, Soxhlet [5] | Traditional sample preparation | Solid Phase Microextraction, Stir-Bar Sorptive Extraction [5] |

| Solvents | Chloroform, hexane, other hazardous solvents [3] | Sample preparation and analysis | Bio-based reagents, less toxic alternatives [2] |

| Sample Containers | Glass vials, plastic containers [5] | Sample storage and processing | Reusable containers, appropriate material selection [5] |

| Preservation Chemicals | Acids, bases, other additives [5] | Sample preservation for stability | Green alternatives with less environmental impact [5] |

| Digestion Reagents | Strong acids, oxidizers [5] | Metal analysis preparation | Microwave-assisted digestion, reduced reagent volumes [5] |

| Derivatization Agents | Various chemical modifiers [5] | Enhancing detection for GC/HPLC | Method optimization to avoid derivatization [2] |

| Calibration Standards | Pure analyte compounds [5] | Instrument calibration | Minimized use, proper disposal [5] |

| Quality Control Materials | Reference materials, spiking solutions [5] | Ensuring analytical accuracy | Green solvent alternatives, reduced volumes [2] |

The evolution of greenness metrics in analytical chemistry reflects a growing global commitment to sustainable scientific practices [2]. From early binary tools like NEMI to advanced, multidimensional models such as AGREE, the field has progressed toward more holistic and user-friendly assessments [2]. These metrics enable chemists to design, select, and implement methods that are both scientifically robust and ecologically sustainable, balancing the reduction of environmental impact with the maintenance of analytical performance [3]. For researchers beginning in this field, understanding the comparative strengths and limitations of NEMI, Analytical Eco-Scale, and AGREE provides a foundation for selecting appropriate assessment tools based on specific analytical needs and sustainability goals.

In the field of analytical chemistry, Green Analytical Chemistry (GAC) principles have gained significant importance for reducing the environmental impact of analytical procedures [1]. To evaluate and compare the greenness of analytical methods, several assessment tools have been developed, including the National Environmental Method Index (NEMI), Eco-Scale Assessment (ESA), Green Analytical Procedure Index (GAPI), and Analytical GREEnness (AGREE) [1] [6]. Among these, NEMI represents one of the simpler, pictorial tools designed to provide analysts with a quick, at-a-glance assessment of a method's environmental impact [6].

NEMI functions as a qualitative assessment tool that generates a pictogram divided into four quadrants, each representing a different environmental criterion [6]. This tool was developed in response to the growing awareness of environmental sustainability concerns within analytical chemistry [1]. While newer metrics like AGREE and GAPI offer more comprehensive and quantitative evaluations [6], NEMI remains relevant as an introductory tool for beginners in greenness assessment due to its straightforward visual approach and ease of interpretation.

Principles and Methodology of NEMI

The NEMI Pictogram and Assessment Criteria

The NEMI assessment results in a simple pictogram that provides a visual representation of an analytical method's environmental impact. The pictogram consists of a circle divided into four quadrants, with each quadrant indicating whether the method meets one of four specific environmental criteria [6]. A quadrant is colored green if the criterion is met, or remains empty/white if it is not met.

Table 1: The Four Criteria of the NEMI Assessment

| Criterion | Requirement for Green Quadrant | Environmental Concern Addressed |

|---|---|---|

| PBT | Method uses no Persistent, Bioaccumulative, and Toxic chemicals | Long-term environmental contamination and toxicity |

| Hazardous | Method uses no reagents classified as hazardous (corrosive, reactive, toxic, or ignitable) | Immediate safety risks to personnel and ecosystem |

| Corrosive | Method uses no solutions with pH ≤2 or ≥12 | Material degradation and safety hazards |

| Waste | Method generates ≤50 g of waste per analysis | Resource consumption and waste management |

The fundamental principle behind NEMI is to quickly identify whether an analytical method utilizes any chemicals of significant environmental concern or generates excessive waste [6]. This binary (pass/fail) approach to each criterion makes NEMI particularly accessible for those new to green chemistry principles.

Protocol for Applying the NEMI Assessment

Applying NEMI to evaluate an analytical method involves a systematic examination of the chemicals and materials used throughout the analytical procedure. The following protocol outlines the step-by-step methodology:

Chemical Inventory Compilation: Create a comprehensive list of all reagents, solvents, and chemicals used in the analytical procedure, including those for sample preparation, mobile phases, derivatization, and detection [7].

PBT Assessment: For each chemical on the inventory, consult safety data sheets and regulatory lists to determine if it is classified as persistent, bioaccumulative, and toxic. If any chemical meets the PBT criteria, the corresponding quadrant in the NEMI pictogram remains uncolored [6].

Hazard Evaluation: Review each chemical for hazardous properties including corrosivity, reactivity, toxicity, and ignitability. If any hazardous chemicals are identified, the hazardous quadrant remains uncolored [6].

pH Assessment: Identify if any solutions used in the method have extreme pH values (≤2 or ≥12). This includes extraction solutions, mobile phases, and cleaning solutions. If such solutions are present, the corrosive quadrant remains uncolored [6].

Waste Calculation: Calculate the total amount of waste generated per analysis, including solvents, reagents, and consumables. If this exceeds 50 g, the waste quadrant remains uncolored [6].

Pictogram Generation: Create the NEMI pictogram with the appropriate quadrants colored green based on the above assessments.

NEMI Assessment Workflow

Comparative Analysis of Greenness Assessment Tools

NEMI in the Context of Other Assessment Metrics

When comparing NEMI to other greenness assessment tools, it is important to understand their fundamental differences in approach, complexity, and output. The following table provides a comparative analysis of four prominent greenness assessment tools:

Table 2: Comparison of Greenness Assessment Tools for Analytical Methods

| Tool | Assessment Type | Scoring System | Key Characteristics | Best Use Cases |

|---|---|---|---|---|

| NEMI | Qualitative | Pictogram (4 quadrants) | Simple, binary criteria, visual output | Quick screening, educational purposes |

| ESA (Eco-Scale) | Quantitative | Numerical score (0-100) | Penalty points system, higher score = greener | Ranking methods by overall environmental impact |

| GAPI | Semi-quantitative | Pictogram (15 parameters) | Multi-criteria assessment, more detailed than NEMI | Comprehensive evaluation of method greenness |

| AGREE | Quantitative | Numerical score (0-1) with pictogram | Incorporates all 12 GAC principles, automated calculation | Holistic assessment aligning with GAC fundamentals |

Comparative studies have demonstrated that NEMI's primary limitation is its lack of discrimination power. In one study evaluating 16 chromatographic methods for hyoscine N-butyl bromide assay, NEMI classified 14 methods with identical pictograms despite their different environmental impacts [6]. This oversimplification can be problematic when trying to distinguish between methods with subtle but important environmental differences.

Case Study: Application to Chromatographic Methods

A practical example illustrating the application of NEMI in comparison to other tools can be found in the development of analytical methods for pharmaceutical compounds. In a study comparing normal-phase (NP) and reversed-phase (RP) high-performance thin-layer chromatography (HPTLC) for the analysis of ertugliflozin, researchers applied four different greenness assessment tools, including NEMI [7].

The NP-HPTLC method utilized chloroform/methanol (85:15 v/v) as the mobile phase, while the RP-HPTLC method employed ethanol-water (80:20 v/v) [7]. When evaluated using NEMI, the RP-HPTLC method likely demonstrated superior greenness due to its use of ethanol and water instead of the more hazardous chloroform used in the NP-HPTLC method. This case study exemplifies how NEMI can quickly identify methods that utilize less hazardous solvents, though it may not capture more nuanced environmental trade-offs.

Table 3: Research Reagent Solutions in Green Analytical Chemistry

| Reagent/Chemical | Function in Analytical Methods | Greenness Considerations |

|---|---|---|

| Chloroform | Organic solvent in NP chromatography | PBT concern, hazardous, generally avoided in green methods [7] |

| Ethanol | Greener solvent in RP chromatography | Less hazardous, biodegradable, preferred in green methods [7] |

| Methanol | Organic solvent in mobile phases | Hazardous but commonly used; requires proper waste management [7] |

| Water | Green solvent in RP chromatography | Non-hazardous, non-toxic, ideal green solvent [7] |

| Acetonitrile | Organic modifier in HPLC/UHPLC | Hazardous, requires proper disposal [8] |

Limitations and Complementary Use with Other Tools

Critical Limitations of the NEMI Approach

While NEMI provides a straightforward introduction to greenness assessment, it possesses several significant limitations that researchers must recognize:

Limited Scope: NEMI evaluates only four environmental criteria, neglecting other important green chemistry principles such as energy consumption, operator safety, and sample throughput [6].

Binary Assessment: The pass/fail approach lacks granularity, potentially grouping methods with substantially different environmental impacts under the same pictogram [6].

No Quantitative Scoring: Unlike ESA or AGREE, NEMI does not provide a numerical score, making it difficult to rank methods or track incremental improvements in greenness [6] [7].

Oversimplification: The tool does not account for the relative quantities of hazardous chemicals used, potentially penalizing methods that use minimal amounts of necessary reagents [6].

These limitations were clearly demonstrated in a comparative study where NEMI was found to be the "least effective in providing information about the analytical method" compared to ESA, GAPI, and AGREE [6].

Strategic Implementation for Beginners

For researchers new to greenness assessment, NEMI serves as an excellent introductory tool before progressing to more comprehensive metrics. A recommended approach includes:

Preliminary Screening: Use NEMI for initial method selection or quick comparisons between established methods.

Educational Tool: Utilize NEMI's straightforward criteria to introduce team members to fundamental green chemistry concepts.

Progressive Implementation: Begin with NEMI assessment, then incorporate more sophisticated tools like AGREE or GAPI for comprehensive evaluation.

Complementary Use: Apply NEMI alongside other metrics, recognizing that each tool provides different insights into method greenness.

Progressive Learning Path for Greenness Assessment

The National Environmental Method Index represents a foundational approach to greenness assessment in analytical chemistry. Its simplified pictorial output provides an accessible entry point for researchers, scientists, and drug development professionals beginning to incorporate environmental considerations into their method development and selection processes. However, its limitations necessitate complementary use with more advanced tools like ESA, GAPI, and AGREE for comprehensive environmental impact assessment [6].

For beginners in greenness assessment, NEMI offers a conceptual framework for understanding the basic principles of green analytical chemistry. As expertise develops, researchers should progressively incorporate more sophisticated assessment tools that provide quantitative scoring and address a broader range of environmental parameters. This graduated approach ensures both immediate practical application and long-term development of robust green chemistry practices in analytical method development.

The Analytical Eco-Scale (AES) is a semi-quantitative metric tool widely used in Green Analytical Chemistry (GAC) to assess the environmental impact and safety of analytical methods [3]. Proposed by Gałuszka et al. in 2012, it operates on a straightforward penalty point system that evaluates methods against an ideal green analysis [9] [3] [10]. The AES provides researchers, scientists, and drug development professionals with a practical approach to compare and improve the environmental footprint of their analytical procedures, making it an essential component in the move toward more sustainable laboratory practices [3] [10].

Within the broader context of greenness assessment tools, the AES occupies an important position. While simpler than comprehensive metrics like the Green Analytical Procedure Index (GAPI) and the Analytical Greenness Calculator (AGREE), its strength lies in its simplicity and ease of use [3] [10]. For beginners in GAC research, understanding the AES provides a foundational knowledge of how greenness principles can be translated into a practical scoring system, creating a gateway to more complex assessment methodologies [9].

The Fundamental Principles of the Analytical Eco-Scale

The core principle of the AES is the assignment of a total score out of 100 points for an ideal green analysis [3] [10]. From this perfect score, penalty points (PPs) are subtracted based on the amounts of hazardous reagents or solvents used, the energy consumption of the instrumentation, and the quantity of waste generated [3]. The calculation follows a simple formula:

Analytical Eco-Scale Score = 100 − Total Penalty Points

According to the established criteria, an analytical method is considered:

- Excellent green analysis if the score is higher than 75 [10].

- Acceptably green with a score in the range of 50 to 75 [10].

- Inadequately green if the score is below 50 [10].

An "ideal green analysis" must simultaneously fulfill three strict conditions:

- No reagents or solvents used pose any health, environmental, or physical hazards [3].

- The energy consumed per sample is less than 0.1 kWh [3].

- The analytical procedure generates no waste [3].

It is acknowledged that very few analytical methods, typically only direct analysis techniques without sample processing, can meet all these criteria and achieve a perfect score [3].

The Penalty Point Scoring System

The penalty points are assigned based on four major categories: reagent quantity and hazard, occupational hazards, energy consumption, and waste generation [3] [10]. The following tables detail the structured penalty point system.

Table 1: Penalty Points for Reagents Based on Quantity and Hazard [3]

| Reagent Hazard | Penalty Points for Reagent Amount Used per Sample | ||

|---|---|---|---|

| Extremely toxic (PPD* 1-10) | > 10 mL: 5 PP | 1-10 mL: 4 PP | < 1 mL: 3 PP |

| Toxic (PPD 11-100) | > 10 mL: 4 PP | 1-10 mL: 3 PP | < 1 mL: 2 PP |

| Harmful (PPD 101-1000) | > 10 mL: 3 PP | 1-10 mL: 2 PP | < 1 mL: 1 PP |

| Non/high PPD (>1000) | > 10 mL: 2 PP | 1-10 mL: 1 PP | < 1 mL: 0 PP |

*PPD: Probable Poisonous Dose

Table 2: Penalty Points for Occupational Hazards, Waste, and Energy [3] [10]

| Category | Criteria | Penalty Points |

|---|---|---|

| Occupational Hazard | Use of reagents requiring special personal protective equipment or laboratory design | 1-3 PP |

| Waste Generated | More than 50 mL per sample | 4 PP |

| 10 - 50 mL per sample | 3 PP | |

| 1 - 10 mL per sample | 2 PP | |

| Less than 1 mL per sample | 1 PP | |

| Energy Consumption | > 1.5 kWh per sample | 3 PP |

| 0.1 - 1.5 kWh per sample | 2 PP | |

| < 0.1 kWh per sample | 0 PP |

Experimental Protocol for Applying the Analytical Eco-Scale

Applying the AES is a systematic process. The following workflow and protocol guide you through the steps of calculating an AES score for an analytical method.

Step-by-Step Calculation Protocol

- Method Definition and Inventory: Precisely define all steps of the analytical procedure. Create a comprehensive inventory of all reagents, their exact volumes or masses used per sample, and the instrumentation involved, noting operational times and energy requirements [3] [10].

- Reagent Hazard Assessment: For each reagent, consult its Safety Data Sheet (SDS) to determine its hazard classification (e.g., toxic, harmful). Use this classification and the volume used per sample to assign penalty points according to Table 1 [3].

- Occupational Hazard Evaluation: Assess if any reagents require special handling, personal protective equipment (PPE) beyond standard lab wear, or a specific laboratory design. Assign 1 to 3 penalty points accordingly [3].

- Energy Consumption Calculation: Estimate the total energy consumed per sample in kWh. Consider the power rating of all instruments used (e.g., HPLC oven, detector, centrifuge) and their total operational time for a single sample. Assign penalty points based on Table 2 [10].

- Waste Quantification: Calculate the total volume of waste generated per sample, including used solvents, sample residues, and cleaning materials. Assign penalty points based on the waste volume ranges in Table 2 [3].

- Final Score Calculation and Interpretation: Sum all assigned penalty points. Subtract the total from 100 to obtain the final AES score. Interpret the result using the classification: >75 (Excellent green), 50-75 (Acceptably green), <50 (Inadequately green) [10].

AES in the Broader Context of Greenness Assessment

The landscape of Green Analytical Chemistry (GAC) features several metric tools, each with unique characteristics. The following diagram and table place AES within this ecosystem, highlighting its role alongside other common tools.

Table 3: Comparison of AES with NEMI and AGREE for Beginner Research [3] [10]

| Feature | NEMI | Analytical Eco-Scale (AES) | AGREE |

|---|---|---|---|

| Type of Output | Qualitative (Pass/Fail) | Semi-Quantitative (Numerical Score) | Quantitative (Score 0-1) |

| Basis of Assessment | 4 criteria (PBT, hazardous waste, pH, waste <50g) | Penalty points for reagents, hazards, energy, waste | All 12 principles of GAC |

| Ease of Use for Beginners | Very simple, but provides limited information | Straightforward, easy to calculate and interpret | More complex, requires software, but more comprehensive |

| Key Advantage | Quick, visual pictogram | Simple, provides a single numerical score for easy comparison | Most comprehensive and descriptive result |

| Key Limitation | Lacks granularity; no volume or energy consideration | Does not cover all GAC principles in depth | Can be more time-consuming to apply |

| Ideal Use Case | Initial, quick screening of methods | Introductory tool for learning GAC; quick comparative studies | In-depth development and validation of new green methods |

For beginners, the AES serves as an excellent introductory tool due to its straightforward calculation. Its semi-quantitative nature offers more granularity than the purely qualitative NEMI, while being less complex than the comprehensive, principle-based AGREE calculator [3] [10]. A strong understanding of AES creates a solid foundation for progressing to more advanced metrics like GAPI and AGREE, which evaluate the entire analytical procedure from sample collection to final determination more comprehensively [9] [10].

The Scientist's Toolkit: Essential Reagents and Materials

The application and improvement of the AES score in analytical methods often involve a focus on key reagents and instrumentation. The following table lists critical items and their functions in the context of developing greener analytical methods.

Table 4: Key Research Reagent Solutions and Materials in Green Analytical Chemistry [3] [10]

| Item / Reagent | Function in Analytical Chemistry | Consideration for Greenness (AES) |

|---|---|---|

| Ethanol | Less toxic alternative solvent for extraction and chromatography | High PPD; lower penalty points compared to acetonitrile or methanol [3]. |

| Water | Primary green solvent for extractions and mobile phases | Non-hazardous; typically incurs 0 penalty points, ideal for green profiles [3]. |

| Solid-Phase Microextraction (SPME) Fiber | Solvent-less sample preparation and pre-concentration | Eliminates solvent waste, significantly reducing waste penalty points [10]. |

| Microwave Digestion System | Sample preparation and digestion using energy-efficient heating | Reduces reagent consumption and processing time, lowering energy and waste penalties [3]. |

| UPLC/HPLC System | High-efficiency chromatographic separation | Higher energy consumption can incur penalty points; but improved efficiency may reduce overall solvent waste [3] [10]. |

| Acetonitrile | Common organic solvent for HPLC mobile phases | Often classified as toxic; leads to high penalty points due to hazard and volume used [3]. |

The Analytical Eco-Scale provides a foundational, semi-quantitative, and practical framework for assessing the environmental impact of analytical methods. Its straightforward penalty point system makes it an invaluable tool for researchers, scientists, and drug development professionals who are beginning their journey in Green Analytical Chemistry. By enabling the calculation of a single, comparable score, the AES fosters a mindset of continuous improvement toward sustainability. While advanced tools like AGREE offer a more comprehensive evaluation, mastering the AES equips beginners with the essential concepts needed to understand, apply, and critically evaluate greenness metrics, thereby contributing to the development of safer and more environmentally responsible analytical practices in pharmaceutical development and beyond.

The core objective of Green Analytical Chemistry (GAC) is to protect both people and the environment from the harmful effects of analytical waste, with researchers actively promoting sustainable development through its principles [11]. The movement towards GAC has necessitated the development of tools to quantify and compare the environmental impact of analytical methods. Several green assessment tools are commonly applied, including the National Environmental Methods Index (NEMI), Analytical Eco-Scale (AES), and the Analytical GREEnness (AGREE) metric tool [11]. AGREE stands out as a comprehensive, user-friendly scoring model that provides an easily interpretable overview of a method's environmental performance.

The AGREE Metric: Core Principles and Calculation

AGREE is one of the most recent and advanced tools for evaluating the greenness of analytical methods. Its primary advantage lies in its ability to provide a unified, holistic score, simplifying the comparison between different methodologies.

The 0-1 Scoring System and Output Interpretation

The AGREE tool calculates a final score on a scale from 0 to 1 [11]. This score is derived from an algorithm that assesses the analytical method against 12 fundamental principles of Green Analytical Chemistry. The output is typically represented in a circular pictogram, where the circle is divided into 12 segments, each corresponding to one principle. The closer the final score is to 1, the greener the analytical procedure is deemed to be. This intuitive visual and numerical output allows scientists to quickly gauge a method's environmental acceptability and identify specific areas for improvement.

Comparative Analysis of Greenness Assessment Tools

To effectively position AGREE within the scientist's toolkit, it is essential to compare it with other established metrics. The following table summarizes the key characteristics of NEMI, AES, and AGREE.

Table 1: Comparison of Major Greenness Assessment Metrics

| Feature | NEMI | Analytical Eco-Scale (AES) | AGREE |

|---|---|---|---|

| Basis of Assessment | A qualitative pictogram with four criteria [11] | A penalty points system [11] | 12 principles of GAC [11] |

| Output Format | A pictogram with four colored quadrants [7] | A total numerical score [11] | A unified score from 0-1 and a circular pictogram [11] |

| Primary Advantage | Simple, quick visual representation | Provides a semi-quantitative total score | Comprehensive, quantitative, and user-friendly [11] |

| Primary Disadvantage | Lacks granularity and quantitative output | The penalty points can be subjective | A relatively new tool with a shorter track record |

A practical application of these tools can be seen in a 2024 study comparing Normal-Phase (NP) and Reversed-Phase (RP) HPTLC methods for analyzing an antidiabetic drug. The study employed four greenness metrics, including NEMI and AGREE, and concluded that the RP-HPTLC method was greener than the NP-HPTLC approach based on all validation and greenness data [7].

AGREE in Practice: Experimental Protocols and Workflow

The application of AGREE is best understood in the context of a real-world analytical development workflow. A 2024 study on the determination of melatonin (MEL) in various products provides an excellent model protocol [11].

Detailed Methodology from a Cited Experiment

The study developed and validated three separate HPLC methods for MEL analysis, all designed with green principles in mind [11]:

- HPLC-PDA: Utilized a Photo Diode Array detector.

- HPLC-FLD: Utilized a Fluorescence detector, offering higher sensitivity.

- HPLC-ELSD: Utilized an Evaporative Light Scattering Detector.

Chromatographic Conditions:

- Column: C18 column (5 µm particle size, 250 mm x 4.6 mm i.d.)

- Mobile Phase: A mixture of only water and ethanol (HPLC grade) in a ratio of 30:70 (v/v) for the PDA and FLD methods, and 50:50 (v/v) for the ELSD method.

- Flow Rate: 1.0 mL/min for all methods.

- Detection: Specific wavelengths or settings for each detector type (PDA: 229 nm; FLD: Ex/Em 229/348 nm; ELSD: evaporator temperature 50°C).

- Sample Preparation: Involved dissolving samples in the ethanol-water mobile phase, followed by filtration using a polyvinylidene fluoride (PVDF) syringe filter.

Key Green Features: The protocol explicitly avoided toxic organic solvents like acetonitrile or methanol, using a more environmentally friendly ethanol-water mixture throughout all steps, which positively influenced the green profile [11].

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key materials used in the cited green HPLC experiment and their functions [11].

Table 2: Research Reagent Solutions for Green HPLC Analysis

| Item | Function / Rationale |

|---|---|

| C18 Column | Standard stationary phase for reversed-phase separation. |

| Ethanol (HPLC Grade) | Eco-friendly alternative to toxic solvents like acetonitrile or methanol. |

| Ultra-pure Water | The second component of the green mobile phase. |

| PVDF Syringe Filter | For filtering sample solutions to remove particulate matter that could damage the HPLC system. |

| Melatonin Standard | High-purity reference material for method calibration and validation. |

Workflow and Signaling Pathways for Green Method Development

The process of developing and validating an analytical method with integrated greenness assessment follows a logical sequence. The diagram below outlines this workflow, culminating in the application of the AGREE tool.

Green Method Development Workflow

AGREE represents a significant step forward in the standardization of environmental impact assessment for analytical methods. Its comprehensive 0-1 scoring model, based on the 12 principles of GAC, provides a clear, quantitative, and easily communicable measure of greenness. When used in conjunction with other tools like NEMI and AES as part of a broader thesis, it offers beginners and seasoned researchers a robust framework for developing, validating, and selecting analytical methods that align with the critical goals of sustainability and environmental protection. The continued adoption of AGREE will undoubtedly accelerate the integration of green chemistry principles into mainstream analytical science, particularly in regulated fields like pharmaceutical development.

In research, particularly within fields like drug development and analytical chemistry, the choice of methodology is paramount. Approaches are broadly categorized based on the nature of the data they produce and the type of knowledge they generate. Qualitative research deals with words and meanings to understand concepts, thoughts, and experiences, while quantitative research deals with numbers and statistics to test theories and hypotheses [12] [13]. Occupying a middle ground between these two is the semi-quantitative approach, which provides an approximate measurement whose results can be ordered on an ordinal scale (e.g., small, moderate, large) but lack the precision of fully quantitative data [14].

Understanding these distinctions is crucial for researchers, scientists, and drug development professionals. The rigor of a study, the type of data collection and analysis required, and the ultimate interpretation of results all hinge on the selected approach. This guide provides an in-depth technical comparison of these three methodologies, framed within the context of modern research practices. Furthermore, it demonstrates the application of green chemistry principles—specifically the National Environmental Method Index (NEMI), Analytical Eco-Scale (AES), and Analytical GREEnness (AGREE) metrics—in evaluating analytical procedures, offering a practical framework for beginners in sustainable science [7].

Core Principles and Theoretical Foundations

The theoretical underpinnings of each approach dictate its application, data output, and how results are interpreted.

Qualitative Research

Qualitative research is fundamentally exploratory. It is used to gain a deep understanding of underlying reasons, opinions, and motivations. This approach is inherently inductive, meaning that theories or hypotheses are developed from the collected data rather than being tested against it [12] [13]. The focus is on understanding "why" behind a phenomenon, correlation, or behavior. It provides rich, detailed data about individual cases, but its results are more subjective and context-dependent. The researcher's own perspective and interpretation play a significant role in deriving meaning, which necessitates careful management of potential bias [13].

Quantitative Research

In contrast, quantitative research is explanatory and confirmatory. It seeks to quantify variables and uncover patterns, or to test hypotheses within a predefined framework. This is a deductive process, starting with a theory from which testable hypotheses are derived [12]. The approach focuses on answering questions of "what" or "how much" and relies on numerical data to establish facts and identify cause-and-effect relationships. It aims for objectivity and generalizability, with the goal that the results are independent of the researcher. The data produced is typically analyzed using statistical methods to draw conclusions that can be projected to a wider population [13].

Semi-Quantitative Research

Semi-quantitative methods bridge the gap between the qualitative and quantitative worlds. They generate results that are more than mere categories (a nominal property) but are not fully precise measurements. The results can be ordered or ranked by size (an ordinal scale), but the units of measurement are not necessarily identical across the entire scale [14]. In metrology, this is recognized as an ordinal scale, where values can be ranked but lack a true zero point and consistent intervals. These methods are often characterized by less-than-optimal quality indicators for trueness, precision, and detectability compared to fully quantitative methods [14]. They communicate that all measurements have uncertainty, but the uncertainty in semi-quantitative assays is inherently higher.

Data Characteristics and Presentation

The nature of data collected and how it is presented is a primary differentiator among the three approaches. The table below summarizes the key differences.

Table 1: Comparison of Data Characteristics Across Methodologies

| Feature | Qualitative | Semi-Quantitative | Quantitative |

|---|---|---|---|

| Data Type | Words, descriptions, images, narratives [12] | Ranked categories; approximate measurements [14] | Numbers, statistics [12] |

| Scale of Measurement | Nominal (categories without order) [14] | Ordinal (ordered categories) [14] | Interval/Ratio (equal intervals, true zero) [14] |

| Analysis Methods | Thematic analysis, content analysis, discourse analysis [12] [13] | Often involves comparison to a reference or standard to assign a rank | Statistical analysis (descriptive and inferential) [13] |

| Output Examples | Interview transcripts, field notes, thematic maps | "Trace", "1+", "2+", "Moderate", "High" | Concentration values (e.g., 45.2 mg/mL), means, p-values [7] |

| Inherent Uncertainty | Interpretive, subjective | High and often unquantified | Quantified (e.g., confidence intervals, standard deviation) |

Methodologies and Experimental Protocols

The research question dictates the data collection methods. The following workflows and protocols illustrate how each approach is typically executed.

Qualitative Data Collection and Analysis

Qualitative research employs methods designed to capture complex, nuanced information directly from participants.

Figure 1: Workflow for a Qualitative Research Study

Protocol for Qualitative Thematic Analysis:

- Data Collection: Conduct in-depth interviews or focus groups with open-ended questions. For example, "What is the most positive aspect of your study program?" [12]. Record and transcribe the interactions verbatim.

- Familiarization: Immerse yourself in the data by repeatedly reading the transcripts to gain a deep understanding of the content.

- Generating Initial Codes: Systematically identify and label meaningful features of the data across the entire dataset. A code is a brief description of what the data segment represents.

- Searching for Themes: Collate the codes into potential overarching themes, which are patterns of meaning that answer the research question.

- Reviewing Themes: Check if the themes work in relation to the coded extracts and the entire dataset. This involves refining the themes, which may involve splitting, combining, or discarding them.

- Defining and Naming Themes: Develop a clear definition and a concise name for each theme.

- Producing the Report: Write a narrative that tells the story of the data, using vivid, compelling data extracts as evidence for the themes [12] [13].

Quantitative and Semi-Quantitative Analytical Protocols

Quantitative and semi-quantitative methods are prevalent in laboratory sciences, such as pharmaceutical development. The following example, based on a published study, illustrates a quantitative protocol for drug analysis.

Figure 2: HPTLC Workflow for Quantitative Drug Analysis

Detailed Protocol: Quantitative HPTLC Analysis of Ertugliflozin This protocol is adapted from a study comparing the greenness of analytical methods [7].

- Objective: To precisely and accurately quantify Ertugliflozin (ERZ) in marketed pharmaceutical tablets using a Reversed-Phase High-Performance Thin-Layer Chromatography (RP-HPTLC) method.

- Experimental Conditions:

- Stationary Phase: RP-18F254S HPTLC plates.

- Mobile Phase: Ethanol–water (80:20, v/v) [7].

- Detection: Densitometry at 199 nm.

- Procedure:

- Standard Solution Preparation: Prepare a stock solution of ERZ reference standard. Dilute to appropriate concentrations to construct a calibration curve (e.g., 25–1200 ng/band) [7].

- Sample Preparation: Accurately weigh and powder tablets. Extract an amount equivalent to the declared dose of ERZ using a suitable solvent like methanol. Filter the solution before application.

- Chromatography: Using an automated applicator, spot the standard and sample solutions as bands on the HPTLC plate. Develop the plate in a twin-trough chamber pre-saturated with the mobile phase for a set time.

- Analysis and Quantification: After development and drying, scan the plate with a densitometer. Record the peak areas and retardation factor (Rf). Construct a calibration curve by plotting peak area against the applied concentration of the standard. Use the linear regression equation of the calibration curve to calculate the amount of ERZ in the sample solutions [7].

Semi-Quantitative Adaptation: The same HPTLC procedure can be adapted for semi-quantitative analysis. Instead of constructing a precise calibration curve and calculating an exact concentration, the intensity or size of the sample band is visually compared to a series of standard bands of known, ranked concentrations (e.g., "low", "medium", "high"). The result would be an assignment of the sample to one of these ordinal categories, providing an approximate measure rather than a precise numerical value [14].

The Scientist's Toolkit: Essential Reagents and Materials

The following table details key materials used in the HPTLC protocol described above, a common technique in quantitative and semi-quantitative analysis.

Table 2: Essential Research Reagents and Materials for HPTLC Analysis

| Item | Function / Description |

|---|---|

| RP-18F254S HPTLC Plates | The stationary phase. These are glass-backed plates coated with a layer of silica gel modified with C18 chains, used for reversed-phase chromatography [7]. |

| Ertugliflozin (ERZ) Reference Standard | A highly pure form of the drug substance used to prepare calibration standards for accurate quantification [7]. |

| Ethanol (Green Solvent) | A key component of the mobile phase. In the described method, it serves as a more environmentally friendly alternative to toxic solvents like chloroform [7]. |

| Densitometer | An instrument used to measure the intensity of the bands on the developed HPTLC plate by scanning them with light (at 199 nm). This converts the visual band into a quantifiable peak area [7]. |

| Automated Sample Applicator | Precisely applies sample and standard solutions onto the HPTLC plate as uniform bands, which is critical for obtaining reproducible and accurate quantitative results. |

Framework for Greenness Assessment: NEMI, AES, and AGREE

In modern analytical chemistry, evaluating the environmental impact of a method is crucial. The mentioned HPTLC study [7] utilized multiple tools to compare the greenness of a traditional normal-phase (NP) method with a greener reversed-phase (RP) method.

- NEMI (National Environmental Method Index): This tool uses a pictogram to indicate whether a method is "green". It assesses if the chemicals used are persistent, bioaccumulative, or toxic, and if the procedure produces corrosive waste (pH <2 or >12). The RP-HPTLC method using ethanol-water was found to be greener than the NP method using chloroform-methanol [7].

- AES (Analytical Eco-Scale): This is a semi-quantitative assessment tool. It starts with a base score of 100 and subtracts penalty points for hazardous reagents, energy consumption, and waste generation. A score above 75 is considered excellent green analysis, and the RP-HPTLC method achieved a higher score than the NP method [7].

- AGREE (Analytical GREEnness): This is a more comprehensive, quantitative software-based tool that evaluates all 12 principles of Green Analytical Chemistry (GAC). It provides an overall score between 0 and 1, with 1 being ideal. The RP-HPTLC method achieved a higher AGREE score, confirming its superior environmental profile [7].

This comparative framework is essential for beginners and professionals alike to make informed, sustainable choices about their analytical methodologies, aligning scientific progress with environmental responsibility.

From Theory to Practice: A Step-by-Step Guide to Applying Each Metric

The assessment of an analytical method is a systematic process that ensures laboratory techniques are not only scientifically valid and fit-for-purpose but also environmentally sustainable and practical for routine use. This holistic approach is crucial in modern drug development and research, where the reliability of data and the environmental footprint of operations are equally important. The process integrates traditional validation parameters, which guarantee the method's technical performance, with greenness assessment metrics, which evaluate its environmental impact. These greenness metrics have evolved significantly, moving from basic tools to comprehensive frameworks that allow researchers to quantify and minimize the ecological impact of their analytical procedures [2].

This guide is structured within the broader context of comparing three pivotal greenness assessment tools—the National Environmental Methods Index (NEMI), the Analytical Eco-Scale (AES), and the Analytical GREEnness (AGREE) metric. This comparison is designed for beginners in research, providing a clear pathway from method conception to a fully assessed and validated procedure. The core of this workflow lies in understanding that a modern analytical method must balance three key dimensions: analytical performance (accuracy, precision, etc.), practicality (ease of use, cost, time), and greenness (environmental impact)—a concept often referred to as White Analytical Chemistry (WAC) [15] [2]. The following sections provide a detailed, step-by-step protocol for this comprehensive assessment.

Foundational Concepts and Assessment Metrics

Before embarking on the practical workflow, it is essential to understand the key metrics that form the foundation of method assessment. The following table summarizes the core greenness assessment tools discussed in this guide.

Table 1: Key Greenness Assessment Metrics for Analytical Methods

| Metric Name | Type of Output | Key Criteria Assessed | Best Use Case |

|---|---|---|---|

| National Environmental Methods Index (NEMI) [15] [2] | Pictogram (4 quadrants) | PBT chemicals, hazardous chemicals, corrosiveness, waste generation. | Quick, initial screening of a method's environmental profile. |

| Analytical Eco-Scale (AES) [7] [2] | Numerical score (out of 100) | Reagent toxicity, energy consumption, waste amount, operator safety. | Quantitative comparison between methods; higher score indicates a greener method. |

| Analytical GREEnness (AGREE) [1] [2] | Pictogram & numerical score (0-1) | All 12 principles of Green Analytical Chemistry, including energy, waste, toxicity, and operator safety. | Comprehensive, holistic evaluation of the entire analytical method's environmental impact. |

The progression from NEMI to AGREE represents a shift in greenness assessment from simple, binary evaluations to nuanced, multi-criteria analyses. NEMI offers a straightforward pictogram but lacks granularity [2]. The AES provides a more quantitative approach by assigning penalty points for non-ideal conditions, with a score above 75 considered an excellent green analysis [7]. The AGREE metric is currently one of the most comprehensive tools, incorporating the 12 principles of Green Analytical Chemistry (GAC) into a single, easy-to-interpret graphic that also provides a final score on a 0 to 1 scale [1] [2]. For beginners, using these tools in tandem offers a balanced perspective, from a quick check with NEMI to a deep dive with AGREE.

A Step-by-Step Workflow for Method Assessment

The following workflow diagram outlines the comprehensive path for developing and assessing an analytical method, from defining its purpose to its final implementation and monitoring. It integrates traditional validation with modern greenness and practicality evaluation.

Diagram 1: Comprehensive Method Assessment Workflow. This diagram outlines the integrated process from method definition to implementation, highlighting the parallel evaluation of validation, greenness, and practicality.

Step 1: Define Method Purpose & Requirements

The foundation of a robust analytical method is a clear definition of its purpose and requirements [16]. This initial scoping phase involves:

- Identifying Analytes and Sample Matrix: Clearly define the target analyte(s) and the complex sample matrix (e.g., plasma, soil, water) in which they reside. This directly influences sample preparation and detection choices.

- Setting Performance Targets: Establish target values for key validation parameters such as specificity, accuracy, precision, and the Limit of Detection (LOD)/Limit of Quantification (LOQ). These targets should align with the method's intended use.

- Reviewing Constraints: Identify any regulatory guidelines that must be followed and note any safety constraints related to the handling of hazardous samples or reagents.

Step 2: Method Development & Validation

With requirements set, the method is developed and formally validated [16]. This involves experimental work to establish its scientific robustness.

- Perform Validation Experiments: Conduct laboratory experiments to gather data on the method's accuracy, precision, linearity, and robustness. The specific protocols for these experiments are defined by international standards, such as the ICH Q2(R2) guideline [7].

- Pre-validation Check: Before full validation, a pre-validation check is often performed as a quick assessment of the method's performance, allowing for flexible adjustments without the burden of a formal regulatory framework [16].

Step 3: Greenness & Practicality Profiling

This step runs in parallel with validation, assessing the method's environmental and operational characteristics.

- Conduct Greenness Assessment: Apply the NEMI, AES, and AGREE metrics to the developed method. This involves cataloging all chemicals, their quantities, energy consumption, and waste generated, then inputting this data into the respective metric tools (often available as free downloadable software) [1] [15].

- Evaluate Practicality: Assess practical aspects like total analysis time, cost per sample, ease of handling, and potential for automation. This "blue" component of White Analytical Chemistry ensures the method is viable for routine use [2].

Step 4: Comparative Analysis & Selection

In this phase, all collected data is synthesized to make a final decision.

- Synthesize Data: Combine the results from the validation (performance), greenness (environment), and practicality (usability) assessments into a unified decision matrix.

- Select or Optimize Method: Choose the method that offers the best balance for the intended application. If no single method is optimal, this analysis will highlight areas for improvement, guiding a new cycle of method optimization and re-validation [16].

Step 5: Implementation & Monitoring

The final step involves deploying the method and ensuring its long-term reliability.

- Document and Train: Issue the method as a formally validated procedure and ensure all relevant staff are trained on its execution [16].

- Monitor Performance: Continuously monitor the method's performance during routine use with real samples. Be prepared to optimize and revalidate the method if necessary to address any issues that arise [16].

Experimental Protocol: A Greenness Assessment Case Study

This protocol provides a practical example of how to apply the greenness assessment workflow, using a published study comparing two analytical methods as a template [7].

Background and Objective

Objective: To quantitatively compare the greenness of a Normal-Phase HPTLC (NP-HPTLC) method and a Reversed-Phase HPTLC (RP-HPTLC) method for the analysis of a pharmaceutical compound, Ertugliflozin, using NEMI, AES, and AGREE metrics [7]. Rationale: The RP-HPTLC method used a greener solvent system (ethanol-water) compared to the NP-HPTLC method (chloroform-methanol), making it a relevant case for a comparative greenness assessment.

Materials and Reagent Solutions

Table 2: Key Research Reagent Solutions and Materials

| Item | Function in the Experiment | Greenness & Safety Considerations |

|---|---|---|

| Chloroform (CHCl₃) | Organic solvent in NP-HPTLC mobile phase. | Hazardous, toxic reagent. Penalized in AES and results in a non-green profile in NEMI and AGREE [7]. |

| Ethanol (EtOH) | Organic solvent in RP-HPTLC mobile phase. | Biobased, greener solvent. Preferred over hazardous solvents like chloroform [7]. |

| Methanol (MeOH) | Organic solvent in NP-HPTLC mobile phase. | Hazardous solvent. Its use contributes negatively to the greenness score [7]. |

| HPTLC Plates | Stationary phase for chromatographic separation. | -- |

| Analytical Standard | Pure Ertugliflozin for calibration and validation. | -- |

Step-by-Step Procedure

Method Execution:

Data Collection for Greenness:

- For each method, meticulously record:

- Reagents & Solvents: List all chemicals used (e.g., chloroform, methanol, ethanol, water).

- Amounts: Note the volumes of each solvent consumed per analytical run.

- Hazards: Classify the hazards (toxicity, flammability) associated with each chemical based on safety data sheets.

- Waste: Estimate the total volume of waste generated per sample.

- For each method, meticulously record:

Greenness Metric Calculation:

- NEMI: Access the NEMI website (www.nemi.gov) or use its criteria. For a method to be "green" in all four quadrants, it must use no PBT chemicals, no hazardous chemicals, have a pH between 2 and 12, and generate less than 50 g of waste [15]. Check each criterion for both methods.

- Analytical Eco-Scale: Start with a base score of 100. Subtract penalty points for each parameter (reagent amount, hazard, energy, etc.). The method with the higher final score is greener [7] [2].

- AGREE: Use the freely available AGREE software (www.mostwiedzy.pl/AGREE). Input data corresponding to the 12 GAC principles based on the collected method data. The software will generate a pictogram and a final score between 0 and 1 [1] [7].

Expected Results and Interpretation

The case study demonstrates clear differences in greenness. The quantitative results from the published study are summarized below.

Table 3: Expected Greenness Assessment Results from the Case Study [7]

| Assessment Metric | NP-HPTLC Method (CHCl₃/MeOH) | RP-HPTLC Method (EtOH/H₂O) | Interpretation |

|---|---|---|---|

| NEMI Pictogram | Likely 1-2 green fields | Likely 3-4 green fields | The RP method avoids persistent, hazardous solvents like chloroform, resulting in a more complete green pictogram. |

| AES Score | Lower score | Higher score | The RP method incurs fewer penalty points due to the use of ethanol, a safer, bio-derived solvent. |

| AGREE Score | Lower score (e.g., ~0.5) | Higher score (e.g., ~0.7) | The AGREE pictogram for the RP method will show more green segments, indicating better alignment with the 12 GAC principles. |

Conclusion: The RP-HPTLC method, which utilizes a greener solvent system, is consistently evaluated as more environmentally sustainable across all three metrics. This demonstrates the power of microextraction techniques and solvent substitution to enhance the greenness of standard analytical methods [15].

The presented workflow provides a structured, beginner-friendly roadmap for the comprehensive assessment of analytical methods. By integrating traditional validation with a comparative analysis of greenness metrics like NEMI, AES, and AGREE, researchers and drug development professionals can make informed decisions that balance analytical performance, practicality, and environmental responsibility. The case study illustrates that a deliberate choice of materials—such as substituting toxic solvents with greener alternatives—can significantly improve a method's sustainability profile without compromising its analytical validity. As the field moves towards the holistic framework of White Analytical Chemistry, adopting such a practical and multi-faceted assessment strategy is paramount for advancing sustainable science.

The principles of Green Analytical Chemistry (GAC) have gained significant importance in modern analytical laboratories, driven by growing awareness of environmental sustainability and the need to reduce the ecological impact of chemical analyses [1] [17]. GAC aims to mitigate the detrimental effects of analytical techniques on the environment and human health through the use of environmentally acceptable solvent alternatives, minimization of waste generation, and reduction of energy consumption [7] [18]. Within pharmaceutical analysis, High-Performance Thin-Layer Chromatography (HPTLC) has emerged as a promising green technique due to its relatively low solvent consumption, minimal sample preparation requirements, and capability for high-throughput analysis [7] [19].

To standardize the evaluation of analytical methods, several greenness assessment tools have been developed. This case study focuses on three prominent metrics: the National Environmental Method Index (NEMI), Analytical Eco-Scale (AES), and Analytical GREEnness (AGREE) method [1] [17]. Each tool offers a unique approach to quantifying the environmental impact of analytical procedures, allowing researchers to make informed decisions when developing or selecting methods. The application of these metrics is particularly valuable for beginners in green chemistry research, providing structured frameworks for comparative assessment of method sustainability [1].

National Environmental Method Index (NEMI)

The NEMI tool provides a simple, pictogram-based assessment that appears as a circle divided into four quadrants [1] [17]. Each quadrant represents a different environmental criterion: (1) Persistence, (2) Bioaccumulation, (3) Toxicity, and (4) Corrosivity [7]. The quadrant is colored green if the method meets the criteria for being environmentally benign; otherwise, it remains blank. This binary approach offers a quick visual snapshot of a method's greenness but lacks granularity in assessment [17].

Analytical Eco-Scale (AES)

The AES employs a penalty point system to evaluate analytical methods based on their potential environmental impact [18] [17]. The assessment begins with a base score of 100 points, from which penalty points are subtracted for hazardous reagents, energy consumption, waste generation, and occupational hazards [7]. The final score is interpreted as: >75 (excellent green analysis), 50-75 (acceptable green analysis), and <50 (insufficiently green analysis) [17]. This approach provides a more quantitative assessment compared to NEMI.

Analytical GREEnness (AGREE)

The AGREE metric represents the most comprehensive approach, incorporating all 12 principles of Green Analytical Chemistry into its evaluation framework [7] [1] [17]. It generates a pictogram with twelve segmented segments, each corresponding to one GAC principle, with colors ranging from red (poor) to green (excellent). The tool provides an overall score between 0-1, with higher scores indicating better greenness profiles [7] [18]. AGREE offers the most detailed assessment of the three tools, addressing multiple dimensions of method sustainability.

Case Study: Greenness Assessment of HPTLC Methods for Ertugliflozin

Methodological Background

A recent study directly compared normal-phase (NP) and reversed-phase (RP) HPTLC methods for the analysis of ertugliflozin (ERZ), a sodium-glucose cotransporter-2 inhibitor used in managing type 2 diabetes mellitus [7]. The study aimed to develop not only a precise and accurate method but also a more sustainable approach to pharmaceutical analysis.

The NP-HPTLC method utilized silica gel 60 NP-18F254S plates with a chloroform/methanol (85:15 v/v) mobile phase, while the RP-HPTLC method employed silica gel 60 RP-18F254S plates with an ethanol-water (80:20 v/v) mobile phase [7]. Detection for both methods was performed at 199 nm. The methods were validated according to International Council for Harmonisation guidelines and applied to the determination of ERZ in commercial tablets [7].

Experimental Protocols

HPTLC Method Conditions

Table 1: Chromatographic Conditions for NP- and RP-HPTLC Methods

| Parameter | NP-HPTLC Method | RP-HPTLC Method |

|---|---|---|

| Stationary Phase | Silica gel 60 NP-18F254S plates | Silica gel 60 RP-18F254S plates |

| Mobile Phase | Chloroform/methanol (85:15 v/v) | Ethanol-water (80:20 v/v) |

| Detection Wavelength | 199 nm | 199 nm |

| Linear Range | 50-600 ng/band | 25-1200 ng/band |

| Sample Volume Application | 1-7 μL (as bands) | 1-7 μL (as bands) |

| Chromatographic Development | Saturated twin-trough chamber, room temperature, migration distance 85 mm | Saturated twin-trough chamber, room temperature, migration distance 85 mm |

| Analysis Time | ~60 minutes | ~60 minutes |

Method Validation Parameters

Both HPTLC methods were validated according to ICH guidelines, assessing the following parameters [7] [20]:

- Linearity: Constructing calibration curves across the specified concentration ranges

- Precision: Intra-day and inter-day precision expressed as % RSD

- Accuracy: Recovery studies at multiple concentration levels (50%, 100%, 150%)

- Specificity: Ability to measure analyte accurately in presence of degradation products

- Robustness: Deliberate variations in mobile phase composition and development conditions

- Sensitivity: Limit of detection (LOD) and limit of quantification (LOQ) determined

Application of Greenness Assessment Tools

NEMI Assessment

The NEMI assessment for both methods yielded different results [7]:

- NP-HPTLC Method: Not all four quadrants were colored green, indicating certain environmental concerns

- RP-HPTLC Method: All four quadrants were colored green, signifying a better environmental profile

The superior performance of the RP-HPTLC method in NEMI assessment primarily stems from the replacement of chloroform (hazardous) with ethanol (less hazardous) in the mobile phase [7].

AES Assessment

The AES evaluation employed a penalty point system [7]:

- NP-HPTLC Method: Received a lower score due to penalty points for hazardous reagents (chloroform), higher energy consumption, and waste generation

- RP-HPTLC Method: Achieved a higher score (closer to 100) with minimal penalty points, reflecting its greener profile

The AES score for the RP-HPTLC method was significantly higher than for the NP-HPTLC method, confirming its superior environmental friendliness [7].

AGREE Assessment

The AGREE evaluation, which considers all 12 principles of GAC, provided comprehensive assessment [7]:

- NP-HPTLC Method: Lower overall score (closer to 0)

- RP-HPTLC Method: Higher overall score (closer to 1)

The AGREE tool specifically highlighted the advantages of the RP-HPTLC method in terms of waste prevention, safer chemistry, and reduced energy requirements [7].

Comparative Assessment Results

Table 2: Comprehensive Greenness Assessment Scores for HPTLC Methods

| Assessment Tool | NP-HPTLC Method | RP-HPTLC Method | Interpretation |

|---|---|---|---|

| NEMI Pictogram | Not all quadrants green | All quadrants green | Binary assessment (green/not green) |

| AES Score | Lower score | Higher score (>75) | >75 = Excellent green analysis |

| AGREE Score | Lower score (closer to 0) | Higher score (closer to 1) | 0-1 scale (1 = ideal greenness) |

| ChlorTox Score | Higher environmental impact | Lower environmental impact | Lower score = greener |

The consensus across all three assessment tools consistently demonstrated that the RP-HPTLC method using ethanol-water as the mobile phase was environmentally superior to the NP-HPTLC method using chloroform-methanol [7]. This case study exemplifies how green assessment tools can guide researchers toward more sustainable method development in pharmaceutical analysis.

The Scientist's Toolkit: Essential Materials for HPTLC Greenness Assessment

Table 3: Key Research Reagent Solutions and Materials for HPTLC Analysis

| Item | Function/Role in HPTLC | Green Considerations |

|---|---|---|

| HPTLC Plates (Silica gel 60 F254) | Stationary phase for chromatographic separation | Choose无毒 backing materials when possible [21] [22] |

| Mobile Phase Solvents | Liquid phase for compound separation | Prefer ethanol, water, ethyl acetate over chlorinated solvents [7] |

| Sample Applicator (Linomat) | Precise application of samples as bands | Automated systems reduce solvent consumption [21] [19] |

| Chromatography Chamber | Controlled environment for mobile phase development | Saturated chambers improve separation efficiency [21] |

| Densitometer Scanner | Quantitative measurement of separated compounds | Non-destructive detection enables multiple analyses [23] [19] |

| Chemical Standards | Reference materials for method validation and quantification | Proper disposal following environmental guidelines [23] |

Workflow Diagram for Greenness Assessment

Comparative Strengths and Limitations of Assessment Tools

Table 4: Advantages and Limitations of Greenness Assessment Tools

| Tool | Key Advantages | Key Limitations |

|---|---|---|

| NEMI | Simple pictogram, quick visual assessment, easy interpretation | Binary assessment (lacks granularity), limited criteria coverage [17] |

| AES | Quantitative score, comprehensive penalty system, clear thresholds | Does not cover all GAC principles, subjective penalty assignments [7] [17] |

| AGREE | Comprehensive (covers all 12 GAC principles), detailed assessment, visual pictogram | More complex implementation, requires specialized software [1] [17] |

This case study demonstrates the practical application of NEMI, AES, and AGREE assessment tools to evaluate the environmental impact of HPTLC methods for pharmaceutical analysis. The consistent finding across all three tools - that the RP-HPTLC method with ethanol-water mobile phase was environmentally superior to the NP-HPTLC method with chloroform-methanol - validates their utility in guiding sustainable method development [7].

For beginners in green chemistry research, the following recommendations are provided:

- Utilize Multiple Assessment Tools: Each tool offers unique perspectives; using NEMI, AES, and AGREE together provides the most comprehensive evaluation [7] [17].

- Prioritize Solvent Selection: Mobile phase composition significantly impacts greenness scores; prefer ethanol-water systems over chlorinated solvents when possible [7].

- Consider Practical Performance: Balance greenness with analytical performance; the RP-HPTLC method offered better sensitivity and linearity alongside improved greenness [7].

- Incorporate Early in Method Development: Integrate greenness assessment during method development rather than as an afterthought [17].

The expanding toolkit for greenness assessment, including the emerging concept of White Analytical Chemistry that balances analytical efficiency, ecological impact, and economic viability, continues to enhance our ability to develop truly sustainable analytical methods [17]. As the field evolves, these assessment tools will play an increasingly vital role in advancing the principles of green chemistry in pharmaceutical analysis and beyond.

In modern analytical chemistry, particularly within pharmaceutical development, the principles of Green Analytical Chemistry (GAC) have become crucial for minimizing environmental impact while maintaining analytical efficacy [1]. Greenness metrics provide standardized tools to evaluate and compare the environmental footprint of analytical methods, enabling researchers to make informed, sustainable choices [9]. For researchers and drug development professionals, understanding these metrics is no longer optional but a fundamental aspect of method development and validation. This guide provides a comprehensive breakdown of three fundamental greenness assessment tools—NEMI, AES, and AGREE—focusing specifically on the data inputs required for their application.

The evolution of these metrics reflects a growing sophistication in assessing environmental impact. Beginning with simple, binary evaluations like the National Environmental Methods Index (NEMI), the field has progressed to semi-quantitative tools like the Analytical Eco-Scale (AES), and finally to comprehensive, multi-principle frameworks like the Analytical GREEnness (AGREE) metric [2]. Each tool demands specific data inputs and offers varying levels of analytical depth. This guide details the exact information required for each metric, structured for beginners embarking on comparative research in this critical field.

Understanding the Assessment Landscape

Before examining individual metrics, it is essential to recognize that they form part of a broader, color-coded model for evaluating analytical methods. The White Analytical Chemistry (WAC) framework integrates three dimensions: red for analytical performance, green for environmental impact, and blue for practical effectiveness [9] [2]. The green metrics discussed here—NEMI, AES, and AGREE—specifically address the environmental sustainability pillar of this model.

A significant challenge in this field is the lack of standardization in applying these tools, which can lead to inconsistent results and conclusions [9]. This deep dive into data input requirements aims to promote a more standardized, reproducible approach to greenness assessment, ensuring that researchers collect the appropriate information before beginning their evaluation.

Metric 1: National Environmental Methods Index (NEMI)

The National Environmental Methods Index (NEMI) is one of the earliest and simplest greenness assessment tools. It provides a qualitative, binary evaluation represented by a pictogram—a circle divided into four quadrants [9] [2]. Each quadrant turns green if the method meets that specific criterion; otherwise, it remains blank.

NEMI requires minimal data inputs, focusing exclusively on four key environmental criteria. To complete a NEMI assessment, you must gather the following information for your analytical method:

Table 1: Data Requirements for NEMI Assessment

| Criterion | Required Data Input | Specific Information Needed |

|---|---|---|

| PBT Reagents | List of all reagents | Identity of any persistent, bioaccumulative, and toxic (PBT) reagents used (e.g., from EPA's TRI list). |

| Corrosive Reagents | pH information for all solutions | Use of any reagents with pH ≤2 or ≥12. |

| Hazardous Reagents | Safety data for all chemicals | Use of any reagents designated "hazardous" by the EPA (e.g., acetonitrile, methanol). |