Supercritical CO2 Extraction: A Comprehensive Guide for Pharmaceutical Research and Development

This article provides a thorough examination of supercritical CO2 extraction (SFE-CO2) for researchers and drug development professionals.

Supercritical CO2 Extraction: A Comprehensive Guide for Pharmaceutical Research and Development

Abstract

This article provides a thorough examination of supercritical CO2 extraction (SFE-CO2) for researchers and drug development professionals. It covers the fundamental principles of SFE-CO2, explores diverse methodologies and their specific pharmaceutical applications, details strategies for process optimization and troubleshooting, and offers a critical validation against traditional extraction techniques. The content synthesizes current research, including the use of machine learning for solubility prediction and co-solvents for enhanced bioactive compound recovery, to serve as a foundational resource for implementing this green technology in pharmaceutical innovation.

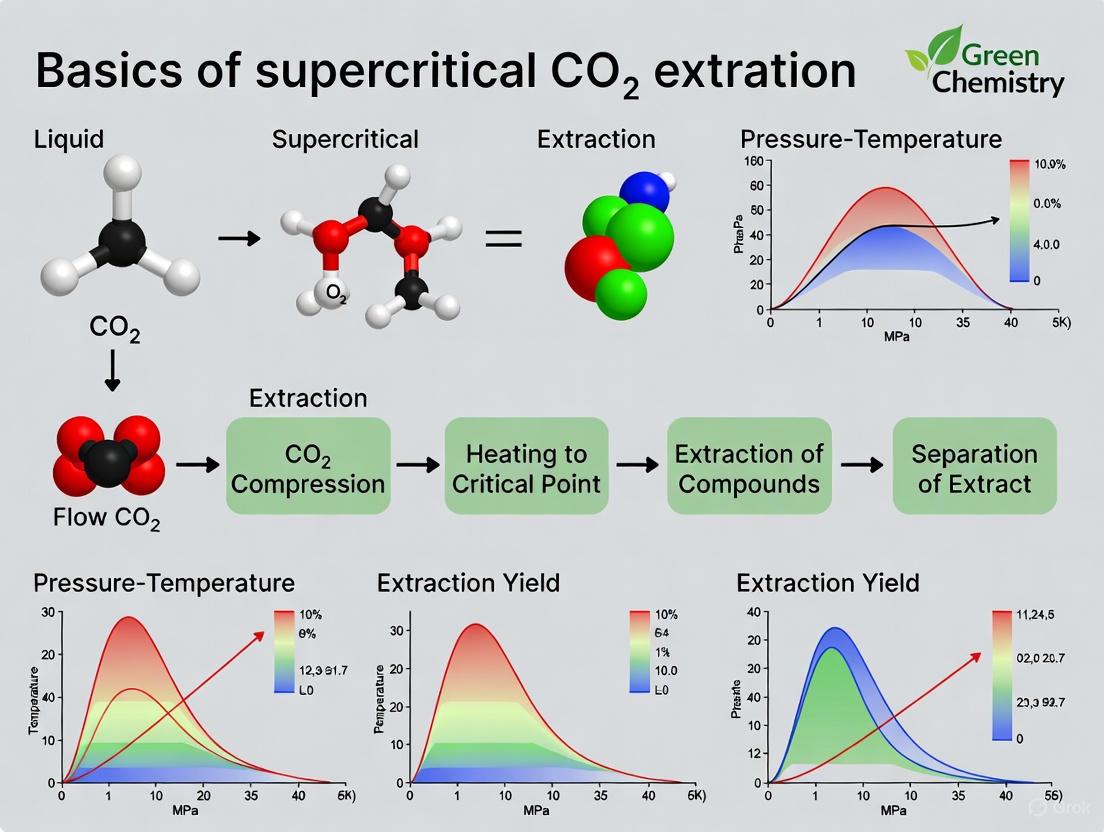

Principles and Foundations of Supercritical CO2 Extraction

A supercritical fluid is a substance maintained above its critical temperature and critical pressure, where it no longer behaves as a typical liquid or gas [1] [2]. In this supercritical state, the substance adopts properties that are intermediate between the two phases, exhibiting gas-like diffusion and viscosity alongside liquid-like density and solvent power [3]. Carbon dioxide (COâ‚‚) is the most prevalent supercritical fluid used in research and industry due to its accessible critical point, low toxicity, and environmental acceptability [4]. Understanding the fundamental thermodynamics of the supercritical state, particularly for COâ‚‚, is crucial for leveraging its unique properties in applications ranging from pharmaceutical extraction to advanced power cycles [1] [5].

This guide details the core principles of the supercritical state of COâ‚‚, with a specific focus on its relevance to extraction research. It provides the quantitative data, theoretical frameworks, and experimental methodologies necessary for scientists to effectively design and optimize processes utilizing supercritical COâ‚‚ (scCOâ‚‚).

The Critical Point of Carbon Dioxide

The critical point of a pure substance is the unique condition of temperature and pressure at which its liquid and gaseous phases coalesce into a single fluid phase [2] [6]. At this point, the meniscus between the liquid and gas vanishes, and properties such as density, refractive index, and enthalpy of vaporization become identical [6]. For carbon dioxide, this critical point is defined by precise values of temperature and pressure, as summarized in Table 1.

Table 1: Critical Point Parameters for Carbon Dioxide

| Parameter | Value | Units |

|---|---|---|

| Critical Temperature (T_c) | 304.128 K / 31.978°C / 87.7604°F [1] | Kelvin / Celsius / Fahrenheit |

| Critical Pressure (P_c) | 7.3773 MPa / 73.773 bar / 72.808 atm [1] | Megapascal / Bar / Atmosphere |

Beyond this critical point, COâ‚‚ exists as a supercritical fluid (scCOâ‚‚). A key phenomenon observed near the critical point is critical opalescence, where the fluid appears cloudy due to large-scale density fluctuations that scatter light [2]. This serves as a visual indicator of the phase transition.

The phase behavior of COâ‚‚ can be visualized through a phase diagram, which maps the states of matter (solid, liquid, gas) and the regions where they coexist as a function of temperature and pressure.

Unique Properties of Supercritical COâ‚‚ as a Solvent

Supercritical COâ‚‚ possesses a combination of physico-chemical properties that make it an exceptional and tunable solvent for research and industrial applications, especially in the extraction of sensitive bioactive compounds [1] [3] [4].

- Tunable Solvation Power: The density of scCOâ‚‚, and consequently its solvating power, is highly sensitive to changes in temperature and pressure near the critical point [3]. This allows researchers to fine-tune the solvent's selectivity, enabling the targeted extraction of specific compounds simply by adjusting system parameters [7] [4].

- Transport Properties: scCOâ‚‚ exhibits transport properties that are favorable for extraction. It has gas-like low viscosity and high diffusivity, which facilitate rapid penetration into porous matrices like plant materials. Simultaneously, it possesses liquid-like density, ensuring sufficient solvent capacity to dissolve target solutes [3].

- Environmental and Safety Profile: COâ‚‚ is non-flammable, chemically inert, and virtually non-toxic [1] [4]. It is also readily available in high purity and is considered a "green" solvent, leaving no harmful residue in extracts [4]. This eliminates the need for complex and costly solvent disposal procedures associated with organic solvents like hexane or acetone [1].

- Low-Temperature Processing: With a critical temperature of just 31°C, scCO₂ is ideal for processing thermolabile compounds found in pharmaceuticals and food products. Extractions can be performed at near-ambient temperatures, preventing thermal degradation of the desired products [1] [4].

A pivotal concept in working with scCO₂ is the Widom line, which represents the pseudo-phase transition where the thermodynamic properties of scCO₂ exhibit extreme values [8]. This region, rather than a single point, guides the operation of scCO₂ systems for optimal properties like heat capacity. Recent molecular dynamics simulations have achieved high accuracy (R² > 97.48%) in fitting Widom line expressions for properties such as density and heat capacity, providing a robust guide for system operation [8].

Experimental Protocol: Observing the Critical Point

This protocol allows for the safe visual demonstration of the critical point of COâ‚‚, a foundational experiment for understanding supercritical fluid behavior [6].

Goal

To demonstrate the phase transition of carbon dioxide from a subcritical (liquid-gas coexistence) state through the critical point to a supercritical state and back again [6].

Theory

In a sealed system at subcritical temperatures, liquid CO₂ and its vapor coexist, separated by a clear meniscus. As the system is heated to the critical temperature (~31°C) under sufficient pressure (>7.38 MPa), the meniscus vanishes due to critical opalescence, forming a single supercritical phase. Upon cooling, the process reverses, and the two phases reappear [2] [6].

Materials (The Researcher's Toolkit)

Table 2: Essential Materials for Critical Point Demonstration

| Item | Function | Critical Safety Note |

|---|---|---|

| Sealed Glass Rod containing subcritical liquid COâ‚‚ | High-pressure vessel for observing the phase transition. The liquid COâ‚‚ is in the lower part, saturated vapour above it [6]. | WARNING: The rod is under extreme pressure (>7 MPa). Handle with extreme caution to avoid shocks or drops [6]. |

| Temperature-Controlled Water Bath (capable of 45-50°C) | Provides uniform heating to bring the CO₂ to its critical temperature [6]. | Ensure stable setup to prevent the rod from slipping. |

| Light Source (e.g., Slide Projector) | Backlighting to project a clear image of the meniscus and critical opalescence onto a screen [6]. | - |

| cis-9-Octadecene-1-thiol | cis-9-Octadecene-1-thiol, CAS:31494-22-1, MF:C18H36S, MW:284.5 g/mol | Chemical Reagent |

| Gibbs Reagent | Gibbs Reagent, CAS:101-38-2, MF:C6H2Cl3NO, MW:210.4 g/mol | Chemical Reagent |

Step-by-Step Procedure

- Setup: Fill the beaker with water heated to 45-50°C. Turn on the slide projector and position the CO₂ rod in front of its lamp so the liquid level is projected onto a screen [6].

- Heating (Transition to Supercritical): Immerse the lower end of the rod into the water bath. Warm the rod gradually while observing the projected image. The meniscus will become wavy and eventually vanish, replaced by a cloudy, opalescent appearance that fills the rod as it reaches the critical point [6].

- Cooling (Transition to Subcritical): Remove the rod from the water bath and allow it to cool in air. Observe the reversal of the process: the opalescence clears, and a faint meniscus reforms, separating the liquid and gaseous COâ‚‚ [6].

Sample Results and Interpretation

Successful execution will show the distinct disappearance and reappearance of the liquid-gas boundary. The critical opalescence observed during the transition is caused by the scattering of light from large density fluctuations within the fluid at the critical point [2] [6]. The following workflow summarizes the experimental and application principles of scCOâ‚‚.

Advanced Thermodynamic Properties and Widom Line Region

For advanced research and precise process design, understanding the thermodynamic properties of scCOâ‚‚ beyond the critical point is essential. The Widom line is a key concept, representing an extension of the coexistence line into the supercritical region, where certain thermodynamic response functions reach their maximum [8]. This region, rather than a single line, guides the operation of scCOâ‚‚ systems for optimal properties.

Recent advances in large-scale molecular dynamics (MD) simulations have enabled highly accurate calculation of these properties. A 2025 study calculated key properties with high precision, as shown in Table 3, providing a valuable dataset for researchers [8].

Table 3: Thermodynamic Properties of scCO₂ from Molecular Dynamics Simulation (300–900 K, 7.3773–20 MPa)

| Thermodynamic Property | Average Relative Error (vs. Expected) | Key Application Implication |

|---|---|---|

| Density | 3.76% [8] | Directly determines solvent power and selectivity for extraction. |

| Isobaric Heat Capacity (Cp) | 3.93% [8] | Critical for heat exchanger and reactor design in power cycles. |

| Isochoric Heat Capacity (Cv) | 3.11% [8] | Informs fundamental thermodynamic models. |

| Volume Expansion Coefficient | 5.76% [8] | Affects flow dynamics and buoyancy-driven convection. |

| Isothermal Compression Coefficient | 7.07% [8] | Important for understanding compressibility and pressure propagation. |

The expressions for the Widom lines of these properties were fitted with a coefficient of determination (R²) above 97.48%, creating a reliable map of the "Widom line region" where scCO₂'s properties transition from liquid-like to gas-like [8]. This knowledge allows scientists to precisely control processes by targeting specific pressure-temperature conditions relative to this region.

The unique properties of scCOâ‚‚ are directly harnessed in extraction processes, forming the basis of its utility in pharmaceuticals, food, and cosmetics [7]. Its tunable solvation power allows for selective extraction; for instance, lower pressures can extract essential oils, while higher pressures can extract heavier compounds like waxes [1]. The gas-like transport properties enable deep penetration into botanical matrices, leading to high extraction yields, while the low operating temperature preserves the integrity of thermolabile active pharmaceutical ingredients (APIs) [1] [4]. Finally, the benign environmental profile ensures that the final extract is free of toxic solvent residues, a critical requirement for drug development [1] [4].

In conclusion, a rigorous understanding of the critical point and the unique, tunable solvent properties of supercritical COâ‚‚ is fundamental for researchers. From observing the foundational phase transition in a laboratory rod to applying advanced molecular dynamics simulations for process optimization, this knowledge empowers the development of more efficient, selective, and sustainable extraction technologies in scientific and industrial contexts.

Why CO2? Advantages as a Non-Toxic, Non-Flammable, and Recyclable Solvent

Supercritical carbon dioxide (scCO₂) is carbon dioxide held at or above its critical temperature of 30.98 °C (304.13 K) and critical pressure of 7.3773 MPa (73.8 bar) [1]. In this supercritical state, CO₂ adopts properties midway between a gas and a liquid, expanding to fill its container like a gas but with a density comparable to that of a liquid [1]. This unique combination of properties makes it an exceptionally effective and versatile solvent for extraction, separation, and purification processes across pharmaceutical, food, and cosmetic industries.

The role of scCOâ‚‚ within broader supercritical COâ‚‚ extraction research is pivotal, as it represents a paradigm shift toward sustainable and green chemistry principles in industrial solvent applications. Its tunable physical properties, coupled with an exceptional safety and environmental profile, offer a viable alternative to conventional organic solvents, which are increasingly scrutinized for their toxicity, flammability, and environmental impact [9] [10]. This technical guide details the fundamental advantages of COâ‚‚, supported by quantitative data, experimental methodologies, and visualizations tailored for researchers and drug development professionals.

Fundamental Advantages of COâ‚‚ as a Solvent

Non-Toxic and Safe Profile

Carbon dioxide is generally recognized as safe (GRAS) by regulatory authorities such as the U.S. Food and Drug Administration (FDA) [11] [12]. This classification is crucial for applications in the food, pharmaceutical, and nutraceutical industries, where solvent residues in final products are a major concern.

- Non-Toxic and Non-Flammable: Unlike traditional solvents such as hexane, methanol, or acetone, COâ‚‚ poses no inherent toxicity or flammability risks [9] [13] [12]. This eliminates significant safety hazards associated with solvent handling, storage, and industrial processing, reducing the need for specialized hazardous location-rated environments [12].

- Solvent-Residue-Free Extracts: The supercritical COâ‚‚ extraction process leaves no solvent residues in the final extract [11] [13] [14]. This is achieved through simple depressurization, which reverts supercritical COâ‚‚ to a gaseous state, leaving behind a pure extract without the need for energy-intensive secondary purification steps [11]. This ensures the safety and purity of extracts intended for consumer products [11].

Environmental and Recyclability Benefits

The environmental benefits of using COâ‚‚ as a solvent are multifaceted, impacting both direct process efficiency and broader ecological footprints.

- Recyclable and Abundant: The COâ‚‚ used in industrial processes is typically captured as a byproduct from other large-scale industrial processes, such as fertilizer production or from geothermal sources [11] [12]. This makes it abundant, readily available, and contributes to a reduced carbon footprint [11] [14]. Furthermore, in a closed-loop supercritical extraction system, COâ‚‚ can be continuously recycled and reused after the extraction and separation steps, significantly reducing solvent consumption and waste [10] [13].

- Reduced Environmental Impact: scCOâ‚‚ extraction replaces petroleum-based and halogenated organic solvents, which are complex to manage, require expensive disposal procedures, and can contribute to environmental pollution [11] [10]. The process is considered carbon-neutral as it typically uses captured COâ‚‚ and does not generate new COâ‚‚ emissions [14]. Additionally, the spent biomass from scCOâ‚‚ extraction is typically non-hazardous, simplifying waste disposal [14].

Tunable Solvent Properties

One of the most powerful features of supercritical COâ‚‚ is its tunable solvent power [9] [12]. The density of scCOâ‚‚, and consequently its solvating power, can be precisely and continuously modulated through incremental changes in pressure and temperature [10].

- Selective Extraction: This tunability allows researchers to fine-tune the process for superior selectivity [9] [13]. It enables the selective isolation of target compounds by adjusting operational parameters to solubilize specific components while leaving others behind [1]. This can be leveraged for fractional separation, where different compounds in a mixture are sequentially separated by manipulating pressure and temperature in a series of separators [15].

- Preservation of Heat-Sensitive Compounds: The relatively low critical temperature of CO₂ (31.1°C) permits extractions to be conducted under mild thermal conditions [9] [16]. This is critical for processing thermally labile bioactive compounds, such as many pharmaceuticals and essential oils, preventing their degradation and preserving their biological activity [9] [10].

Table 1: Critical Point Comparison of Common Supercritical Fluids

| Solvent | Critical Temperature (°C) | Critical Pressure (bar) | Critical Density (kg/m³) |

|---|---|---|---|

| Carbon Dioxide (COâ‚‚) | 31.1 [1] [10] | 73.8 [1] [13] | 467.6 [10] |

| Water (Hâ‚‚O) | ~374 [10] | ~221 [10] | 322 |

| Ethane (C₂H₆) | 32.2 | 48.8 | 203 |

| Nitrous Oxide (Nâ‚‚O) | 36.4 | 72.4 | 457 |

Table 2: Comparison of Physical Properties of Gases, Supercritical COâ‚‚, and Liquids

| Physical Property | Gas | Supercritical COâ‚‚ | Liquid |

|---|---|---|---|

| Density (kg/m³) | 0.6-2.0 [10] | 200-900 [10] (Tunable) | 600-1600 [10] |

| Viscosity (Pa·s) | 0.01-0.03 [10] | 0.01-0.09 [10] | 0.2-3.0 [10] |

| Diffusivity (cm²/s) | 0.01-0.04 [10] | 0.07-0.2 [10] | < 0.00005 [10] |

Experimental Protocols and Methodologies

Standard Supercritical COâ‚‚ Extraction Workflow

A typical laboratory-scale supercritical COâ‚‚ extraction process follows a systematic protocol to ensure reproducibility and efficiency. The following methodology is adapted for the extraction of bioactive compounds from plant materials (e.g., herbs, leaves) [13] [14].

Principle: To utilize the tunable solvating power of supercritical COâ‚‚ to extract target compounds from a solid matrix, followed by separation via depressurization.

Materials and Reagents:

- Raw Material: Dried and finely ground plant matter (e.g., Artemisia annua leaves).

- Extraction Solvent: High-purity carbon dioxide (COâ‚‚) gas supply.

- Optional Co-solvent: Food-grade or HPLC-grade ethanol or methanol.

- Equipment: Supercritical fluid extraction system comprising a COâ‚‚ pump, co-solvent pump (if used), pre-heater, extraction vessel, pressure control valves (e.g., back-pressure regulators), one or more separators, and a COâ‚‚ recycling or venting system.

Procedure:

- Sample Preparation: The raw plant material is dried to a low moisture content (increased moisture reduces extraction efficiency [16]) and milled to a consistent particle size (e.g., 0.2-0.5 mm) to increase the surface area for mass transfer [16].

- System Pressurization and Heating:

- The prepared sample is loaded into the extraction vessel.

- The system is sealed and brought to the desired operational temperature using the pre-heater and vessel heating jacket.

- COâ‚‚ is pumped into the system until the target pressure is achieved, bringing the COâ‚‚ to its supercritical state.

- If a co-solvent is used (e.g., 1-10% ethanol), it is introduced via a separate pump and mixed with the scCOâ‚‚ stream before entering the extraction vessel [9].

- Static and Dynamic Extraction:

- The system may be held under static conditions (no flow) for a predetermined time (e.g., 15-30 minutes) to allow for saturation.

- The supercritical COâ‚‚ is then allowed to flow dynamically through the vessel at a controlled flow rate (e.g., 1-10 g/min) for a set duration (e.g., 1-4 hours), dissolving the target compounds.

- Separation and Collection:

- The COâ‚‚-rich stream containing the dissolved solutes passes from the extractor into a separator.

- In the separator, the pressure is precisely reduced using a back-pressure regulator, causing a drastic drop in the solvent power of COâ‚‚ [14] [15].

- The extracted compounds precipitate out and are collected from the bottom of the separator.

- For complex mixtures, multiple separators in series can be used, each at successively lower pressures, to fractionate different classes of compounds based on their solubility [15].

- Solvent Recovery: The now-gaseous COâ‚‚ exits the separator. It can be vented or, in a closed-loop system, recompressed and recycled back to the COâ‚‚ pump, significantly reducing solvent consumption [11] [10].

Protocol for Fractional Separation of Extract Components

Fractional separation, or fractionation, is a powerful technique to isolate specific components from a complex extract [15].

Principle: To separate a mixture into its individual components by leveraging their different dissolution pressures in scCOâ‚‚ through a multi-stage separation process.

Procedure:

- Primary Extraction: Perform steps 1-3 from the standard extraction protocol above. The output is a scCOâ‚‚ stream containing a mixture of dissolved compounds.

- Multi-Stage Separation:

- The mixture is passed through a series of separators (e.g., Separator 1, Separator 2).

- Separator 1 is maintained at a specific high pressure (e.g., 150 bar) and temperature. At these conditions, only the least soluble component(s) precipitate, while others remain dissolved in the scCOâ‚‚.

- The stream then flows to Separator 2, which is maintained at a lower pressure (e.g., 80 bar) and temperature. This second pressure drop causes the next fraction of compounds to precipitate.

- Precise pressure control in each separator, achieved using specialized back-pressure regulators, is critical for obtaining pure fractions [15].

- Collection: Each separator yields a distinct fraction of the extract. The final gaseous COâ‚‚ is recycled.

Diagram 1: SCO2 Extraction and Fractionation Workflow.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of supercritical COâ‚‚ extraction requires specific reagents and equipment. The following table details key components of a research-scale setup.

Table 3: Essential Materials and Reagents for Supercritical COâ‚‚ Extraction Research

| Item | Function/Description | Research Considerations |

|---|---|---|

| High-Purity COâ‚‚ Supply | Primary extraction solvent. Must be free of impurities that could contaminate the extract or interfere with the process. | Purity > 99.9% is typical. Source (bulk tank or cylinders) impacts long-term operational costs [12]. |

| Co-Solvents | Modifies the polarity of scCOâ‚‚ to enhance solubility of target compounds. | Ethanol is common due to its GRAS status [9]. Methanol offers higher polarity. Concentration (1-15%) is optimized empirically [9]. |

| Extraction Vessel | High-pressure cell that holds the solid sample during extraction. | Constructed from 316 stainless steel. Volume determines batch size. Must withstand pressures up to 700 bar [12]. |

| Precision Pumps | To deliver COâ‚‚ (and co-solvent) at a constant, precise flow rate against high back-pressure. | Syringe pumps offer high precision for lab-scale work. Dual-pump systems allow independent control of COâ‚‚ and co-solvent flows [17]. |

| Back-Pressure Regulator (BPR) | Maintains consistent system pressure upstream. Critical for fractionation and controlling solvent power. | Must provide precise pressure control and resist blockage from ice formation during COâ‚‚ expansion [15]. Diaphragm-based regulators are often used. |

| Heated Oven/Jacket | Maintains the entire system (vessels, lines) at a temperature above the critical point of CO₂. | Requires precise temperature control (±1°C) to ensure stable supercritical conditions and reproducible results [13]. |

| Separator(s) | Vessel(s) where pressure is reduced to precipitate the extract. | Multiple separators enable fractionation. Often equipped with sight glasses and temperature control [14] [15]. |

| Senkirkin | Senkirkin, CAS:2318-18-5, MF:C19H27NO6, MW:365.4 g/mol | Chemical Reagent |

| Thozalinone | Thozalinone, CAS:655-05-0, MF:C11H12N2O2, MW:204.22 g/mol | Chemical Reagent |

Quantitative Data and Solubility Behavior

The efficiency of scCOâ‚‚ extraction is governed by the solubility of target compounds, which is a direct function of pressure and temperature. The following data illustrates key relationships.

Table 4: Influence of Operational Parameters on Extraction Yield and Selectivity

| Parameter | Effect on Process | Typical Experimental Range | Impact on Yield/Selectivity |

|---|---|---|---|

| Pressure | Directly controls COâ‚‚ density and solvent power. | 80 - 600 bar [16] [10] | Increased pressure generally increases yield for most compounds (e.g., lipids, essential oils) by enhancing solubility [16] [14]. |

| Temperature | Has a dual effect: increases solute vapor pressure but decreases CO₂ density. | 35 - 80 °C [10] | The net effect is compound-specific. A "crossover region" exists where solubility is influenced by the competing effects [10]. |

| COâ‚‚ Flow Rate | Influences the mass transfer kinetics and extraction time. | 1 - 10 g/min (lab-scale) | Higher flow reduces extraction time but may decrease efficiency if equilibrium is not reached. Optimized to balance throughput and COâ‚‚ consumption [17]. |

| Particle Size | Affects the diffusion path length and internal mass transfer resistance. | 0.1 - 0.5 mm [16] | Smaller particles increase yield and rate by increasing surface area, but excessive fining can cause channeling [16]. |

Diagram 2: Primary Pressure Effect on Extraction Yield.

The solubility of a model compound like naphthalene in scCO₂ vividly demonstrates this pressure dependence. At a constant temperature of 50°C, the solubility can increase from a negligible 0.1 wt% at 70 atm to a significant 10 wt% at 300 atm [14]. This strong dependence is the foundational principle for both extraction and fractional separation.

Supercritical carbon dioxide stands as a superior solvent choice for modern, sustainable research and industrial processes due to its compelling combination of safety, environmental, and tunable physicochemical properties. Its status as a non-toxic, non-flammable, and recyclable solvent aligns perfectly with the principles of green chemistry, while its tunability offers researchers unparalleled control over separation processes. The experimental protocols and data outlined in this guide provide a foundation for scientists and drug development professionals to harness this versatile technology, contributing to safer, cleaner, and more efficient extraction methodologies in line with the evolving demands of scientific discovery and regulatory standards.

Core Components of a Supercritical CO2 Extraction System

Supercritical Carbon Dioxide (SC-CO2) Extraction is a sophisticated separation technology that utilizes carbon dioxide above its critical temperature (31.1 °C) and pressure (73.9 bar) as a solvent [18] [19]. In this supercritical state, CO2 exhibits unique properties, combining the penetrative ability of a gas with the solvating power of a liquid, making it an exceptionally efficient extraction medium [14]. This guide details the core components of an SFE system, providing researchers and drug development professionals with the technical foundation necessary for implementing this technology in analytical and process-scale applications across natural product extraction, pharmaceutical compound isolation, and nutraceutical development [20].

Core Components and Their Functions

A supercritical CO2 extraction system is an integrated assembly of several specialized components designed to maintain CO2 in its supercritical state throughout the extraction process. The synergy between these components ensures efficient, reproducible, and safe operation [18] [19].

Table 1: Core Components of a Supercritical CO2 Extraction System

| Component | Primary Function | Technical Specifications & Common Types |

|---|---|---|

| CO2 Supply & Pumping System | Pressurizes liquid CO2 to supercritical conditions [18]. | Pump Types: Reciprocating or syringe pumps (small scale); Diaphragm pumps (large scale) [18].Requirement: CO2 is typically cooled (e.g., below 5°C) before pumping to maintain liquid state and ensure pump efficiency [18]. |

| Extraction Vessel | Holds the solid or liquid raw material (matrix) for extraction [18] [19]. | Pressure Rating: Must withstand high pressures, typically at least 74 bar and often up to 350-800 bar [18].Heating: Jacketed or placed in an oven to maintain temperature above critical point [18]. |

| Heating System / Oven | Heats the pressurized CO2 and extraction vessel to achieve and maintain supercritical conditions [18] [20]. | Precisely controls extraction temperature, which significantly impacts solvent density and selectivity [18] [21]. |

| Pressure Maintenance Device | Maintains system pressure upstream. | Types: Capillary restrictor (analytical scale), needle valve, or automated Back Pressure Regulator (BPR) [18] [15]. Challenge: Requires heating to prevent freezing from adiabatic CO2 expansion [18] [15]. |

| Separation Vessel (Separator) | Receives CO2-extract mixture; precipitates extract by reducing CO2 solvating power [18] [19]. | Method: Pressure reduction, temperature increase, or both [18] [14]. Multiple separators in series enable fractional separation of different compounds [15]. |

| Heat Exchangers | Cools CO2 pre-pump and heats/cools streams at various process points [18] [20]. | Manages thermal energy to maintain specific conditions and counteract cooling from CO2 expansion [18]. |

| CO2 Recycling System | Cools, re-liquefies, and recirculates CO2 gas from the separator, reducing operational costs and environmental impact [19] [14]. | Essential for large-scale industrial processes to ensure economic viability [14]. |

The following diagram illustrates the logical workflow and the interconnection of these core components in a typical supercritical CO2 extraction system.

Advanced System Configuration: Fractional Separation

For complex extracts, a single separator is often insufficient. Fractional Separation employs multiple separators in series, each set at a progressively lower pressure (and/or different temperature), to selectively precipitate different classes of compounds based on their varying solubility in CO2 [15]. This multi-stage process, controlled by precise back-pressure regulators, enables the selective and sequential isolation of specific components from a complex mixture, greatly enhancing the selectivity and purity of the final products [15] [20].

Detailed Experimental Protocol for System Operation

To ensure reproducible results, a standardized operational sequence must be followed. The protocol below synthesizes general best practices with specific parameters from published research on extracting lycopene from grapefruit [21] and bioactive compounds from jamun fruit [22].

Raw Material Preparation

- Commutation: The plant material (e.g., grapefruit, jamun pulp) must be dried and ground into a fine powder [21] [22]. A particle size of 250 µm (passed through a 40-60 mesh sieve) is often optimal to increase surface area for extraction while avoiding excessive packing that can impede fluid flow [21].

- Loading: The prepared biomass is mixed with an inert material like glass wool and loaded into the extraction vessel to prevent channeling and ensure uniform solvent passage [22]. For the referenced study, a 100 g sample was used [21].

System Pressurization and Heating

- The system is sealed, and liquid CO2 is pumped into the extraction vessel.

- Pressure and Temperature: The system is brought to the desired operating conditions. For example, a study might use 305 bar and 70 °C [21]. The pressure and temperature are maintained by the pump and heating system, respectively.

Dynamic Extraction

- Supercritical CO2 is continuously passed through the extraction vessel at a controlled mass flow rate. A common flow rate in research settings is 35 g/min [21].

- Use of Co-solvent: To enhance the extraction of polar compounds, a food-grade co-solvent like ethanol can be introduced. It is typically added at 2-5% of the total solvent volume [21] [22]. A co-solvent pump is used for this purpose.

Separation and Collection

- The CO2-rich stream containing the dissolved solutes passes through a back-pressure regulator into the separation vessel.

- In the separator, a reduction in pressure (e.g., to atmospheric or a controlled intermediate pressure) causes the CO2 to revert to a gaseous state, precipitating the extracted material [18] [19]. The extract is collected from the separator valve.

Solvent Recycling and System Depressurization

- The gaseous CO2 exiting the separator can be vented or directed to a recycling system where it is cooled, re-liquefied, and returned to the CO2 supply tank for reuse [14].

- After the set extraction time (e.g., 135 minutes [21]), the pump is stopped, and the system is slowly depressurized.

Table 2: Example Experimental Parameters from Peer-Reviewed Studies

| Extraction Target | Optimal Pressure | Optimal Temperature | CO2 Flow Rate | Co-solvent (Ethanol) | Extraction Time | Reference |

|---|---|---|---|---|---|---|

| Lycopene from Grapefruit | 305 bar | 70 °C | 35 g/min | 5% | 135 min | [21] |

| Bioactives from Jamun Fruit | 162 bar | 50 °C | Not Specified | 2.0 g/min (flow) | Not Specified | [22] |

The Scientist's Toolkit: Essential Research Reagents & Materials

Successful supercritical CO2 extraction relies on more than just equipment. The following table lists key consumables and materials essential for research and development in this field.

Table 3: Essential Research Reagents and Materials for SFE

| Reagent/Material | Function in SFE Research | Technical Notes |

|---|---|---|

| SFE-Grade CO2 | Primary extraction solvent. | High purity (≥ 99.9%) is essential to prevent contamination and ensure consistent solvent strength [22]. |

| Food-Grade Co-solvents (e.g., Ethanol) | Modifies polarity of SC-CO2 to enhance extraction efficiency of polar compounds (e.g., polyphenols, anthocyanins) [18] [22]. | Preferred for food and pharmaceutical applications. Must be anhydrous to prevent ice formation during expansion [21] [20]. |

| Raw Biomass | The source material for extraction. | Requires standardized pre-processing (drying, milling, sieving) for reproducible results [21] [22]. |

| Analytical Standards | Used for quantifying and identifying extracted compounds via techniques like HPLC, GC-MS, or SFC [21] [22]. | Critical for method validation and accurate yield calculation (e.g., using cyanidin-3-glucoside for anthocyanins [22]). |

| Inert Packing Material | Used to fill void space in the extraction vessel, improving flow dynamics and preventing channeling [22]. | Glass wool is a common example used to ensure uniform packing and solvent distribution [22]. |

| Orforglipron | Orforglipron, CAS:2212020-52-3, MF:C48H48F2N10O5, MW:883.0 g/mol | Chemical Reagent |

| 3-(N-methyl4-methylbenzenesulfonamido)-N-{[3-(trifluoromethyl)phenyl]methyl}thiophene-2-carboxamide | 3-(N-methyl4-methylbenzenesulfonamido)-N-{[3-(trifluoromethyl)phenyl]methyl}thiophene-2-carboxamide, CAS:1115871-56-1, MF:C21H19F3N2O3S2, MW:468.51 | Chemical Reagent |

The supercritical CO2 extraction system is a sophisticated integration of components designed to precisely control the physical state and solvating power of carbon dioxide. Understanding the role of each core part—from the high-pressure pump and extraction vessel to the separator and recycling system—is fundamental for researchers aiming to develop efficient, scalable, and reproducible extraction protocols. The adaptability of the system, particularly through the use of co-solvents and fractional separation, allows for remarkable selectivity, making it an indispensable tool in modern natural product and pharmaceutical research. By adhering to detailed experimental protocols and utilizing high-quality reagents, scientists can leverage this green technology to isolate high-purity bioactive compounds effectively.

Supercritical fluid extraction using carbon dioxide (SFE-CO2) is a advanced separation process that utilizes carbon dioxide above its critical temperature and pressure as the primary solvent to isolate one component (the extractant) from another (the matrix) [18]. This technology has gained significant prominence as a green and sustainable method, particularly in pharmaceutical, food, and cosmetic industries, due to its ability to eliminate the need for hazardous organic solvents while protecting heat-sensitive bioactive compounds [9]. The core principle leverages the unique properties of supercritical CO2, which exhibits liquid-like densities with gas-like diffusivity and viscosity, enabling superior penetration into solid matrices and efficient extraction [18] [16].

The critical point of carbon dioxide is defined by a temperature of 31°C and a pressure of 74 bar [18]. Beyond this point, CO2 enters a supercritical state that is neither liquid nor gas but possesses properties of both, making it an exceptionally tunable solvent. The tunable dissolving power of supercritical CO2, achieved by simply varying pressure and temperature conditions, allows for remarkable selectivity in extracting target compounds without thermal degradation [18] [23]. This technical guide provides a comprehensive breakdown of the fundamental SFE-CO2 process, detailing each operational stage from initial pressurization to final collection, and situates this technology within broader research on sustainable extraction methodologies.

The SFE-CO2 System: Core Components and Functions

A typical SFE-CO2 system consists of several integrated components that work in concert to maintain supercritical conditions and achieve efficient extraction. Each component plays a critical role in the process integrity and efficiency.

CO2 Supply and Pump: Liquid carbon dioxide is supplied from a reservoir or cylinder and pumped as a liquid, typically below 5°C and approximately 50 bar pressure [18]. Pumping CO2 as a liquid is essential for efficiency, as liquids are nearly incompressible; pumping supercritical fluid would consume much of the pump stroke in compression rather than fluid transfer [18]. For small-scale extractions (up to a few grams per minute), reciprocating CO2 pumps or syringe pumps are common, while diaphragm pumps are preferred for larger scale operations [18].

Pressure Vessel (Extraction Cell): This vessel contains the sample matrix and must withstand high pressures—typically at least 74 bar, with most extractions conducted below 350 bar, though some applications (e.g., vegetable oil extraction) may require pressures up to 800 bar [18]. The vessel requires precise temperature control, achieved through placement in an oven for small systems or via heated jackets for larger vessels [18].

Pressure Maintenance System: The system pressure must be maintained consistently from the pump through the pressure vessel. In smaller systems, this is often accomplished with a simple restrictor (capillary tube or needle valve), while larger systems employ back pressure regulators that maintain upstream pressure via spring, compressed air, or electronically controlled valves [18]. A critical consideration is the heating of this component, as adiabatic expansion of CO2 causes significant cooling that can lead to blockages from frozen water or extracted materials [18].

Collection Vessel: This is where the extracted material is ultimately recovered. The supercritical solvent, now laden with solubilized compounds, passes into this vessel at lower pressure, causing a sharp decrease in CO2 density and dissolving power, which precipitates the extracted material [18]. For analytical-scale SFE, the gaseous CO2 is often bubbled through a solvent trap after depressurization to capture the precipitated components [18].

Heating and Cooling System: Temperature management is crucial throughout the system. The CO2 must be cooled before pumping to maintain liquid conditions, heated after pressurization to achieve supercriticality, and the separator may require heating to prevent cooling during expansion [18].

Step-by-Step Process Breakdown

The SFE-CO2 process follows a logical sequence where each step directly influences extraction efficiency and selectivity.

Step 1: Preparation of the Matrix

The solid matrix containing the target compounds must undergo specific preparation steps to maximize extraction efficiency. The sample is typically freeze-dried and ground to a fine powder with a particle size ranging from 0.4–0.8 mm [24]. Reducing particle size increases the surface area for mass transfer, while freeze-drying removes moisture that can interfere with extraction efficiency [24]. The prepared sample is then precisely loaded into the extraction vessel.

Step 2: Pressurization and Heating

Liquid CO2 is pumped from its reservoir into the system. The pump must deliver CO2 at a pressure exceeding the critical pressure of 74 bar [18]. The mass flow rate should be carefully controlled and measured using Coriolis flow meters, as the density of CO2 changes with temperature [18]. The pressurized liquid CO2 then passes through a heating zone where it is heated above its critical temperature of 31°C, transitioning it into a supercritical state before it enters the extraction vessel [18].

Step 3: Supercritical Extraction

Once in the extraction vessel, the supercritical CO2 rapidly diffuses into the solid matrix, dissolving the target material [18]. The process involves two essential mass transfer steps: (1) diffusion of the solvent into the matrix, and (2) dissolution of the material into the supercritical fluid followed by its diffusion out of the matrix into the bulk solvent [18]. The properties of the supercritical fluid can be altered by varying pressure and temperature, allowing for selective extraction—for instance, volatile oils can be extracted at lower pressures (around 100 bar), while lipids require higher pressures [18]. The duration of this dynamic extraction phase varies significantly based on the application, ranging from 10-60 minutes for some materials to several hours for others [18] [24].

Step 4: Depressurization and Separation

The solution of dissolved extract in supercritical CO2 is swept from the extraction cell into a separator or collection vessel maintained at lower pressure [18]. This pressure reduction dramatically decreases the density and solvating power of the CO2, causing the extracted material to precipitate out [18]. It is possible to implement fractionation using a series of vessels at progressively reducing pressures to separate different compound classes based on their solubility characteristics [18].

Step 5: Collection and Solvent Recovery

The precipitated extract is collected in the separation vessel. Meanwhile, the CO2 can follow one of two paths: (1) it can be cooled, re-compressed, and recycled back to the pump to minimize solvent consumption and operational costs, or (2) it can be depressurized to atmospheric pressure and vented [18] [25]. For analytical applications where solvent recycling isn't implemented, the gaseous CO2 is typically bubbled through a solvent to trap any remaining precipitated components [18].

Step 6: System Cleanup

Following collection, the system must be purged of any residual extract to prevent cross-contamination between batches. The extraction vessel requires cleaning, and all components should be inspected for potential clogging or wear, particularly when processing materials with high lipid or moisture content [18].

The following workflow diagram illustrates the complete SFE-CO2 process:

Process Modeling and Mass Transfer Fundamentals

The efficiency of SFE-CO2 is governed by fundamental mass transfer principles. A simple model conceptualizes two essential steps: (1) transport of the solid particles to the surface (via diffusion or other mechanisms), and (2) dissolution in the supercritical fluid [18]. The relative rates of these steps determine the overall extraction kinetics and can be visualized through concentration profiles within a spherical particle [18].

In scenarios where dissolution is fast relative to diffusion, material is carried away from the particle edge faster than it can diffuse from the center, resulting in a concentration profile that drops to zero at the surface [18]. This creates a diffusion-limited extraction where the rate can be increased by raising temperature to enhance diffusion, but not by increasing solvent flow rate [18]. Conversely, when solubility is low relative to diffusion, the extractant diffuses to the edge faster than the solvent can carry it away, resulting in a relatively flat concentration profile across the particle [18]. This solubility-limited extraction can be accelerated by increasing solvent flow rate [18].

The extraction curve (% recovery vs. time) reveals the dominant mechanism: diffusion-controlled extractions show initially rapid rates that slow dramatically once surface concentration drops to zero; solubility-limited extractions demonstrate nearly constant rates until completion; and extractions with significant matrix effects (e.g., desorption from active sites) may plateau before achieving complete recovery [18].

Optimization of SFE-CO2 Parameters

Optimizing SFE-CO2 requires balancing competing factors of completeness, speed, selectivity, and cost. The optimal configuration depends on the extraction purpose—analytical applications prioritize complete extraction in the shortest time, while production-scale operations may target 70-80% yield for economic reasons, considering solvent consumption and throughput [18].

Key Operational Parameters

- Pressure and Temperature: These interdependent parameters directly control solvent density and selectivity. Generally, higher pressure increases solubility, while temperature effects are more complex—near the critical point, increasing temperature decreases density and dissolving power, but at higher pressures, solubility typically increases with temperature [18].

- CO2 Flow Rate: Measured as mass flow rather than volume due to CO2 compressibility [18]. High flow rates maximize extraction speed but waste solvent in diffusion-limited regimes, while low flows minimize solvent use but extend processing time significantly [18].

- Extraction Time: Must be optimized for each application. Research indicates that dynamic extraction times can range from 40-70 minutes for initial optimization [24] to 7 hours for complete extraction of certain compounds like polyprenol [24].

- Co-solvents: Modifiers such as ethanol or methanol can significantly enhance the extraction of polar compounds that have limited solubility in pure CO2 [18] [9]. Food-grade ethanol is particularly valuable in pharmaceutical and food applications, acting as a polarity modifier that expands the range of extractable compounds while maintaining regulatory compliance [18] [9]. Typical co-solvent flow rates are much lower than main CO2 flow, for instance 0.05 mL/min against a CO2 flow of 10 mL/min [24].

Quantitative Process Parameters

The following table summarizes key operational parameters and their effects on SFE-CO2 efficiency, compiled from research applications:

Table 1: SFE-CO2 Operational Parameters and Optimization Guidelines

| Parameter | Typical Range | Effect on Process | Research Example |

|---|---|---|---|

| Pressure | 100-350 bar (up to 800 bar for oils) | Higher pressure increases solvent density and dissolving power; enables selective extraction of different compound classes [18]. | Polyprenol extraction optimized at 200 bar; 300 bar preferred for faster kinetics [24]. |

| Temperature | 40-70°C | Complex effect: near critical point, higher T decreases density; at higher pressures, increases solubility [18] [24]. | 70°C effective for polyprenol extraction from conifers [24]. |

| CO2 Flow Rate | Varies by scale (e.g., 10 mL/min) | Higher flows reduce extraction time but increase solvent use; optimal flow balances time and cost [18] [24]. | Mass flow measurement recommended via Coriolis flow meters [18]. |

| Extraction Time | 10-60 min (up to 7 hours) | Duration depends on matrix and compound; longer times increase completeness but diminish throughput [18] [24]. | 7-hour dynamic extraction provided highest polyprenol yield [24]. |

| Co-solvent (Ethanol) | 0.5-10% modifier | Enhances polarity and solubility of polar compounds; ethanol preferred for food/pharma applications [24] [9]. | 0.05 mL/min ethanol flow rate significantly improved polyprenol recovery [24]. |

| Particle Size | 0.4-0.8 mm | Smaller particles increase surface area and reduce diffusion path length, improving kinetics [24]. | Freeze-dried, homogenized tissue improves extraction efficiency [24]. |

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of SFE-CO2 requires specific materials and reagents tailored to research objectives. The following table details essential components for establishing a robust SFE-CO2 process.

Table 2: Essential Research Reagents and Materials for SFE-CO2

| Item | Specification/Function | Research Application Notes |

|---|---|---|

| Carbon Dioxide | >99.9% purity [24] | High-purity, residue-free CO2 is essential to prevent contamination of extracts and system fouling. |

| Co-solvents | HPLC grade ethanol, methanol, acetone [24] [9] | Ethanol (food-grade) is preferred for pharmaceutical and nutraceutical applications due to low toxicity [9]. |

| Collection Solvents | HPLC grade 2-propanol, methanol, acetonitrile, hexane, chloroform [24] | Used to trap extracts post-depressurization in analytical SFE; selection depends on extract polarity. |

| Matrix Preparation | Freeze-dryer, laboratory mill [24] | Enables moisture removal and particle size reduction (~0.4-0.8 mm) to optimize mass transfer [24]. |

| Saponification Reagents | Potassium hydroxide, formic acid [24] | Used for post-processing of lipid extracts to isolate compounds like polyprenols from fatty acids [24]. |

| Analytical Standards | Compound-specific standards (e.g., polyprenol mixes) [24] | Essential for qualitative and quantitative analysis of target compounds via HPLC or LC-MS [24]. |

| 9,9-Bis(6-bromohexyl)fluorene | 9,9-Bis(6-bromohexyl)fluorene, CAS:269059-34-9, MF:C25H32Br2, MW:492.339 | Chemical Reagent |

| N-(2,2-dimethoxyethyl)prop-2-enamide | N-(2,2-dimethoxyethyl)prop-2-enamide, CAS:49707-23-5, MF:C7H13NO3, MW:159.18 g/mol | Chemical Reagent |

Advantages, Limitations, and Research Applications

Comparative Advantages

SFE-CO2 offers compelling advantages over conventional solvent extraction:

- Selectivity: Solvent properties can be fine-tuned by adjusting pressure and temperature, enabling selective extraction sequences [18].

- Speed: Diffusivities are much faster in supercritical fluids than liquids, and the lack of surface tension with low viscosity enables penetration into matrices inaccessible to liquids, reducing extraction time from hours to minutes [18] [16].

- Product Quality: Extraction occurs at moderate temperatures, protecting heat-sensitive compounds, and the process leaves no solvent residues in the final product [18] [9].

- Sustainability: CO2 is non-toxic, non-flammable, and can be recycled within the process, eliminating the use of petroleum-based solvents and reducing environmental impact [25] [9].

Technical and Economic Limitations

Despite its advantages, SFE-CO2 presents significant challenges:

- High Capital Cost: The requirement for high-pressure vessels, pumps, and pressure maintenance systems increases initial investment compared to conventional extraction [18] [9].

- Operational Complexity: Optimizing multiple interdependent parameters (pressure, temperature, flow, time) requires specialized expertise [9].

- Limited Polarity Range: Pure supercritical CO2 is non-polar and has limited effectiveness for highly polar compounds without modifiers [18] [9].

- Energy Intensity: Maintaining supercritical conditions is energy-intensive, particularly for large-scale systems [9].

- Scalability Challenges: Engineering large-scale systems that maintain control and extraction efficiency presents significant design hurdles [9].

Research and Industrial Applications

SFE-CO2 has demonstrated remarkable versatility across numerous research and industrial domains, including:

- Pharmaceutical/Nutraceutical Extraction: Isolation of bioactive compounds like polyprenols from plant materials (e.g., conifer species) with yields comparable to organic solvents but superior purity [24] [9].

- Food Industry: Decaffeination of coffee and tea, extraction of essential oils, spices, and colors, and removal of unwanted components (e.g., lipids) [18] [9].

- Environmental Applications: Cleaning and decontamination of precision components, medical devices, and recycled materials without generating hazardous solvent waste [25].

- Advanced Materials Processing: Aerogel drying, impregnation of polymers and textiles, and micronization of pharmaceutical compounds [25].

The following diagram illustrates the relationship between key process parameters and their effects on extraction performance:

The basic SFE-CO2 process represents a sophisticated yet highly controllable platform technology for sustainable extraction across multiple industries. From initial matrix preparation through pressurized extraction to final collection, each stage offers opportunities for optimization based on the specific properties of target compounds and the composition of the source matrix. While challenges remain in equipment cost and operational complexity, ongoing research continues to expand applications and improve efficiency. As industries increasingly prioritize green technologies and solvent-free products, SFE-CO2 stands positioned as a cornerstone technology for the future of separation science, particularly in pharmaceutical and nutraceutical development where purity, selectivity, and preservation of bioactivity are paramount.

SFE-CO2 Methods and Pharmaceutical Applications

Supercritical Carbon Dioxide (SC-CO₂) extraction represents a revolutionary advancement in separation technology, offering an environmentally friendly and efficient alternative to conventional solvent-based methods. This technology utilizes carbon dioxide above its critical temperature (304.12 K or 31.1 °C) and pressure (73.8 bar or 1071 psi), where it exhibits unique properties intermediate between gases and liquids [20] [26]. In this state, CO₂ possesses liquid-like densities with gas-like diffusivity and viscosity, enabling exceptional penetration into solid matrices and enhanced mass transfer rates [20]. The growing adoption of SC-CO₂ extraction across pharmaceuticals, food processing, and cosmetics underscores its significance in modern industrial applications, particularly as industries increasingly prioritize green chemistry principles [27] [20].

This technical guide provides an in-depth examination of three fundamental SC-COâ‚‚ extraction processes: Batch, Continuous Flow, and Dynamic extraction. Understanding the operational principles, applications, and comparative advantages of these methods is essential for researchers and drug development professionals seeking to implement supercritical fluid technology. The selectivity, efficiency, and sustainability of SC-COâ‚‚ extraction make it particularly valuable for processing thermolabile bioactive compounds, where preserving molecular integrity is paramount [28] [20].

Fundamental Principles of Supercritical COâ‚‚ Extraction

Supercritical CO₂ extraction operates on the principle of utilizing carbon dioxide in a state beyond its critical point, where it exhibits tunable solvent properties. The critical point of CO₂ is readily achievable (Tc = 31.1°C, Pc = 73.8 bar), making it practical for processing heat-sensitive compounds [20] [26]. In this supercritical state, CO₂ displays liquid-like solvation power while maintaining gas-like transport properties, with densities typically ranging from 0.3 to 0.9 g/cm³ [26].

The solvent power of SC-COâ‚‚ is primarily density-dependent and can be precisely controlled through manipulation of pressure and temperature parameters [20] [29]. This tunability enables selective extraction of target compounds by adjusting solvation characteristics. SC-COâ‚‚ is particularly effective for non-polar compounds; however, the addition of polar co-solvents (e.g., ethanol) can significantly enhance extraction efficiency for more polar molecules [27] [30] [20]. The basic SFE process comprises two fundamental stages: extraction (where SC-COâ‚‚ dissolves target compounds from the matrix) and separation (where pressure reduction causes solute precipitation) [20].

Table 1: Critical Properties of Common Substances for Supercritical Extraction

| Substance | Critical Temperature (°C) | Critical Pressure (bar) | Key Applications |

|---|---|---|---|

| Carbon Dioxide (COâ‚‚) | 31.1 | 73.8 | Universal solvent for non-polar to moderately polar compounds (essential oils, cannabinoids, antioxidants) |

| Water (Hâ‚‚O) | 374.0 | 220.6 | Extraction of polar compounds (rarely used due to harsh conditions) |

| Ethane (C₂H₆) | 32.2 | 48.8 | Alternative for non-polar compounds (limited use due to flammability) |

| Ethanol (Câ‚‚Hâ‚…OH) | 241.0 | 61.4 | Primarily used as polar co-solvent with SC-COâ‚‚ |

| Propane (C₃H₈) | 96.7 | 42.5 | Lipid extraction (limited use due to flammability risk) |

Core Extraction Methodologies

Batch Extraction

Principles and Operation: Batch extraction involves processing a fixed quantity of raw material in a closed system where the substrate remains stationary throughout the extraction cycle [27]. In this method, the extraction vessel is loaded with a specific amount of pre-treated biomass, sealed, and brought to the desired operating conditions. Supercritical COâ‚‚ is introduced and maintained in contact with the material for a predetermined period, allowing diffusion and solubilization of target compounds. Upon completion, the system is depressurized, and the extract is collected from the separation vessel [27] [29]. This approach is characterized by its operational simplicity and flexibility in handling diverse feedstocks.

Experimental Protocol for Batch Extraction:

- Sample Preparation: Biomass is typically dried (e.g., at 50°C for 48 hours) and milled to a specific particle size range (e.g., 0.25-0.50 mm) to enhance mass transfer while avoiding excessive channeling [31] [29].

- System Loading: The prepared material is packed into a tea bag or similar porous container and positioned in the extraction vessel to ensure even COâ‚‚ flow distribution [29].

- Pressurization and Heating: The system is sealed and pressurized with CO₂ using a syringe pump or compressor while temperature is adjusted to achieve supercritical conditions (typically 40-80°C, 150-450 bar) [30] [31].

- Static Extraction Phase: The supercritical COâ‚‚ remains in contact with the biomass for a specified static extraction period (e.g., 5-55 minutes) to allow saturation with solutes [30].

- Depressurization and Collection: The solute-laden COâ‚‚ is transferred to a separator where pressure reduction causes solute precipitation, and the extract is collected [29].

- System Purge: Residual COâ‚‚ is vented, and the spent biomass is removed [29].

Key Process Parameters:

- Particle size distribution (significantly impacts extraction kinetics) [31]

- Static extraction time (typically 5-55 minutes) [30]

- Temperature (40-80°C) and pressure (150-450 bar) [30]

- CO₂ to biomass ratio (e.g., ≥ 0.99 mass fraction) [29]

- Use of co-solvents (e.g., ethanol at 0-9% w/w) to enhance polarity [29]

Figure 1: Batch Extraction Workflow

Continuous Flow Extraction

Principles and Operation: Continuous flow extraction involves the steady passage of supercritical COâ‚‚ through an extraction chamber where raw material is continuously fed and extracted material is simultaneously removed [27]. This method maintains constant extraction conditions, allowing for uninterrupted operation and making it particularly suitable for large-scale industrial applications. The counter-current flow arrangement, where COâ‚‚ and biomass move in opposite directions, maximizes the concentration gradient driving force throughout the system, leading to enhanced extraction efficiency and higher throughput compared to batch systems [27].

Experimental Protocol for Continuous Flow Extraction:

- System Stabilization: The extraction system is brought to operational temperature and pressure before biomass introduction (typically 40-80°C, 150-450 bar) [30].

- Continuous Feeding: Prepared biomass is steadily fed into the extraction vessel using specialized high-pressure feeding mechanisms.

- Counter-current Operation: Supercritical COâ‚‚ is pumped through the system in the opposite direction to biomass flow, maximizing contact efficiency [27].

- Dynamic Extraction: The continuous flow of SC-COâ‚‚ through the biomass bed dissolves target compounds (dynamic extraction time typically 25-55 minutes) [30].

- Separation and Collection: The solute-rich COâ‚‚ stream passes through a pressure reduction valve into a separation chamber where extracts precipitate and are continuously collected.

- COâ‚‚ Recycling: The depressurized COâ‚‚ is condensed, re-pressurized, and returned to the extraction vessel in a closed-loop system [20].

Key Process Parameters:

- Solvent flow rate (significantly impacts extraction kinetics and specific consumption) [31]

- Biomass feed rate (determines residence time)

- Extractor diameter to length ratio (affects extraction rate and COâ‚‚ specific consumption) [31]

- Temperature (40-80°C) and pressure (150-450 bar) gradients along the system [30]

- Bed porosity and compaction (influence flow distribution and channeling) [31]

Figure 2: Continuous Flow Extraction System

Dynamic Extraction

Principles and Operation: Dynamic extraction combines elements of both batch and continuous processes, featuring periodic replenishment of raw material while maintaining a continuous flow of supercritical COâ‚‚ [27]. This hybrid approach allows for extended extraction times without interruption for vessel loading/unloading, striking a balance between operational efficiency and extraction effectiveness. The method is particularly advantageous for processes where raw material requires extended contact time with the solvent but where fully continuous feeding presents technical challenges [27].

Experimental Protocol for Dynamic Extraction:

- Initial System Charging: The extraction vessel is loaded with an initial batch of biomass.

- Continuous Solvent Flow: Supercritical CO₂ is continuously pumped through the system at predetermined conditions (e.g., 40-80°C, 150-450 bar) [30].

- Semi-continuous Operation: While COâ‚‚ flows continuously, biomass is periodically replenished either through multiple extraction vessels in parallel or specialized feeding systems.

- Extended Extraction Phases: The continuous COâ‚‚ flow is maintained for extended periods (dynamic extraction time typically 25-55 minutes per cycle) [30].

- Separation and Collection: Similar to continuous systems, solute-rich COâ‚‚ is expanded in separators for product recovery.

- Modular Operation: Multiple extraction vessels may be employed in tandem, allowing one vessel to be unloaded/loaded while others remain operational.

Key Process Parameters:

- Cycle time for biomass replenishment

- Dynamic extraction duration (typically 25-55 minutes) [30]

- COâ‚‚ flow rate (impacts extraction kinetics)

- Number of extraction vessels in parallel systems

- Temperature (40-80°C) and pressure (150-450 bar) stability during material transitions [30]

Comparative Analysis of Extraction Methods

Table 2: Comparative Analysis of SC-COâ‚‚ Extraction Methods

| Parameter | Batch Extraction | Continuous Flow Extraction | Dynamic Extraction |

|---|---|---|---|

| Process Scale | Laboratory to pilot scale (typically < 10L) | Large industrial scale | Pilot to medium industrial scale |

| Throughput | Low to medium | High | Medium to high |

| Operational Complexity | Low | High | Medium |

| Capital Cost | Low to medium | High | Medium to high |

| Flexibility | High (easy parameter changes) | Low (fixed parameters) | Medium |

| Optimal Applications | Research, high-value compounds, multiple small batches | Bulk commodities, single product lines | Medium-volume production, multiple similar compounds |

| Solvent Consumption | Higher per unit product | Lower per unit product | Intermediate |

| Yield Efficiency | Variable, often lower | High and consistent | Consistently high |

| Typical Extraction Time | 0.5 - 4 hours | Continuous operation | Extended cycles with periodic replenishment |

| Process Control | Simple | Complex | Moderately complex |

Advanced Technical Considerations

Process Optimization and Modeling

Optimizing SC-CO₂ extraction requires careful consideration of multiple interacting parameters. Mathematical modeling plays a crucial role in process design and scale-up, with the Sovová model being widely employed for simulating extraction kinetics from seed and plant materials [31]. This model accounts for both internal and external mass transfer limitations, distinguishing between "free" and "bound" solute in cellular structures. Recent advances incorporate machine learning approaches, with XGBoost algorithms demonstrating exceptional predictive capability for drug solubility in SC-CO₂ (R² = 0.9984, RMSE = 0.0605) [32].

Energy consumption analysis reveals significant nonlinearities in SC-COâ‚‚ processes, with regression models achieving Mean Absolute Percentage Errors of 7.6% in steady-state electricity consumption prediction [33]. Identification of dynamic energy consumption patterns enables real-time optimization strategies, particularly important for batch and dynamic systems where transient conditions prevail.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Essential Research Reagents and Materials for SC-COâ‚‚ Extraction

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Food-Grade COâ‚‚ (99.995%) | Primary supercritical solvent | Must be moisture-free; critical for all extraction types [29] [26] |

| Anhydrous Ethanol | Polar co-solvent | Enhances extraction of polar compounds (0-9% w/w typical) [30] [29] |

| Glass Beads/Pearls | Dispersant agent | Prevents selective channeling of COâ‚‚; improves yield [30] |

| Inert Ceramic Balls | Bed structuring | Improves flow distribution in continuous systems [31] |

| Silica Gel | Moisture scavenger | Protects system from moisture; critical for yield optimization [16] |

| Stainless Steel Porous Frits | Flow distribution | Ensures even COâ‚‚ flow through biomass beds [31] |

| High-Pressure Vessel Seals | System integrity | Material compatibility with COâ‚‚ essential (e.g., PTFE, special elastomers) |

| Analytical Reference Standards | Quantification | Essential for method validation and yield calculations |

| 9-Ethyldodecahydro-1H-carbazole | 9-Ethyldodecahydro-1H-carbazole, CAS:146900-30-3, MF:C14H25N, MW:207.35 g/mol | Chemical Reagent |

| 7-chloro-2H-benzo[e][1,2,4]thiadiazin-3(4H)-one 1,1-dioxide | 7-chloro-2H-benzo[e][1,2,4]thiadiazin-3(4H)-one 1,1-dioxide, CAS:5800-59-9, MF:C7H5ClN2O3S, MW:232.64 g/mol | Chemical Reagent |

Recent Technological Advances

Recent innovations in SC-CO₂ extraction have focused on enhancing selectivity, efficiency, and applicability to challenging matrices. Modifiers-assisted extraction utilizing ethanol, water, or other GRAS solvents significantly expands the polarity range of extractable compounds [27] [30]. Studies demonstrate that co-solvent implementation is the most significant factor (p < 0.05) for extracting bioactive metabolites from Arthrospira platensis, substantially improving yields of riboflavin, α-tocopherol, and β-carotene [30].

Fractionation techniques employing multiple separators in series enable selective recovery of different compound classes based on their unique solubility characteristics [27] [20]. This approach is particularly valuable for complex natural product extracts containing multiple valuable components with varying polarities.

Expanded bed extraction represents another innovation, increasing the contact surface area between COâ‚‚ and raw material by expanding the bed volume, thereby enhancing mass transfer and extraction efficiency, especially for materials with complex matrices [27].

Applications in Pharmaceutical and Natural Product Research

SC-CO₂ extraction has demonstrated exceptional utility in pharmaceutical and natural product research, particularly for thermolabile bioactive compounds. Research on Arthrospira platensis has shown that optimized SC-CO₂ extraction (450 bar, 60°C, 11 g/min ethanol co-solvent) effectively recovers functional extracts with significant antioxidant and antimicrobial activities [30]. The extracts obtained exhibited substantial bioactivity against clinically relevant pathogens including Staphylococcus aureus ATCC 25923, Pseudomonas aeruginosa ATCC 27853, Escherichia coli ATCC 25922, and Candida albicans ATCC 10231 [30].

In drug development, SC-CO₂ extraction enables recovery of high-purity active pharmaceutical ingredients without solvent residues. Recent research has successfully extracted astaxanthin from engineered Corynebacterium glutamicum, achieving 93.3% recovery using optimized conditions (9% w/w ethanol, 68°C, 550 bar) [29]. The efficiency of SC-CO₂ extraction for intracellular compounds highlights its capability to penetrate cellular membranes while maintaining compound integrity.

Bibliometric analysis reveals a significant growth in SC-COâ‚‚ extraction research, with an annual publication increase of 8.79% and collaborative efforts spanning 42 countries, reflecting the method's expanding importance in pharmaceutical and natural product sciences [28].

Batch, continuous flow, and dynamic extraction methods each offer distinct advantages within the spectrum of supercritical COâ‚‚ extraction technologies. Batch processes provide maximum flexibility for research applications and small-scale production of high-value compounds. Continuous flow systems deliver unmatched efficiency and throughput for industrial-scale operations, while dynamic extraction represents a versatile intermediate approach suitable for pilot-scale development and medium-volume production.

The selection of an appropriate extraction methodology must consider multiple factors including target compound characteristics, scale requirements, economic constraints, and desired product quality. Ongoing advancements in process modeling, energy optimization, and hybrid approaches continue to expand the capabilities and applications of supercritical fluid technology across the pharmaceutical and natural products sectors. As green chemistry principles increasingly influence process development across industries, SC-COâ‚‚ extraction methodologies are poised for continued adoption and innovation.

Supercritical Carbon Dioxide (SC-CO₂) extraction has established itself as a cornerstone of green chemistry, providing an environmentally friendly alternative to conventional organic solvents. Its core principle utilizes carbon dioxide above its critical point (31.1 °C and 73.8 bar), where it exhibits unique liquid-like solvation power and gas-like diffusivity and viscosity [28] [20]. While the fundamentals of SC-CO₂ extraction are well-documented, advancing the technique's efficiency and selectivity requires sophisticated approaches. This guide details three advanced methodologies that push the boundaries of SC-CO₂ applications: fractionation, counter-current extraction, and modifiers-assisted extraction. These techniques enable researchers to tackle complex separation challenges, achieve higher purity extracts, and recover thermally labile or polar bioactive compounds with precision, thereby enhancing the scope of SC-CO₂ in pharmaceutical, nutraceutical, and food research [16] [20].

Core Principles and System Configuration

A standard SC-COâ‚‚ extraction system is comprised of several key components: a chiller for cooling COâ‚‚, a pump for pressurization and fluid delivery, an extraction vessel (or column) to hold the sample, an oven to maintain the system above COâ‚‚'s critical temperature, one or more separators for collecting the extract, and a back-pressure regulator to maintain system pressure [20]. The process can operate in dynamic mode, where SC-COâ‚‚ continuously flows through the sample, or static mode, where the fluid is held in contact with the sample for a set period before release [20].

The solvation power of SC-COâ‚‚ is highly tunable, primarily governed by its density, which is a function of temperature and pressure [26]. This tunability is the foundational principle behind advanced techniques. A moderate increase in pressure at constant temperature significantly increases fluid density, thereby enhancing its ability to dissolve target compounds [16]. The selection of advanced techniques depends on the research objective, as shown in Table 1.

Table 1: Guide to Selecting Advanced SFE Techniques

| Technique | Primary Research Objective | Key Mechanism | Ideal for Compound Types |

|---|---|---|---|

| Fractionation | Separate a complex extract into distinct fractions of different polarities or molecular weights. | Sequential or staged changes in pressure/temperature across multiple separators. | Mixtures of triglycerides, fatty acids, tocopherols, and sterols [16]. |

| Counter-Current Extraction | Continuous, high-efficiency separation of compounds with similar solubilities. | Continuous contact of ascending SC-COâ‚‚ with descending liquid feed in a packed column. | Concentrating minor components like tocopherols and sterols from deodorizer distillates [16]. |

| Modifiers-Assisted Extraction | Enhance yield and selectivity for polar bioactive compounds. | Addition of a small volume of polar co-solvent (e.g., ethanol) to SC-COâ‚‚ to modify its polarity. | Polyphenols, flavonoids, alkaloids, and other medium-to-high polarity molecules [24] [20]. |

Fractionation and Sequential Separation

Concept and Workflow

Fractionation refers to the process of separating a complex crude extract into two or more distinct fractions based on differences in compound solubility, molecular weight, or polarity. This is achieved by coupling multiple separators in series and manipulating the pressure and temperature in each vessel to create a solubility gradient [20]. As the SC-COâ‚‚ stream, laden with dissolved compounds, passes through successive separators, conditions are altered to cause specific compound classes to precipitate out in a controlled manner.

A typical workflow for a two-stage fractionation is illustrated below. This setup allows for the separation of a crude extract into a volatile/oily fraction and a less volatile/waxy fraction.

Experimental Protocol for Lipid Fractionation

The following protocol, adapted from industrial processes for deodorizer distillates, outlines a two-step fractionation to obtain a sterol-enriched fraction [16].

- Objective: To recover sterol-enriched triglyceride fractions from vegetable oil deodorizer distillate (DD).

- Sample Preparation: The DD is first chemically modified via esterification to convert free fatty acids (FFA) into fatty acid methyl esters (FAME), which increases the solubility of the oil matrix in SC-COâ‚‚ and improves subsequent separation efficiency [16].

- SC-COâ‚‚ System Setup: Configure the system with at least two separators in series.

- Extraction & Fractionation Steps:

- First Extraction Step: Load the esterified DD into the extraction vessel. Set the extraction pressure to 14 MPa and temperature to 45 °C. The SC-CO₂ will primarily dissolve and carry the FAME.

- First Separation Step: Direct the fluid to the first separator. Maintain similar conditions (e.g., 14 MPa, 45 °C). The FAME-rich fraction is collected here.

- Second Extraction Step: Continue the extraction, but now increase the pressure to 20 MPa and temperature to 80 °C. These more severe conditions will dissolve the less soluble, higher molecular weight compounds like sterols and tocopherols.

- Second Separation Step: Direct the fluid to the second separator. The sterol- and tocopherol-enriched fraction precipitates here for collection.

- Key Parameters: This method does not leave solvent residues, but the sterol fraction obtained may require an additional purification step to achieve high purity [16].

Counter-Current Supercritical Fluid Extraction

Concept and Workflow

Counter-current supercritical fluid extraction (CC-SFE) is a continuous and highly efficient contact method for separating liquid mixtures. In a CC-SFE column, the liquid feed (e.g., a pre-extracted oil) flows downward by gravity, while the SC-COâ‚‚ solvent flows upward. This continuous counter-current flow creates multiple equilibrium stages within a single column, allowing for highly selective separation of compounds with similar solubilities, such as concentrating tocopherols from fatty acid esters [16].

The process is visualized in the following diagram, showing the interaction between the liquid feed and the SC-COâ‚‚ solvent stream.

Experimental Protocol for Tocopherol Concentration

This protocol details the application of CC-SFE for concentrating tocopherols from chemically modified sunflower oil deodorizer distillate (SfODD) [16].

- Objective: To concentrate tocopherols in the raffinate stream by removing fatty acid ethyl esters (FAEE).

- Sample Pretreatment: Chemically modify the SfODD via esterification to transform the mixture into a system primarily containing tocopherols, sterols, and FAEE. A solid sterol fraction can be isolated as a by-product at this stage [16].