Predicting Gas-to-Organic Solvent Partitioning: A Comprehensive Guide to the LSER Model for Pharmaceutical Research

This article provides a comprehensive exploration of the Linear Solvation Energy Relationship (LSER) model for predicting gas-to-organic solvent partition coefficients (K_S), a critical parameter in pharmaceutical research for understanding solute-solvent...

Predicting Gas-to-Organic Solvent Partitioning: A Comprehensive Guide to the LSER Model for Pharmaceutical Research

Abstract

This article provides a comprehensive exploration of the Linear Solvation Energy Relationship (LSER) model for predicting gas-to-organic solvent partition coefficients (K_S), a critical parameter in pharmaceutical research for understanding solute-solvent interactions. It covers the fundamental thermodynamics underpinning the LSER equation, practical methodologies for determining solute descriptors and system coefficients, strategies for troubleshooting common experimental and predictive challenges, and the validation of model accuracy against experimental data and alternative predictive approaches. Tailored for researchers, scientists, and drug development professionals, this guide synthesizes theoretical foundations with practical applications to enhance predictive modeling in areas such as drug solubility, bioavailability, and environmental fate.

The Thermodynamic Principles and LSER Equation: Foundations of Gas-to-Solvent Partitioning

Theoretical Foundation of the Abraham Model

The Abraham Solvation Parameter Model is a linear free energy relationship (LFER) that quantitatively predicts the partitioning behavior of solutes in physicochemical and biological systems. It is an essential tool for researchers predicting the environmental fate, bioavailability, and pharmacokinetic properties of organic compounds [1] [2]. The model expresses a solute's property as a linear combination of its molecular descriptors, which encode specific aspects of its interaction potential.

The model is particularly valuable for estimating gas-to-organic solvent partition coefficients, denoted as ( K_S ), which are crucial for understanding volatility, extraction efficiency, and solvent-solute interactions [3]. The general form of the equation for gas-to-solvent partitioning is:

[ \log(K_S) = c + eE + sS + aA + bB + lL ]

In this equation, the lowercase letters (( c, e, s, a, b, l )) are the system constants—they characterize the solvent phase and are determined through multiple linear regression of experimental data [2]. The uppercase letters (( E, S, A, B, L )) are the solute descriptors, which are intrinsic properties of the compound being studied.

Table 1: Solute Descriptor Definitions and Their Physicochemical Significance

| Descriptor | Symbol | Molecular Interaction it Represents |

|---|---|---|

| Excess Molar Refractivity | ( E ) | Polarizability from ( \pi ) and ( n ) electrons |

| Dipolarity/Polarizability | ( S ) | Dipole-dipole and dipole-induced dipole interactions |

| Overall Hydrogen Bond Acidity | ( A ) | Solute's ability to donate a hydrogen bond |

| Overall Hydrogen Bond Basicity | ( B ) | Solute's ability to accept a hydrogen bond |

| Gas-Hexadecane Partition Coefficient | ( L ) | Dispersion interactions and hydrophobicity |

The McGowan's characteristic volume (( V_x )) is sometimes used in place of ( L ) in certain forms of the model, particularly for partitioning between two condensed phases [2]. The success of the model lies in its linearity, which has a firm thermodynamic basis, even when accounting for strong, specific interactions like hydrogen bonding [2].

Experimental Determination of Solute Descriptors

A solute's descriptors are experimentally determined by measuring its behavior in well-characterized partitioning systems. These descriptors are considered system-independent properties and can be used to predict a vast array of other partition coefficients once known [3].

Table 2: Key Experimental Methods for Determining Solute Descriptors

| Descriptor | Primary Experimental Methods | Key Measurements Required |

|---|---|---|

| ( L ) | Gas-liquid chromatography (GLC) | Retention time on n-hexadecane stationary phase at 25°C [2] |

| ( E ) | Measurement of refractive index | Refractive index of the solute, typically at 20°C |

| ( S, A, B ) | Measurement of partition coefficients | Water-solvent and gas-solvent partition coefficients in multiple systems (e.g., water/octanol, gas/hexadecane, gas/solvent) [3] |

| ( V_x ) | Computational / Structural data | Molecular structure and atomic volumes |

For example, descriptors for adamantane and its derivatives were determined by constructing a set of simultaneous equations using experimental solubility data and gas-hexadecane partition coefficients across numerous solvent systems [3]. This process requires high-quality experimental data, such as solubilities in organic solvents, partition coefficients, and chromatographic retention times.

Research Reagent Solutions and Computational Tools

Successful application of the Abraham model relies on both laboratory reagents and specialized software for prediction and data analysis.

Table 3: Essential Research Reagents and Computational Tools

| Reagent / Tool Name | Type | Function in KS Research |

|---|---|---|

| n-Hexadecane | Reference Solvent | Used in GLC to determine the fundamental descriptor ( L ) [2] |

| n-Octanol | Partitioning Solvent | Used in the standard water-octanol system to measure a key partition coefficient for descriptor determination [3] |

| UFZ-LSER Database | Online Database | Publicly accessible database for obtaining system constants and calculating partitioning [4] |

| ACD/Absolv | Commercial Software | Predicts Abraham solvation parameters and partition coefficients directly from molecular structure; includes a database of descriptors for >5,000 compounds [5] |

Application Protocol: Predicting a Gas-Solvent Partition Coefficient

This protocol details the steps to predict the gas-to-organic solvent partition coefficient (( K_S )) for a novel compound using the Abraham model.

Step 1: Obtain Solute Descriptors

- Option A (Experimental Determination): Follow the methodologies outlined in Section 2 and Table 2 to determine the full set of descriptors (( E, S, A, B, L )) through laboratory measurements.

- Option B (Literature/Software): Consult the ACD/Absolv database [5] or published literature (e.g., the adamantane study [3]) to retrieve pre-determined descriptors for your solute of interest.

Step 2: Identify System Constants

- For your target organic solvent, retrieve the system constants (( c, e, s, a, b, l )). These can be found in the UFZ-LSER database [4] or in primary literature describing the Abraham model for that specific solvent system.

Step 3: Calculate log(( K_S ))

- Substitute the solute descriptors and system constants into the Abraham model equation: [ \log(K_S) = c + eE + sS + aA + bB + lL ]

- Perform the calculation to obtain the predicted log(( K_S )).

Step 4: Experimental Validation (Optional but Recommended)

- Design a gas-solvent partitioning experiment to measure the experimental ( K_S ) value.

- Compare the experimentally measured value with the model's prediction to validate the accuracy of the descriptors and the model for your specific system.

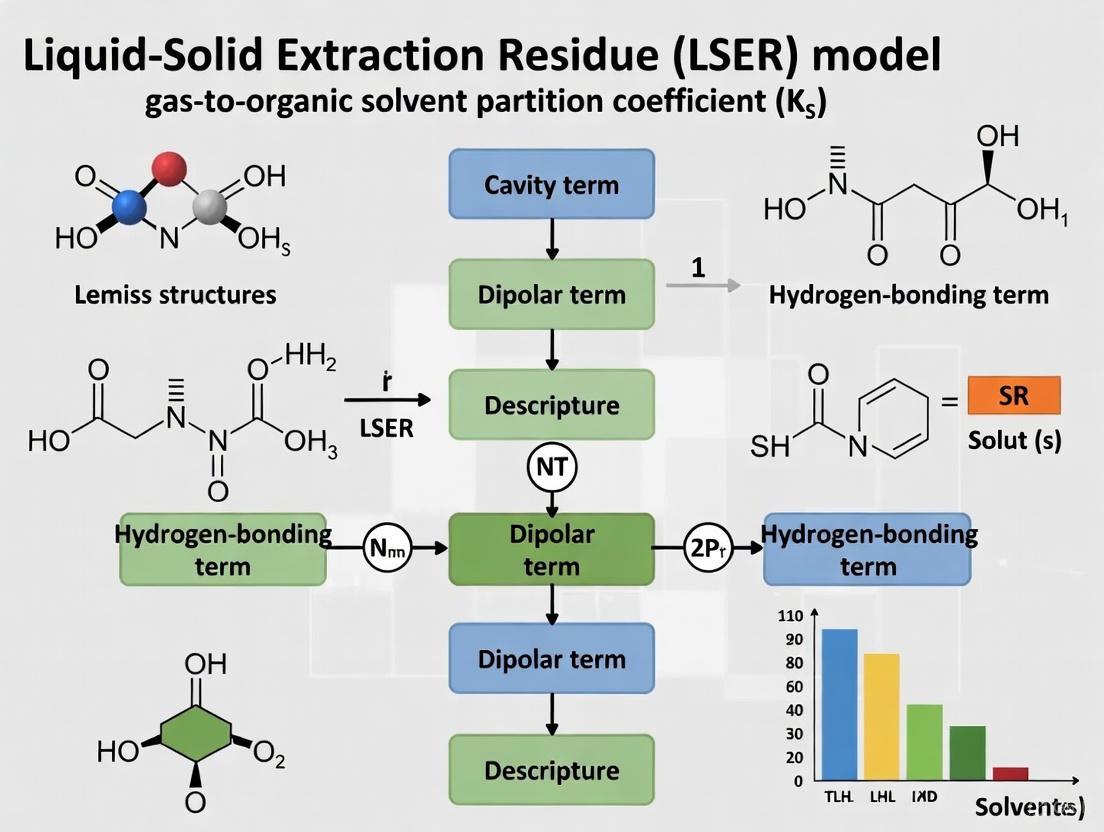

The following workflow diagram illustrates this multi-step protocol.

Worked Example: Prediction for Adamantane

To illustrate the application, consider the prediction of gas-solvent partition coefficients for adamantane, a polycyclic aliphatic hydrocarbon. Its descriptors have been firmly established [3]:

- ( E = 0.70 ) (moderate polarizability)

- ( S = 0 ) (no dipole moment)

- ( A = 0 ) (no hydrogen bond acidity)

- ( B \approx 0 ) (very low hydrogen bond basicity)

- ( L ) (a specific value determined experimentally)

By inserting these descriptors, along with the system constants for a target solvent (e.g., hexane, octanol, or a more complex organic solvent), into the ( K_S ) equation, one can predict its partition coefficient into that solvent. The descriptors confirm that adamantane is a very hydrophobic molecule, with its partitioning dominated by dispersion forces (reflected in its ( E ) and ( L ) descriptors) and not by polar or hydrogen-bonding interactions [3].

Advanced Applications in Pharmaceutical Research

The Abraham model and the ( K_S ) equation are extensively applied in pharmaceutical and medical device industries, particularly in extractables and leachables (E&L) studies [1]. Key applications include:

- Evaluating Extraction Solvents: Understanding the extraction power of various solvents towards polymeric materials used in packaging and device components.

- Chromatographic Retention Prediction: Correlating and predicting the retention behavior of E&L compounds in chromatographic systems to aid in the identification of unknown compounds.

- Developing Drug Product Simulating Solvents: Aiding in the design and evaluation of solvents that simulate a drug product for migration studies.

The Linear Solvation Energy Relationship (LSER) model, particularly the Abraham model, is a cornerstone methodology for predicting the partitioning behavior of solutes in various chemical and biological systems. For research focused on the gas-to-organic solvent partition coefficient (Ks), the model provides an interpretative framework that connects a solute's partition coefficient to its fundamental physicochemical properties through a linear free-energy relationship [6]. The general form of the Abraham model for gas-to-solvent partitioning is expressed as [7] [6]:

log Ks = c + e·E + s·S + a·A + b·B + l·L

In this equation, the uppercase letters (E, S, A, B, L) are the solute descriptors, each quantifying a specific molecular interaction property of the solute. The lowercase letters (c, e, s, a, b, l) are the solvent coefficients that characterize the complementary properties of the solvent phase [6]. The model's power lies in its ability to deconstruct complex solvation phenomena into discrete, quantifiable intermolecular interactions, providing researchers and drug development professionals with a predictive tool for solubility, partitioning, and other pharmacokinetic properties [7] [8].

Deconstructing the Solute Descriptors

The solute descriptors are the core of the LSER model. Each descriptor encodes a specific aspect of the solute's potential for intermolecular interactions and its size.

Definitions and Molecular Interpretations

- E - Excess Molar Refractivity: This descriptor is measured in units of (cm³/mol)/10 and represents the solute's polarizability arising from π- and n-electrons [7] [6]. It is related to the solute's ability to engage in non-specific van der Waals interactions.

- S - Dipolarity/Polarizability: This descriptor quantifies the solute's ability to stabilize a neighboring charge or dipole through non-specific dielectric interactions [6]. It encompasses both the solute's permanent dipole moment and its polarizability.

- A - Overall Hydrogen-Bond Acidity: This is the summation hydrogen-bond acidity descriptor, representing the solute's total capacity to donate a hydrogen bond [7] [6]. A higher A value indicates a stronger hydrogen bond donor.

- B - Overall Hydrogen-Bond Basicity: This is the summation hydrogen-bond basicity descriptor, representing the solute's total capacity to accept a hydrogen bond [7] [6]. A higher B value indicates a stronger hydrogen bond acceptor.

- L - Logarithm of the Gas-Hexadecane Partition Coefficient at 298 K: This descriptor encodes the solute's ability to partition from the gas phase into a condensed, non-polar phase (n-hexadecane) [7] [6]. It is a measure of the solute's dispersion interactions and its characteristic volume.

- Vx - McGowan Characteristic Volume: Measured in units of (cm³/mol)/100, this descriptor is the easiest to obtain as it can be calculated directly from molecular structure using atomic contributions [7]. It encodes size-related solvent-solute dispersion interactions, including a measure of the energy required to form a cavity in the solvent to accommodate the solute.

Table 1: Abraham Solute Descriptors: Definitions and Interpretations

| Descriptor | Molecular Interpretation | Units | Experimental/Calculational Basis |

|---|---|---|---|

| E | Excess molar refractivity / polarizability | (cm³/mol)/10 | Calculated from refractive index or predicted via software/fragments [7] |

| S | Dipolarity/Polarizability | Dimensionless | Determined by regression of experimental solubility/partition data [7] |

| A | Overall Hydrogen-Bond Acidity | Dimensionless | Determined by regression of experimental solubility/partition data [7] |

| B | Overall Hydrogen-Bond Basicity | Dimensionless | Determined by regression of experimental solubility/partition data [7] |

| L | Gas-Hexadecane partition coefficient | Dimensionless (log unit) | Experimentally determined or predicted [7] |

| Vx | McGowan Characteristic Volume | (cm³/mol)/100 | Calculated directly from molecular structure [7] |

Determination of Solute Descriptors

The determination of solute descriptors follows a hierarchical process. The descriptor V is the most straightforward, as it is calculated from the molecular structure using the McGowan method [7]. The descriptor E can be calculated for liquids from their refractive index or estimated for solids using prediction software or fragment methods [7]. The remaining descriptors (S, A, B, L) are typically determined using regression analysis with a large set of experimental data, such as solubility values in multiple organic solvents and partition coefficients [7]. For example, in the case of trans-cinnamic acid, which can exist as a monomer in polar solvents and a dimer in non-polar solvents, descriptors for both forms were determined by separately regressing solubility data from polar and non-polar solvents [7]. Modern approaches also leverage machine learning; the AbraLlama-Solute model, a fine-tuned large language model, can predict Abraham solute descriptors directly from a SMILES string with high accuracy [9].

Experimental Protocols for LSER Applications

The following protocols outline the key methodologies for applying the LSER model to determine partition coefficients and related properties.

Protocol 1: Determining Gas-to-Organic Solvent Partition Coefficients (Ks)

Principle: This protocol describes the experimental and computational workflow for determining the gas-to-organic solvent partition coefficient, a key parameter in predicting the behavior of volatile compounds, such as anesthetics [8] [6].

Materials:

- Equilibrium Chamber: A sealed vessel capable of maintaining a constant temperature (e.g., 298 K) where the solute in the gas phase equilibrates with the organic solvent.

- Analytical Instrumentation: Gas Chromatography (GC) or Headspace-GC for precise measurement of solute concentration in the gas phase and/or the solvent phase.

- Temperature-Controlled Water Bath: To maintain isothermal conditions during the experiment.

- High-Purity Solutes and Solvents.

Procedure:

- System Preparation: Introduce a known volume of the pure, dry organic solvent into the equilibrium chamber. Seal the chamber.

- Solute Introduction: Inject a known, precise amount of the volatile solute into the chamber's headspace using a gas-tight syringe.

- Equilibration: Place the sealed chamber in a temperature-controlled water bath (e.g., 298 K) with constant agitation to facilitate partitioning. Allow the system to reach equilibrium, which can be confirmed by repeated measurement of headspace concentration until it stabilizes.

- Sampling and Analysis:

- Sample the gas phase (headspace) using a gas-tight syringe and inject into the GC for analysis.

- Alternatively, sample the liquid solvent phase, ensuring no gas bubbles are present, and inject into the GC.

- Calculation: The partition coefficient Ks is calculated as the ratio of the solute's concentration in the solvent phase to its concentration in the gas phase at equilibrium: ( Ks = \frac{[solute]{solvent}}{[solute]_{gas}} ).

- Regression: To obtain the solvent coefficients for the Ks equation, the log Ks values for a large set of solutes with known Abraham descriptors are regressed against the solute descriptors (E, S, A, B, L) [7] [6].

Protocol 2: Calculating Solute Descriptors from Solubility Data

Principle: This protocol uses measured solubility data in multiple solvents to determine the Abraham descriptors for a new solute, expanding the available database for predictive modeling [7].

Materials:

- Open Data Sources: Databases such as the Open Notebook Science Challenge which provide open-access solubility data for organic compounds in various solvents [7].

- Computational Software: Tools for linear regression analysis (e.g., R, Python with SciKit-Learn) or specialized software like Absolv (part of ACD/ADME Suite) [7].

- Solvents with Known Coefficients: A diverse set of organic solvents (polar, non-polar, protic, aprotic) for which the Abraham solvent coefficients (e, s, a, b, v, l) are already established.

Procedure:

- Data Collection: Gather experimental molar solubility values (Ss) for the solute in a wide range of organic solvents. Gather or estimate the solute's aqueous solubility (Sw) [7].

- Data Conversion: For each solvent, calculate the water-solvent partition coefficient as ( P = \frac{Cs}{Cw} ), where Cs is the molar solubility in the organic solvent and Cw is the aqueous solubility [7].

- Model Application: Use the Abraham model for partitioning in the form of ( \log P = c + e \cdot E + s \cdot S + a \cdot A + b \cdot B + v \cdot V ) [7].

- Regression Analysis: Perform multilinear regression with log P as the dependent variable and the known solvent coefficients (e, s, a, b, v) for each solvent as the independent variables. The regression will solve for the solute's descriptors (E, S, A, B, V), which are the fitted parameters [7].

- Special Cases: For compounds like carboxylic acids that can dimerize in non-polar solvents, treat the data from polar and non-polar systems separately to calculate descriptors for both the monomeric and dimeric forms [7].

Visualizing the LSER Workflow and Solute-Solvent Interactions

The following diagram illustrates the logical workflow and the key solute-solvent interactions characterized by the LSER model.

LSER Model Workflow and Molecular Interactions

Successful application of the LSER model relies on a combination of experimental data, computational tools, and curated databases.

Table 2: Essential Research Tools for LSER Applications

| Tool / Resource | Type | Function in LSER Research | Example / Source |

|---|---|---|---|

| Abraham Solute Descriptor Database | Database | Provides a curated set of experimentally derived solute descriptors (E, S, A, B, V, L) for thousands of compounds, essential for regression and prediction. | UFZ-LSER Database [9] |

| Abraham Solvent Coefficients | Dataset | A compiled set of solvent coefficients (c, e, s, a, b, v, l) for common organic solvents, required for predicting partition coefficients and solubilities. | Literature compilation by Acree et al. [9] |

| AbraLlama Models | AI Prediction Tool | Fine-tuned large language models (LLMs) that predict Abraham solute descriptors and modified solvent parameters directly from SMILES strings. | AbraLlama-Solute & AbraLlama-Solvent on Hugging Face [9] |

| Open Notebook Science Challenge | Data Repository | An open data collection of solubility measurements for organic compounds, used to determine new solute descriptors. | Royal Society of Chemistry sponsored project [7] |

| Quantum Chemical (QC) Software | Computational Tool | Performs calculations (e.g., COSMO-RS) to derive molecular charge densities and predict solvation energies, aiding in descriptor determination. | COSMO-RS implementations [6] |

| Random Forest Solvent Models | Predictive Model | Machine learning models that predict Abraham solvent coefficients for new organic solvents, extending the model's applicability. | Bradley et al. open models [10] |

The deconstruction of the LSER solute descriptors (E, S, A, B, L, Vx) provides a powerful, quantitative framework for understanding and predicting solute behavior in gas-to-solvent partitioning. By following the detailed protocols for determining partition coefficients and solute descriptors, and by leveraging the modern computational tools and databases outlined in the Scientist's Toolkit, researchers can effectively apply the Abraham model to advance research in drug development, environmental chemistry, and chemical engineering. The ongoing integration of machine learning and quantum chemical calculations promises to further expand the accuracy and scope of this foundational model.

The Abraham solvation parameter model, or Linear Solvation Energy Relationship (LSER), is a powerful predictive tool in chemical, environmental, and pharmaceutical research, successfully correlating free-energy-related properties of a solute with its molecular descriptors [2]. The model's core principle rests on linear free energy relationships (LFERs), which quantitatively describe how the standard free energy change ( \Delta G^{0} ) of a solvation or partitioning process correlates with molecular interaction parameters [11]. For a solute transferring from the gas phase to an organic solvent, the process is quantified by the gas-to-organic solvent partition coefficient, ( KS ), through the fundamental LSER equation [2]: [ \log (KS) = ck + ekE + skS + akA + bkB + lkL ] Here, the solute is described by its molecular descriptors: ( Vx ) (McGowan’s characteristic volume), ( L ) (gas–hexadecane partition coefficient), ( E ) (excess molar refraction), ( S ) (dipolarity/polarizability), ( A ) (hydrogen bond acidity), and ( B ) (hydrogen bond basicity). The system's characteristics are captured by the solvent-specific coefficients ( ck ), ( ek ), ( sk ), ( ak ), ( bk ), and ( l_k ), which are determined via multiple linear regression of experimental data [2]. The very existence of this linearity, even for strong, specific interactions like hydrogen bonding, has been a subject of scientific inquiry, with recent work verifying its robust thermodynamic basis by combining equation-of-state solvation thermodynamics with the statistical thermodynamics of hydrogen bonding [2].

The Thermodynamic Basis of LSER Linearity

The Role of Free Energy and Enthalpy-Underscoring Linearity

The remarkable linearity observed in LSER models finds its foundation in the principles of thermodynamics. The quantitative relationships developed via theoretical derivation in physical chemistry are inherently robust and independent of the specific compounds studied [11]. The partition coefficient ( \log (KS) ) is directly proportional to the standard free energy change ( \Delta G^{0}{tr} ) for the solute transfer process ( \Delta G^{0}{tr} = -RT \ln KS ). This free energy change itself is a function of the corresponding standard enthalpy ( \Delta H^{0}{tr} ) and entropy ( \Delta S^{0}{tr} ) changes [11]. The LSER model effectively deconvolutes this overall ( \Delta G^{0}{tr} ) into contributions from distinct, independent types of intermolecular interactions, with each term in the LSER equation ( ekE, skS, akA, bkB, lkL ) representing a partial free energy contribution associated with a specific interaction mode [2] [11].

A major challenge has been understanding why these relationships remain linear despite the presence of strong, specific interactions like hydrogen bonding. Research confirms there is a solid thermodynamic basis for this LFER linearity. The combination of equation-of-state solvation thermodynamics with the statistical thermodynamics of hydrogen bonding verifies that the linearity holds because the LSER formalism effectively captures the free energy contributions of these interactions in a way that remains additive across diverse solute-solvent systems [2]. This linearity extends to other thermodynamic properties, such as solvation enthalpy ( \Delta HS ), which can be described by a similar linear equation [2]: [ \Delta HS = cH + eHE + sHS + aHA + bHB + lHL ] This equation allows for the extraction of enthalpic information on intermolecular interactions, providing a more detailed thermodynamic picture of the solvation process.

Key Molecular Descriptors and Intermolecular Interactions

Table 1: LSER Solute Descriptors and Their Physicochemical Significance

| Descriptor | Symbol | Related Interaction Type | Thermodynamic Interpretation |

|---|---|---|---|

| McGowan's Characteristic Volume | ( V_x ) | Dispersion/Cavity Formation | Energy cost of creating a cavity in the solvent and the gain from dispersion forces. |

| Gas-Hexadecane Partition Coefficient | ( L ) | Dispersion Interactions | Free energy of solvation in an aliphatic hydrocarbon reference solvent. |

| Excess Molar Refraction | ( E ) | Polarizability from ( \pi )- and ( n )-electrons | Measures solute polarizability and its contribution to dispersion and polarization interactions. |

| Dipolarity/Polarizability | ( S ) | Dipolar & Polarization Interactions | Free energy contribution from dipole-dipole and dipole-induced dipole interactions. |

| Hydrogen Bond Acidity | ( A ) | Hydrogen Bond Donating Ability | Free energy contribution from the solute acting as a hydrogen bond donor (acid) to the solvent. |

| Hydrogen Bond Basicity | ( B ) | Hydrogen Bond Accepting Ability | Free energy contribution from the solute acting as a hydrogen bond acceptor (base) from the solvent. |

Experimental Protocols for LSER Model Application

Protocol 1: Determination of Gas-to-Organic Solvent Partition Coefficients (( K_S )) Using Headspace Gas Chromatography (HSGC)

This protocol outlines the experimental determination of gas-liquid partition coefficients for neutral organic solutes, providing the primary data for constructing and validating LSER models [12].

1. Primary Reagents and Materials:

- Analyte Solutes: High-purity volatile organic compounds (e.g., alkanes, alcohols, ketones, aromatic compounds).

- Organic Solvents: Anhydrous solvents of high purity (e.g., n-hexadecane, n-octanol, chloroform) to cover a range of interaction types.

- Gas Chromatograph: Equipped with a flame ionization detector (FID) or mass spectrometer (MS).

- Headspace Vials: Sealed vials with PTFE/silicone septa.

- Gas-tight Syringes: For precise injection of headspace samples.

2. Procedure: 1. Sample Preparation: Prepare a series of headspace vials containing a known, constant volume of the organic solvent. Inject a range of microgram quantities of the analyte solute into the vials to establish a concentration series. Ensure vials are immediately sealed to prevent volatile loss [12]. 2. Equilibration: Place the prepared vials in a thermostated agitator (e.g., 25°C / 298.15 K) for a sufficient time to ensure equilibrium partitioning between the gas and liquid phases is achieved [12]. 3. Headspace Sampling: Using a gas-tight syringe, extract a defined volume of the equilibrated gas phase from the headspace of the vial. 4. GC Analysis: Inject the headspace sample into the GC system. Use an appropriate column (e.g., a non-polar capillary column) to separate the analyte. Record the peak area or height. 5. Calibration: Construct a calibration curve by analyzing headspace samples above a reference system (e.g., the pure analyte) or by using standard addition methods. 6. Data Calculation: The gas-to-solvent partition coefficient ( KS ) is calculated as ( KS = C{\text{solvent}} / C{\text{gas}} ), where ( C ) is the concentration in the respective phase at equilibrium, derived from the GC signal and the calibration curve [12].

3. Analysis and LSER Data Generation: 1. For each solute-solvent pair, perform multiple replicates to ensure precision. 2. Compile the log ( KS ) values for a wide range of chemically diverse solutes in the solvent of interest. 3. Use multiple linear regression analysis to fit the experimental log ( KS ) data against the known solute descriptors ( (E, S, A, B, L, Vx) ), thereby obtaining the solvent-specific coefficients ( (ck, ek, sk, ak, bk, l_k) ) for the LSER model [2] [12].

Protocol 2: In Silico Prediction of Polymer-Water Partition Coefficients using the UFZ-LSER Database

This protocol describes the use of a publicly available database to predict partition coefficients for neutral compounds, which is highly relevant for assessing the distribution of drug molecules or environmental contaminants [4] [13].

1. Primary Reagents and Materials:

- UFZ-LSER Database: Access the online database at https://www.ufz.de/lserd/ [4].

- Compound List: A list of neutral organic compounds for which predictions are needed.

- Solute Descriptors: Experimental or in silico predicted LSER solute descriptors (E, S, A, B, V, L) for the compounds of interest.

2. Procedure: 1. Database Navigation: - Access the UFZ-LSER database. The interface allows the calculation of various partitioning properties [4]. - Select the appropriate calculation module, such as "Calculate the sorbed concentration" or "Calculate the fraction of solute in the solvent" depending on the required output. 2. System Definition: - For polymer-water partitioning (e.g., Low-Density Polyethylene (LDPE)/Water), the database contains pre-defined LSER system parameters. For LDPE/water, the model is: log ( K_{i,\text{LDPE/W}} = -0.529 + 1.098E - 1.557S - 2.991A - 4.617B + 3.886V ) [13]. - If using a custom solvent system, the corresponding solvent coefficients must be available or determined first via Protocol 1. 3. Input of Solute Data: - Input the solute descriptors for the target compounds. The database contains a built-in chemical list, or users can input custom descriptor values [4]. 4. Calculation and Output: - Execute the calculation. The database will return the predicted partition coefficient (log P or log K) [4]. - Export the results for further analysis.

3. Analysis and Validation: - Benchmarking: For critical applications, validate the in silico predictions against a limited set of experimental data, if available. The LSER model for LDPE/water has been benchmarked with an independent validation set, yielding high accuracy (R² = 0.985, RMSE = 0.352) when using experimental solute descriptors [13]. - Domain of Applicability: Note that the model is only valid for neutral chemicals, and the domain of applicability for each descriptor should be considered [4].

Computational Workflow and Data Visualization

The following diagram illustrates the integrated experimental and computational workflow for developing and applying an LSER model, from data generation to prediction and validation.

The Scientist's Toolkit: Key Research Reagents and Materials

Table 2: Essential Materials and Resources for LSER-Based Research

| Item/Resource | Function in LSER Research | Example/Specification |

|---|---|---|

| UFZ-LSER Database | A curated, publicly accessible database for obtaining solute descriptors and calculating partition coefficients for neutral compounds in various systems [4]. | https://www.ufz.de/lserd/; Contains over 390,000 data points [4]. |

| Reference Solvents | Used in experiments to determine solute descriptors or solvent coefficients. They cover a spectrum of interaction types. | n-Hexadecane (dispersion), n-Octanol (H-bonding), Chloroform (H-bond acidity), Diethyl Ether (H-bond basicity) [2] [12]. |

| High-Purity Solutes | Chemically diverse analytes used to parameterize LSER models through measurement of their partition coefficients. | Linear/Branched Alkanes, Alcohols, Ketones, Ethers, Aromatic Compounds [12]. |

| Headspace Gas Chromatograph (HSGC) | The primary analytical instrument for the accurate determination of gas-liquid partition coefficients without interference from interfacial adsorption [12]. | System equipped with FID/MS detector and thermostated headspace autosampler. |

| Quantum-Chemical (QC) Descriptors | Molecular descriptors derived from computational chemistry that can be used to supplement or predict LSER parameters, aiding in the extension to compounds lacking experimental data [14]. | Descriptors calculated via methods like COSMO-RS or other QC packages; sometimes referred to as QC-LSER descriptors [14]. |

| Colorblind-Friendly Palette | A set of colors for creating accessible data visualizations and charts, ensuring interpretability for all researchers. | Palette of #d55e00, #cc79a7, #0072b2, #f0e442, #009e73 [15]. |

| Hsd17B13-IN-29 | Hsd17B13-IN-29, MF:C23H14Cl2N4O3, MW:465.3 g/mol | Chemical Reagent |

| Nisoldipine-d3 | Nisoldipine-d3, MF:C20H24N2O6, MW:391.4 g/mol | Chemical Reagent |

Understanding System Coefficients as Complementary Solvent Properties

Within the Linear Solvation Energy Relationship (LSER) framework for predicting gas-to-organic solvent partition coefficients (K_S), the system coefficients (e, s, a, b, l, c) are not merely fitting parameters. They represent the complementary properties of the solvent phase, quantitatively describing its capacity for various intermolecular interactions. This application note delineates the protocol for determining and interpreting these coefficients, framing them as essential descriptors for predicting solute partitioning in pharmaceutical and environmental research.

The Abraham solvation parameter model is a powerful tool for predicting a wide array of chemical, biomedical, and environmental processes [2]. For the gas-to-organic solvent partition coefficient (K_S), the model employs the following linear free-energy relationship (LFER) [16]:

log(K_S) = c + eE + sS + aA + bB + lL

In this equation, the capital letters (E, S, A, B, L) are solute descriptors—molecular properties that are intrinsic to the solute and remain constant across different systems [16]. In contrast, the lower-case letters (e, s, a, b, l, c) are the system coefficients (or solvent coefficients). These coefficients are complementary properties of the solvent phase. They are determined through multiple linear regression of experimental partition data for a diverse set of solutes with known descriptors and represent the solvent's capacity to participate in specific intermolecular interactions [2] [16]. The practical application of this model relies on the availability of both solute descriptors and pre-determined system coefficients for the solvent of interest.

Thermodynamic Interpretation of Coefficients

The LSER model is grounded in a cavity theory of solvation, where the process is divided into creating a cavity in the solvent, reorganizing the solvent, and establishing solute-solvent interactions [17]. The system coefficients in the log(K_S) equation are linearly related to the free energy of transfer from the gas phase to the solvent [17]. Each coefficient quantifies the complementary effect of the solvent on a specific interaction type:

- Cavity Formation and Dispersive Interactions: The

lcoefficient is primarily associated with the solvent's response to the cavity formation energy and dispersive (van der Waals) interactions, characterized by the solute's L descriptor (logarithmic hexadecane-air partition coefficient) [16]. - Polar Interactions: The

scoefficient reflects the solvent's dipolarity/polarizability and its complementary interaction with the solute's dipolarity/polarizability (S descriptor) [16]. - Hydrogen-Bonding Interactions: The

aandbcoefficients describe the solvent's hydrogen-bond basicity and acidity, respectively. They interact complementarily with the solute's hydrogen-bond acidity (A descriptor) and basicity (B descriptor) [2] [16]. - Non-Specific Interactions: The

ecoefficient relates to the solvent's interaction with the solute's excess molar refraction (E descriptor) [16].

A significant advancement is the development of a single LSER equation that can predict partitioning between any two bulk phases, simplifying the application of the thermodynamic cycle and improving predictions for specific compound classes like highly fluorinated molecules [16].

Protocol for Determining System Coefficients

This protocol details the experimental and computational methodology for determining the system coefficients (e, s, a, b, l, c) for a new organic solvent.

Experimental Determination of Gas-Solvent Partition Coefficients (K_S)

Principle: The system coefficients for a solvent are derived by correlating experimentally measured log(K_S) values for a set of reference solutes with their known solute descriptors.

Materials & Equipment:

- Gas Chromatograph: Equipped with a flame ionization detector (FID) or mass spectrometer (MS).

- Capillary Column: Coated with the solvent of interest as the stationary phase.

- Reference Solutes: A training set of 30-50 compounds with known Abraham solute descriptors (E, S, A, B, L). The set must be chemically diverse, encompassing a wide range of polarity, hydrogen-bonding ability, and size.

- Syringe: For sample injection.

- Data Acquisition System: To record retention times.

Procedure:

- Column Preparation: Coat a deactivated capillary column with the solvent of interest, ensuring a uniform and stable stationary phase film to minimize adsorption effects [17].

- Dead Time Determination: Inject a non-retained compound (e.g., methane or air) at the desired temperature (commonly 25°C or other relevant temperatures) to determine the column's dead time (t_m).

- Retention Time Measurement: For each reference solute in the training set, inject a small sample onto the column and record its retention time (t_R). Ensure all measurements are conducted at the same, constant temperature.

- Calculate Capacity Factor: For each solute, calculate the capacity factor (k) using the formula:

k = (t_R - t_m) / t_m[17]. - Calculate log(KS): Determine the gas-liquid partition coefficient, KS. For a capillary column, this can be related to the capacity factor and the phase ratio (Φ = VS / VM). The specific calculation may vary based on the chromatographic setup and available parameters [17].

Computational Regression for Coefficient Determination

Procedure:

- Data Compilation: Create a data matrix with the experimentally determined log(K_S) values for all reference solutes and their corresponding known solute descriptors (E, S, A, B, L).

- Multiple Linear Regression: Use statistical software (e.g., R, Python with scikit-learn) to perform a multiple linear regression. The model is:

log(K_S) = c + eE + sS + aA + bB + lL - Output Analysis: The output of the regression will provide the best-fit values for the system coefficients (e, s, a, b, l, c). The quality of the fit is typically assessed by the correlation coefficient (R²), standard error, and the significance (p-values) of each coefficient.

Data Presentation: Solvent-System Coefficients

The following table summarizes example system coefficients for different organic solvents, illustrating how these values reflect the chemical nature of the solvent. The coefficients a and b are particularly indicative of a solvent's hydrogen-bonding character.

Table: Exemplar System Coefficients for Selected Organic Solvents in the Gas-to-Solvent Partitioning LSER Equation [16]

| Solvent | e | s | a | b | l | c |

|---|---|---|---|---|---|---|

| n-Hexadecane | 0.000 | 0.000 | 0.000 | 0.000 | 1.000 | 0.000 |

| Diethyl Ether | 0.000 | 0.250 | 0.000 | 0.450 | 0.950 | -0.300 |

| Ethyl Acetate | 0.000 | 0.620 | 0.000 | 0.450 | 0.900 | -0.500 |

| Methanol | 0.000 | 0.400 | 0.300 | 0.500 | 0.800 | -0.500 |

| Water | 0.000 | 0.600 | 1.000 | 0.200 | 0.500 | -1.200 |

Note: The values in this table are illustrative examples. For actual research, coefficients should be sourced from comprehensive, peer-reviewed databases.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table: Key Materials for LSER-Based Partition Coefficient Studies

| Item | Function/Description |

|---|---|

| n-Hexadecane | A non-polar reference solvent for determining the solute's L descriptor and for calibrating GC systems [17]. |

| Apolane-C87 | A branched, high-molecular-weight alkane stationary phase for GC, allowing for the determination of log L for heavy, non-volatile compounds at elevated temperatures [17]. |

| Reference Solute Training Set | A chemically diverse library of compounds with pre-established, high-quality Abraham solute descriptors for regression analysis [16]. |

| Deactivated Capillary GC Columns | Inert columns that minimize adsorption of polar solutes onto the column surface, ensuring accurate measurement of partition coefficients [17]. |

| LSER & PSP Databases | Freely accessible databases containing solute descriptors and system coefficients, which are rich sources of thermodynamic information [2]. |

| Dat-IN-1 | Dat-IN-1, MF:C29H34F2N2O2S, MW:512.7 g/mol |

| Dhodh-IN-25 | Dhodh-IN-25, MF:C22H19ClF5N3O5, MW:535.8 g/mol |

Visualizing the LSER Coefficient Determination Workflow

The following diagram illustrates the logical flow and sequence of steps from experimental setup to the final determination of the system coefficients.

Experimental Workflow for LSER Coefficient Determination

Visualizing the Conceptual Framework of LSER

This diagram deconstructs the LSER equation to show the complementary relationship between solute descriptors and solvent system coefficients in determining the overall partition coefficient.

LSER Conceptual Framework: Solute-Solvent Complementarity

The Significance of K_S in Pharmaceutical and Environmental Contexts

The Abraham solvation parameter model, also known as the Linear Solvation Energy Relationship (LSER), is a cornerstone predictive tool in chemical, environmental, and pharmaceutical research [2]. It provides a robust framework for understanding and quantifying the partitioning behavior of solutes between different phases. A fundamental parameter within this model is the gas-to-organic solvent partition coefficient, denoted as K_S. This coefficient describes the equilibrium distribution of a neutral compound between a gaseous phase and an organic solvent, providing direct insight into solute-solvent interactions [2].

The LSER model correlates free-energy-related properties, such as log KS, with a set of six empirically derived solute descriptors [2]. The governing equation for KS is expressed as:

log (K_S) = ck + ekE + skS + akA + bkB + lkL [2]

In this equation:

- K_S: Gas-to-organic solvent partition coefficient.

- E: Excess molar refraction.

- S: Solute dipolarity/polarizability.

- A: Solute hydrogen-bond acidity.

- B: Solute hydrogen-bond basicity.

- L: The logarithm of the gas–hexadecane partition coefficient at 298 K.

- ck, ek, sk, ak, bk, lk: System-specific coefficients (solvent descriptors) determined through multiple linear regression of experimental data.

The remarkable feature of this model is that the coefficients (e.g., ak, bk) are solvent-specific descriptors, reflecting the complementary properties of the solvent phase, while the variables (e.g., A, B) are solute-specific molecular descriptors [2]. This separation makes the LSER model a powerful tool for predicting partitioning behavior for a wide array of chemicals, including those for which experimental data are scarce.

LSER Fundamentals and K_S Equation Coeients

The predictive power of the K_S equation stems from its detailed accounting of different intermolecular interaction modes. Each term in the equation quantifies a specific contribution to the overall solvation energy.

Table 1: Interpretation of Coefficients and Descriptors in the log K_S Equation

| Symbol | Name | Interpretation | Role in Solvation Energy |

|---|---|---|---|

| E | Excess Molar Refraction | Measures solute ability to interact with solvent via n- and π-electron pairs | ekE represents polarization interactions |

| S | Dipolarity/Polarizability | Measures solute ability to stabilize a neighboring charge or dipole | skS represents dipole-dipole and dipole-induced dipole interactions |

| A | Hydrogen-Bond Acidity | Measures solute ability to donate a hydrogen bond | akA represents the energy from solute-acid/solvent-base H-bonding |

| B | Hydrogen-Bond Basicity | Measures solute ability to accept a hydrogen bond | bkB represents the energy from solute-base/solvent-acid H-bonding |

| L | Gas-Hexadecane Partition Coefficient | Measures dispersion interactions and cavity formation energy | lkL represents the energy cost of forming a cavity in the solvent |

The system constants (ck, ek, sk, ak, bk, lk) describe the solvent's properties. A positive system constant indicates that the corresponding solute property increases the partition coefficient K_S, favoring solvation in the liquid phase. For instance, a large positive ak value for a solvent indicates that it is a strong hydrogen-bond base and will strongly solvate solutes with high hydrogen-bond acidity (A) [2].

Applications in Pharmaceutical and Environmental Sciences

The LSER model for K_S is indispensable in pharmaceutical development and environmental risk assessment, where predicting the partitioning behavior of organic compounds is critical.

Application Notes: K_S in Pharmaceutical Development

In the pharmaceutical and medical device industries, the Abraham model is widely applied in extractables and leachables (E&L) studies to ensure product safety [1]. Key applications include:

- Evaluation of Drug Product Simulating Solvents: K_S values and LSER models help select and validate solvents that simulate the chemical properties of a drug product for extraction studies, ensuring that laboratory tests accurately predict the leaching potential from container closure systems or medical devices [1].

- Prediction of Chromatographic Retention: LSER models can correlate and predict the retention behavior of E&L compounds in chromatographic systems. This application aids in the identification of unknown compounds, a major challenge in E&L profiling [1].

- Understanding Solvent Extraction Power: The model allows scientists to rationally select extraction solvents for polymeric materials used in medical devices and packaging by quantitatively understanding the specific interactions (dipolarity, hydrogen-bonding, etc.) that govern a solvent's extraction efficiency toward a target analyte [1].

Application Notes: K_S in Environmental Risk Assessment

Environmental risk assessment (ERA) for human pharmaceuticals is a growing regulatory focus worldwide. The LSER model, particularly through K_S and related partition coefficients, plays a vital role in this process.

- Predicting Environmental Fate and Transport: Partition coefficients are key parameters in mass transport models that predict the distribution and concentration of pharmaceutical residues in environmental compartments such as water, soil, and air [13]. For example, a robust LSER model has been established for the partition coefficient between low-density polyethylene (LDPE) and water, which is critical for assessing the sorption of contaminants to plastic materials in the environment [13].

- Regulatory Compliance: The revised "Guideline on the Environmental Risk Assessment of Medicinal Products for Human Use" mandates a comprehensive evaluation of a pharmaceutical's environmental impact [18]. LSER models provide a reliable, predictive tool to generate the necessary partitioning data, especially for compounds in the early stages of development where experimental data may be lacking. The ability of LSERs to predict partition coefficients for a "wide set of chemically diverse compounds" makes them exceptionally valuable for this purpose [13].

- Prioritization of Compounds: LSER-predicted K_S values can help prioritize which pharmaceuticals warrant more extensive and costly experimental testing based on their potential to persist, bioaccumulate, or partition into sensitive environmental compartments [18].

Experimental Protocols

This section provides a detailed methodology for determining the gas-to-organic solvent partition coefficient (K_S) and its subsequent use in developing and applying LSER models.

Protocol 1: Determination of log K_S via Headspace Gas Chromatography

Objective: To experimentally determine the gas-to-organic solvent partition coefficient (K_S) for a volatile solute using static headspace gas chromatography (HS-GC).

Principle: The concentration of a solute in the headspace gas above a solvent is measured at equilibrium. The partition coefficient is calculated from the relative concentrations in the gas and solvent phases.

Table 2: Key Research Reagent Solutions for K_S Determination

| Reagent/Material | Function | Critical Specifications |

|---|---|---|

| Organic Solvent | Partitioning phase | High purity (e.g., HPLC grade), low volatility, known water content |

| Analyte (Solute) | Compound whose K_S is being measured | High purity, volatile and stable under experimental conditions |

| Internal Standard | Reference for GC quantification | Chemically similar, non-interfering, and known partitioning behavior |

| Gas-Tight Syringes | Sampling headspace and liquid | Heated syringe to prevent condensation during transfer |

| Headspace Vials | Contain equilibrated system | Certified with precise volume, sealed with PTFE/silicone septa |

Procedure:

- Solution Preparation: Precisely prepare a stock solution of the analyte in the organic solvent. Introduce a known aliquot of this solution into a headspace vial, ensuring there is significant headspace. Seal the vial immediately with a crimp cap.

- Equilibration: Place the sealed vials in a thermostated HS-GC autosampler and allow them to equilibrate at a constant temperature (e.g., 25°C ± 0.1°C) with continuous agitation for a time sufficient to reach equilibrium (typically 30-60 minutes).

- Headspace Sampling & GC Analysis: Using a heated gas-tight syringe, extract a defined volume of the headspace vapor from the equilibrated vial and inject it into the gas chromatograph. Use an appropriate detector (e.g., FID).

- Calibration: Construct a calibration curve by analyzing headspace samples above standard solutions of the analyte with known concentrations.

- Data Analysis: Calculate the concentration of the analyte in the gas phase (Cgas) directly from the GC peak area and the calibration curve. The concentration in the solvent phase (Csolv) can be determined by mass balance from the initial amount added and the measured amount in the headspace. The partition coefficient is then calculated as KS = Csolv / Cgas. The logarithm of this value, log KS, is used in LSER analysis.

Protocol 2: Developing a Solvent-Specific LSER Model

Objective: To derive the system constants (ck, ek, sk, ak, bk, lk) for a specific organic solvent.

Principle: By measuring log K_S for a training set of solutes with known and diverse molecular descriptors (E, S, A, B, L), the system constants for the solvent can be determined via multiple linear regression.

Procedure:

- Solute Selection: Carefully select a training set of 30-50 solutes that collectively exhibit a wide range of E, S, A, B, and L values. The diversity is critical for a robust and meaningful model.

- Data Collection: For each solute in the training set, determine the log K_S value in the target solvent using Protocol 1 or obtain reliable data from literature. Obtain the solute's molecular descriptors (E, S, A, B, L, Vx) from a curated database, such as the UFZ-LSER database [4].

- Multiple Linear Regression: Input the matrix of solute descriptors (independent variables) and the experimental log K_S values (dependent variable) into a statistical software package capable of multiple linear regression.

- Model Validation: Validate the derived LSER equation by predicting log K_S for a separate validation set of solutes not included in the training set. Compare the predicted values against experimental results. A robust model is indicated by high R² values (>0.95) and low root mean square error (RMSE) [13].

Data Presentation and Analysis

The following tables present LSER model coefficients and predictive performance data to illustrate practical applications.

Table 3: Exemplary LSER System Constants for log K_S in Various Solvents

| Solvent | ck | ek | sk | ak | bk | lk | R² | n |

|---|---|---|---|---|---|---|---|---|

| n-Hexadecane | -0.23 | 0.00 | 0.00 | 0.00 | 0.00 | 1.00 | 0.999 | 150 |

| Diethyl Ether | -0.32 | 0.25 | 0.42 | 0.00 | 1.05 | 0.85 | 0.995 | 120 |

| Ethyl Acetate | -0.21 | 0.38 | 1.17 | 0.00 | 1.84 | 0.74 | 0.992 | 130 |

| Methanol | -0.17 | 0.41 | 0.60 | 3.68 | 1.89 | 0.52 | 0.987 | 140 |

Table 4: Benchmarking of an LSER Model for LDPE/Water Partitioning [13]

| Dataset | Number of Compounds (n) | Determination Coefficient (R²) | Root Mean Square Error (RMSE) | Notes |

|---|---|---|---|---|

| Training Set | 104 | 0.991 | 0.264 | Model development |

| Validation Set (Exp. Descriptors) | 52 | 0.985 | 0.352 | Independent model validation |

| Validation Set (Pred. Descriptors) | 52 | 0.984 | 0.511 | Real-world scenario for new chemicals |

The Scientist's Toolkit

Table 5: Essential Resources for LSER and K_S Research

| Tool / Resource | Description | Utility in K_S Research |

|---|---|---|

| UFZ-LSER Database | A freely accessible, curated database of LSER solute descriptors and calculation tools [4]. | Primary source for obtaining solute descriptors (E, S, A, B, L, Vx) needed for predictions. |

| Headspace GC System | Gas chromatograph equipped with a static headspace autosampler. | Core experimental apparatus for the accurate determination of gas-to-solvent partition coefficients (K_S). |

| Statistical Software | Package capable of multiple linear regression (e.g., R, Python with scikit-learn). | Essential for deriving system constants from experimental log K_S data and validating model performance. |

| QSPR Prediction Tools | In-silico tools for predicting LSER solute descriptors from chemical structure alone. | Enables K_S estimation for novel compounds for which experimental descriptors are not available [13]. |

| GLP-Certified Laboratory | Laboratory operating under Good Laboratory Practice standards. | Required for generating environmental risk assessment (ERA) data for regulatory submission to agencies like the EMA and FDA [18]. |

| Notrilobolide | Notrilobolide, MF:C26H36O10, MW:508.6 g/mol | Chemical Reagent |

| Bace1-IN-14 | Bace1-IN-14, MF:C26H20FN3O, MW:409.5 g/mol | Chemical Reagent |

The gas-to-organic solvent partition coefficient, KS, as formalized within the Abraham LSER model, is a parameter of profound significance. Its power lies in a rigorous thermodynamic foundation that decouples solute properties from solvent properties, enabling the accurate prediction of partitioning behavior for diverse compounds [2]. As demonstrated, the application of KS and LSER models is critical in pharmaceutical development, particularly for E&L studies and medical device characterization [1], and in environmental science for forecasting the fate and impact of pollutants and pharmaceuticals [18] [13]. The ongoing development of curated databases and predictive tools ensures that the LSER approach will remain a vital, evolving resource for researchers and regulators committed to product safety and environmental health.

From Theory to Practice: Determining Descriptors and Applying the LSER Model

Experimental Methods for Determining log L16 Using Gas Chromatography

Within the Linear Solvation Energy Relationship (LSER) model, the log L16 solute descriptor is a fundamental parameter, defined as the logarithm of the gas-hexadecane partition coefficient at 298 K [2] [19]. It quantifies a solute's capacity for dispersion interactions and the energy required for cavity formation within the solvent matrix, serving as a key characteristic in the Abraham solvation parameter model [20] [17]. Accurate determination of log L16 is crucial for predicting thermodynamic properties and molecular interactions in various chemical, biomedical, and environmental processes [2] [21]. This Application Note details validated chromatographic methods for the precise experimental measurement of log L16, providing essential protocols for researchers engaged in LSER-based studies of gas-to-organic solvent partition coefficients (KS).

Theoretical Background and Significance

The LSER model for characterizing solvent-solute interactions utilizes two primary equations for partitioning processes. For gas-to-solvent partitioning, the model is expressed as:

log (KS) = ck + ekE + skS + akA + bkB + lkL [2] [21]

In this equation, the capital letters (E, S, A, B, L) represent solute-specific molecular descriptors, while the lower-case letters are system-specific coefficients that reflect the complementary properties of the solvent phase. The L descriptor, and specifically log L16, characterizes the solute's partitioning into n-hexadecane, a solvent chosen for its ability to engage almost exclusively in non-specific, predominantly dispersive interactions [20] [19]. The determination of log L16 is therefore a critical first step in characterizing a solute's complete set of LSER descriptors, as it anchors the scale for dispersion interactions and cavity formation [17].

Research Reagent Solutions

The following table catalogues essential materials and their specific functions in the experimental determination of log L16.

Table 1: Key Research Reagents and Materials for log L16 Determination

| Material/Reagent | Function and Critical Specifications |

|---|---|

| n-Hexadecane Stationary Phase | Reference partitioning phase for defining log L16; high purity (>99%) is essential to minimize polar interactions [22] [17]. |

| Squalane Packed Columns | A surrogate non-polar stationary phase for log L16 determination; requires correction for interfacial adsorption at the liquid-solid interface [22] [23]. |

| Poly(methyloctylsiloxane) Columns | Immobilized open-tubular column phase; less cohesive with no hydrogen-bond basicity, suitable for a wider temperature range [22] [23]. |

| Apolane-87 (C87H176) Stationary Phase | A branched, high-molecular-weight alkane for studying high-boiling compounds; stable at temperatures up to 550 K [17]. |

| Inert Gas (Helium or Nitrogen) | Serves as the mobile phase (carrier gas) in GC systems; must be high-purity to avoid detector noise and baseline drift [24]. |

Methodologies and Experimental Protocols

Core Principles and Thermodynamic Basis

The chromatographic determination of log L16 is based on measuring the gas-liquid partition coefficient (KL). The retention factor (k) of a solute is directly related to KL and the phase ratio (Φ) of the column:

KL = k / Φ [17]

The log L16 value is then the logarithm of this partition coefficient determined specifically on an n-hexadecane stationary phase at 25°C. The process of solvation in gas-liquid chromatography is interpreted through a three-step cavity theory: (1) creation of a solute-sized cavity in the solvent (endoergic), (2) reorganization of solvent molecules, and (3) establishment of solute-solvent interactions (exoergic) [20] [17]. The retention factor is a direct measure of the overall Gibbs energy change for this solvation process.

Protocol 1: Determination on n-Hexadecane Packed Columns

This protocol outlines the direct measurement of log L16 using custom-packed GC columns.

- Column Preparation: Pack a stainless-steel or glass column (e.g., 1-2 m length) with an inert diatomaceous earth support coated with 15-20% (m/m) n-hexadecane stationary phase. A high phase loading is critical to minimize the contribution of interfacial adsorption on the support surface [22] [17].

- Instrument Calibration: Precisely determine the column void time (tM) using a non-retained compound (e.g., methane or air). Calculate the phase ratio (Φ) from the known volumes of the stationary (VS) and mobile (VM) phases [17].

- Retention Measurement: Inject the solute of interest and record its retention time (tR). The retention factor is calculated as k = (tR - tM) / tM. The partition coefficient is KL = k / Φ. The value of log L16 is log KL after correction to 25°C [17].

- Temperature Control and Adsorption Correction: Conduct measurements isothermally within the 80-120°C temperature range to optimize efficiency and reduce adsorption effects. For the most accurate results, the gas-liquid partition coefficient should be used as the model variable to correct for any residual temperature-dependent interfacial adsorption, allowing log L16 to be estimated to within ± 0.026 log units [22].

Protocol 2: Determination Using Poly(methyloctylsiloxane) Capillary Columns

This protocol utilizes a more robust, commercially available stationary phase as a surrogate system.

- Column Selection: Use a capillary column coated with an immobilized film of poly(methyloctylsiloxane). This phase is preferred over poly(dimethylsiloxane) due to its lower cohesion and lack of hydrogen-bond basicity, making it more suitable for log L16 determination [22] [23].

- Relative Retention Method: Since directly determining the exact mass of stationary phase in a capillary column is difficult, use a relative method. The partition coefficient for the solute at temperature T can be related to the known partition coefficient of a reference compound (e.g., n-hexane) at a specific temperature [17]. The relationship is derived from the linear correlation of partition coefficients at different temperatures for a given stationary phase.

- Data Interpretation: A single-column estimation of log L16 over the temperature range 60-140°C is possible with an error of ±0.05–0.09 log units. Note: This method requires prior knowledge of the solute's dipolarity/polarizability (S) descriptor to avoid significant errors for polar compounds [22].

Protocol 3: Determination for High-Boiling Compounds Using Temperature Gradients

For compounds less volatile than n-hexadecane, isothermal measurement at 25°C is impractical. Temperature Gradient Gas Chromatography (TGGC) offers a solution.

- System Setup: Utilize a GC system equipped for precise temperature programming. A column with a highly retentive non-polar phase like Apolane-87 is recommended for its thermal stability [19] [17].

- Linear Temperature-Programmed Retention Index (LTPRI): Within a homologous series, a linear relationship exists between the logarithm of the distribution coefficient (log K) and the LTPRI, which is calculated from retention times during a temperature ramp [19].

- Calibration and Prediction: Establish a calibration curve by measuring the LTPRI of compounds with known log L16 values. The log L16 for an unknown solute can then be predicted from its measured LTPRI using this calibration curve. This method also allows for the estimation of vapor pressures of high-boiling compounds [19].

The following workflow diagram illustrates the decision process for selecting the appropriate experimental protocol.

Data Analysis and Comparison of Methodologies

The following table summarizes the performance characteristics of the primary chromatographic methods for determining log L16, enabling researchers to select the most appropriate protocol for their needs.

Table 2: Comparison of Chromatographic Methods for log L16 Determination

| Method | Typical Stationary Phase | Temperature Range | Estimated Accuracy | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Direct Packed Column | n-Hexadecane (15-20% loading) | 80-120 °C | ± 0.026 log units [22] | Direct measurement; minimal model assumptions. | Requires custom-packed column; adsorption corrections needed. |

| Surrogate Capillary Column | Poly(methyloctylsiloxane) | 60-140 °C | ± 0.05 - 0.09 log units [22] | Uses robust commercial columns; wider temp range. | Requires solute's S descriptor for polar compounds [22]. |

| Temperature Gradient (TGGC) | Apolane-87 | Programmable | Varies with calibration [19] | Applicable to high-boiling, non-volatile compounds. | Indirect method; requires calibration with known compounds. |

The accurate experimental determination of the log L16 solute descriptor is a foundational activity in the application of the LSER model. The chromatographic protocols detailed herein—utilizing packed n-hexadecane columns, surrogate poly(methyloctylsiloxane) capillary columns, and temperature-gradient methods for high-boiling compounds—provide researchers with a robust toolkit. The selection of the optimal method depends on the volatility of the solute, available instrumentation, and the required precision. By carefully applying these protocols, scientists can generate high-quality log L16 data essential for reliable predictions of gas-to-organic solvent partition coefficients and other thermodynamic properties in drug development and environmental research.

Computational and Predictive Approaches for Non-Volatile Solute Descriptors

Within the framework of Linear Solvation Energy Relationship (LSER) research for gas-to-organic solvent partition coefficients (K~S~), a significant challenge arises when characterizing non-volatile solutes. For such compounds, direct experimental determination of solute descriptors, particularly the L descriptor (the logarithmic hexadecane/air partition coefficient at 298 K), is often impossible via conventional gas chromatography (GC) methods at standard temperatures [25] [17]. This application note details established and emerging computational and predictive methodologies designed to overcome this limitation, enabling the reliable estimation of a complete set of Abraham solute descriptors for non-volatile compounds essential for environmental fate and drug distribution modeling.

The LSER model for gas-to-organic solvent partitioning is described by the equation [2]: log (K~S~) = c~k~ + e~k~E + s~k~S + a~k~A + b~k~B + l~k~L Here, the capital letters (E, S, A, B, L) represent the solute's molecular descriptors, while the lowercase letters are system constants characteristic of the solvent phase. The inability to determine L for non-volatile solutes creates a critical gap in this predictive framework.

Computational & Predictive Methodologies

Two parallel, complementary strategies have been developed to address the descriptor gap for non-volatile solutes: one based on extrapolative experimental techniques and the other on quantum chemical computations.

Chromatographic Extrapolation and Predictive Modeling

For compounds that are slightly volatile or have low volatility, a practical experimental approach involves measuring retention factors at elevated temperatures where analysis is feasible, followed by extrapolation to the target temperature of 298 K [25] [17].

A key technique utilizes apolane (C~87~H~176~) as a stationary phase. This branched alkane is stable at high temperatures (up to 550 K), allowing for the measurement of gas-apolane partition coefficients (log L~87~) for heavy compounds [17]. A linear correlation between log L~87~ and the desired log L~16~ has been demonstrated, enabling the estimation of L descriptors for non-volatile solutes [17]. The workflow for this method is integrated into the protocol below.

For completely non-volatile compounds, predictive methods become necessary. Research indicates that log L~16~ can be estimated for siloxanes and other organosilicon compounds by leveraging established LSER models that predict various physicochemical properties (e.g., vapor pressure, aqueous solubility) from their descriptors [25]. This suggests that once a foundational set of descriptors is known for a compound class, predictive models can be generalized for other members.

Quantum Chemical (QM) Approaches

Quantum mechanical methods provide a fundamental, non-experimental path to obtaining solute descriptors and partition coefficients. These approaches calculate the solvation energy (ΔG~solv~) in different solvents of interest (e.g., hexadecane, water, octanol) from first principles [26].

The calculated ΔG~solv~ values are directly related to the partition coefficients required for descriptor determination or can be used to parameterize the LSER equations directly [26] [27]. A significant advantage of QM methods is their ability to model complex molecules, including modern drug molecules, which are often difficult to handle experimentally due to legal restrictions or complex molecular structures [26]. Studies have successfully calculated log K~OW~, log K~OA~, log K~AW~, and log K~HdA~ (L) for diverse drug molecules in this way [26].

Table 1: Comparison of Approaches for Non-Volatile Solute Descriptor Determination

| Methodology | Fundamental Principle | Key Advantage | Primary Limitation |

|---|---|---|---|

| Chromatographic Extrapolation | Measurement of retention factors at high temperature followed by extrapolation to 298 K [17]. | Based on empirical data, high precision for semi-volatile compounds. | Requires the compound to be sufficiently volatile at elevated temperatures. |

| Predictive LFER Modeling | Uses known descriptors from a compound class to predict descriptors for similar, non-volatile compounds [25]. | Bypasses experimentation entirely; useful for homologues. | Accuracy depends on the model and the similarity between the target and reference compounds. |

| Quantum Chemical Calculation | Computational calculation of solvation free energies in different phases to derive partition coefficients and descriptors [26]. | Universally applicable, no experimental hurdles; suitable for novel/regulated compounds. | Requires significant computational resources and expert knowledge. |

Experimental Protocol: Determination of log L~16~ for Semi-Volatile Compounds

This protocol describes the procedure for estimating the log L~16~ descriptor using a high-temperature apolane stationary phase, based on established chromatographic methods [25] [17].

Materials and Equipment

Table 2: Research Reagent Solutions and Essential Materials

| Item Name | Function/Application |

|---|---|

| Apolane-coated Capillary GC Column (C~87~H~176~ stationary phase) | High-temperature stationary phase for determining gas-apolane partition coefficients (log L~87~) [17]. |

| n-Hexane Standard | Reference compound for determining dead time and establishing relative retention [17]. |

| n-Hexadecane | Reference non-polar stationary phase; the definition of the L descriptor (log K~HdA~) [25] [17]. |

| GC-MS System | Equipped with an autosampler and temperature-programmable injector for precise retention time measurement [27]. |

Step-by-Step Procedure

- Column Preparation: Install a capillary GC column coated with apolane (C~87~H~176~). Ensure the column is conditioned according to the manufacturer's specifications.

- Dead Time (t~0~) Determination: Inject a small volume of air or methane and record the retention time of the argon peak (m/z 40) or the solvent front. This is the column dead time, t~0~ [27].

- n-Hexane Calibration: Inject n-hexane at the same high temperature (T') used for the solute analysis. Record its retention time (t~R,hex~) and calculate its partition coefficient on apolane at T' using established data or methods [17].

- Solute Analysis: Dissolve the target semi-volatile solute in a suitable volatile solvent (e.g., acetone). Inject the solution onto the apolane column at a temperature (T) high enough to produce a measurable retention time. Record the solute's retention time (t~R~).

- Retention Factor Calculation: For the solute and for n-hexane, calculate the retention factor, k, using the formula:

k = (t~R~ - t~0~) / t~0~[17] [27]. - Partition Coefficient Estimation: The gas-apolane partition coefficient for the solute at temperature T (log L~87,T~) can be found relative to n-hexane. A general relationship is used [17]:

log L~X,T~ = log k~X,T~ + log L~Ref,T'~ + log (V~M~/V~S~)where L~Ref,T'~ is the known partition coefficient of the reference compound (n-hexane) at a specific temperature. - Extrapolation to log L~16~: Utilize the established linear correlation between log L~87~ (determined at temperature T) and the target log L~16~ (at 298 K) to obtain the final L descriptor for the solute [17].

Diagram 1: Experimental workflow for determining the L descriptor for semi-volatile solutes using high-temperature gas chromatography.

Quantum Chemical Calculation Protocol

This protocol outlines the general steps for calculating the L descriptor and other solute parameters using quantum chemical methods, as applied in environmental and pharmaceutical research [26] [27].

- Software: Quantum chemical software packages (e.g., Gaussian, ORCA, COSMOlogic suite).

- Method: Density Functional Theory (DFT) with appropriate functionals (e.g., B3LYP) and basis sets (e.g., 6-311+G(d,p)).

- Solvation Model: A continuum solvation model such as COSMO-RS (Conductor-like Screening Model for Real Solvents) or SMD (Solvation Model based on Density).

Step-by-Step Procedure

- Geometry Optimization: Generate a 3D structure of the target molecule and perform a quantum chemical geometry optimization in the gas phase to find its most stable conformation.

- Frequency Calculation: Perform a frequency calculation on the optimized structure to confirm it is a true minimum (no imaginary frequencies) and to obtain thermodynamic corrections.

- Solvation Energy Calculations: Calculate the solvation free energy (ΔG~solv~) for the molecule in various phases:

- n-Hexadecane: ΔG~solv,hd~

- Air/Gas Phase: Effectively zero by definition.

- (Optional) Water and octanol for other descriptors.

- Partition Coefficient Calculation: The hexadecane/air partition coefficient (K~HdA~) is related to the solvation free energy:

log K~HdA~ (L) = -ΔG~solv,hd~ / (RT ln(10))where R is the gas constant and T is the temperature (298 K). - Descriptor Validation: Compare the predicted partition coefficients (e.g., log K~OW~) for which some experimental or QSAR data might exist to assess the plausibility of the QM results [26].

Table 3: Key Solute Descriptors and their Determination Methods

| Solute Descriptor | Molecular Property | Determination Method for Non-Volatiles |

|---|---|---|

| L | Gas–hexadecane partition coefficient | Calculation from ΔG~solv~ in n-hexadecane via QM methods [26] or extrapolation from high-T GC [17]. |

| V | McGowan's characteristic molar volume | Calculation by summation of atom volumes and bond contributions; trivial from structure [25]. |

| E | Excess molar refraction | Calculation from characteristic volume V and refractive index (experimental or estimated) [25]. |

| S | Dipolarity/Polarizability | Determined from GC on polar stationary phases or liquid-liquid partitions, often requiring inversion of LSER equations [25]. |

| A & B | Hydrogen-Bond Acidity/Basicity | Determined from liquid-liquid distribution in totally organic biphasic systems (e.g., n-hexane-acetonitrile) [25] or via QM-based methods. |

The accurate prediction of environmental transport and biological distribution of non-volatile compounds using LSER models depends critically on the availability of reliable solute descriptors. The methodologies outlined herein—chromatographic extrapolation and quantum chemical calculation—provide robust, complementary pathways for obtaining the essential L descriptor and other parameters that are inaccessible by standard experiments. The choice between these methods depends on the specific compound, available instrumentation, and computational resources. The integration of these computational and predictive approaches ensures the continued applicability and expansion of the LSER framework to complex, non-volatile organic compounds in environmental and pharmaceutical sciences.

Accessing and Utilizing the UFZ-LSER Database for System Coefficients

The UFZ-LSER database serves as a critical repository for solvation parameters and system coefficients essential for applying Linear Solvation Energy Relationships (LSERs). For research focused on predicting the gas-to-organic solvent partition coefficient (K_S), this database provides the experimentally derived system constants that quantify a solvent's capacity for various types of intermolecular interactions [2]. The Abraham LSER model, which underpins this database, describes K_S using the following general equation, where the capital letters represent solute-specific molecular descriptors and the lowercase letters represent the solvent-specific system coefficients obtainable from the database [2]:

log (K_S) = c_k + e_k*E + s_k*S + a_k*A + b_k*B + l_k*L

This equation allows researchers to predict partition coefficients for neutral compounds based on a set of six molecular descriptors characterizing their volume, polarity, and hydrogen-bonding capabilities [2] [28]. The UFZ-LSER database is freely accessible and represents a wealth of thermodynamic information validated through extensive experimental measurements, making it particularly valuable for drug development professionals seeking to understand compound solubilization and distribution [29] [30].

Accessing System Coefficients from the UFZ-LSER Database

Database Navigation and Interface

The UFZ-LSER database is hosted by the Helmholtz Centre for Environmental Research-UFZ and is accessible online. The interface provides multiple calculation modules, including those for biopartitioning, sorbed concentration, and extraction efficiencies [29]. For researchers investigating K_S, the core functionality lies in the database's ability to provide the system coefficients (c_k, e_k, s_k, a_k, b_k, l_k) for a wide range of organic solvents.