Greenness Assessment in HPTLC: A Comprehensive Comparison of NP-HPTLC vs. RP-HPTLC for Sustainable Pharmaceutical Analysis

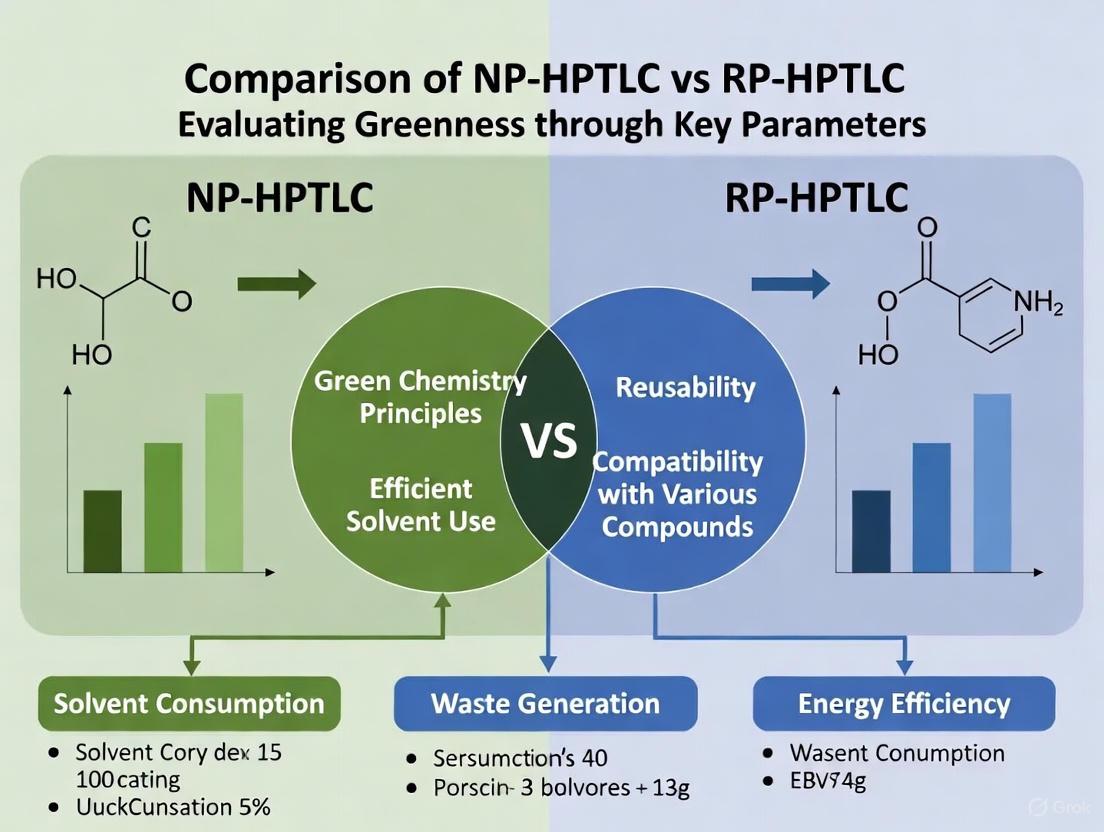

This article provides a systematic comparison of the greenness profiles of Normal-Phase (NP) and Reversed-Phase (RP) High-Performance Thin-Layer Chromatography (HPTLC) for pharmaceutical analysis.

Greenness Assessment in HPTLC: A Comprehensive Comparison of NP-HPTLC vs. RP-HPTLC for Sustainable Pharmaceutical Analysis

Abstract

This article provides a systematic comparison of the greenness profiles of Normal-Phase (NP) and Reversed-Phase (RP) High-Performance Thin-Layer Chromatography (HPTLC) for pharmaceutical analysis. Aimed at researchers, scientists, and drug development professionals, it explores the foundational principles of green analytical chemistry (GAC) as applied to HPTLC, details sustainable method development for both techniques, and offers practical troubleshooting guidance. By contrasting validation parameters and applying multiple greenness assessment tools (AGREE, NEMI, AES, ChlorTox), it demonstrates that RP-HPTLC often provides a superior eco-friendly profile without compromising analytical performance, offering a validated pathway for implementing more sustainable quality control and research practices.

Principles of Green HPTLC: Foundations for Sustainable Pharmaceutical Analysis

Core Principles of Green Analytical Chemistry (GAC) in HPTLC

Green Analytical Chemistry (GAC) represents a transformative approach to developing analytical methods that minimize environmental impact while maintaining analytical performance. The twelve principles of GAC provide a comprehensive framework for designing sustainable methodologies, focusing on reducing or eliminating hazardous substances, decreasing energy consumption, and preventing waste generation throughout the analytical process [1]. High-Performance Thin-Layer Chromatography (HPTLC) has emerged as a technique that aligns exceptionally well with these principles due to its inherently low solvent consumption, minimal sample preparation requirements, and capability for high-throughput analysis without generating significant waste [2].

The application of GAC principles in HPTLC has become increasingly important in pharmaceutical analysis and quality control, where traditional methods often employ large volumes of hazardous organic solvents. The greenness profile of HPTLC methods can be systematically evaluated using multiple metric tools, including the Analytical GREEnness (AGREE) approach, Analytical Eco-Scale (AES), National Environmental Methods Index (NEMI), Green Analytical Procedure Index (GAPI), and ChlorTox, which together provide a comprehensive assessment of a method's environmental impact [3] [4] [5]. These tools enable researchers to quantify and compare the greenness of different analytical approaches, driving the adoption of more sustainable practices in analytical laboratories.

Core GAC Principles and Their Implementation in HPTLC

Direct Application of GAC Principles in HPTLC Methodology

The core principles of Green Analytical Chemistry find direct and practical application in HPTLC methodologies, positioning this technique as a leader in sustainable analytical practice:

Reduced Solvent Consumption and Waste Generation: HPTLC typically requires only 5-15 mL of mobile phase per analysis, significantly less than HPLC methods which may consume hundreds of milliliters [2]. This substantial reduction in solvent usage directly supports the GAC principles of waste prevention and safer solvent selection. The minimal solvent volumes also translate to reduced waste disposal requirements and lower environmental impact [6].

Energy Efficiency: Unlike HPLC systems that often operate with high-pressure pumps and heated columns, HPTLC separation occurs at ambient temperature and pressure without requiring energy-intensive instrumentation during the development process [2]. This alignment with energy reduction principles makes HPTLC particularly suitable for laboratories aiming to decrease their carbon footprint.

Multi-sample Parallel Processing: A single HPTLC plate can simultaneously separate up to 20 samples or standards under identical conditions, dramatically increasing analytical throughput while reducing solvent consumption and analysis time per sample [7] [8]. This capability supports the GAC principles of enabling real-time analysis and minimizing the number of samples without compromising reliability.

Minimal Sample Preparation: HPTLC often requires less extensive sample cleanup compared to other chromatographic techniques, reducing the consumption of additional reagents and solvents [1]. Many pharmaceutical applications require only simple dissolution and filtration steps before analysis, supporting the GAC principle of avoiding unnecessary derivatization [9].

Greenness Assessment Tools for HPTLC Methods

The implementation of GAC principles in HPTLC can be quantitatively evaluated using several established metric systems:

Table 1: Greenness Assessment Tools for HPTLC Methods

| Assessment Tool | Key Evaluation Parameters | Scoring System | Application in HPTLC |

|---|---|---|---|

| AGREE | All 12 GAC principles | 0-1 scale (≥0.75 indicates excellent greenness) | Comprehensive evaluation of entire method [5] [10] |

| Analytical Eco-Scale | Penalty points for hazardous reagents, energy consumption, waste | >75 indicates excellent green method | Practical assessment of operational parameters [3] [9] |

| NEMI | Persistence, bioaccumulation, toxicity, hazardousness | Pictogram with four quadrants | Quick visual assessment of solvent hazards [4] [1] |

| GAPI | Multiple aspects from sample collection to final determination | Pictogram with five pentagrams | Detailed evaluation of method lifecycle [1] [7] |

| ChlorTox | Chlorinated solvent content and toxicity | Quantitative score (lower is better) | Specific assessment of chlorinated solvent impact [3] [9] |

The AGREE metric system has gained particular prominence in recent HPTLC research due to its comprehensive approach that incorporates all twelve GAC principles and provides an easily interpretable pictogram output [5] [10]. This tool allows researchers to identify specific areas for improvement in their method development process and objectively compare the environmental performance of different analytical approaches.

Experimental Comparison of NP-HPTLC vs. RP-HPTLC Greenness

Methodology for Greenness Comparison

Direct comparative studies between Normal-Phase (NP) and Reversed-Phase (RP) HPTLC methodologies provide valuable experimental data for assessing their relative greenness profiles. In these studies, researchers typically develop both NP and RP methods for the same analyte and systematically compare their performance using validation parameters and greenness metrics [3] [5] [10].

For NP-HPTLC methods, the stationary phase typically consists of silica gel 60 F254s plates, while mobile phases often incorporate mixtures such as chloroform-methanol or ethyl acetate-methanol in varying proportions [3] [5]. In contrast, RP-HPTLC methods employ RP-18F254s plates with mobile phases containing ethanol-water or acetone-water combinations [3] [9]. The methodological development process involves optimizing mobile phase compositions to achieve satisfactory separation while simultaneously maximizing the use of greener solvents.

The validation protocols for these comparative studies follow ICH Q2(R1) guidelines, assessing parameters including linearity range, accuracy, precision, robustness, and sensitivity (LOD and LOQ) for both NP and RP approaches [3] [5] [10]. Following method validation, the greenness profiles are evaluated using multiple assessment tools, with particular emphasis on AGREE scoring due to its comprehensive nature.

Comparative Experimental Data

Recent comparative studies provide quantitative data demonstrating the greenness differences between NP-HPTLC and RP-HPTLC approaches:

Table 2: Experimental Comparison of NP-HPTLC vs. RP-HPTLC Greenness Profiles

| Analyte | NP-HPTLC Mobile Phase | RP-HPTLC Mobile Phase | NP-HPTLC AGREE Score | RP-HPTLC AGREE Score | Reference |

|---|---|---|---|---|---|

| Ertugliflozin | Chloroform-methanol (85:15, v/v) | Ethanol-water (80:20, v/v) | 0.74 | 0.86 | [3] |

| Flibanserin | Ethyl acetate-methanol (95:5, v/v) | Acetone-water (80:20, v/v) | 0.80 | 0.86 | [5] |

| Dasatinib | Methanol:n-butylacetate:glacial acetic acid (50:50:0.2, v/v/v) | 2-propanol:water:glacial acetic acid (60:40:0.2, v/v/v) | 0.88 | 0.90 | [10] |

The experimental data consistently demonstrates that RP-HPTLC methods achieve higher AGREE scores compared to their NP-HPTLC counterparts, indicating superior alignment with GAC principles. This advantage primarily stems from the replacement of hazardous solvents like chloroform and ethyl acetate with greener alternatives such as ethanol and water in RP-HPTLC mobile phases [3] [5].

Beyond greenness metrics, RP-HPTLC methods frequently demonstrate superior analytical performance characteristics, including wider linear ranges, enhanced sensitivity, and better peak symmetry [3]. For instance, in the analysis of ertugliflozin, the RP-HPTLC method showed linearity in the 25-1200 ng/band range compared to 50-600 ng/band for the NP-HPTLC approach, while also providing greater accuracy (99.28% vs. 87.41% recovery) [3].

The following diagram illustrates the logical relationship between GAC principles, HPTLC advantages, and the resulting greenness outcomes:

GAC-HPTLC Implementation Pathway

Detailed Experimental Protocols

Protocol for Green RP-HPTLC Method Development

The development of a green RP-HPTLC method follows a systematic approach focused on maximizing environmental friendliness while maintaining analytical performance:

Instrumentation and Materials: The analysis is performed using a CAMAG HPTLC system comprising an Automatic TLC Sampler 4 (ATS4) sample applicator, automated developing chamber 2 (ADC2), and TLC scanner 3 with WinCATS software [9] [6]. The stationary phase consists of pre-coated RP-18F254S HPTLC plates with particle size of 5μm. Green solvents include ethanol, acetone, isopropanol, and water classified as environmentally preferable [5] [10] [6].

Mobile Phase Optimization: Initial screening involves testing various proportions of ethanol-water and acetone-water combinations (e.g., from 40:60 to 90:10 v/v) to identify the optimal separation efficiency [3] [5]. The selection criterion prioritizes mobile phases with >50% water content when possible to enhance greenness [3]. Chamber saturation time is optimized between 10-30 minutes at ambient temperature (20-25°C) to ensure reproducibility [9] [6].

Sample Application: Standard and sample solutions are applied as 6-mm bands using an automatic applicator with application rate set at 150 nL/s [9] [6]. The distance from the bottom edge is maintained at 10 mm with 10 mm between bands to prevent edge effects and cross-contamination [8].

Chromatographic Development: Plates are developed in the ascending mode to a distance of 70-80 mm using the optimized green mobile phase [9] [6]. Development time typically ranges from 10-20 minutes depending on the mobile phase viscosity and analyte characteristics.

Detection and Quantification: After development, plates are dried at room temperature and scanned at the appropriate wavelength (typically 200-300 nm for UV-absorbing compounds) using a deuterium lamp [3] [9]. Densitometric analysis is performed in reflectance-absorbance mode with slit dimensions of 4-6 × 0.45 mm and scanning speed of 20 mm/s [9] [8].

Greenness Assessment Protocol

Following method development and validation, the greenness profile is systematically evaluated using multiple assessment tools:

AGREE Assessment: Using the AGREE calculator software, all 12 GAC principles are scored based on the method parameters [5] [10]. Input parameters include information about sample preparation, reagent toxicity, energy consumption, waste generation, and operator safety. The software generates a pictogram with an overall score between 0-1, where scores >0.75 indicate excellent greenness [5].

Analytical Eco-Scale Calculation: Penalty points are assigned for each aspect deviating from ideal green conditions: hazardous reagents (1-5 points), energy consumption >1.5 kWh/sample (1 point), waste generation per sample (1-3 points), and occupational hazards (1-3 points) [3] [9]. The Eco-Scale score is calculated by subtracting total penalty points from 100, with scores >75 representing excellent green methods [9].

NEMI and GAPI Pictograms: These qualitative assessments evaluate whether the method avoids persistent, bioaccumulative, and toxic chemicals and whether it generates hazardous waste [4] [1]. The pictograms provide a quick visual representation of the method's environmental performance across its entire lifecycle.

Essential Research Reagent Solutions for Green HPTLC

The implementation of GAC principles in HPTLC requires careful selection of reagents and materials to minimize environmental impact while maintaining analytical performance:

Table 3: Essential Research Reagents for Green HPTLC

| Reagent/Material | Function in HPTLC | Green Characteristics | Application Examples |

|---|---|---|---|

| Water | Mobile phase component in RP-HPTLC | Non-toxic, renewable, biodegradable | Ethanol-water mixtures [3] [6] |

| Ethanol | Mobile phase component | Renewable, low toxicity, biodegradable | Ethanol-water mobile phases [3] [6] |

| Acetone | Mobile phase component | Low toxicity, readily biodegradable | Acetone-water mixtures [5] |

| Isopropanol | Mobile phase component | Lower toxicity than acetonitrile or methanol | Isopropanol-water-acetic acid [10] |

| n-Butyl acetate | Mobile phase component in NP-HPTLC | Greener alternative to chlorinated solvents | Methanol:n-butyl acetate:acetic acid [10] |

| RP-18F254S Plates | Stationary phase for RP-HPTLC | Enables use of aqueous mobile phases | Analysis of pharmaceuticals [3] [9] |

| Silica Gel 60 F254 Plates | Stationary phase for NP-HPTLC | Standard normal-phase separation | For less polar compounds [5] [7] |

| Ammonia Solution | Mobile phase modifier | Volatile, minimal residual waste | Methanol-ethyl acetate-ammonia [1] [8] |

The strategic selection of reagents directly impacts the greenness profile of HPTLC methods. Replacement of traditional hazardous solvents like chloroform, hexane, and chlorinated solvents with greener alternatives such as ethanol, acetone, and ethyl acetate significantly improves AGREE scores and reduces environmental impact [3] [5]. Similarly, the use of water as a major component in RP-HPTLC mobile phases enhances method greenness while reducing costs [3] [6].

The integration of Green Analytical Chemistry principles into HPTLC methodologies represents a significant advancement in sustainable pharmaceutical analysis. Experimental evidence consistently demonstrates that RP-HPTLC methods generally outperform NP-HPTLC approaches in terms of greenness metrics while maintaining or enhancing analytical performance. The systematic application of assessment tools like AGREE, Analytical Eco-Scale, and GAPI provides objective data to guide researchers in developing environmentally responsible analytical methods.

The movement toward greener HPTLC methodologies aligns with broader sustainability initiatives in the pharmaceutical industry, offering practical solutions for reducing the environmental footprint of quality control and research laboratories. By adopting the principles and protocols outlined in this guide, researchers can contribute to the advancement of sustainable analytical chemistry while maintaining the high standards of accuracy, precision, and reliability required in pharmaceutical analysis.

High-Performance Thin-Layer Chromatography (HPTLC) has emerged as a sophisticated, flexible, and environmentally considerate analytical technique, particularly valuable for pharmaceutical analysis and natural product characterization. Its advantages include minimal solvent consumption, reduced sample preparation, and the ability to analyze multiple samples in parallel, significantly increasing throughput and reducing solvent waste per sample compared to sequential techniques like HPLC [11]. Within this field, a critical distinction exists between Normal-Phase (NP-HPTLC) and Reversed-Phase (RP-HPTLC) methods, primarily defined by the nature of their stationary phases and the consequent mechanisms of separation.

The drive towards Green Analytical Chemistry (GAC) has further intensified the comparison between these techniques. The core principle of GAC is to redesign analytical methods to minimize their environmental impact, which involves reducing or eliminating hazardous solvent use, lowering energy consumption, and preventing waste generation [10] [12]. This review objectively compares NP-HPTLC and RP-HPTLC within the context of sustainability, examining their fundamental mechanisms, performance metrics, and ecological footprints based on contemporary research data.

Fundamental Separation Mechanisms and Stationary Phase Ecology

The primary difference between NP and RP-HPTLC lies in the polarity of their stationary phases, which dictates the mechanism of interaction with analytes.

NP-HPTLC Mechanism: This method employs a polar stationary phase, typically unmodified silica gel with silanol groups (Si–OH). Separation occurs based on the adsorption of analytes onto this active solid surface. The mobile phase is a non-polar or moderately polar organic solvent. Analytes interact with the stationary phase through hydrogen bonding, dipole-dipole interactions, and ionic interactions. In this mode, the more polar a compound is, the more strongly it adsorbs to the stationary phase, resulting in a lower retardation factor (Rf) value [13].

RP-HPTLC Mechanism: This method uses a non-polar stationary phase, created by chemically bonding hydrophobic ligands like C18 (octadecylsilane) or C8 chains to the silica backbone. Separation is governed by partitioning of the analytes between the polar mobile phase (e.g., water-ethanol mixtures) and the hydrophobic stationary phase. The dominant molecular interaction is hydrophobic. Consequently, more hydrophobic (non-polar) compounds have a stronger affinity for the stationary phase and exhibit higher retention (lower Rf), while polar compounds elute faster [14].

The following diagram illustrates the fundamental ecological and mechanistic differences between these two techniques.

Experimental Protocols and Performance Comparison

The development of both NP- and RP-HPTLC methods requires systematic optimization of the mobile phase to achieve robust and valid separation. The following experimental data and protocols, drawn from recent studies, highlight the practical differences in their application and performance.

Experimental Protocols for Method Development

A standard protocol common to both techniques involves several key steps [3] [15]:

- Sample Application: Standard and sample solutions are spotted as narrow bands (e.g., 6 mm) onto the HPTLC plate (NP or RP) using an automatic applicator.

- Chromatogram Development: The spotted plate is developed in a saturated chamber with the optimized mobile phase until the solvent front migrates a fixed distance (e.g., 80 mm).

- Densitometric Detection: After development and drying, the plate is scanned with a densitometer at a specific wavelength optimal for the target analyte(s).

- Data Analysis: Peak areas and Rf values are recorded for the construction of calibration curves and calculation of validation parameters.

Mobile Phase Optimization: This is the most critical step where NP and RP diverge.

- For NP-HPTLC, different combinations of non-polar and polar organic solvents (e.g., chloroform/methanol, cyclohexane/ethyl acetate) are tested in varying proportions [3] [16].

- For RP-HPTLC, binary mixtures of water with green organic solvents like ethanol or isopropanol are typically optimized [3] [15].

Table 1: Exemplary Mobile Phase Compositions from Published Studies

| Analyte(s) | NP-HPTLC Mobile Phase | RP-HPTLC Mobile Phase | Citation |

|---|---|---|---|

| Thymoquinone | Cyclohexane-Ethyl Acetate (90:10, v/v) | Ethanol-Water (80:20, v/v) | [16] |

| Ertugliflozin | Chloroform-Methanol (85:15, v/v) | Ethanol-Water (80:20, v/v) | [3] |

| Dasatinib | Methanol:n-butylacetate:Acetic Acid (50:50:0.2, v/v/v) | 2-propanol:water:Acetic Acid (60:40:0.2, v/v/v) | [10] |

| Antiviral Drugs (RMD, FAV, MOL) | Ethyl acetate:ethanol:water (9.4:0.4:0.25, v/v) | Ethanol-Water (6:4, v/v) | [17] |

Comparative Performance and Validation Data

When developed and validated according to International Council for Harmonisation (ICH) guidelines, both methods demonstrate high accuracy, precision, and linearity. However, direct comparisons often reveal performance differences.

Table 2: Contrast of Validation Parameters for NP-HPTLC and RP-HPTLC from Comparative Studies

| Validation Parameter | NP-HPTLC Performance (Ertugliflozin) | RP-HPTLC Performance (Ertugliflozin) | NP-HPTLC Performance (Thymoquinone) | RP-HPTLC Performance (Thymoquinone) |

|---|---|---|---|---|

| Linear Range | 50–600 ng/band | 25–1200 ng/band | 25–1000 ng/band | 50–600 ng/band |

| Theoretical Plates/m (N/m) | ~4472 | ~4652 | Data not specified | Data not specified |

| Tailing Factor (As) | ~1.06 | ~1.08 | Data not specified | Data not specified |

| Sensitivity (LOD/LOQ) | Less sensitive compared to RP | More sensitive (wider linear range) | More sensitive (lower linear range) | Less sensitive compared to NP |

| Reference | [3] | [3] | [16] | [16] |

As evidenced by the ertugliflozin study, the RP-HPTLC method showed a wider linear range and superior sensitivity. The authors concluded that the RP-HPTLC method was "more robust, accurate, precise, linear, sensitive, and eco-friendly" [3]. Conversely, for thymoquinone, NP-HPTLC demonstrated a lower detection range, indicating higher sensitivity for that specific compound in its optimized normal-phase system [16].

Greenness Assessment and Sustainability Profile

The ecological impact of an analytical method, often referred to as its "greenness," has become a critical metric for evaluation. Modern assessment tools like the Analytical GREEnness (AGREE) calculator use the 12 principles of Green Analytical Chemistry to provide a comprehensive score from 0 to 1, where a higher score indicates a greener method [16] [10].

The core ecological difference between NP and RP methods stems from mobile phase selection. RP-HPTLC has a distinct advantage due to its compatibility with water and ethanol—solvents classified as green and benign [15]. In contrast, NP-HPTLC often relies on more hazardous and volatile organic solvents like chloroform, hexane, and ethyl acetate, which pose greater environmental and safety risks [3] [17].

Table 3: Comparative Greenness Assessment Using AGREE and Other Metrics

| Study & Method | AGREE Score | Key Greenness Observations | Citation |

|---|---|---|---|

| Thymoquinone (NP) | 0.82 | Uses cyclohexane-ethyl acetate; excellent score but lower than RP. | [16] |

| Thymoquinone (RP) | 0.84 | Uses ethanol-water; excellent score, marginally greener than NP. | [16] |

| Ertugliflozin (NP) | Not Specified | Uses chloroform-methanol; described as less eco-friendly. | [3] |

| Ertugliflozin (RP) | Not Specified | Uses ethanol-water; four greenness tools confirmed it as greener. | [3] |

| Dasatinib (NP) | 0.88 | Uses methanol/n-butylacetate; high greenness score. | [10] |

| Dasatinib (RP) | 0.90 | Uses 2-propanol/water; extremely green profile. | [10] |

The data shows a consistent trend: RP-HPTLC methods typically achieve higher AGREE scores than their NP counterparts when the NP method employs traditional organic solvents. However, as seen in the dasatinib and thymoquinone studies, NP methods can still achieve "excellent" greenness scores (AGREE > 0.8) if the mobile phase is carefully chosen from less hazardous, greener organic solvents [16] [10].

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of green NP- and RP-HPTLC methods requires specific materials. The following toolkit details essential items and their functions.

Table 4: Essential Research Reagent Solutions for Green HPTLC

| Item | Function/Description | Application in NP-HPTLC | Application in RP-HPTLC |

|---|---|---|---|

| HPTLC Plates (Silica gel 60) | The polar stationary phase for adsorption chromatography. | Essential. Standard base material. | Not used in its unmodified form. |

| HPTLC Plates (RP-18, e.g., F254S) | The non-polar stationary phase for partition chromatography. | Not used. | Essential. Base material chemically modified with C18 chains. |

| Ethanol | A green, renewable, and less toxic solvent. | Used as a modifier in mobile phases. | Primary mobile phase component, often mixed with water. |

| Water (HPLC grade) | A non-toxic, green solvent. | Used in small amounts as a modifier. | Primary mobile phase component, often mixed with ethanol. |

| Ethyl Acetate | A solvent with a better eco-toxicological profile than others. | Common component of greener NP mobile phases [16] [17]. | Rarely used. |

| Automatic Developing Chamber | Ensures reproducible, saturated development conditions. | Used for both NP and RP method development. | Used for both NP and RP method development. |

| Densitometer (Scanner) | Quantifies the analyte bands by UV/Vis absorbance. | Used for detection and quantification post-development. | Used for detection and quantification post-development. |

| Ergothioneine-d9 | Ergothioneine-d9, MF:C9H15N3O2S, MW:238.36 g/mol | Chemical Reagent | Bench Chemicals |

| Chitin synthase inhibitor 5 | Chitin Synthase Inhibitor 5|For Research Use | Chitin Synthase Inhibitor 5 is a high-purity compound for antifungal research. It targets chitin biosynthesis. For Research Use Only. Not for human consumption. | Bench Chemicals |

The choice between NP-HPTLC and RP-HPTLC is multifaceted, involving a trade-off between analytical objectives, chemical nature of the analytes, and environmental considerations.

- NP-HPTLC remains a powerful technique for separating polar compounds and is highly effective when methods are optimized with greener organic solvents. Its historical reliance on hazardous solvents is being successfully challenged, as evidenced by high AGREE scores for modern methods.

- RP-HPTLC holds a inherent advantage for green analytical chemistry due to its compatibility with ethanol-water mobile phases. It frequently demonstrates superior sensitivity, wider linearity, and a lower ecological footprint, making it increasingly the first choice for developing new, sustainable methods.

The overarching trend in analytical science is a concerted shift towards sustainability. The comparative assessment using AGREE metrics provides a clear, data-driven framework for this transition. While both techniques have a permanent place in the analytical arsenal, the future undoubtedly leans towards the adoption and further refinement of reversed-phase systems that utilize green solvents, effectively balancing the demands of analytical performance with responsibility towards environmental safety.

The paradigm of analytical chemistry is undergoing a fundamental transformation, driven by the urgent need for sustainable practices that align with the principles of Green Analytical Chemistry (GAC). Within high-performance thin-layer chromatography (HPTLC), this shift necessitates a critical reevaluation of mobile phase selection, particularly when comparing normal-phase (NP) and reversed-phase (RP) techniques [12]. Traditional NP-HPTLC methods frequently rely on hazardous organic solvents derived from non-renewable petroleum sources, posing significant ecological and occupational health risks [12] [18]. In contrast, RP-HPTLC offers a more versatile platform for incorporating green alternative solvents, notably ethanol and water, which are biodegradable, less toxic, and can be sourced renewably [3] [19]. This guide provides an objective, data-driven comparison of the greenness profiles of NP- and RP-HPTLC methods, equipping scientists with the experimental evidence and validated metrics needed to make informed, sustainable choices in chromatographic method development for drug analysis and quality control.

Greenness Assessment Metrics for Analytical Methods

Evaluating the environmental impact of an analytical method requires robust, multi-faceted metrics. Several standardized tools have been developed to quantitatively assess and compare the greenness of analytical procedures. Table 1 summarizes the most prominent greenness assessment tools used in modern HPTLC research.

Table 1: Key Greenness and Sustainability Assessment Metrics for Analytical Methods

| Metric Name | Acronym | What It Assesses | Output Format | Interpretation |

|---|---|---|---|---|

| Analytical GREEnness [20] | AGREE | All 12 principles of Green Analytical Chemistry | Radial diagram with a score 0-1 | Closer to 1.0 indicates excellent greenness |

| Analytical Eco-Scale [3] | AES | Toxicity of reagents, energy consumption, waste generation | Total score (100 = ideal) | Higher score indicates a greener method |

| National Environmental Method Index [3] | NEMI | Persistence, toxicity, corrosiveness of chemicals | Pictogram with 4 quadrants | All green quadrants indicate a greener method |

| Green Analytical Procedure Index [20] | GAPI | Entire analytical workflow from sampling to disposal | Color-coded pictogram | More green colors indicate a greener method |

| Blue Applicability Grade Index [17] | BAGI | Practicality and applicability in routine labs | Score and "asteroid" pictogram | Higher score indicates better practicality |

Beyond the "green" pillar, the emerging concept of White Analytical Chemistry (WAC) seeks to balance the three critical pillars of analytical performance (Red), ecological impact (Green), and practical applicability (Blue). A "white" method harmoniously balances all three dimensions [17].

Comparative Analysis: NP-HPTLC vs. RP-HPTLC Greenness Profiles

Direct comparative studies provide compelling evidence for the superior greenness of RP-HPTLC methods that utilize ethanol-water mobile phases over traditional NP-HPTLC systems. The data below is drawn from validated methods for pharmaceutical analysis.

Table 2: Quantitative Greenness Comparison of NP-HPTLC and RP-HPTLC Methods for Pharmaceutical Analysis

| Analyte (Source) | HPTLC Mode (Mobile Phase) | Key Greenness Metric Scores | Inference |

|---|---|---|---|

| Ertugliflozin [3] | NP: Chloroform/Methanol (85:15 v/v) | Scores not provided, but method deemed less green | The NP strategy was less green than the RP strategy. |

| RP: Ethanol-Water (80:20 v/v) | Scores not provided, but method deemed more green | The RP strategy was greener than the NP strategy. | |

| Lemborexant [21] | NP: Acetone-Petroleum Ether (40:60 v/v) | AGREE: Lower than RP; NEMI: Not all green | NP strategy was less green. |

| RP: Ethanol-Water (85:15 v/v) | AGREE: 0.89; NEMI: All four circles green; AES: 93 | RP strategy was greener and more sustainable. | |

| Caffeine [19] | RP: Ethanol-Water (55:45 v/v) | AGREE: 0.80 | The method has an "excellent greener profile." |

| Three Antivirals [17] | NP: Ethyl acetate/Ethanol/Water | Not directly comparable to RP in same study | The RP method was superior in greenness. |

| RP: Ethanol-Water (60:40 v/v) | Superior greenness, blueness, and whiteness | The RP method was superior in greenness. |

Experimental Protocol for Greenness Comparison

The following workflow, derived from the cited studies, outlines a standardized approach for developing and directly comparing NP and RP methods.

Interpretation of Comparative Data

The data in Table 2 demonstrates a consistent trend. RP-HPTLC methods employing ethanol-water mobile phases achieve significantly higher scores across multiple greenness metrics [3] [21] [19]. For instance, the AGREE score of 0.89 for the RP-HPTLC method for Lemborexant indicates strong alignment with all 12 principles of GAC [21]. Similarly, an Analytical Eco-Scale score of 93 (out of 100) confirms a method with minimal environmental impact, as a score above 75 is considered excellent [21].

The fundamental advantage of RP-HPTLC lies in its compatibility with ethanol-water mixtures. Ethanol is classified as a green solvent due to its low toxicity, ready biodegradability, and renewable origin from plant biomass [18] [19]. In contrast, typical NP-HPTLC solvents like chloroform, petroleum ether, and hexane are problematic due to their high volatility, toxicity, persistence in the environment, and derivation from non-renewable fossil fuels [12] [18]. Replacing these with greener NP solvents like ethyl acetate or bio-based terpenes (e.g., limonene) is an area of active research but is not yet as straightforward as using ethanol-water in RP mode [18].

Essential Research Reagents and Materials

The transition to greener HPTLC requires specific materials and reagents. The following toolkit is essential for developing and validating sustainable methods.

Table 3: Scientist's Toolkit for Green HPTLC Method Development

| Item Category | Specific Examples & Specifications | Green Function & Rationale |

|---|---|---|

| Green Solvents | Ethanol (Bio-based) [19], Water [19], Ethyl Acetate [17] | Low toxicity, biodegradable, renewable sourcing. Replace hazardous solvents like chloroform and n-hexane. |

| HPTLC Plates | Silica gel 60 RP-18 F254S [19] | Enable the use of aqueous-organic (e.g., ethanol-water) mobile phases. |

| Standard HPTLC Instrumentation | CAMAG system: ATS4 sample applicator, ADC2 development chamber, TLC Scanner 3 with WinCATS software [19] | Ensures precise, automated, and reproducible application, development, and detection, minimizing errors and solvent waste. |

| Greenness Assessment Software | AGREE Calculator [20], BAGI Calculator [17] | Provides objective, quantitative scoring of a method's environmental impact and practicality. |

The empirical evidence from recent comparative studies unequivocally demonstrates that RP-HPTLC methods utilizing ethanol-water mobile phases offer a superior greenness profile compared to traditional NP-HPTLC methods that rely on classical, hazardous organic solvents. The consistentl high scores achieved by RP methods across multiple validated greenness metrics (AGREE, AES, NEMI) provide a compelling, data-backed rationale for this choice [3] [21] [19].

The future of sustainable HPTLC lies in the widespread adoption of the White Analytical Chemistry framework, which balances the greenness of a method with its analytical performance (red) and practical applicability (blue) [17]. For researchers and drug development professionals, the path forward is clear: prioritize RP-HPTLC with green solvents like ethanol-water during initial method development. This strategy not only minimizes ecological impact and ensures a safer working environment but also leads to robust, cost-effective, and regulatory-compliant analytical procedures suitable for the modern, sustainability-focused laboratory.

The growing emphasis on environmental sustainability has made Green Analytical Chemistry (GAC) a critical discipline, focusing on minimizing the environmental footprint of analytical methods while maintaining their efficacy [22]. Greenness assessment metrics provide a standardized approach to evaluate and compare the environmental impact of analytical procedures, helping researchers and pharmaceutical professionals make informed, sustainable choices [23]. This guide focuses on four key metrics—AGREE, NEMI, AES, and ChlorTox—providing a objective comparison of their applications, particularly within the context of comparing Normal-Phase and Reversed-Phase High-Performance Thin-Layer Chromatography (NP-HPTLC and RP-HPTLC).

The evolution of these metrics reflects a shift from basic to comprehensive evaluations. Foundational tools like NEMI offered simple, binary assessments, while newer metrics like AGREE provide a more holistic, quantitative evaluation based on all 12 principles of GAC [22] [24]. Proper application of these tools is governed by a Good Evaluation Practice (GEP), which recommends using quantitative, empirical data and combining multiple metrics with different structures to ensure a comprehensive and reliable picture [25].

Understanding the Four Key Greenness Metrics

Analytical GREEnness (AGREE) Metric

AGREE is a comprehensive assessment tool that evaluates analytical methods against all 12 principles of GAC [22]. It provides a final score between 0 and 1, where higher scores indicate superior greenness, accompanied by an intuitive circular pictogram [24] [3]. This output offers a quick visual summary of a method's environmental performance across multiple criteria. A major strength of AGREE is its balanced perspective, considering factors like energy consumption, waste generation, and operator safety alongside traditional solvent toxicity concerns [24]. Scores exceeding 0.75 generally indicate greener analytical techniques [10].

National Environmental Methods Index (NEMI)

As one of the first greenness assessment tools, NEMI uses a simple pictogram with four quadrants indicating whether a method meets basic criteria: whether chemicals used are persistent, bioaccumulative, or toxic (PBT); whether waste is generated; whether chemicals are corrosive; and whether hazardous reagents are used [22] [24]. Its binary (yes/no) assessment approach is easy to interpret but lacks granularity. The primary limitation of NEMI is its inability to distinguish degrees of greenness, as it does not provide a quantitative score and offers limited insight into the full analytical workflow [24].

Analytical Eco-Scale (AES)

The Analytical Eco-Scale offers a semi-quantitative approach by assigning penalty points to non-green aspects of an analytical method [3]. The calculation begins with a base score of 100, from which penalties are subtracted for hazardous reagent use, high energy consumption, and other environmental concerns [24]. The final score facilitates direct comparison between methods, with higher scores indicating greener procedures. While more detailed than NEMI, AES still relies on expert judgment in assigning penalty points and lacks a visual component, which can limit its accessibility for some users [24].

ChlorTox Scale

The ChlorTox Scale provides a specialized assessment focused specifically on chlorinated solvent toxicity [3]. This metric addresses the significant environmental and health concerns associated with chlorinated solvents, which are commonly used in analytical chemistry despite their hazards. Unlike broader metrics, ChlorTox offers targeted evaluation of this particular aspect of method greenness, helping researchers identify and mitigate specific risks. Its focused nature means it should be used alongside other metrics for a complete environmental assessment [3].

Table 1: Comparison of Key Characteristics of Greenness Assessment Metrics

| Metric | Assessment Approach | Output Format | Key Parameters Evaluated | Primary Advantage |

|---|---|---|---|---|

| AGREE | Comprehensive, quantitative | Score (0-1) + Pictogram | All 12 GAC Principles | Most holistic assessment; combines score with visual output |

| NEMI | Binary, qualitative | Pictogram (4 quadrants) | PBT, Waste, Corrosiveness, Hazard | Simple, quick visual assessment |

| AES | Semi-quantitative | Numerical Score (0-100) | Reagents, Energy, Waste | Direct numerical comparison between methods |

| ChlorTox | Specialized, focused | Specific Risk Assessment | Chlorinated Solvent Toxicity | Targeted evaluation of high-risk solvents |

Application in NP-HPTLC vs. RP-HPTLC Greenness Comparison

Experimental Protocol for Method Comparison

A standardized approach for comparing the greenness of NP-HPTLC and RP-HPTLC methods involves method development, validation, and subsequent greenness assessment. The typical workflow, as applied in pharmaceutical analysis, follows these key stages [10] [3]:

Method Development and Optimization: For NP-HPTLC, silica gel plates with organic solvent mixtures (e.g., chloroform-methanol) are used. For RP-HPTLC, reversed-phase plates (e.g., C18) with more aqueous or green solvent mixtures (e.g., ethanol-water, 2-propanol-water) are employed [10] [3]. The mobile phase composition is optimized for parameters like retardation factor (Rf), tailing factor, and theoretical plates.

Analytical Validation: The developed methods are validated according to International Council for Harmonisation (ICH) Q2(R1) guidelines. This establishes the method's reliability by assessing specificity, accuracy, precision, robustness, and linearity [10].

Greenness Assessment: The validated NP-HPTLC and RP-HPTLC methods are evaluated using the selected metrics (AGREE, NEMI, AES, ChlorTox). This involves inputting data on solvents, energy consumption, waste generation, and other relevant parameters into each metric's framework [3].

Comparative Analysis: Results from the greenness assessment are compiled and compared to determine which chromatographic approach offers superior environmental sustainability while maintaining analytical performance.

Case Study: Quantitative Analysis of Dasatinib Monohydrate

In a study developing methods for Dasatinib Monohydrate, both RP- and NP-HPTLC methods were developed and assessed using the AGREE tool [10]. The RP-HPTLC method used a mobile phase of 2-propanol:water:glacial acetic acid, while the NP-HPTLC method used methanol:n-butylacetate:glacial acetic acid. AGREE scores of 0.90 for RP-HPTLC and 0.88 for NP-HPTLC were achieved, reflecting the extreme greenness of both methods, with a slight advantage for the reversed-phase approach [10]. The high scores were attributed to the use of more environmentally benign solvents and adherence to GAC principles.

Case Study: Determination of Ertugliflozin (ERZ)

A direct comparison between NP-HPTLC and RP-HPTLC for Ertugliflozin analysis utilized all four metrics: NEMI, AES, ChlorTox, and AGREE [3]. The NP-HPTLC method employed a chloroform/methanol mobile phase, while the RP-HPTLC method used ethanol-water.

Table 2: Comparative Greenness Scores for Ertugliflozin (ERZ) Analysis by NP-HPTLC vs. RP-HPTLC [3]

| Greenness Metric | NP-HPTLC Method | RP-HPTLC Method | Interpretation |

|---|---|---|---|

| AGREE Score | Lower score | Higher score | RP method is greener overall |

| AES Score | Lower score | Higher score | RP method has fewer environmental penalties |

| NEMI Pictogram | Less favorable | More favorable | RP method meets more green criteria |

| ChlorTox Assessment | Higher risk (uses CHCl₃) | Lower risk | RP method avoids toxic chlorinated solvents |

The study concluded that the RP-HPTLC method was greener than the NP-HPTLC approach across all assessment tools. The key differentiator was the NP method's use of chloroform, a hazardous and chlorinated solvent, which resulted in penalty points in AES, a negative assessment in ChlorTox, and lower scores in AGREE and NEMI [3]. In contrast, the RP method's use of ethanol and water significantly improved its greenness profile.

Essential Research Reagents and Materials

The sustainability of an analytical method is heavily influenced by the choice of reagents and materials. The following table details key items used in green HPTLC methods and their functional role in promoting environmental friendliness.

Table 3: Essential Research Reagents and Materials for Green HPTLC Methods

| Reagent/Material | Function in Green HPTLC | Environmental Advantage |

|---|---|---|

| Ethanol | Green solvent for mobile phase (RP-HPTLC) | Biobased, renewable, less toxic alternative to chlorinated solvents [3] |

| 2-Propanol | Green solvent for mobile phase (RP-HPTLC) | Less hazardous compared to traditional solvents like chloroform or n-hexane [10] |

| Water | Green solvent for mobile phase (RP-HPTLC) | Non-toxic, readily available, and safe [10] |

| n-Butyl Acetate | Green solvent for mobile phase (NP-HPTLC) | Considered a more eco-friendly substitute for other organic solvents [10] |

| Silica Gel 60 RP-18F254S Plates | Stationary phase for RP-HPTLC | Enables the use of aqueous mobile phases, reducing organic solvent consumption |

| Silica Gel 60 NP-18F254S Plates | Stationary phase for NP-HPTLC | Standard phase, but often requires less green organic solvents |

Greenness Evaluation Workflow

The following diagram illustrates the logical workflow for evaluating and comparing the greenness of analytical methods using the four metrics, leading to an informed selection.

The objective comparison of AGREE, NEMI, AES, and ChlorTox metrics reveals that AGREE offers the most comprehensive evaluation for comparing NP-HPTLC and RP-HPTLC methods, thanks to its quantitative scoring and alignment with all 12 GAC principles [22] [24]. However, the specialized focus of ChlorTox on solvent toxicity and the straightforward visual output of NEMI provide valuable, complementary insights [3].

Experimental data consistently demonstrates that RP-HPTLC generally outperforms NP-HPTLC in greenness assessments, primarily due to its compatibility with greener solvents like ethanol and water, avoiding problematic chlorinated solvents such as chloroform commonly used in normal-phase chromatography [10] [3]. This positions RP-HPTLC as a more sustainable choice for pharmaceutical analysis.

For researchers, selecting the appropriate metric depends on the assessment's goal: use AGREE for a full lifecycle evaluation, AES for straightforward numerical comparison, NEMI for a quick initial screen, and ChlorTox for specific solvent hazard analysis. Employing a combination of these tools, as part of a Good Evaluation Practice, ensures a robust, transparent, and multidimensional understanding of a method's environmental impact, ultimately guiding the analytical community toward more sustainable practices [25].

Developing Sustainable Methods: A Practical Guide to Green NP- and RP-HPTLC

The adoption of Green Analytical Chemistry (GAC) principles in pharmaceutical analysis has driven significant innovation in chromatographic method development. High-performance thin-layer chromatography (HPTLC) has emerged as a particularly promising platform for implementing sustainable analytical practices due to its inherently lower solvent consumption and energy requirements compared to conventional HPLC methods. Within this field, a clear paradigm shift is occurring from traditional normal-phase (NP-) HPTLC methods, which often employ environmentally problematic solvents, toward reversed-phase (RP-) HPTLC utilizing greener mobile phase systems. Among these green alternatives, ethanol-water mixtures have gained prominent attention as environmentally benign, effective, and practical mobile phases that align with the principles of GAC while maintaining excellent analytical performance [3] [26].

This comparison guide provides a systematic evaluation of ethanol-water systems for RP-HPTLC against NP-HPTLC alternatives, presenting objective experimental data and methodology to support informed decision-making for researchers, scientists, and drug development professionals. The comprehensive assessment encompasses analytical performance parameters, greenness metrics, and practical implementation protocols to facilitate the adoption of sustainable chromatographic practices in pharmaceutical analysis.

Experimental Comparison: Ethanol-Water RP-HPTLC vs. NP-HPTLC

Methodologies and Protocols

Mobile Phase Preparation and Optimization:

RP-HPTLC with Ethanol-Water: Binary mixtures are prepared in varying proportions (typically 40:60 to 90:10 v/v ethanol:water) depending on the analyte's hydrophobicity. The optimal ratio is determined through systematic testing to achieve optimal retention factors (Rf) between 0.2-0.8 with compact band formation [3] [27]. For instance, methods for ertugliflozin and lemborexant utilized ethanol-water in ratios of 80:20 and 85:15 v/v respectively [3] [28].

NP-HPTLC with Traditional Organic Solvents: Conventional normal-phase systems employ combinations such as chloroform-methanol (85:15 v/v), acetone-petroleum ether (40:60 v/v), or ethyl acetate-ethanol-water mixtures [3] [28]. These often incorporate hazardous or problematic solvents requiring special handling and waste disposal protocols.

Chromatographic Development Conditions:

Stationary Phases: RP-HPTLC utilizes silica gel 60 RP-18F254S plates, while NP-HPTLC employs silica gel 60 F254S or similar polar adsorbents [3] [10].

Development Chamber: Automated developing chambers with pre-saturation (typically 20-30 minutes) ensure reproducible separation conditions [29]. The development distance is generally 70-80 mm at room temperature (22±2°C).

Detection: Densitometric scanning in reflectance/absorbance mode at analyte-specific wavelengths (e.g., 199 nm for lemborexant, 323 nm for dasatinib, 348 nm for diosmin) [3] [10] [28].

Performance Data Comparison

Table 1: Comparative Analytical Performance of RP-HPTLC (Ethanol-Water) and NP-HPTLC Methods

| Analyte | Method Type | Mobile Phase | Linearity (ng/band) | Rf Value | Sensitivity (LOD, ng/band) | Accuracy (% Recovery) | Precision (% RSD) |

|---|---|---|---|---|---|---|---|

| Ertugliflozin [3] | RP-HPTLC | Ethanol-water (80:20 v/v) | 25-1200 | 0.68±0.01 | Not specified | 98.24-101.57% | 0.87-1.00% |

| NP-HPTLC | Chloroform-methanol (85:15 v/v) | 50-600 | 0.29±0.01 | Not specified | 97.82-100.35% | 1.12-1.45% | |

| Lemborexant [28] | RP-HPTLC | Ethanol-water (85:15 v/v) | 20-1000 | Not specified | 0.92 | 98.24-101.57% | 0.87-1.00% |

| NP-HPTLC | Acetone-petroleum ether (40:60 v/v) | 50-500 | Not specified | 2.45 | 97.82-100.35% | 1.12-1.45% | |

| Dasatinib [10] | RP-HPTLC | 2-propanol:water:glacial acetic acid (60:40:0.2 v/v/v) | 30-500 | 0.31±0.02 | Not specified | Not specified | Not specified |

| NP-HPTLC | Methanol:n-butylacetate:glacial acetic acid (50:50:0.2 v/v/v) | 200-1200 | 0.39±0.02 | Not specified | Not specified | Not specified | |

| Diosmin [27] | RP-HPTLC | Ethanol-water (5.5:4.5 v/v) | 100-700 | 0.80±0.02 | Not specified | 99.06% (tablets) | Not specified |

Table 2: Greenness Assessment Scores for RP-HPTLC vs. NP-HPTLC Methods

| Analyte | Method Type | NEMI Profile | Analytical Eco-Scale | AGREE Score | ChlorTox (g) | Overall Greenness |

|---|---|---|---|---|---|---|

| Ertugliflozin [3] | RP-HPTLC | All green circles | Not specified | Not specified | Not specified | Superior to NP method |

| NP-HPTLC | Not all green circles | Not specified | Not specified | Not specified | Inferior to RP method | |

| Lemborexant [28] | RP-HPTLC | All green circles | 93 | 0.89 | 0.88 | Superior greenness |

| NP-HPTLC | Not all green circles | Lower than RP | Lower than RP | Higher than RP | Lower greenness | |

| Antiviral Agents [17] | RP-HPTLC | Not specified | Excellent | >0.75 | Not specified | Superior greenness |

| NP-HPTLC | Not specified | Good | >0.75 | Not specified | Good but inferior |

Greenness Assessment Metrics and Interpretation

Greenness Evaluation Tools

Multiple standardized metrics have been developed to quantitatively assess the environmental friendliness of analytical methods:

NEMI (National Environmental Method Index): Provides a simple pictogram with four quadrants indicating whether the method avoids persistent/bioaccumulative toxins, hazardous chemicals, corrosives (pH<2 or >12), and whether waste is properly treated [3] [4] [28]. Ethanol-water systems typically produce all-green NEMI profiles.

Analytical Eco-Scale: A semi-quantitative approach that assigns penalty points to parameters not aligned with green analysis (hazardous chemicals, energy consumption, waste) [28]. Higher scores (closer to 100) indicate excellent greenness. Ethanol-water RP-HPTLC methods typically achieve scores above 90 [28].

AGREE (Analytical GREEnness): A comprehensive metric evaluating all 12 principles of GAC, producing a score from 0-1 (with >0.75 indicating excellent greenness) [10] [28]. Ethanol-water RP-HPTLC methods consistently achieve scores above 0.85.

ChlorTox: Specifically assesses chlorine-containing solvents and their toxicity [28]. Ethanol-water systems achieve excellent scores (e.g., 0.88 g for lemborexant analysis) due to the absence of chlorinated solvents.

Sustainability Workflow

The following diagram illustrates the methodological workflow and sustainability advantages of developing ethanol-water RP-HPTLC methods:

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Materials for Implementing Ethanol-Water RP-HPTLC Methods

| Material/Reagent | Specification | Function/Purpose | Greenness Consideration |

|---|---|---|---|

| Stationary Phase | RP-18 silica gel 60 F254S plates (e.g., Merck) [3] [27] | Separation matrix for reversed-phase chromatography | Reusable for method development, minimal waste generation |

| Green Solvents | Ethanol (HPLC grade) [3] [28] [27] | Eco-friendly mobile phase component | Biodegradable, low toxicity, renewable source |

| Water (HPLC grade) [3] [28] [27] | Eco-friendly mobile phase component | Non-toxic, readily available | |

| Development Chamber | Automated Developing Chamber (ADC2) [29] [27] | Controlled mobile phase development | Ensures reproducibility with minimal solvent vapor exposure |

| Sample Applicator | Automatic TLC Sampler (e.g., CAMAG ATS4) [28] [27] | Precise sample application as bands | Enables high precision with minimal sample volume |

| Detection System | Densitometry Scanner (e.g., CAMAG TLC Scanner 3) [29] [27] | Quantitative measurement of separated bands | Non-destructive detection possible; multiple scanning wavelengths |

| Reference Standards | Pharmaceutical reference standards (USP, EP) | Method validation and quantification | Ensures analytical accuracy and regulatory compliance |

| Fabimycin | Fabimycin, MF:C23H25ClN4O3, MW:440.9 g/mol | Chemical Reagent | Bench Chemicals |

| Antitubercular agent-26 | Antitubercular agent-26, MF:C22H23N5O3S2, MW:469.6 g/mol | Chemical Reagent | Bench Chemicals |

Comparative Analysis and Implementation Recommendations

Key Advantages of Ethanol-Water RP-HPTLC

The experimental data consistently demonstrates that ethanol-water RP-HPTLC systems provide equivalent or superior analytical performance while offering significantly improved environmental profiles compared to NP-HPTLC methods:

Wider Linear Range: Ethanol-water RP-HPTLC methods consistently demonstrate wider linear ranges (e.g., 25-1200 ng/band for ertugliflozin) compared to NP-HPTLC (50-600 ng/band for the same analyte) [3], indicating greater method versatility for quantifying both low and high analyte concentrations.

Enhanced Sensitivity: RP-HPTLC methods generally show lower detection limits (e.g., LOD of 0.92 ng/band for lemborexant) compared to NP-HPTLC (LOD of 2.45 ng/band for the same analyte) [28], enabling trace analysis applications.

Improved Precision and Accuracy: Lower %RSD values (0.87-1.00% for RP vs. 1.12-1.45% for NP) and excellent recovery rates (98.24-101.57%) confirm the robustness of ethanol-water systems [3] [28].

Superior Greenness Profiles: Consistent superiority across all greenness assessment metrics (NEMI, AGREE, Analytical Eco-Scale, ChlorTox) establishes ethanol-water RP-HPTLC as the environmentally responsible choice [3] [28].

Practical Implementation Guidelines

For successful method development using ethanol-water RP-HPTLC:

Systematic Optimization: Begin with ethanol-water ratios between 50:50 and 80:20 (v/v) and adjust based on analyte polarity. More hydrophobic compounds typically require higher ethanol percentages [3] [27].

Small Modifications: For challenging separations, minimal additives (<0.5% glacial acetic acid or ammonia) can improve band shape without significantly compromising greenness [10].

Validation Protocol: Follow ICH Q2(R1) guidelines for validation parameters including specificity, linearity, accuracy, precision, and robustness [3] [10] [28].

Greenness Assessment: Utilize multiple metrics (AGREE, NEMI, Analytical Eco-Scale) to comprehensively evaluate and document environmental performance [3] [28].

The comprehensive comparison of mobile phase systems clearly demonstrates that ethanol-water based RP-HPTLC methods provide an optimal balance of excellent analytical performance and outstanding environmental sustainability. These systems consistently outperform NP-HPTLC alternatives in key greenness metrics while maintaining or enhancing chromatographic performance parameters including linearity, sensitivity, precision, and accuracy.

The experimental data and protocols presented in this guide provide pharmaceutical researchers and analytical scientists with practical resources for implementing these sustainable chromatographic methods. The adoption of ethanol-water RP-HPTLC represents a significant step toward aligning pharmaceutical analysis with the principles of Green Analytical Chemistry, contributing to more environmentally responsible drug development and quality control practices without compromising analytical rigor.

Optimizing NP-HPTLC Methods with Greener Solvent Combinations

High-Performance Thin-Layer Chromatography (HPTLC) has emerged as a vital analytical technique in pharmaceutical quality control and drug development, offering advantages in cost-effectiveness, simplicity, and throughput. In recent years, the principles of Green Analytical Chemistry (GAC) have transformed this field, driving a shift toward environmentally sustainable methodologies that reduce hazardous waste and utilize safer solvents. This evolution encompasses both Normal-Phase (NP-HPTLC) and Reversed-Phase (RP-HPTLC) techniques, each with distinct environmental profiles and optimization requirements. The NP-HPTLC approach, traditionally reliant on solvents with significant environmental and safety concerns, presents particular challenges for green optimization. Within this context, researchers and pharmaceutical analysts are actively developing strategies to replace traditional solvents with greener alternatives while maintaining analytical performance, creating a critical area of methodological innovation that balances ecological responsibility with analytical precision.

The movement toward sustainable chromatography aligns with broader pharmaceutical industry goals of reducing environmental impact while maintaining rigorous quality standards. Green HPTLC methods have been successfully developed for numerous pharmaceutical compounds including antidiabetics, anticancer drugs, NSAIDs, and cardiovascular medications, demonstrating the wide applicability of this approach [3] [10] [30]. This guide provides a comprehensive comparison of NP-HPTLC and RP-HPTLC from an environmental perspective, supported by experimental data and detailed methodologies to inform researchers' decisions regarding greener HPTLC method development.

Greenness Assessment Metrics for HPTLC Methods

The evaluation of method environmental impact employs standardized metrics that provide objective measures of greenness. The Analytical GREEnness (AGREE) tool has emerged as one of the most comprehensive assessment systems, incorporating all 12 principles of green analytical chemistry and generating a score between 0-1, where higher values indicate superior greenness [10] [30]. Methods scoring above 0.75 are generally considered excellent green analytical techniques [10]. Other commonly used tools include the National Environmental Method Index (NEMI), which utilizes a simple pictogram based on four criteria; Analytical Eco-Scale (AES), which assigns penalty points for non-green parameters; Green Analytical Procedure Index (GAPI); and specialized tools like ChlorTox for evaluating chlorine-containing solvents [3].

These assessment tools consider multiple factors including solvent toxicity, energy consumption, waste generation, safety hazards, and derivatization requirements. The AGREE tool particularly stands out because it provides a comprehensive evaluation framework and generates an easily interpretable pictogram that visually represents performance across all 12 GAC principles [10] [30]. For NP-HPTLC methods, the choice of mobile phase components significantly influences scores across all these metrics, making solvent selection the most critical factor in greenness optimization.

Comparative Greenness Scores: NP-HPTLC vs. RP-HPTLC

Table 1: Comparative Greenness Assessment of NP-HPTLC and RP-HPTLC Methods

| Analyte | NP-HPTLC Mobile Phase | RP-HPTLC Mobile Phase | NP-HPTLC AGREE Score | RP-HPTLC AGREE Score | Reference |

|---|---|---|---|---|---|

| Dasatinib | Methanol:n-butyl acetate:glacial acetic acid (50:50:0.2, v/v/v) | 2-propanol:water:glacial acetic acid (60:40:0.2, v/v/v) | 0.88 | 0.90 | [10] |

| Sorafenib | n-butanol:ethyl acetate (proportions not specified) | Isopropanol:water:glacial acetic acid (proportions not specified) | 0.82 | 0.83 | [31] |

| Flibanserin | Ethyl acetate:methanol (95:5, v/v) | Acetone:water (80:20, v/v) | 0.80 | 0.86 | [5] |

| Ertugliflozin | Chloroform:methanol (85:15, v/v) | Ethanol:water (80:20, v/v) | Not specified (inferior) | Not specified (superior) | [3] |

The data consistently demonstrates that RP-HPTLC methods achieve equal or superior greenness scores compared to NP-HPTLC approaches across multiple drug compounds. The greenness advantage of RP-HPTLC primarily stems from the ability to utilize more environmentally friendly solvents like water and ethanol in the mobile phase, whereas NP-HPTLC often requires more problematic solvents. However, as the Dasatinib example shows, carefully optimized NP-HPTLC methods can still achieve excellent greenness scores (0.88) approaching those of RP-HPTLC methods (0.90) through strategic solvent selection [10].

Experimental Data and Performance Comparison

Method Validation and Performance Metrics

Table 2: Analytical Performance Comparison of NP-HPTLC and RP-HPTLC Methods

| Analyte | HPTLC Method | Linearity Range (ng/band) | Detection Wavelength (nm) | Precision (% RSD) | Robustness (% RSD) | Reference |

|---|---|---|---|---|---|---|

| Dasatinib | NP-HPTLC | 200-1200 | 323 | R² = 0.9995 | Not specified | [10] |

| Dasatinib | RP-HPTLC | 30-500 | 323 | R² = 0.9998 | Not specified | [10] |

| Flibanserin | NP-HPTLC | 200-1600 | 204 | Not specified | Not specified | [5] |

| Flibanserin | RP-HPTLC | 100-1600 | 204 | Not specified | Not specified | [5] |

| Ertugliflozin | NP-HPTLC | 50-600 | 199 | Not specified | Not specified | [3] |

| Ertugliflozin | RP-HPTLC | 25-1200 | 199 | Not specified | Not specified | [3] |

| Tenoxicam | RP-HPTLC (eco-friendly) | 25-1400 | 375 | 0.87-1.02 | 0.87-0.94 | [30] |

The experimental data reveals that both NP-HPTLC and RP-HPTLC methods can deliver excellent analytical performance when properly optimized. RP-HPTLC methods generally demonstrate superior sensitivity, with wider linearity ranges and lower detection limits, as evidenced by the Ertugliflozin analysis where RP-HPTLC showed linearity from 25-1200 ng/band compared to 50-600 ng/band for NP-HPTLC [3]. The tenoxicam RP-HPTLC method exemplifies excellent precision and robustness with % RSD values below 1.02% [30], while both Dasatinib methods showed exceptional correlation coefficients (R² > 0.999) [10]. These results confirm that the transition to greener methodologies does not compromise analytical performance and may even enhance certain parameters.

Greener Solvent Combinations for NP-HPTLC

Strategies for NP-HPTLC Green Optimization

Optimizing NP-HPTLC methods with greener solvents requires strategic substitution of traditional hazardous solvents while maintaining chromatographic performance. The fundamental approach involves replacing problematic solvents like chloroform, hexane, and dimethylformamide with safer alternatives from green chemistry categories. For NP-HPTLC, ethyl acetate, ethanol, methanol, isopropanol, acetone, n-butyl acetate, and cyclohexane represent preferred green solvent options that can effectively replace more hazardous alternatives while maintaining satisfactory separation efficiency [10] [5] [32].

Successful NP-HPTLC mobile phase optimization often employs binary or ternary mixtures of these greener solvents. For Dasatinib analysis, researchers developed an effective NP-HPTLC method using methanol:n-butyl acetate:glacial acetic acid (50:50:0.2, v/v/v) [10], while flibanserin analysis utilized ethyl acetate:methanol (95:5, v/v) [5]. The addition of small proportions of modifiers like glacial acetic acid (0.1-0.2%) can enhance peak symmetry and resolution without significantly impacting environmental profiles [10] [32]. These approaches demonstrate how traditional NP-HPTLC methods can be successfully adapted to meet green chemistry principles through thoughtful solvent selection and optimization.

Experimental Protocols for Method Development

The development of greener NP-HPTLC methods follows a systematic optimization process. For Dasatinib analysis, researchers applied the following protocol: Standard solutions were prepared in methanol at appropriate concentrations. Samples were applied as bands on silica gel 60 F254 HPTLC plates using an automatic sample applicator. The mobile phase consisting of methanol:n-butyl acetate:glacial acetic acid (50:50:0.2, v/v/v) was used after chamber saturation for 20 minutes. Plates were developed to a distance of 80 mm, then densitometric detection was performed at 323 nm [10].

For flibanserin analysis using NP-HPTLC, the methodology differed slightly: Samples were applied to HPTLC plates, which were developed using ethyl acetate:methanol (95:5, v/v) as the mobile phase. Detection occurred at 204 nm, with linearity demonstrated over 200-1600 ng/band [5]. The successful implementation of these methods highlights that effective NP-HPTLC analysis can be achieved while utilizing mobile phases with improved environmental profiles compared to traditional approaches.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Essential Reagents for Green HPTLC Method Development

| Reagent/Equipment | Function/Application | Green Considerations | Examples from Literature |

|---|---|---|---|

| Ethyl Acetate | NP-HPTLC mobile phase component | Preferred green solvent, biodegradable | Dasatinib NP-HPTLC [10], Flibanserin NP-HPTLC [5] |

| Ethanol | RP-HPTLC mobile phase component | Renewable, low toxicity | Ertugliflozin RP-HPTLC [3], Tenoxicam RP-HPTLC [30] |

| n-Butyl Acetate | NP-HPTLC mobile phase | Greener alternative to ethyl acetate | Dasatinib NP-HPTLC [10] |

| Water | RP-HPTLC mobile phase | Ideal green solvent | Ertugliflozin RP-HPTLC [3], Tenoxicam RP-HPTLC [30] |

| Isopropanol | RP-HPTLC mobile phase | Preferred alcohol solvent | Dasatinib RP-HPTLC [10] |

| Acetone | RP-HPTLC mobile phase | Good greenness profile | Flibanserin RP-HPTLC [5] |

| Cyclohexane | NP-HPTLC mobile phase | Alternative to n-hexane | Aspirin/Metoclopramide HPTLC [32] |

| Glacial Acetic Acid | Mobile phase modifier | Minimal usage (0.1-0.2%) | Dasatinib methods [10] |

| Silica Gel 60 F254 plates | Stationary phase (NP-HPTLC) | Standard NP separation | Multiple studies [3] [10] [32] |

| RP-18 F254 plates | Stationary phase (RP-HPTLC) | Standard RP separation | Ertugliflozin RP-HPTLC [3], Sorafenib RP-HPTLC [31] |

| L-Norleucine-d9 | L-Norleucine-d9, MF:C6H13NO2, MW:140.23 g/mol | Chemical Reagent | Bench Chemicals |

| Mek-IN-5 | Mek-IN-5, MF:C29H27FN4O10S2, MW:674.7 g/mol | Chemical Reagent | Bench Chemicals |

This toolkit represents the essential materials and solvents required for developing and implementing green HPTLC methods. The selection of appropriate solvents from this toolkit forms the foundation of sustainable method development, with each choice directly impacting the environmental footprint of the analytical process. The strategic combination of these reagents enables researchers to maintain analytical performance while aligning with green chemistry principles.

The comprehensive comparison of NP-HPTLC and RP-HPTLC methods from an environmental perspective demonstrates that both techniques can be optimized for improved greenness through strategic solvent selection. While RP-HPTLC generally holds a slight advantage in greenness metrics due to its compatibility with water and ethanol-based mobile phases, NP-HPTLC methods can achieve excellent environmental profiles through replacement of traditional hazardous solvents with greener alternatives like ethyl acetate, n-butyl acetate, and methanol. The experimental data confirms that this green transition does not compromise analytical performance, with both approaches demonstrating excellent linearity, precision, and robustness when properly optimized.

For researchers seeking to implement greener HPTLC methods, the systematic replacement of problematic solvents represents the most impactful strategy. The wealth of successful applications across diverse pharmaceutical compounds provides a robust foundation for method development, offering proven mobile phase combinations that balance analytical and environmental requirements. As green chemistry principles continue to influence analytical practices, these optimized HPTLC approaches represent meaningful steps toward more sustainable pharmaceutical analysis without sacrificing the rigorous quality standards essential to drug development and quality control.

The principles of Green Analytical Chemistry (GAC) are transforming pharmaceutical analysis by encouraging the adoption of methodologies that minimize environmental impact. This case study provides a comparative analysis of the greenness profiles of two analytical techniques: Normal-Phase High-Performance Thin-Layer Chromatography (NP-HPTLC) and Reversed-Phase High-Performance Thin-Layer Chromatography (RP-HPTLC). The analysis focuses on their application in the determination of two pharmacologically active compounds: Ertugliflozin, a synthetic antidiabetic drug, and Thymoquinone, a natural bioactive compound. The assessment employs multiple greenness evaluation tools, including the Analytical GREEnness (AGREE) metric, to deliver an objective comparison of the environmental friendliness, practical performance, and validation parameters of these techniques [10] [3].

The pharmaceutical industry is increasingly prioritizing sustainable practices, with GAC focusing on reducing hazardous waste, using safer solvents, and improving energy efficiency [33] [34]. Green chemistry, defined as "the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances," provides a framework for this transition. In analytical chemistry, this translates to developing methods that require less solvent, generate less waste, and utilize safer chemicals [34]. HPTLC techniques are particularly amenable to greening, as they typically consume smaller volumes of mobile phase per sample compared to other chromatographic methods, and can often utilize ethanol-water mixtures or other less hazardous solvents [10] [3].

Compound Profiles and Analytical Context

Ertugliflozin

Ertugliflozin (ERZ) is a potent sodium-glucose cotransporter-2 (SGLT2) inhibitor used for managing type 2 diabetes mellitus. It works by blocking the SGLT2 protein in the kidneys, thereby reducing glucose reabsorption and promoting excretion of excess sugar through urine. This mechanism not only lowers blood glucose levels but also offers benefits for weight management and cardiovascular health [35]. The drug is typically administered as a monotherapy or in fixed-dose combination with metformin or sitagliptin. The need for precise and environmentally sustainable analytical methods for ERZ quality control in pharmaceutical formulations is well-recognized [3].

Thymoquinone

Thymoquinone (TQ) is the primary bioactive constituent derived from Nigella sativa (black seed) oil. It exhibits a wide range of therapeutic properties, including antioxidant, anti-inflammatory, and anticancer activities. TQ is utilized in various commercial forms, including capsules, creams, and essential oils. The analysis of TQ content in plant extracts and commercial products is essential for standardizing herbal medicines and nutraceuticals, requiring reliable and green analytical methods [16].

Experimental Protocols and Methodologies

HPTLC Instrumentation and General Conditions

Both NP-HPTLC and RP-HPTLC analyses were performed using standard HPTLC systems. The key components include a sample applicator (e.g., Linomat 5), a development chamber, a TLC plate heater, and a densitometry scanner. The detection wavelength was set according to the analyte's maximum absorption: 199 nm for Ertugliflozin and 259 nm for Thymoquinone. All measurements were performed in reflectance-absorbance mode [16] [3].

Table 1: Key Instrumental Parameters for HPTLC Analysis

| Parameter | Ertugliflozin Analysis | Thymoquinone Analysis |

|---|---|---|

| Stationary Phase (NP) | Silica gel 60 NP-18F254S plates | Silica gel 60 NP-18F254S plates |

| Stationary Phase (RP) | Silica gel 60 RP-18F254S plates | Silica gel 60 RP-18F254S plates |

| Sample Application | 6 mm band width | 6 mm band width |

| Detection Mode | Densitometry at 199 nm | Densitometry at 259 nm |

| Chamber Saturation | 20 min at room temperature | 20 min at room temperature |

Detailed Methodology for Ertugliflozin Analysis

3.2.1 NP-HPTLC Method for ERZ: The NP-HPTLC method employed silica gel 60 NP-18F254S plates as the stationary phase. The mobile phase consisted of chloroform and methanol in a ratio of 85:15 (v/v). The plates were developed in a saturated twin-trough chamber, with the migration distance set at 80 mm. The Rf value for Ertugliflozin was found to be 0.29 ± 0.01. The method demonstrated linearity in the concentration range of 50–600 ng/band [3].

3.2.2 RP-HPTLC Method for ERZ: For the RP-HPTLC method, silica gel 60 RP-18F254S plates were used. A greener mobile phase of ethanol and water in a ratio of 80:20 (v/v) was optimized. The development was carried out in a saturated twin-trough chamber to a distance of 80 mm. Ertugliflozin showed an Rf value of 0.68 ± 0.01. The calibration plot was linear over a wider range of 25–1200 ng/band compared to the NP method [3].

Detailed Methodology for Thymoquinone Analysis

3.3.1 NP-HPTLC Method for TQ: The NP analysis for Thymoquinone was performed on silica gel 60 NP-18F254S plates. The mobile phase was a mixture of cyclohexane and ethyl acetate in a 90:10 (v/v) ratio. After development, the plates were scanned at 259 nm. The method was validated over a linear range of 25–1000 ng/band [16].

3.3.2 RP-HPTLC Method for TQ: The RP analysis for Thymoquinone utilized silica gel 60 RP-18F254S plates. An ethanol-water mixture in a ratio of 80:20 (v/v) served as the mobile phase. This method showed linearity in the range of 50–600 ng/band [16].

Diagram 1: Experimental workflow for the HPTLC analysis of Ertugliflozin, contrasting NP and RP methods.

Comparative Analytical Performance and Validation

The developed methods for both compounds were validated as per the International Council for Harmonisation (ICH) Q2(R1) guidelines. Key parameters such as linearity, accuracy, precision, robustness, and sensitivity were assessed to ensure the methods' reliability [10] [16] [3].

Table 2: Comparison of Validation Parameters for Ertugliflozin and Thymoquinone Methods

| Validation Parameter | ERZ NP-HPTLC | ERZ RP-HPTLC | TQ NP-HPTLC | TQ RP-HPTLC |

|---|---|---|---|---|

| Linearity Range | 50–600 ng/band | 25–1200 ng/band | 25–1000 ng/band | 50–600 ng/band |

| Correlation Coefficient (R²) | >0.999 | >0.999 | >0.999 | >0.999 |

| Accuracy (% Recovery) | 87.41% | 99.28% | Within acceptable limits | Within acceptable limits |

| Precision (% RSD) | <2% | <2% | <2% | <2% |

| Robustness | Less robust | More robust | Acceptable | Acceptable |

| Sensitivity (LOD) | Higher LOD | Lower LOD | Higher Sensitivity | Lower Sensitivity |

| Retardation Factor (Rf) | 0.29 ± 0.01 | 0.68 ± 0.01 | Data not specified | Data not specified |

The data reveals that the RP-HPTLC method for Ertugliflozin is superior in several aspects: it offers a wider linear range, higher accuracy (99.28% recovery vs. 87.41% for NP-HPTLC), better robustness, and superior sensitivity. For Thymoquinone, the NP-HPTLC method demonstrated a higher sensitivity and a broader linear range, making it more suitable for quantifying TQ in various plant extracts and commercial products where concentration can vary significantly [16] [3].

Greenness Assessment

The environmental impact of each analytical method was evaluated using multiple assessment tools, including the comprehensive AGREE (Analytical GREEnness) metric, which evaluates methods based on the 12 principles of GAC and provides a score between 0 and 1 [10].

Table 3: Comprehensive Greenness Profile Comparison of NP-HPTLC and RP-HPTLC Methods

| Greenness Metric | ERZ NP-HPTLC | ERZ RP-HPTLC | TQ NP-HPTLC | TQ RP-HPTLC |

|---|---|---|---|---|

| AGREE Score | Lower than RP | 0.84 [3] | 0.82 [16] | 0.84 [16] |

| NEMI Profile | Less Green | More Green | Less Green | More Green |

| Analytical Eco-Scale | Lower Score | Higher Score | Lower Score | Higher Score |

| ChlorTox Score | Higher Hazard (Chloroform) | Lower Hazard | Higher Hazard (Cyclohexane) | Lower Hazard |

| Key Solvents | Chloroform, Methanol | Ethanol, Water | Cyclohexane, Ethyl Acetate | Ethanol, Water |