Reducing Process Mass Intensity in API Synthesis: Strategies for Sustainable Pharmaceutical Manufacturing

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on strategies to reduce Process Mass Intensity (PMI) in Active Pharmaceutical Ingredient (API) synthesis.

Reducing Process Mass Intensity in API Synthesis: Strategies for Sustainable Pharmaceutical Manufacturing

Abstract

This article provides a comprehensive guide for researchers, scientists, and drug development professionals on strategies to reduce Process Mass Intensity (PMI) in Active Pharmaceutical Ingredient (API) synthesis. It covers the foundational principles of PMI as a key green chemistry metric, explores advanced methodologies like catalytic processes and continuous manufacturing, addresses common troubleshooting and optimization challenges, and evaluates validation through quality-by-design and comparative life-cycle assessment. The content synthesizes current industry best practices and emerging innovations to help teams design more efficient, sustainable, and economically viable API manufacturing processes.

Understanding Process Mass Intensity: The Cornerstone of Green API Synthesis

Defining Process Mass Intensity (PMI) and Its Role in Green Chemistry Metrics

Frequently Asked Questions (FAQs)

1. What is Process Mass Intensity (PMI) and how is it calculated?

Process Mass Intensity (PMI) is a key green chemistry metric used to benchmark the environmental efficiency of a process. It measures the total mass of materials required to produce a given mass of a product [1]. The formula for PMI is:

PMI = Total Mass of Materials Used in the Process (kg) / Mass of Product (kg)

This calculation includes all materials used within a pharmaceutical process, including reactants, reagents, solvents (used in reaction and purification), and catalysts [1]. Lower PMI values indicate more efficient and environmentally friendly processes.

2. Why is PMI considered superior to simpler metrics like yield for assessing "greenness"?

Unlike reaction yield, which only accounts for the mass of the target product versus the main reactant, PMI provides a comprehensive view of all mass inputs, including solvents, reagents, and catalysts [1]. This holistic approach reveals hidden resource consumption and drives focus on the main areas of process inefficiency, cost, environmental impact, and health and safety [1].

3. What are the limitations of using PMI as a standalone metric?

While PMI is valuable for measuring material efficiency, recent research shows it cannot fully capture the multi-criteria nature of environmental sustainability [2]. PMI does not account for:

- Origin of input materials (renewable vs. fossil-based)

- Energy consumption during manufacturing

- Toxicity or hazardous properties of materials

- Environmental impacts beyond resource use

Studies indicate that expanding system boundaries from gate-to-gate to cradle-to-gate strengthens correlations with Life Cycle Assessment (LCA) environmental impacts, but a single mass-based metric cannot fully represent environmental performance [2].

4. How does PMI relate to more comprehensive sustainability assessments like Life Cycle Assessment (LCA)?

PMI serves as a simpler, faster alternative to full Life Cycle Assessment, which evaluates multiple environmental impacts across a product's entire life cycle but requires extensive data collection and expertise [2] [3]. The ACS GCI Pharmaceutical Roundtable is currently developing a PMI-LCA tool to bridge these approaches, enabling easier calculation of sustainability metrics in API manufacture [4]. For comprehensive assessments, LCA provides more nuanced insights by including impacts on human health, ecosystem quality, and global warming potential [3].

5. What are typical PMI benchmark values for pharmaceutical manufacturing?

Pharmaceutical manufacturing traditionally showed high PMI values, but green chemistry improvements have significantly reduced these. While specific benchmarks vary by process complexity, modern green chemistry approaches aim for substantial reductions. For instance, award-winning processes have demonstrated ~75% PMI reductions through innovative route design [5] [6].

Table 1: Green Chemistry Metrics Comparison

| Metric | What It Measures | Target Values |

|---|---|---|

| PMI | Total mass input per product mass | <20 for pharmaceuticals |

| E-factor | Mass waste per mass product | <5 for specialty chemicals |

| Atom Economy | Efficiency of molecular incorporation | >70% considered good |

| Solvent Intensity | Solvent mass per product mass | <10 target |

Troubleshooting Common PMI Challenges

Problem: High PMI due to excessive solvent use

Solution:

- Implement solvent recovery and recycling systems

- Replace high-volume solvents with greener alternatives

- Consider solvent-free reaction conditions where feasible

- Utilize the ACS GCI PR Solvent Selection Guide to choose environmentally preferable solvents

The ACS GCI Pharmaceutical Roundtable has developed several tools to address this, including a PMI Calculator, Convergent PMI Calculator, and PMI Prediction Calculator to help researchers evaluate and compare potential route changes [1].

Problem: Inaccurate PMI calculation due to undefined system boundaries

Solution:

- Clearly document whether using gate-to-gate (process-only) or cradle-to-gate (including supply chain) boundaries

- Standardize system boundaries across comparative assessments

- For meaningful environmental assessment, consider expanding to cradle-to-gate boundaries, as studies show this significantly improves correlation with LCA environmental impacts [2]

Recent research emphasizes that "expanding the system boundary from gate-to-gate to cradle-to-gate strengthens correlations for fifteen of sixteen environmental impacts" when comparing mass intensities with comprehensive LCA results [2].

Problem: Difficulty reducing PMI in multi-step syntheses

Solution:

- Implement convergent synthesis strategies rather than linear sequences

- Eliminate unnecessary protecting groups and derivatization steps

- Identify and address specific hotspots through mass balance analysis

Award-winning case studies demonstrate successful approaches. For example, a Merck team developing an antibody-drug conjugate linker streamlined a 20-step synthesis to just 3 steps, reducing PMI by approximately 75% while cutting chromatography time by >99% [5] [6].

Problem: Disconnect between PMI improvement and actual environmental benefit

Solution:

- Use PMI in conjunction with other green chemistry metrics

- Incorporate early-stage LCA where possible

- Consider developing specific emission factors for pharmaceutical-grade materials, as standard LCA databases may not reflect the higher purity and intensive processing requirements [4]

The pharmaceutical industry is addressing this through tools like the PMI-LCA tool development challenge, which aims to create better integration between mass-based metrics and environmental impact assessment [4].

Experimental Protocols for PMI Assessment

Standard Protocol for PMI Calculation in API Synthesis

Materials Required:

- Detailed process flow diagram with all input streams

- Mass balances for all process steps

- Analytical methods for yield and purity determination

Procedure:

- Create a comprehensive inventory of all materials entering the process (reactants, reagents, catalysts, solvents)

- Document all process outputs (products, byproducts, waste streams)

- Calculate total mass input across all process steps

- Determine mass of final purified API

- Compute PMI using the standard formula

- For convergent syntheses, use the ACS GCI Convergent PMI Calculator to properly account for parallel synthesis branches [1]

Table 2: Research Reagent Solutions for PMI Reduction

| Reagent Category | Function | Green Chemistry Advantage |

|---|---|---|

| Biocatalysts | Enzyme-mediated transformations | High selectivity, mild conditions, reduced protection/deprotection steps [5] [6] |

| Renewable Feedstocks | Starting materials from biomass | Reduced fossil fuel dependence, lower carbon footprint [5] |

| Heterogeneous Catalysts | Solid-supported catalysts | Easier recovery and reuse, reduced metal leaching |

| Green Solvents | Water, bio-based solvents | Reduced VOC emissions, safer waste profiles |

Protocol for PMI-Based Process Optimization

This iterative methodology enables continuous improvement of synthetic routes through PMI analysis:

PMI Optimization Workflow

Advanced Protocol: Integrating PMI with Early-Stage LCA

For research focused on reducing PMI in API synthesis, incorporating LCA elements provides more meaningful sustainability assessment:

- Compile life cycle inventory for all major process inputs

- Calculate PMI using cradle-to-gate system boundaries where possible

- Identify environmental hotspots through contribution analysis

- Develop alternative scenarios targeting high-impact areas

- Evaluate trade-offs between PMI reduction and other environmental impacts

A recent study on antiviral drug synthesis demonstrated this approach, using LCA to identify that "Pd-catalyzed Heck cross coupling" and "large solvent volumes for purification" were key hotspots despite favorable traditional metrics [3].

Best Practices for PMI Reduction in API Research

Route Selection Strategy

- Prioritize synthetic routes with inherent atom economy

- Maximize convergence to reduce cumulative mass intensity

- Minimize protection/deprotection sequences

- Consider biocatalytic or chemocatalytic approaches to replace stoichiometric reagents

Process Intensification Approaches

- Implement continuous flow processing where applicable

- Optimize reaction concentration to minimize solvent volume

- Develop in-line purification methods to reduce workup mass

- Explore solvent recycling and recovery systems

Design for Circularity

- Select materials with recycling or regeneration potential

- Consider waste valorization opportunities for byproducts

- Design processes compatible with renewable feedstocks

- Incorporate real-time analytics to prevent off-spec production

As the industry moves toward defossilized production, the relationship between mass intensity and environmental impacts may change, necessitating continued methodology refinement [2]. The ongoing development of integrated PMI-LCA tools represents a promising direction for more accurate sustainability assessment in pharmaceutical research [4].

Process Mass Intensity (PMI) is a key green chemistry metric used to quantify the efficiency of a chemical process. It is defined as the total mass of materials (raw materials, reactants, solvents, and water) used to produce a specified mass of an Active Pharmaceutical Ingredient (API). A lower PMI indicates a more efficient, less wasteful, and more sustainable process [7] [8].

PMI matters because it creates a direct link between mass efficiency, environmental impact, and cost in pharmaceutical development. It provides a holistic benchmark for the pharmaceutical industry to drive more sustainable processes, focusing attention on the main drivers of process inefficiency, cost, and environment, safety, and health impact [7]. Optimizing PMI leads to reduced material consumption, lower waste disposal costs, and decreased environmental footprint, making it a critical indicator for modern API synthesis research [9] [10].

Frequently Asked Questions (FAQs)

1. What is the formula for calculating PMI?

PMI is calculated using the following formula:

PMI = Total Mass of Materials Input (kg) / Mass of API Output (kg)

This includes the mass of all raw materials, reactants, solvents, and process water used in the synthesis, purification, and isolation stages [8].

2. How does PMI differ from other green chemistry metrics? Unlike simpler metrics like atom economy (which only considers the atoms in the stoichiometric reactants), PMI provides a more comprehensive assessment by including all materials actually used in the process, such as solvents and reagents in excess. This offers a more realistic picture of the total resource consumption and waste generation [8].

3. What is a typical PMI value for an API process? PMI can vary significantly depending on the molecular complexity and the stage of process development.

- Small Molecule APIs: The median PMI ranges from 168 to 308 kg material per kg of API [8] [11].

- Synthetic Peptides: PMI is significantly higher, averaging approximately 13,000 per kg of API, largely due to excess solvents and reagents used in Solid-Phase Peptide Synthesis (SPPS) [8].

- Biologics: The average PMI is about 8,300 per kg of API [8].

4. What are the main drivers of high PMI in API synthesis? The primary contributors to high PMI are typically:

- Solvents: Often account for the largest mass input in API processes [7] [9].

- Low-yielding reaction steps and multi-step syntheses [12].

- Inefficient purification processes, such as chromatography [8] [11].

- High reagent excesses used to drive reactions to completion [8].

5. Can you provide a real-world example of PMI improvement? Yes. For the API MK-7264, process development efforts successfully reduced the PMI from 366 to 88, a dramatic improvement in efficiency and sustainability [13]. In another case, a redesign of a route to an investigational drug reduced the PMI from over 1,000 to 59, a 94% reduction [10].

Troubleshooting Common High-PMI Problems

Problem 1: Excessive Solvent Usage

Symptoms: High overall PMI, with solvent mass being the dominant contributor. High waste disposal costs and environmental impact [9].

Guides:

- Implement Solvent Recovery: Investigate distillation, stripping, or membrane separation technologies to purify and reuse solvents. Increasing the solvent recovery rate from 30% to 70% can reduce cradle-to-grave API emissions by 26% [9].

- Evaluate Solvent Substitution: Replace problematic solvents (e.g., DMF, NMP, DCM) with greener alternatives. Tools like the CHEM21 solvent selection guide can help in choosing safer and more sustainable options [8].

- Adopt Novel Reaction Media: Consider technologies like nanodispersed surfactants (e.g., TPGS-750-M in water), which act as nanoreactors and can drastically reduce solvent volume [10].

Problem 2: Low-Yielding or Multi-Step Reactions

Symptoms: Low overall yield, high consumption of raw materials and reagents relative to the final API output, complex process schematics [12].

Guides:

- Route Scouting and Redesign: Explore alternative synthetic pathways that are more convergent and have fewer steps. For example, adopting green-chemistry principles allowed one company to cut solvent and reagent consumption by 61% and reduce synthesis steps by 33% for 14 different APIs [9].

- Apply Catalysis: Utilize advanced catalytic methods (e.g., palladium-catalyzed cross-couplings, biocatalysis) to improve reaction efficiency, reduce step count, and minimize waste. Biocatalysis can sometimes offer a 35 times lower carbon footprint compared to traditional chemical routes [9].

- Process Intensification: Transition from batch to continuous processing. Flow chemistry can enhance heat and mass transfer, improve safety, and enable more efficient use of reagents, leading to a lower PMI [10] [12].

Problem 3: Inefficient Purification and Isolation

Symptoms: High material losses during work-up, crystallization, or isolation; reliance on energy-intensive purification techniques like chromatography [8] [12].

Guides:

- Optimize Crystallization: Develop a robust crystallization procedure to maximize yield and purity, reducing the need for further purification. This includes optimizing solvent systems, cooling profiles, and seeding strategies [12].

- Minimize Chromatography: Avoid chromatographic purification in large-scale manufacturing by refining reaction conditions to improve crude purity. If chromatography is unavoidable, investigate more efficient stationary phases or simulated moving bed systems [10] [11].

ACS GCI PMI and LCA Tools

The ACS Green Chemistry Institute Pharmaceutical Roundtable provides essential tools for sustainability assessment.

- PMI Calculator: A tool to quickly determine the PMI value by accounting for raw material inputs against the bulk API output [7].

- Convergent PMI Calculator: An enhanced version that accommodates multi-branch or convergent syntheses [7].

- Streamlined PMI-LCA Tool: This tool combines simple PMI calculation with a "cradle-to-gate" Life Cycle Assessment (LCA), incorporating the environmental footprint of the synthesis’ raw materials without the high data demands of a full LCA [13] [4].

Quantitative PMI Benchmarks

Use this table to benchmark your process against industry standards.

| Process Type | Typical PMI (kg/kg API) | Key Drivers & Notes |

|---|---|---|

| Small Molecule API | 168 - 308 (Median) [8] | Solvent use is a major contributor. PMI < 100 is an excellent target for optimized processes [13]. |

| Biologics / mAbs | ~ 8,300 (Average) [8] | Energy and water-intensive fermentation and purification [8]. |

| Oligonucleotides | 3,035 - 7,023 (Range) [8] | Solid-phase synthesis with large excesses of reagents and solvents [8]. |

| Synthetic Peptides | ~ 13,000 (Average) [8] | Dominated by solvent use (e.g., DMF, DCM) and reagent excess in SPPS [8]. |

The Scientist's Toolkit: Key Reagent Solutions for PMI Reduction

| Reagent / Technology | Function | Benefit for PMI Reduction |

|---|---|---|

| TPGS-750-M | A surfactant forming nanomicelles in water [10] | Replaces large volumes of organic solvents, enabling reactions in water at room temperature [10]. |

| Palladium Catalysts (e.g., for Suzuki Coupling) | Facilitates carbon-carbon bond formation [10] | Enables more efficient and convergent syntheses, potentially reducing steps and waste. |

| High-Temperature Heat Pumps | Captures and recycles waste heat [9] | Reduces primary energy consumption, indirectly lowering the PMI associated with utilities. |

| Enzymes (Biocatalysts) | Catalyze specific reactions (e.g., hydrolysis, reduction) [9] | Often provide high selectivity and milder reaction conditions, reducing protection/deprotection steps and waste. |

| Continuous Flow Reactors | Provides a platform for continuous chemical processing [10] [12] | Improves reaction control and safety, enables smaller reactors, and reduces solvent use and waste. |

| Isoderrone | Isoderrone | | Supplier | Isoderrone is a potent natural isoflavone for cancer research, targeting AMPK & ERβ. For Research Use Only. Not for human or veterinary use. |

| Sorbic chloride | Sorbic Chloride | Reagent for Research Use Only | Sorbic chloride is a key reagent for organic synthesis & derivatization. For Research Use Only. Not for human or veterinary diagnostic or therapeutic use. |

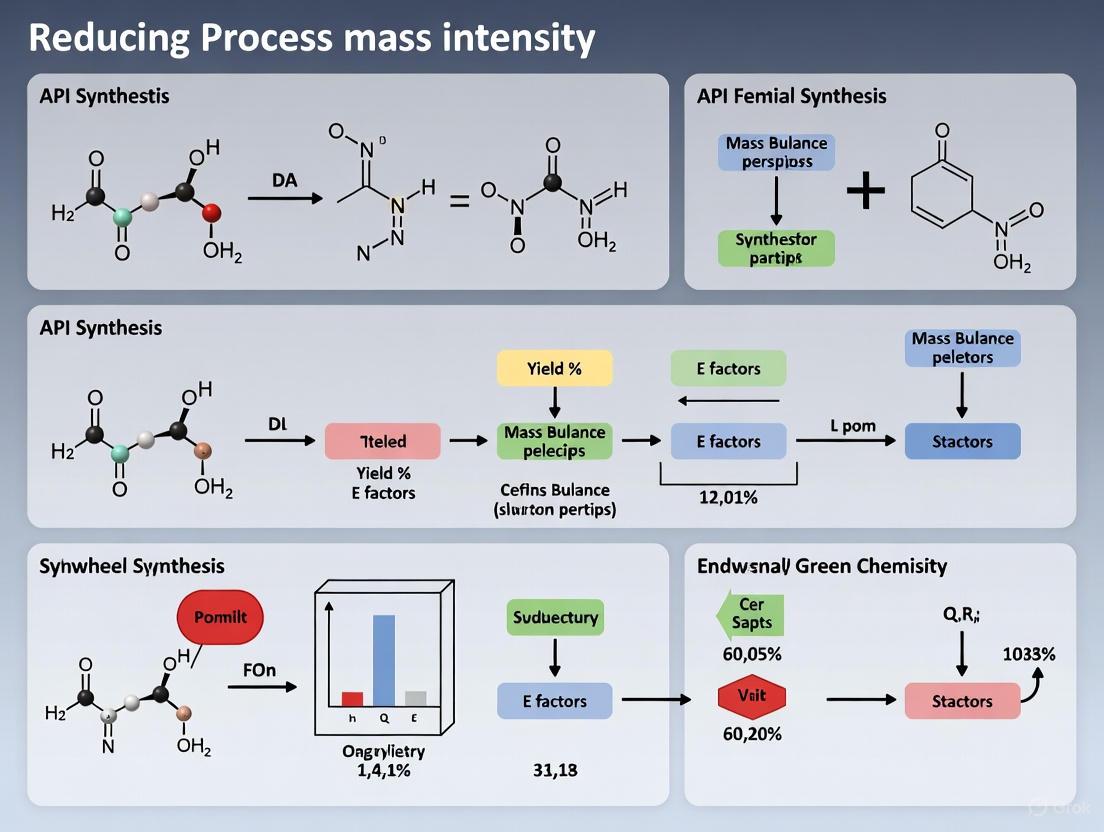

Visualizing the PMI Reduction Strategy

The following diagram illustrates the interconnected strategy for reducing PMI, which directly links to improved sustainability and cost.

Frequently Asked Questions (FAQs)

Q1: What is Process Mass Intensity (PMI) and why is it a critical metric in API synthesis research?

Process Mass Intensity (PMI) is a key green metric used to evaluate the efficiency and environmental impact of processes used to manufacture active pharmaceutical ingredients (APIs). It quantifies the total mass of input materials (including solvents, water, reagents, and process chemicals) required per unit mass of the final API output [14] [7]. In the context of a thesis focused on reducing the environmental footprint of pharmaceutical manufacturing, PMI is indispensable. It provides a direct measure of resource efficiency, helps benchmark progress towards more sustainable manufacturing, and focuses attention on the main drivers of process inefficiency, cost, and environment, safety, and health impact [7]. A lower PMI signifies a more efficient, less wasteful, and more sustainable process.

Q2: What is the fundamental difference between Gate-to-Gate and Cradle-to-Gate system boundaries for PMI?

The difference lies in the scope of the inputs included in the calculation:

- Gate-to-Gate: This is a partial assessment that considers only the inputs and emissions from a single, specific manufacturing process within a company's own facility [15]. Its system boundaries start and end at the "gate" of one particular process.

- Cradle-to-Gate: This broader assessment includes all inputs from the extraction of raw materials (the "cradle") through all processing and manufacturing stages until the product leaves the final factory gate [16] [17]. It encompasses the entire supply chain up to the point the API is produced.

Q3: When should a researcher use a Gate-to-Gate PMI calculation?

A Gate-to-Gate approach is most appropriate for internal process optimization and benchmarking [15]. Use it when you need to:

- Compare the efficiency of different synthetic routes or reaction conditions for a specific step within your lab or pilot plant.

- Identify waste hotspots in a discrete unit operation.

- Focus improvement efforts solely on the transformational chemistry under your direct control, excluding upstream supply chain variations.

Q4: When is a Cradle-to-Gate PMI calculation more appropriate?

A Cradle-to-Gate calculation is essential when you want to understand the total resource burden and environmental impact of your API [16] [17]. It is more appropriate for:

- Making holistic sustainability claims about a final API.

- Providing data to customers or partners down the value chain so they can accurately calculate the footprint of their own products [16].

- Complying with emerging regulatory standards that require broader environmental disclosures [17].

- Identifying significant resource inputs or environmental impacts that originate from your raw material suppliers.

Q5: What are the common pitfalls when collecting data for a Cradle-to-Gate PMI?

- Inconsistent Boundaries: The most common error is not clearly defining and consistently applying the chosen system boundary across all calculations, making comparisons invalid.

- Incomplete Solvent Accounting: Overlooking solvent volumes from work-up and purification steps, or not properly accounting for solvent recovery.

- Omitting Catalysts and Reagents: Failing to include the masses of catalysts, ligands, and stoichiometric reagents.

- Poor Data Quality: Relying on theoretical stoichiometric values instead of experimentally measured masses from actual reactions.

- Neglecting Water: Excluding process water from the total mass input, which can significantly underreport the PMI.

Troubleshooting Common PMI Calculation Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Inconsistent PMI values for the same process. | Varying system boundaries between calculations (e.g., sometimes including water, other times excluding it). | Create and strictly adhere to a standardized data collection sheet that explicitly lists all included and excluded inputs. |

| PMI value is unexpectedly high. | High solvent usage is the most likely culprit, particularly in work-up and isolation steps. Poor atom economy or low yield can also be factors. | Focus on solvent reduction strategies: switch to greener solvents, investigate solvent recycling, or employ concentration optimization. |

| Difficulty obtaining upstream (Cradle) data. | Lack of transparency or cooperation from suppliers; treated as proprietary information. | Use industry-average data or life cycle inventory (LCI) databases for common raw materials as an initial estimate. Engage suppliers in sustainability dialogues. |

| Uncertainty in how to handle convergent syntheses. | The PMI calculation for linear vs. convergent syntheses differs and can be confusing. | Use the Convergent PMI Calculator provided by the ACS GCI Pharmaceutical Roundtable, which is specifically designed for this purpose [7]. |

| The calculated PMI does not align with a life cycle assessment (LCA). | PMI and LCA are related but distinct. PMI is a mass-based metric, while LCA translates those masses into multiple environmental impact categories (e.g., global warming, toxicity). | Ensure you are comparing like-with-like. A Cradle-to-Gate PMI provides the foundational mass data that can be used to perform a Cradle-to-Gate LCA. |

Quantitative Data Comparison: PMI System Boundaries

The following table summarizes the key characteristics of different system boundaries to guide your methodological choice.

Table 1: Comparison of PMI System Boundaries

| Characteristic | Gate-to-Gate | Cradle-to-Gate |

|---|---|---|

| Scope | Single, specific process step [15]. | All steps from raw material extraction to finished API at the factory gate [16] [17]. |

| Primary Use Case | Internal process optimization and benchmarking [15]. | Holistic sustainability assessment; reporting to customers and regulators [16] [17]. |

| Data Complexity | Low (data is typically readily available from lab notebooks). | High (requires reliable data from the entire supply chain). |

| Advantages | Simple, fast, ideal for troubleshooting specific reactions. | Provides a complete picture of the upstream resource burden; aligns with standard LCA scopes. |

| Disadvantages | Provides a limited view that can miss major impacts from raw material production. | Data collection can be challenging and resource-intensive. |

Experimental Protocol: Conducting a Cradle-to-Gate PMI Assessment

This protocol provides a step-by-step methodology for calculating a Cradle-to-Gate PMI for an API synthesis, suitable for inclusion in a thesis methodology section.

Objective: To determine the total mass of inputs required to produce 1 kg of a specified API, from raw material extraction to the final API isolation.

Principles: The core calculation is based on the formula below. The critical task is to accurately define and sum all mass inputs (m_input) across the defined system boundary.

PMI = Total Mass of Inputs (kg) / Mass of API (kg)

Procedure:

Goal and Scope Definition:

- Clearly state that the assessment is a Cradle-to-Gate analysis.

- Define the functional unit as 1 kg of [Insert API Name and Purity Specification].

Process Mapping and Boundary Setting:

- Create a detailed flow diagram of the entire synthetic route, including all reaction steps, isolations, and purifications.

- Mark the system boundary as starting with the extraction/acquisition of all raw materials (e.g., crude oil, minerals, biomass) and ending when the API is packaged and leaves the final manufacturing facility.

Data Collection Inventory:

- For each input in the process, collect the total mass required to produce the 1 kg functional unit. This must include:

- All starting materials and reagents

- All solvents (including those for reaction, work-up, crystallization, and washing)

- Catalysts and ligands

- Process water

- Materials for purification (e.g., chromatography silica gel)

- Data Source Hierarchy: Prioritize primary data from your own experiments or supplier records. For upstream raw material production, secondary data from peer-reviewed literature or life cycle inventory databases (e.g., Ecoinvent) should be used.

- For each input in the process, collect the total mass required to produce the 1 kg functional unit. This must include:

PMI Calculation:

- Sum the masses of all inputs (

Σm_input) that fall within the Cradle-to-Gate boundary. - Divide the total input mass by the mass of the API output (1 kg in this case).

- PMI = Σm_input (kg) / 1 kg API

- Sum the masses of all inputs (

Reporting:

- Report the final PMI value.

- Clearly document the system boundary, data sources, and any assumptions or exclusions (e.g., if capital equipment or energy were excluded, as is standard practice).

Workflow Diagram: PMI Calculation and System Boundary Selection

The following diagram illustrates the logical decision process for selecting the appropriate system boundary and the key steps involved in the PMI calculation workflow.

Diagram: PMI System Boundary Selection and Calculation Workflow

The Scientist's Toolkit: Research Reagent Solutions for PMI Reduction

The following table details key reagents and methodologies that are central to modern research aimed at reducing PMI in API synthesis.

Table 2: Key Reagents and Methods for Sustainable API Synthesis

| Research Reagent / Method | Function in PMI Reduction | Key Consideration |

|---|---|---|

| Micellar Catalysis | Uses water and designer surfactants (e.g., TPGS-750-M) as a reaction medium, dramatically reducing or eliminating the mass of organic solvents, which are the largest contributor to high PMI [18]. | Requires optimization of surfactant type and concentration. Effective for a wide range of metal-catalyzed C-C bond formations and other transformations. |

| Designer Surfactants (e.g., TPGS-750-M, Nok) | Self-assemble in water to form nanoreactors that solubilize organic substrates and catalysts, enabling high-efficiency reactions in water [18]. | Commercially available and designed specifically for catalytic applications, offering a drop-in replacement for organic solvents. |

| PPM Level Catalysis | Employing catalysts at parts-per-million levels significantly reduces the mass of often expensive and resource-intensive transition metals and ligands in the process [18]. | Demands highly active and selective catalyst systems. Critical for reducing the environmental and cost impact of metal residues. |

| Convergent Synthesis | Building complex molecules by synthesizing key fragments separately and then combining them. This often leads to a higher overall yield and lower PMI compared to a long linear sequence [7]. | Strategic route design is essential. The Convergent PMI Calculator can help benchmark the improvement [7]. |

| ABT-925 anhydrous | ABT-925 anhydrous | High Purity D3 Antagonist | ABT-925 anhydrous is a selective dopamine D3 receptor antagonist for neuropsychiatric research. For Research Use Only. Not for human or veterinary use. |

| but-1-ene;(E)-but-2-ene | but-1-ene;(E)-but-2-ene, CAS:119275-53-5, MF:C8H16, MW:112.21 g/mol | Chemical Reagent |

FAQs: Understanding PMI and Its Limitations

What is Process Mass Intensity (PMI), and why is it used in API synthesis?

Process Mass Intensity (PMI) is a key green chemistry metric used to benchmark the environmental performance of chemical processes, particularly in pharmaceutical development. It is calculated as the total mass of materials used to produce a unit mass of the final product, such as an Active Pharmaceutical Ingredient (API) [7].

PMI is popular because it uses an easy-to-determine process mass balance, helping scientists identify inefficient processes, reduce waste, and improve resource efficiency. The ACS GCI Pharmaceutical Roundtable provides a PMI calculator to help standardize this benchmarking across the industry [7].

What are the primary limitations of using PMI as a sole environmental metric?

Relying solely on PMI has several critical limitations:

- It Lacks Environmental Context: PMI is a mass-based metric and does not reflect actual interactions with the environment. It ignores the ecotoxicity, resource scarcity, and carbon footprint associated with different materials [2].

- It Oversimplifies System Boundaries: A standard "gate-to-gate" PMI (considering only materials directly used in the factory) ignores the significant environmental impacts embedded in the supply chain (the "cradle-to-gate" footprint) [2].

- It Fails to Capture Material Criticality: PMI treats all mass equally. A kilogram of a benign, renewable solvent and a kilogram of a rare, energy-intensive metal would contribute identically to the PMI score, despite their vastly different environmental impacts [2].

How can I accurately assess the environmental impact of my synthesis process beyond PMI?

For a robust assessment, Life Cycle Assessment (LCA) is the recommended methodology. LCA is a holistic approach that evaluates multiple environmental impacts—such as climate change, water usage, and ecotoxicity—across the entire life cycle of a product, from raw material extraction to end-of-life [2].

While conducting a full LCA can be complex, researchers can:

- Use expanded "cradle-to-gate" metrics that account for upstream material production [2].

- Integrate simple LCA tools tailored for chemical processes where full data is unavailable [2].

- Focus on key impact categories most relevant to their process, such as global warming potential, in addition to mass efficiency.

What are some practical strategies for reducing PMI in oligonucleotide synthesis?

Oligonucleotide synthesis is traditionally PMI-intensive. Innovative strategies to reduce it include:

- Adopting Continuous Chromatography: Technologies like Multicolumn Countercurrent Solvent Gradient Purification (MCSGP) can reduce solvent consumption by over 30% compared to traditional batch methods, directly lowering PMI [19].

- Exploring Alternative Synthesis Methods: One-pot liquid-phase oligonucleotide synthesis is a promising hybrid method that uses liquid anchor molecules instead of solid-phase resins. This can eliminate excessive washing steps and potentially halve the PMI contribution from solvents [19].

Troubleshooting Guides: Addressing Common Experimental Challenges

Challenge: High PMI in API Purification Steps

Problem: Purification, particularly chromatography, is a major contributor to high Process Mass Intensity due to large solvent volumes.

Solution: Evaluate and implement more efficient purification technologies.

| Solution | Methodology | Key Experimental Parameters to Monitor | Expected Outcome |

|---|---|---|---|

| Continuous Chromatography (MCSGP) [19] | Utilize a system with multiple columns that operate in a counter-current fashion, continuously recycling mixed fractions. | - Solvent consumption per gram of API- Product yield and purity profile- Process cycle time | - ≥30% reduction in solvent use- Maintained or improved yield/purity- Up to 70% reduction in cycle time |

| Solvent Selection & Recycling | Implement an in-process solvent recovery system or select solvents with lower environmental impact (e.g., ethanol over acetonitrile). | - Purity of recovered solvent- Effect of solvent switch on product purity and recovery | - Direct reduction in solvent-related PMI- Lower waste disposal costs |

Challenge: Accounting for Upstream Environmental Impacts

Problem: Your "gate-to-gate" PMI looks excellent, but the overall environmental footprint of the process may still be high due to energy-intensive or harmful raw materials.

Solution: Expand your system boundary to a "cradle-to-gate" perspective.

Experimental Protocol: Screening Raw Material Impact

- Create an Inventory: List all input materials (solvents, reagents, catalysts) for your API synthesis step.

- Categorize Materials: Classify materials into groups (e.g., petroleum-based solvents, biobased reagents, rare metal catalysts).

- Apply a Simple Proxy Metric: Use a Value-Chain Mass Intensity (VCMI) approach. Calculate the total mass of natural resources (e.g., crude oil, metal ores, water) needed to produce your input materials [2].

- Analyze and Substitute: Identify materials with the highest VCMI and explore greener alternatives (e.g., a biobased solvent instead of a fossil-fuel-derived one).

This expanded view helps identify "hotspots" that a simple PMI calculation would miss. Research shows that expanding the system boundary from gate-to-gate to cradle-to-gate strengthens the correlation between mass metrics and actual environmental impacts for most impact categories [2].

Experimental Data and Metrics

The table below summarizes PMI data and reduction targets for different process types, highlighting the scale of the challenge and opportunity.

| Process Type | Typical / Reported PMI (kg input/kg API) | Reduction Target / Achievement | Key Driver for High PMI |

|---|---|---|---|

| Traditional Oligonucleotide Synthesis (20-mer) [19] | ~4,300 kg/kg | Target: Halving via one-pot liquid-phase synthesis [19] | Large volumes of solvents for washing and purification |

| General API Synthesis (Industry Benchmarking) [7] | Varies widely; focus of industry benchmarking | Continuous improvement via route selection and solvent optimization [7] | Solvent use, number of synthetic steps, and atom economy |

| Ideal Green Process | Approaches theoretical minimum | Focus on waste prevention and inherently benign materials [2] | N/A |

The Scientist's Toolkit: Key Research Reagent Solutions

When designing experiments to reduce PMI and environmental impact, consider these key materials and tools.

| Tool / Material | Function in PMI Reduction & Environmental Assessment |

|---|---|

| Life Cycle Assessment (LCA) Database [2] | Provides scientific data on the environmental impact of chemicals and materials, enabling cradle-to-gate analysis beyond simple PMI. |

| Continuous Chromatography Systems [19] | Purification technology designed to significantly reduce solvent consumption and waste generation compared to traditional batch chromatography. |

| Alternative Solvents (e.g., Bio-derived, Green Solvent List) | Replacing hazardous or resource-intensive solvents with safer, renewable alternatives can lower both PMI and toxicity impacts. |

| One-Pot Synthesis Methodologies | Combining multiple reaction steps into a single pot reduces intermediate isolation, purification, and associated solvent and material use. |

| Heterogeneous Catalysts | Can be recovered and reused across multiple reaction cycles, reducing the PMI contribution from expensive or resource-intensive catalysts. |

| 4-(Piperidin-4-yl)aniline | 4-(Piperidin-4-yl)aniline | High-Purity Building Block |

| Acetic anhydride-1,1'-13C2 | Acetic anhydride-1,1'-13C2 | 13C-Labeled Reagent | RUO |

Methodologies and Visualization

Workflow: Integrating Environmental Assessment in API Process Development

The following diagram illustrates a strategic workflow for evaluating and improving the environmental performance of an API synthesis, moving beyond simple PMI calculation.

Relationship Between Mass Metrics and Environmental Impact

This diagram conceptualizes why a single mass-based metric like PMI is insufficient to capture the multi-criteria nature of environmental sustainability, and how different input materials act as proxies for different environmental impacts [2].

This technical support center provides troubleshooting guides and FAQs to help researchers and scientists navigate the evolving landscape of pharmaceutical development, where sustainability and regulatory compliance are increasingly critical.

Frequently Asked Questions (FAQs)

What is Process Mass Intensity (PMI) and why is it a key green metric?

Process Mass Intensity (PMI) is a cornerstone metric for assessing the environmental impact and efficiency of an API synthesis. It is calculated as the total mass of materials used in a process divided by the mass of the final API product [20] [21]. A lower PMI indicates a more efficient and less wasteful process.

The PMI metric is crucial because it provides a holistic view of resource consumption. In a typical pharmaceutical synthesis, solvents and water are the largest contributors to PMI [20]. By focusing on reducing PMI, researchers directly address the core environmental challenges of waste reduction and resource efficiency, aligning with global sustainability goals and corporate environmental targets.

How do regulatory pressures directly impact my API process development?

Regulatory bodies are increasingly linking environmental considerations to traditional quality and safety standards. While current Good Manufacturing Practice (cGMP) regulations don't yet mandate a specific number of validation batches, the emphasis is on a science-based, lifecycle approach to process validation [22].

Furthermore, global policies like the U.S. Inflation Reduction Act and similar EU initiatives, which employ direct pricing agreements and reference pricing, are putting a spotlight on cost management and efficient evidence development [23]. This creates a direct operational and financial incentive to develop efficient, low-PMI processes that are not only greener but also more cost-effective to manufacture at scale.

Unexpected quality problems are a major source of production downtime and supply chain disruptions. Common root causes include [24] [25]:

- Contaminated raw materials: Incoming APIs and excipients can introduce impurities.

- Equipment malfunctions: Abrasion or failures can introduce particulate contaminants.

- Cross-contamination: Inadequate cleaning or facility design can lead to product mixing.

- Human error: Deviations from established hygiene or operational procedures.

A thorough root cause analysis is required to investigate these deviations, assess product quality and safety, and define preventive measures to avoid future incidents [25].

Troubleshooting Guides

Guide 1: Addressing Particulate Contamination in API Batches

Problem: Visible particulate matter is identified during in-process quality control.

Investigation Protocol: A systematic analytical approach is key to resolving contamination issues quickly and minimizing production downtime [25]. The following workflow outlines a best-practice strategy for identifying unknown contaminants.

Methodology Details:

- Information Gathering: Before analysis, collect all relevant data: a description of the problem, the time frame, and the people, materials, and equipment involved [25].

- Physical Analysis (First Line): These methods are fast, cost-effective, and non-destructive.

- SEM-EDX (Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy): Ideal for identifying inorganic compounds like metallic abrasion from equipment, rust, or other metal contaminants [25].

- Raman Spectroscopy: Effectively identifies organic particles by comparing their spectral signature to known databases and reference materials [25].

- Chemical Analysis (Second Line): If physical methods are inconclusive, proceed to chemical structure elucidation.

- Solubility Tests: Qualitative tests in various media provide initial data on the contaminant's polarity and chemical nature [25].

- Advanced Chromatography and Spectroscopy: For soluble particles, techniques like LC-HRMS (Liquid Chromatography-High Resolution Mass Spectrometry) and NMR (Nuclear Magnetic Resonance) are powerful tools for definitive structure identification [25].

Guide 2: Implementing Green Chemistry Principles for PMI Reduction

Problem: Your existing API synthesis route has a high Process Mass Intensity (PMI), leading to excessive waste and cost.

Optimization Strategy: Adopting a "Green-by-Design" approach involves re-evaluating the entire synthetic route. The following framework outlines key strategic areas to target for significant PMI reduction.

Experimental Protocols:

Route Strategy Evaluation:

- Adopt Catalytic Processes: Replace stoichiometric reagents with catalysts. Biocatalysis is particularly attractive, as enzymes offer high chemo-, regio-, and stereoselectivity, often eliminating the need for protection/deprotection steps and enabling milder reaction conditions [26] [20].

- One-Pot and Multicomponent Reactions (MCRs): Design synthetic sequences that combine multiple steps in a single reactor without intermediate purification. This minimizes solvent and reagent use for workup, significantly improving atom economy and reducing waste [20].

Process Conditions Optimization:

- Shift to Continuous Processing (CP): Evaluate moving from traditional batch to continuous manufacturing. CP offers better mass and heat transfer, easier scale-up, more consistent product quality, and a significant reduction in Process Mass Intensity, especially in separation steps [26] [20].

- Apply Solvent Selection Guides: Utilize established guides (e.g., from Pfizer, GSK, ACS GCI) to rank solvents by their environmental, health, and safety attributes. Selecting a greener solvent is one of the most effective ways to reduce the PMI of a process, as solvents are typically the largest mass input [20].

The following table details key tools and resources essential for developing sustainable and robust API synthesis processes.

| Tool/Resource Name | Function & Application | Key Rationale |

|---|---|---|

| PMI Predictor Calculator [21] | A web-based application that predicts the Process Mass Intensity of a proposed synthetic route, enabling "Green-by-Design". | Allows for virtual screening and comparison of synthetic routes for environmental impact before any lab work begins. |

| Solvent Selection Guides [20] | Guides (e.g., from Pfizer, GSK) that rank common solvents based on safety, health, and environmental criteria. | Provides a standardized method to select greener solvents, the primary contributor to PMI, during process development. |

| Biocatalysts / Enzymes [26] [20] | Enzymes used as biological catalysts for specific chemical transformations (e.g., chiral synthesis, functionalization). | Offer high selectivity under mild conditions, often reducing the need for protective groups and harsh reagents, thereby simplifying synthesis and reducing waste. |

| Analytical Method Greenness Score (AMGS) Calculator [21] | A tool to evaluate and improve the environmental footprint of analytical methods used for quality control. | Extends green chemistry principles beyond synthesis to the analytical lab, promoting overall process sustainability. |

| Computer-Assisted Synthesis Planning (CASP) [27] | AI-powered platforms that use machine learning to propose viable retrosynthetic pathways and reaction conditions. | Augments chemist intuition, generates innovative route ideas, and helps identify more efficient and direct synthetic pathways. |

Advanced Strategies and Technologies for PMI Reduction

Troubleshooting Guides

Troubleshooting Guide 1: High Process Mass Intensity (PMI) in API Synthesis

Problem: The calculated Process Mass Intensity (PMI) for your synthetic route is unacceptably high, indicating poor material efficiency and significant waste generation. A high PMI is a key indicator of an unsustainable process, leading to elevated costs and environmental impact [28].

Solution: Investigate and optimize the synthetic route and reaction conditions to minimize the total mass of materials used per mass of API produced.

| Observation | Possible Cause | Recommended Action |

|---|---|---|

| High solvent usage | Use of excessive solvent volumes in reactions and work-ups; use of non-recyclable solvents. | Switch to greener solvents where possible; implement solvent recovery and recycling protocols; consider process intensification to reduce volume [28]. |

| Low reaction yield | Suboptimal reaction conditions (temperature, catalyst, stoichiometry); side reactions forming impurities. | Re-optimize reaction parameters; employ Design of Experiments (DoE); investigate alternative catalysts to improve selectivity and conversion [28] [11]. |

| Long, multi-step synthesis | Inefficient bond-forming strategy from discovery chemistry; use of protecting groups. | Re-evaluate route design for convergence; apply late-stage functionalization to introduce diversity late in the synthesis, reducing steps [29] [28]. |

| Inefficient purification | Reliance on chromatographic purification instead of crystallization or direct isolation. | Develop a direct-drop or telescoped process where intermediates are carried forward without isolation; optimize crystallization protocols [11]. |

| Stoichiometric use of reagents | Use of excess reagents or reagents that generate substantial by-products. | Replace stoichiometric reagents with catalytic alternatives (e.g., biocatalysis, metal catalysis) to reduce waste [28]. |

Detailed Methodology for PMI Assessment & Reduction:

- Calculate Baseline PMI: For your current process, sum the total mass of all input materials (reactants, solvents, reagents) used to produce 1 kg of the final API. This is your baseline PMI [28].

- Identify Major Contributors: Analyze the mass balance to pinpoint which steps and materials contribute most to the total mass. Solvents are often the largest contributor.

- Apply Green Chemistry Principles: Systematically address the major contributors using the principles of green chemistry.

- Catalysis: Replace stoichiometric oxidants/reductants with catalytic versions. For example, replace a palladium-catalyzed reaction with a more sustainable nickel-based catalyst, which has led to reductions of over 75% in CO2 emissions, freshwater use, and waste generation [28].

- Solvent Selection: Refer to the Solvent Selection Guide and replace hazardous or non-recyclable solvents (e.g., dichloromethane, DMF) with greener alternatives (e.g., 2-MeTHF, Cyrene).

- Process Intensification: Explore telescoping, where the output of one reaction is used directly in the next without isolation and purification, saving solvents and time.

- Re-calculate and Compare: After optimization, re-calculate the PMI to quantify the improvement.

Troubleshooting Guide 2: Scalability Issues in Route Development

Problem: A synthesis that works well in the laboratory fails or performs unpredictably when scaled up to pilot or manufacturing scale. Issues include poor heat transfer, uncontrolled exotherms, or inconsistent mixing.

Solution: Proactively identify and design out scale-up risks during the route selection and early development phase.

| Observation | Possible Cause | Recommended Action |

|---|---|---|

| Uncontrolled exotherm | Highly energetic reaction with rapid heat release that is manageable at small scale but dangerous at large scale. | Use reaction calorimetry to understand thermal accumulation. Redesign the route to avoid highly energetic reagents or implement controlled addition strategies and continuous flow chemistry [29]. |

| Extended reaction times | Inefficient mixing or mass transfer limitations at larger scales. | Evaluate mixing sensitivity; consider switching to a continuous flow reactor which offers superior heat and mass transfer compared to batch reactors [30] [31]. |

| Formation of new impurities | Changes in reaction profile due to different heat/mass transfer kinetics. | Use scale-down modeling to study process parameters. Ensure the analytical control strategy is robust and can detect new impurities. |

| Difficulty in isolation | Changes in crystal form, particle size, or oiling out at larger scales. | Conduct thorough solid-form screening early in development. Engineer the crystallization process for consistent particle size distribution. |

Detailed Methodology for Scalability Risk Assessment:

- Route Safety Profiling: Screen all starting materials, reagents, intermediates, and reactions for thermal hazards and potentially dangerous properties.

- Process Modeling: Utilize software and engineering principles to model the process at a larger scale, identifying potential heat and mass transfer bottlenecks.

- Technology Selection: For high-risk reactions, consider alternative technologies early. Continuous flow reactors can safely handle exothermic reactions, high pressures, and reactions with unstable intermediates, making them suitable for scaling challenging chemistries [30] [31].

Frequently Asked Questions (FAQs)

1. What is the single most important factor in route design for reducing PMI? While multiple factors are important, the choice of synthetic bond formation strategy (the route itself) is foundational [29]. A longer, linear route with poor atom economy will inherently have a higher PMI than a shorter, more convergent one. Identifying the most effective synthetic route can reduce the cost of manufacturing by orders of magnitude [29]. After route selection, solvent selection and catalysis are critical areas for PMI reduction.

2. How can machine learning (ML) assist in route selection and optimization? Machine learning algorithms can analyze vast datasets of chemical reactions to predict outcomes and optimize conditions, making processes more efficient and sustainable [28] [31]. For example:

- Predicting Reactivity: ML models can forecast where a particular chemical reaction (like borylation) will occur within complex molecules, outperforming previous methods and streamlining development [28].

- Reaction Optimization: ML can help identify the optimal set of reaction parameters (temperature, concentration, catalyst loading) to maximize yield and minimize waste without the need for exhaustive experimentation [31].

- Predicting PMI: Novel methods are being developed to predict the PMI of all possible synthetic routes without experimentation, saving significant time and resources during development [28].

3. What are the trade-offs between speed and sustainability in accelerated development programs? Expedited clinical programs demand fast API supply, often favoring the "first" available route from discovery. This can sometimes conflict with developing the most sustainable, long-term process [11]. The strategy is to frontload development activities and engage process chemists early during lead optimization. This allows for the identification of a scalable and sustainable route from the outset, even under tight timelines. The initial focus may be on optimizing the final steps for quality, with further sustainability improvements (like switching to a biocatalyst) performed after launch, especially for small patient populations [11].

4. When should we consider switching from a batch process to a continuous manufacturing process? Continuous Manufacturing (CM) should be considered when you need greater efficiency, lower production costs, and higher quality control [30]. CM is particularly advantageous for:

- Fast, highly exothermic, or hazardous reactions that are difficult to control in a large batch reactor.

- Processes with unstable intermediates that benefit from being generated and consumed immediately in a continuous flow.

- APIs requiring precise control over reaction parameters to ensure consistency. CM shortens production cycles, reduces manufacturing costs, and ensures faster time-to-market [30] [31].

5. How do I justify the investment in a new, greener catalytic technology? Justification should be based on a holistic analysis of benefits beyond just the cost of the catalyst itself. Build a business case that considers:

- Reduced Waste Disposal Costs: Catalytic processes often generate less hazardous waste.

- Improved Efficiency: Higher yields and shorter cycle times increase facility throughput.

- Regulatory & Reputational Benefits: Adherence to green chemistry principles simplifies regulatory approval and enhances corporate sustainability credentials [28] [32].

- Total Cost of Ownership: Include savings from reduced solvent use, energy consumption, and raw material costs.

Quantitative Data for Route Selection

This table summarizes key metrics to evaluate and compare different synthetic routes for an API, with a focus on Process Mass Intensity.

| Metric | Definition | Calculation | Target / Benchmark |

|---|---|---|---|

| Process Mass Intensity (PMI) | Total mass of materials used to produce a unit mass of API. | Total mass of inputs (kg) / Mass of API (kg) | Minimize. The ideal PMI is as close to 1 as possible. Industry benchmarks vary, but significant reductions (e.g., >75% in waste and emissions) are achievable via catalysis [28]. |

| Reaction Mass Efficiency (RME) | Proportion of reactant mass converted to product mass. | (Mass of product (kg) / Total mass of reactants (kg)) x 100% | Maximize. Target >70-80% for a highly efficient step. |

| Carbon Efficiency | Proportion of carbon from reactants retained in the product. | (Moles of carbon in product / Moles of carbon in reactants) x 100% | Maximize. High carbon efficiency indicates less wasted carbon in byproducts. |

| Number of Synthesis Steps | Total linear steps from starting materials to API. | Count of isolated intermediates + 1. | Minimize. Each step adds to PMI. Convergent syntheses are often superior to linear ones. |

| Solvent Intensity | Mass of solvent used per mass of API. | Total mass of solvent (kg) / Mass of API (kg) | Minimize. Solvents are the largest contributor to PMI. Implement recovery and recycling. |

Experimental Protocol: Late-Stage Functionalization to Reduce Synthetic Steps

Purpose: To demonstrate how Late-Stage Functionalization (LSF) can introduce molecular diversity or key functional groups in a single step late in the synthesis, thereby reducing the total number of steps, improving PMI, and accelerating the discovery of drug candidates [28].

Principle: Instead of building a complex functionalized molecule from scratch, a pre-constructed core scaffold is selectively modified at a late stage using powerful catalysis (e.g., photocatalysis, C-H activation).

Materials:

- Core scaffold molecule (e.g., a complex heterocycle)

- Functionalizing reagent (e.g., 'magic methyl' source, alkyl radical precursor)

- Catalyst (e.g., Photoredox catalyst like Ir(ppy)₃, Pd catalyst)

- Solvent (Green solvent preferred, e.g., 2-MeTHF, EtOAc, or MeCN)

- Light source (for photocatalysis, e.g., blue LEDs) or other required equipment (e.g., electrochemical cell)

Procedure:

- Reaction Setup: In a dried reaction vial, combine the core scaffold (1.0 equiv), functionalizing reagent (1.5-2.0 equiv), and catalyst (1-5 mol%). Add degassed solvent to achieve a concentration of 0.1-0.2 M.

- Reaction Execution:

- For photocatalysis: Seal the vial and place it under a bank of blue LEDs with stirring. Monitor reaction completion by TLC or LCMS.

- For electrocatalysis: Perform the reaction in an electrochemical cell equipped with electrodes (e.g., carbon anode, platinum cathode). Apply a constant current and monitor the reaction.

- Work-up: Once complete, quench the reaction as appropriate (e.g., addition of water or a quenching agent). Transfer to a separatory funnel and extract with a suitable solvent. Combine the organic layers.

- Purification: Concentrate the organic phase under reduced pressure. Purify the crude product using flash chromatography or recrystallization to obtain the desired functionalized API analogue.

Key Considerations:

- Regioselectivity: The success of LSF hinges on achieving high regioselectivity. This can be controlled by the catalyst system and the inherent electronic/steric properties of the scaffold.

- Advantage: This method allows for the generation of dozens of analogues from a single advanced intermediate in just one step, dramatically improving synthetic efficiency and reducing the PMI associated with a multi-step de novo synthesis for each analogue [28].

Process Optimization Workflow

The following diagram illustrates a logical workflow for optimizing an API synthesis route with a focus on reducing Process Mass Intensity.

The Scientist's Toolkit: Key Research Reagent Solutions

This table details essential reagents and catalysts that are pivotal for implementing modern, efficient API synthesis strategies.

| Item | Function & Application |

|---|---|

| Photoredox Catalysts (e.g., Ir(ppy)₃, Ru(bpy)₃²âº) | Enable unique reaction pathways using light energy. Used for radical generation and difficult bond formations (e.g., C-H functionalization) under mild conditions, replacing harsh stoichiometric oxidants [28]. |

| Electrocatalytic Setup | Uses electricity to drive redox reactions, replacing hazardous chemical oxidants/reductants. A sustainable tool for selective late-stage drug diversification [28]. |

| Biocatalysts (Engineered Enzymes) | Highly selective and efficient catalysts for asymmetric synthesis and functional group interconversions. Can achieve in one step what takes many with traditional chemistry, streamlining routes to complex molecules [28]. |

| Non-Precious Metal Catalysts (e.g., Ni, Fe) | Sustainable alternatives to expensive palladium catalysts. For example, nickel-based catalysts in borylation and Suzuki reactions can drastically reduce environmental impact and cost [28]. |

| Late-Stage Functionalization Reagents | Reagents designed to install key groups (e.g., -CF₃, -CH₃, alkyl chains) onto complex scaffolds. Central to generating diverse drug analogues from a common intermediate without de novo synthesis [28]. |

| Acetyl bromide-13C2 | Acetyl bromide-13C2, CAS:113638-93-0, MF:C2H3BrO, MW:124.93 g/mol |

| (E)-5-Ethyl-3-nonen-2-one | (E)-5-Ethyl-3-nonen-2-one | High Purity | For Research Use |

Troubleshooting Guides and FAQs

This section addresses common experimental challenges in implementing catalytic methods for sustainable API synthesis, focusing on olefin metathesis, biocatalysis, and asymmetric reactions.

Olefin Metathesis Troubleshooting

Q1: My olefin metathesis reaction in aqueous or complex media shows poor conversion. What strategies can improve catalyst performance and stability?

- Problem: Traditional ruthenium metathesis catalysts often decompose or show inhibited activity in aqueous buffers or cellular environments due to interaction with nucleophiles like glutathione (GSH) [33].

- Solutions:

- Employ Artificial Metathases: Use engineered artificial metalloenzymes (ArMs) where the ruthenium cofactor is shielded within a protein scaffold (e.g., de novo-designed dnTRP or HaloTag). This protein environment protects the catalyst from inactivation, allowing for ring-closing metathesis (RCM) in the cytoplasm of E. coli with turnover numbers (TON) ≥1,000 [33].

- Optimize Reaction Additives: Supplement the reaction mixture with bis(glycinato)copper(II) [Cu(Gly)â‚‚] (e.g., 5 mM) when working in cell-free extracts. This additive partially oxidizes and depletes GSH, mitigating catalyst poisoning [33].

- Utilize Polar Cofactor Designs: For supramolecular ArMs, use designed Hoveyda-Grubbs type catalysts with polar sulfamide groups. This improves water solubility and facilitates H-bonding interactions within the engineered protein pocket, enhancing binding affinity (KD ≤ 0.2 μM) and catalytic performance [33].

Q2: How can I achieve high diastereoselectivity in asymmetric Tsuji reductions to construct complex polyketide stereotriads?

- Problem: Achieving catalyst-directed diastereocontrol in Tsuji reductions of allylic carbonates to form synthetically challenging

syn,anti-stereotriads is difficult with standard ligands [34]. - Solutions:

- Ligand Selection is Critical: Avoid common bidentate phosphine ligands and MOP-type ligands, which offer low conversion or poor diastereocontrol. Instead, select P-stereogenic monodentate phosphine ligands like AntPhos [34].

- Catalyst System: Employ a palladium catalyst modified by AntPhos. This system has been proven to achieve high catalyst-directed diastereoselectivity (up to 8:1 dr) in the synthesis of complex targets like soraphen A, successfully forming the required

syn,anti-stereotriad [34]. - Protocol: The asymmetric Tsuji reduction of an allylic carbonate using a Pd-AntPhos catalyst can be performed to convert a metathesis-inactive allylic carbonate into a terminal olefin, enabling successive olefin metathesis events in a convergent synthesis [34].

Biocatalysis Troubleshooting

Q3: The free enzyme I am using for a key chiral step is unstable and cannot be recovered. How can I improve operational stability and enable reuse?

- Problem: Free enzymes in solution can denature quickly, are difficult to separate from the reaction mixture, and cannot be reused, increasing process costs and waste [35].

- Solutions:

- Implement Enzyme Immobilization: Covalently bind or adsorb enzymes onto solid supports. This technique increases stability towards pH and temperature, facilitates easy recovery by filtration, and allows for multiple reuse cycles, drastically improving process economics [35].

- Select Appropriate Support: For high efficiency, use supports like octadecyl polymethacrylate resin for lipase B from Candida antarctica or Nuvia IMAC resin for evolved galactose oxidase. This method has been used industrially for the synthesis of APIs like Islatravir and Odanacatib [35].

- Advance to Nanobiocatalysts (NBCs): For further enhanced properties, immobilize enzymes on nano-supports. NBCs often show superior activity, stability, and selectivity due to high surface area and unique material properties [35].

Q4: How can I rapidly identify a high-performing and sustainable synthetic route for an API candidate during early development?

- Problem: Selecting a synthetic route based solely on yield can lead to processes with high waste generation (high PMI) and poor environmental performance, which is costly to rectify later [36] [37].

- Solutions:

- Use PMI Prediction Tools: Utilize open-source predictive analytics applications that leverage historical data to forecast the Process Mass Intensity (PMI) of proposed synthetic routes before laboratory experimentation. This allows scientists to select the most efficient and sustainable option at the route design stage [37].

- Employ Bayesian Optimization (BO): After selecting a route, use machine learning-driven Experimental Design via Bayesian optimization (e.g., EDBO+) to rapidly identify optimal reaction conditions. This approach minimizes the number of experiments needed, saving resources while maximizing yield and selectivity. In one case, it achieved 80% yield and 91% ee in only 24 experiments, outperforming 500 traditional "one-factor-at-a-time" experiments [37].

Experimental Protocols

Protocol 1: Ring-Closing Metathesis (RCM) Using an Artificial Metathase in Cellulo

This protocol describes RCM catalyzed by an artificial metathase (Ru1·dnTRP_R0) in E. coli cytoplasm [33].

- Objective: To perform abiological catalysis in a whole-cell system for sustainable synthesis.

- Materials:

- E. coli cells expressing the de novo-designed protein dnTRP_R0.

- Synthetic cofactor Ru1.

- RCM substrate (e.g., diallylsulfonamide).

- LB growth medium.

- Buffer (e.g., pH 4.2).

- Bis(glycinato)copper(II) [Cu(Gly)â‚‚].

- Procedure:

- Culture Preparation: Grow E. coli cells harboring the dnTRPR0 expression plasmid to the desired optical density.

- Protein Expression: Induce protein expression and incubate to produce dnTRPR0.

- Cofactor Incorporation: Add cofactor Ru1 (0.05 equiv. relative to protein) to the cells or cell-free extract and incubate to form the Ru1·dnTRP_R0 complex.

- Reaction Setup: Add the RCM substrate (5,000 equiv. relative to Ru1) to the system.

- Additive for Stability: Supplement with [Cu(Gly)â‚‚] (5 mM final concentration) to oxidize intracellular glutathione and protect the cofactor.

- Incubation: Allow the reaction to proceed at the specified temperature for 18 hours.

- Analysis: Quench the reaction, extract products, and analyze by UPLC-MS or

^1H NMR to determine conversion and TON.

- Key Parameters: The hyper-stability of the dnTRP_R0 scaffold (T50 > 98°C) and high binding affinity (KD ≤ 0.2 μM) are crucial for success.

Protocol 2: Asymmetric Tsuji Reduction for Successive Olefin Metathesis

This protocol outlines a key step from an 11-step soraphen A synthesis, where an asymmetric Tsuji reduction enables a convergent metathesis strategy [34].

- Objective: Diastereoselective reduction of an allylic carbonate to a terminal olefin, unmasking a metathesis site.

- Materials:

- Allylic carbonate substrate (e.g., compound 10 from [34]).

- Palladium source.

- Chiral ligand: AntPhos.

- Silane reducing agent (e.g., dimethylphenylsilane).

- Anhydrous solvent (e.g., THF).

- Procedure:

- Catalyst Preparation: Pre-form or generate in situ the palladium catalyst modified by the AntPhos ligand.

- Reaction Setup: Charge the allylic carbonate substrate and the Pd-AntPhos catalyst into an anhydrous solvent under an inert atmosphere.

- Reduction: Add the silane reducing agent.

- Reaction Monitoring: Stir the reaction mixture at the specified temperature and monitor by TLC or LC-MS for consumption of the starting material.

- Work-up: Upon completion, quench the reaction and extract the product.

- Purification: Purify the product (e.g., terminal olefin 11) via flash chromatography.

- Key Parameters: The use of the P-stereogenic AntPhos ligand is critical for achieving high catalyst-directed diastereoselectivity (8:1 dr or greater) to form the desired

syn,anti-stereotriad.

The following tables consolidate key performance metrics for the catalytic methods discussed.

Table 1: Performance Metrics for Catalytic Systems in API Synthesis

| Catalytic System | Reaction Type | Key Metric | Performance | Context / Benefit |

|---|---|---|---|---|

| Pd-AntPhos [34] | Asymmetric Tsuji Reduction | Diastereomeric Ratio (dr) | 8:1 | Enables formation of challenging syn,anti-stereotriads. |

| Artificial Metathase (Ru1·dnTRP) [33] | Ring-Closing Metathesis (RCM) | Turnover Number (TON) | ≥ 1,000 | In E. coli cytoplasm; demonstrates high biocompatibility. |

| HaloTag-based ArM (N8-HT) [38] | Ring-Closing Metathesis (RCM) | Turnover Number (TON) | > 48 | In aqueous buffer at pH 7.0; covalent anchoring. |

| Bayesian Optimization (EDBO+) [37] | Reaction Condition Optimization | Number of Experiments / Yield | 24 expts. / 80% yield | Outperformed 500 traditional experiments (70% yield). |

| Solvent Recycling Initiative [36] | Waste Reduction | Solvent Recovery Rate | > 80% | Significantly reduces PMI and waste disposal. |

Table 2: Biocatalyst Immobilization and Applications in Pharma

| Biocatalyst | Immobilization Method | API / Intermediate | Key Advantage |

|---|---|---|---|

| Evolved Galactose Oxidase [35] | Affinity on Nuvia IMAC resin | Islatravir | Enables efficient, multi-enzyme synthesis. |

| Lipase B from C. antarctica [35] | Adsorption on polymethacrylate resin | Odanacatib | High stability and reusability in industrial process. |

| Transaminase [35] | Adsorption | Sitagliptin | Critical for chiral amine synthesis with high selectivity. |

| Penicillin G Amidase [35] | Covalent on polymer | Amoxicillin/Ampicillin | Allows continuous production of antibiotics. |

Workflow and Pathway Diagrams

Artificial Metathase Development Workflow

Title: Artificial Metathase Design and Optimization Path

Sustainable Route Development Strategy

Title: Green-by-Design API Synthesis Strategy

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Materials for Catalytic API Synthesis

| Item | Function / Application | Key Feature / Example |

|---|---|---|

| Hoveyda-Grubbs Type Catalysts | Catalyzing olefin metathesis (RCM, CM) in organic and aqueous media. | Modified versions (e.g., with polar sulfamide groups) are used for constructing artificial metathases [33]. |

| Chiral Monodentate Ligands (AntPhos) | Enabling asymmetric transformations (e.g., Tsuji reduction) with high diastereocontrol. | P-stereogenic nature is critical for catalyst-directed selectivity in complex molecule synthesis [34]. |

| De Novo-Designed Proteins (dnTRP) | Scaffolds for artificial metalloenzymes (ArMs). | Provide hyper-stability (T50 > 98°C) and a customizable pocket for abiotic cofactors [33]. |

| HaloTag Protein | Self-labeling protein scaffold for covalent anchoring of metal cofactors. | Creates stable ArM bioconjugates via a stable ester bond, useful for metathesis in buffer [38]. |

| Immobilized Enzymes (e.g., Lipase B) | Performing enantioselective hydrolyses, aminolyses, and other key steps under mild conditions. | Adsorbed on octadecyl polymethacrylate resin for synthesis of APIs like Odanacatib; enables reuse and stability [35]. |

| Bis(glycinato)copper(II) [Cu(Gly)â‚‚] | Protective additive for metathesis in biological media. | Mitigates catalyst poisoning by oxidizing glutathione in cell lysates or whole-cell systems [33]. |

| Pyrido[1,2-a]benzimidazol-8-ol | Pyrido[1,2-a]benzimidazol-8-ol, CAS:123444-29-1, MF:C11H8N2O, MW:184.19 g/mol | Chemical Reagent |

| 1-O-Dodecylglycerol | 3-Dodecyloxypropane-1,2-diol | Lipids Research Compound | High-purity 3-Dodecyloxypropane-1,2-diol for lipid & membrane research. For Research Use Only. Not for human or veterinary use. |

The Power of Continuous Manufacturing for Improved Mass Efficiency

Process Mass Intensity (PMI) is a key metric used to benchmark the environmental "greenness" of a manufacturing process by calculating the total mass of materials used to produce a given mass of product. In pharmaceutical synthesis, PMI accounts for all materials used, including reactants, reagents, solvents, and catalysts, providing a comprehensive measure of resource efficiency and environmental impact. The drive to reduce PMI has become a critical focus in pharmaceutical development, pushing the industry toward more sustainable and cost-effective manufacturing processes. [1]

Traditional batch manufacturing methods for Active Pharmaceutical Ingredients (APIs) often exhibit high PMI values due to discrete unit operations with intermediate hold times, lengthy setup and changeover periods, lower equipment utilization, and higher process losses. [39] Recent cross-company assessments reveal that synthetic peptides manufactured via traditional solid-phase peptide synthesis (SPPS) demonstrate particularly high PMI values averaging approximately 13,000, significantly higher than small molecule APIs (PMI median 168-308) and even biopharmaceuticals (PMI ≈ 8,300). [8] This substantial resource intensity highlights the urgent need for more efficient manufacturing approaches in pharmaceutical production.

Quantitative Benefits: Continuous vs. Batch Manufacturing

Continuous Manufacturing (CM) represents a paradigm shift in pharmaceutical production, where input materials are continuously fed into an integrated process and transformed into output products in a seamless, uninterrupted flow. This approach contrasts sharply with traditional batch processing, which produces pharmaceuticals in discrete steps with hold times between operations. [40] [39] The fundamental difference in operational methodology translates to significant improvements in mass efficiency, as quantified in the table below.

Table 1: PMI Comparison Across Manufacturing Modalities

| Manufacturing Modality | Typical PMI Range (kg material/kg API) | Key Contributing Factors |

|---|---|---|

| Small Molecule APIs (Batch) | 168 - 308 | Solvent usage, multiple isolation steps, process losses |

| Biopharmaceuticals (Batch) | ~8,300 | Cell culture media, purification steps, buffer solutions |

| Oligonucleotides (Solid-Phase) | 3,035 - 7,023 (avg. 4,299) | Excess reagents/solvents, challenging purifications, burdensome isolations |

| Synthetic Peptides (SPPS - Batch) | ~13,000 | Large solvent volumes (DMF, DCM), excess reagents, resin-based synthesis |

| Continuous Manufacturing | Significant reduction vs. batch (industry reports 30-50% waste reduction) | Integrated unit operations, real-time monitoring, smaller equipment footprint |

The environmental burden of traditional peptide synthesis is particularly noteworthy, with PMI values approximately 40-75 times higher than those for small molecule APIs. [8] This inefficiency stems from several factors: the use of large excesses of hazardous reagents and solvents, problematic solvents like N,N-dimethylformamide (DMF) and dichloromethane (DCM), poor atom-efficiency of protected amino acids, and substantial solvent consumption for isolation and purification. [8]

Continuous manufacturing addresses these inefficiencies through its fundamental operational principles. CM systems feature steady-state operation with consistent process conditions, integrated unit operations, real-time process analytics for quality control, and a significantly smaller equipment footprint. [40] The pharmaceutical industry is increasingly adopting CM, with the global market calculated at USD 919.7 million in 2020 and projected to increase at a compound annual growth rate (CAGR) of 13.85% from 2021 to 2027. [39]

Systematic Troubleshooting for Continuous Manufacturing Systems

A Structured Approach to Fault Diagnosis

Effective troubleshooting of continuous manufacturing systems requires a methodical, systematic approach to maintain operational efficiency and product quality. The following step-by-step methodology adapts general maintenance troubleshooting principles to the specific context of continuous API manufacturing: [41]

Review Historical Records: Upon identifying a process issue, begin by reviewing equipment histories and maintenance reports through your Computerized Maintenance Management System (CMMS) to determine if similar problems have occurred previously with the same or similar equipment. [41]

Retrieve Relevant Documentation: Consult operating instructions, process flow diagrams, P&IDs, and manufacturer manuals for information on how the equipment should function under normal conditions. [41]