A Practical Guide to CHEM21 Solvent Greenness Assessment for Sustainable Research and Development

This article provides a comprehensive guide to the CHEM21 Solvent Selection Guide, a globally recognized framework developed by a European consortium for assessing solvent sustainability.

A Practical Guide to CHEM21 Solvent Greenness Assessment for Sustainable Research and Development

Abstract

This article provides a comprehensive guide to the CHEM21 Solvent Selection Guide, a globally recognized framework developed by a European consortium for assessing solvent sustainability. Tailored for researchers, scientists, and drug development professionals, it details the methodology for scoring solvents based on Safety, Health, and Environment (SHE) criteria aligned with the Global Harmonized System (GHS). The content covers foundational principles, practical application of the selection tool, strategies for troubleshooting and optimizing solvent choices, and a comparative analysis with other green metrics. The guide aims to empower scientists to make informed, data-driven decisions that minimize the environmental impact of chemical processes, particularly in pharmaceutical development where solvents can constitute over half of the material mass used.

Understanding the CHEM21 Framework: Principles and Pillars of Green Solvent Selection

THE ORIGIN AND MISSION OF THE CHEM21 CONSORTIUM

The CHEM21 Consortium (Chemical Manufacturing Methods for the 21st Century Pharmaceutical Industries) is a European public-private partnership established to promote sustainable manufacturing in the chemical and pharmaceutical sectors [1]. It was formed under the Innovative Medicines Initiative (IMI) and comprises a consortium of six pharmaceutical companies from the European Federation of Pharmaceutical Industries and Associations (EFPIA), ten universities, and five small to medium enterprises [1]. Its core mission is to develop and embed sustainable biological and chemical methodologies, supported by research projects and educational training packages to instill these principles in future scientists [1].

The CHEM21 Solvent Selection Guide

A key output of CHEM21 is its solvent selection guide, which provides a standardized framework for choosing greener solvents. The guide categorizes solvents based on explicit Safety, Health, and Environment (SH&E) criteria aligned with the Globally Harmonized System (GHS) and European regulations [1] [2]. Solvents are ranked into four categories, as shown in the table below.

Table 1: CHEM21 Solvent Ranking Categories

| Category | Description | Example Instruction |

|---|---|---|

| Recommended | Preferred, greener solvents | Test first in a screening exercise, provided no chemical incompatibility exists [1]. |

| Problematic | Solvents with specific scale-up constraints | Can be used in the lab, but implementation at production scale requires specific measures or significant energy consumption [1]. |

| Hazardous | Solvents with significant constraints | Substitution during process development is a priority due to very strong constraints on scale-up [1]. |

| Highly Hazardous | Solvents to be avoided | Avoided even in the laboratory [1]. |

The Quantitative Assessment Framework

The CHEM21 guide employs a quantitative scoring system from 1 to 10 for Safety, Health, and Environment, with 10 representing the highest hazard. The scores are combined to provide an overall preliminary ranking [1]. The specific criteria for each category are detailed below.

Table 2: CHEM21 Safety, Health, and Environment (SH&E) Scoring Criteria

| Category | Core Basis for Scoring | Key Scoring Parameters |

|---|---|---|

| Safety | Flammability and physical hazards [1]. | Primarily based on flash point (e.g., >60°C scores 1; <-20°C scores 7) [1]. Score is incremented for low auto-ignition temperature (<200°C), high electrostatic charge risk (resistivity >10^8 Ω m), or peroxide-forming ability [1]. |

| Health | Occupational hazard [1]. | Based on GHS hazard statements (e.g., H330 "fatal if inhaled" scores 9; H332 "harmful if inhaled" scores 4) [1]. One point is added if the solvent's boiling point is <85°C, increasing the risk of inhalation exposure [1]. |

| Environment | Environmental impact and toxicity [1]. | A 10-point criteria system is used, with the highest hazard dictating the final score (3, 5, or 7) [1]. Considers factors like environmental toxicity (e.g., H400 "very toxic to aquatic life") and boiling point [3]. |

Experimental Protocol for Solvent Greenness Assessment Using CHEM21 Principles

This protocol outlines how to use the CHEM21 methodology to select a greener solvent for a chemical process, using the replacement of xylene in a painting varnish as a model application [2].

1. Initial Solvent Selection and SH&E Assessment

- Objective: Identify potential substitute solvents and perform an initial hazard screening.

- Procedure:

- Define Target Properties: Use software tools (e.g., SUSSOL) or Hansen Solubility Parameters (HSP) to generate a list of candidate solvents with physical properties similar to the target solvent (e.g., xylene) [2].

- Apply CHEM21 Screening: Evaluate each candidate solvent using the CHEM21 SH&E criteria [2].

- Shortlist Solvents: Eliminate all solvents with a health score greater than 3 (on the 1-10 scale) or any score of 10, which indicates a highly hazardous substance [2]. This yields a shortlist of potentially viable and greener alternatives.

2. Determination of Hansen Solubility Parameters (HSP)

- Objective: Experimentally determine the solubility sphere of the material (e.g., a resin) to guide solvent selection based on solubility.

- Materials:

- The material to be dissolved (e.g., Dammar resin, Paraloid B72).

- A range of 15-20 test solvents with known HSP values, covering a broad Hansen space [2].

- Procedure:

- Prepare small-scale vials (e.g., 2-4 mL) with a fixed mass of the resin.

- Add a fixed volume of each test solvent to the vials and agitate for 24 hours.

- Visually assess and score the solubility result (e.g., 1 for complete dissolution, 0 for no dissolution).

- Input the solubility data and the known HSP of the test solvents into HSPiP (Hansen Solubility Parameters in Practice) software.

- The software will calculate the Hansen Solubility Parameters (δD, δP, δH) for the resin and define the radius of its solubility sphere [2].

3. Final Solvent Selection and Varnish Preparation

- Objective: Select the best solvent and prepare the final resin solution.

- Procedure:

- Use the HSPiP software to identify solvents from the CHEM21 shortlist that fall within the solubility sphere of the resin [2].

- Prepare resin solutions using the selected alternative solvents and a control with the original solvent (e.g., xylene).

- Proceed to application-specific testing (e.g., on test boards or actual artworks) to evaluate working properties, film formation, and aesthetic results [2].

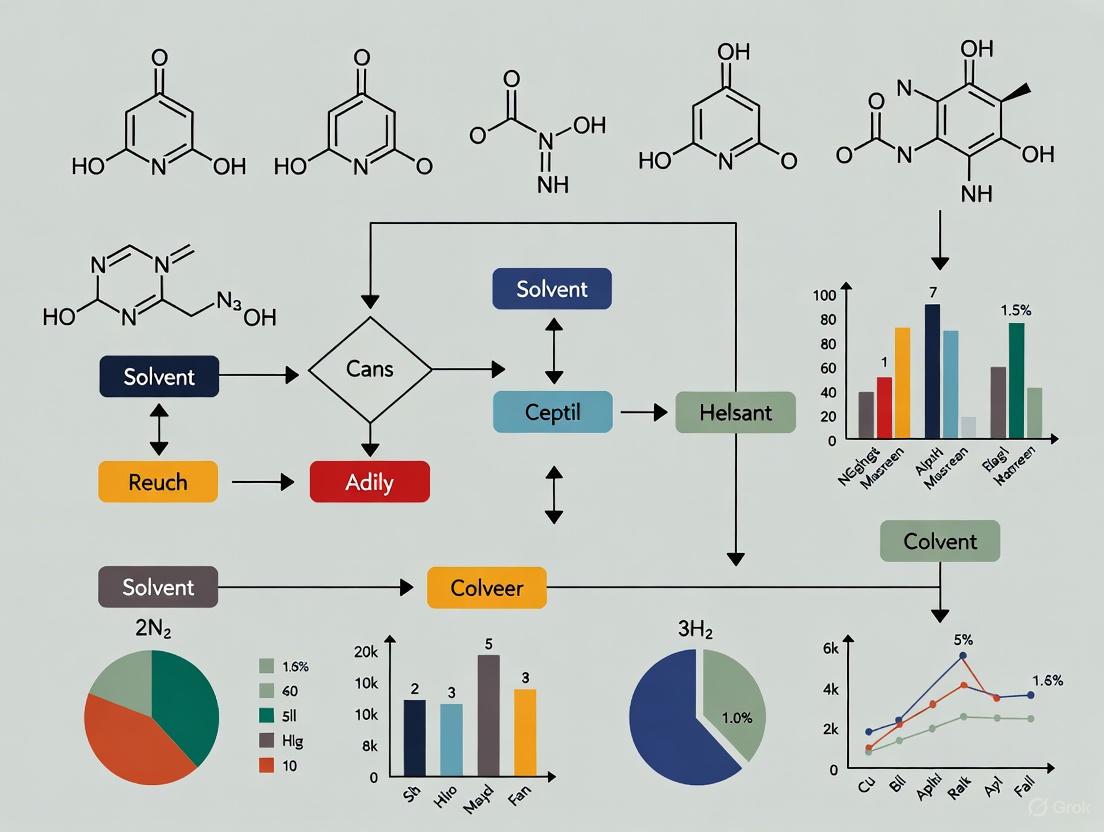

Diagram 1: CHEM21 Solvent Selection Workflow. This diagram illustrates the systematic process for selecting greener solvents, integrating computational screening with experimental validation.

The Scientist's Toolkit: Research Reagent Solutions

The following table details key tools and materials used in the CHEM21-guided solvent selection process.

Table 3: Essential Research Reagents and Tools for CHEM21 Assessment

| Tool / Material | Function / Description | Role in the CHEM21 Workflow |

|---|---|---|

| SUSSOL Software [2] | A software tool that uses a database of 500 solvents and a clustering algorithm to suggest alternative solvents based on similarity in physical properties. | Enables the initial, data-driven generation of candidate solvents to replace a target solvent. |

| HSPiP Software [2] | Software for calculating Hansen Solubility Parameters, which predict whether one material will dissolve in another. | Used to determine the solubility sphere of a resin and identify which candidate solvents will effectively dissolve it. |

| Test Solvent Kit | A curated collection of solvents with known, diverse Hansen Solubility Parameters (δD, δP, δH). | Essential for the experimental determination of a resin's HSP through solubility testing. |

| CHEM21 Selection Guide [1] | The guide itself, providing the ranked solvent lists and the explicit SH&E scoring criteria. | Serves as the primary reference for assessing and comparing the greenness of candidate solvents. |

| GHS/CLP Regulation Data [1] | Safety Data Sheets (SDS) and regulatory classifications from the Globally Harmonized System. | Provides the necessary hazard statements (e.g., H-codes) required to assign accurate CHEM21 Health and Safety scores. |

| 4-Fluorodeprenyl | 4-Fluorodeprenyl|CAS 103596-43-6|MAO-B Inhibitor | |

| 7-(2-Hydroxypropoxy)theophylline | 7-(2-Hydroxypropoxy)theophylline|CAS 19729-83-0 | 7-(2-Hydroxypropoxy)theophylline for research. Explore its applications as a theophylline derivative. For Research Use Only. Not for human or veterinary use. |

Environment, Health, and Safety (EHS), also referred to as SHE, represents a multidisciplinary field focused on implementing measures to preserve the health and safety of workers while protecting the surrounding environment [4]. This framework encompasses the laws, policies, programs, and practices designed to protect the well-being of employees, customers, and the environment within an organization [5]. The SHE approach forms a holistic system for risk management and responsible business operations, with particular significance in chemical and pharmaceutical industries where solvent use represents at least half of the materials used in chemical processes [1].

The historical development of formal SHE management systems gained momentum following industrial tragedies such as the 1984 Bhopal disaster, which highlighted the catastrophic consequences of inadequate safety and environmental controls [4]. Today, SHE has evolved into a strategic priority for organizations worldwide, with health and safety ranking as the #1 concern among corporate directors globally according to a 2024 survey [5]. In the specific context of solvent selection and greenness assessment, the SHE framework provides the foundational principles for evaluating and mitigating the potential hazards associated with chemical substances throughout their lifecycle.

The CHEM21 Solvent Selection Guide and SHE Integration

The CHEM21 selection guide was developed by a European consortium of pharmaceutical companies, universities, and small to medium enterprises as part of the Innovative Medicines Initiative (IMI) to promote sustainable biological and chemical methodologies [1] [3]. This guide represents one of the most comprehensive tools for assessing solvent greenness from a SHE perspective, aligning with the Global Harmonized System (GHS) and European regulations [1]. The primary objective of the CHEM21 guide is to provide researchers with a standardized methodology for comparing the sustainability of solvents used in chemical processes, particularly relevant for drug substance synthesis where solvents typically constitute 50-80% of the total mass of materials used [1].

The guide employs a straightforward classification system that ranks solvents into four categories:

- Recommended (or preferred): Solvents to be tested first in screening exercises, assuming no chemical incompatibility with process conditions

- Problematic: Solvents that can be used in laboratory or kilolab scale but require specific measures or significant energy consumption at pilot plant or production scale

- Hazardous: Solvents where constraints on scale-up are substantial, making substitution during process development a priority

- Highly hazardous: Solvents to be avoided, even in laboratory settings [1]

This classification system enables researchers and process chemists to make informed decisions early in development stages, potentially avoiding costly solvent substitutions later in the development pipeline.

SHE Pillars in Solvent Assessment

The CHEM21 guide evaluates solvents based on explicit Safety, Health and Environment (SH&E) criteria, with each category scored from 1 to 10 (10 representing the highest hazard) and associated with a color code (green for 1-3, yellow for 4-6, and red for 7-10) [1]. This scoring system directly corresponds to the three SHE pillars, creating a standardized assessment framework.

Table 1: CHEM21 Safety Scoring Criteria Based on Flammability and Physical Hazards

| Basic Safety Score | Flash Point (°C) | GHS Classification | Additional Increments |

|---|---|---|---|

| 1 | >60 | — | +1 for each: AIT < 200°C, Resistivity > 10⸠Ω·m, Peroxide formation (EUH019) |

| 3 | 24 to 60 | H226 | |

| 4 | 23 to 0 | H225 or H224 | |

| 5 | -1 to -20 | H225 or H224 | |

| 7 | < -20 | H225 or H224 |

Source: Adapted from CHEM21 Selection Guide [1]

The Safety criterion primarily addresses flammability hazards based on flash point (FP) and boiling point (BP) characteristics, aligned with GHS/CLP regulations [1]. As shown in Table 1, the basic safety score increases as the flash point decreases, with additional increments applied for specific hazards such as low auto-ignition temperature (AIT < 200°C), ability to accumulate electrostatic charges (resistivity > 10⸠Ω·m), or tendency to form explosive peroxides (hazard statement EUH019) [1]. For example, diethyl ether receives a combined safety score of 10 due to its extremely low flash point (-45°C) combined with multiple additional hazards including low auto-ignition temperature and peroxide formation potential [1].

Table 2: CHEM21 Health Scoring Based on GHS/CLP Hazard Statements

| Health Score | GHS/CLP Hazard Statements | Boiling Point Adjustment |

|---|---|---|

| 2 | H319, H315, H335, H336 | +1 if BP < 85°C |

| 4 | H317, H320, H335, H336 | |

| 6 | H301, H311, H331, H314 | |

| 7 | H330, H310, H370, H371 | |

| 9 | H340, H350, H360 |

Source: Adapted from CHEM21 Selection Guide [1] [3]

The Health criterion reflects occupational hazards and is based primarily on GHS/CLP hazard statements as outlined in Table 2 [1]. The scoring system accounts for the relative severity of health hazards, where H330 ("fatal if inhaled") represents a more severe hazard than H331 ("toxic if inhaled"), which in turn exceeds H332 ("harmful if inhaled") [1]. Additionally, the system incorporates a volatility adjustment where one point is added to the health score if the solvent's boiling point is lower than 85°C, reflecting the increased occupational exposure risk with volatile solvents [1]. This adjustment results in volatile carcinogens such as benzene and 1,2-dichloroethane receiving the maximum health score of 10 [1].

The Environment criterion focuses on environmental impact and persistence, utilizing a simplified scoring system based primarily on boiling point ranges and associated GHS environmental hazard statements (Table 3) [3]. Solvents with boiling points between 70-139°C generally receive the most favorable environmental scores, while those boiling below 50°C or above 200°C typically score poorly due to increased environmental dispersion or persistence, respectively [3].

Table 3: CHEM21 Environmental Scoring Criteria

| Environmental Score | Boiling Point Range (°C) | GHS Environmental Hazard Statements |

|---|---|---|

| 3 | 70 to 139 | No H4xx assigned |

| 5 | 50 to 69 or 140 to 200 | H412, H413 |

| 7 | <50 or >200 | H400, H410, H411 |

Source: Adapted from CHEM21 Selection Guide [3]

Experimental Protocols for Solvent Assessment

Protocol 1: SHE-Based Solvent Selection for Process Development

Purpose: To systematically evaluate and select solvents for chemical processes based on SHE criteria using the CHEM21 guide.

Materials:

- CHEM21 solvent selection guide

- Safety Data Sheets (SDS) for candidate solvents

- Physical property data (flash point, boiling point, vapor pressure)

- GHS/CLP classification data

- Process temperature and pressure parameters

Procedure:

- Compile solvent candidate list: Identify all solvents chemically compatible with the reaction system based on solubility parameters and mechanistic considerations.

- Gather SHE data: For each candidate solvent, collect the following data:

- Flash point, boiling point, and auto-ignition temperature

- GHS/CLP hazard statements for health and environmental hazards

- Vapor pressure and occupational exposure limits (where available)

- Environmental fate data (biodegradability, bioaccumulation potential)

- Apply CHEM21 scoring: Calculate safety, health, and environmental scores for each solvent using the criteria in Tables 1-3.

- Categorize solvents: Classify each solvent as recommended, problematic, hazardous, or highly hazardous based on combined SHE scores.

- Process compatibility assessment: Evaluate the top-ranked "recommended" solvents for technical compatibility with process requirements (reaction efficiency, separation, recovery).

- Lifecycle considerations: For final candidate solvents, assess broader environmental impacts including production energy requirements and waste management implications.

- Document selection rationale: Record the SHE assessment and final solvent selection with justification based on both technical and SHE criteria.

Expected Outcomes: Identification of solvents that provide optimal balance between process performance and SHE considerations, with documentation demonstrating due diligence in solvent selection.

Protocol 2: Workplace Exposure Assessment for Solvent Handling

Purpose: To quantitatively assess workplace exposure to solvents during handling and manufacturing operations.

Materials:

- Passive diffusion samplers (e.g., Radiello passive samplers)

- Personal protective equipment (PPE)

- Sampling pumps (for active sampling comparison)

- Thermal desorption tubes

- Gas chromatography with flame ionization detector (GC-FID) or mass spectrometry (GC-MS)

- Temperature-controlled storage (<5°C)

- Worksheet for activity recording

Procedure:

- Study design: Define sampling strategy based on work tasks, duration, and frequency of solvent handling operations.

- Sampler preparation: According to manufacturer specifications, prepare passive samplers while wearing appropriate PPE in a clean environment.

- Participant instruction: Verbally instruct operators on proper use of passive samplers, including:

- Correct attachment to lapel or breathing zone

- Proper opening and closing procedures

- Completion of activity worksheets recording sampling times, tasks performed, and solvents handled

- Sample collection: Conduct measurements over consecutive workdays, covering at least 80% of the work shift [6].

- Sample storage and transport: Store samples at <5°C immediately after collection and transport to analytical laboratory under temperature-controlled conditions.

- Chemical analysis:

- Extract samples using appropriate solvent (e.g., CSâ‚‚ for VOC analysis)

- Analyze using GC-FID or GC-MS with DB-624 or equivalent column

- Quantify concentrations using internal standard method and calibration curves

- Data interpretation:

- Calculate time-weighted average exposures

- Compare with occupational exposure limits

- Identify tasks and conditions associated with highest exposure levels

- Control implementation: Based on findings, implement appropriate engineering controls, administrative controls, or PPE to maintain exposures below acceptable limits.

Expected Outcomes: Quantitative exposure assessment data enabling evidence-based decisions on exposure control measures and verification of compliance with occupational exposure limits.

SHE Implementation Workflows

The integration of SHE principles into solvent selection and assessment processes requires systematic implementation. The following workflow diagrams visualize the key procedural relationships and decision pathways.

Figure 1: SHE Integration in Solvent Selection Workflow

Figure 2: Interrelationship of SHE Pillars in Solvent Management

Research Reagent Solutions and Materials

Table 4: Essential Materials for Solvent SHE Assessment

| Category | Item/Reagent | Specification | Function in SHE Assessment |

|---|---|---|---|

| Assessment Tools | CHEM21 Selection Guide | Current version | Provides standardized scoring system for solvent SHE performance |

| GHS/CLP Classification Database | Updated regulatory data | Supplies hazard statements for health and environmental scoring | |

| Physical Property Database | Contains FP, BP, VP data | Enables safety scoring and volatility assessments | |

| Analytical Materials | Passive Diffusion Samplers | Radiello or equivalent | Collects personal exposure samples for workplace monitoring |

| GC-FID/MS System | DB-624 or equivalent column | Quantifies solvent concentrations in exposure assessment | |

| Thermal Desorption Tubes | Standard sorbent materials | Alternative sampling method for VOC analysis | |

| Reference Materials | Certified Reference Standards | Analytical grade purity | Enables calibration and quantification in exposure monitoring |

| SDS Documentation | Manufacturer-provided | Supplies hazard information and handling precautions | |

| Safety Equipment | Personal Protective Equipment | Lab-appropriate | Protects researchers during solvent handling and assessment |

| Flammable Storage Cabinets | Certified safety design | Secure storage for solvent samples and references | |

| Ventilation Systems | Fume hoods, local exhaust | Controls airborne exposures during experimental work |

The Three-Pillar Approach to Safety, Health, and Environment (SHE) provides a comprehensive framework for evaluating solvent greenness within the context of the CHEM21 guide. By integrating systematic SHE assessment early in process development, researchers and drug development professionals can make informed decisions that balance technical requirements with safety, health, and environmental considerations. The experimental protocols and workflows presented in this document offer practical methodologies for implementing SHE principles in solvent selection and workplace exposure assessment. As regulatory pressures and sustainability expectations continue to evolve, robust SHE integration will remain essential for responsible chemical process development in pharmaceutical and related industries.

Decoding the GHS/CLP Alignment for Standardized Hazard Assessment

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a universal framework for classifying chemical substances and mixtures according to their physical, health, and environmental hazards. Developed by the United Nations, GHS establishes standardized hazard communication elements, including pictograms, signal words, and hazard statements, to ensure consistent safety information across international borders. As a non-binding international standard, GHS operates on a "building blocks" approach, allowing individual countries and regions to select which provisions to implement within their own legislation [7].

The CLP Regulation (Classification, Labelling and Packaging, Regulation (EC) No 1272/2008) is the European Union's binding legislation that implements GHS within its jurisdiction [8] [7]. Enforced from January 2009, CLP fully aligns with GHS principles while incorporating specific regional adaptations to address unique EU safety concerns. This regulation directly replaced previous EU directives on dangerous substances and preparations, establishing a unified system for hazard identification and communication throughout the European market [8]. For researchers applying the CHEM21 solvent selection guide, understanding the nuanced relationship between these two systems is fundamental for accurate solvent greenness assessment and regulatory compliance.

Comparative Analysis: GHS vs. CLP

Core Alignment Principles

GHS and CLP share the fundamental objective of ensuring that chemical hazards are clearly identified and effectively communicated to users. Both systems employ identical hazard communication elements, including:

- Pictograms: Red diamond-shaped symbols with black hazard symbols on a white background [8]

- Signal words: "Danger" or "Warning" to indicate the relative level of hazard severity

- Hazard statements: Standardized phrases describing the nature and degree of a hazard (e.g., H226 for flammable liquids) [7]

- Precautionary statements: Measures to minimize or prevent adverse effects from exposure [8]

This alignment ensures a consistent understanding of chemical hazards and facilitates the global trade of chemicals while maintaining high safety standards within the EU [8].

Key Divergences in Implementation

Despite their common foundation, significant differences exist between the purely international GHS system and its European implementation through CLP. These divergences primarily manifest in two key areas: the adoption of specific hazard categories and the introduction of supplementary EU-specific hazards.

Table 1: GHS Hazard Classes Not Fully Adopted in CLP

| Hazard Class | GHS Category | CLP Status | Rationale for Omission |

|---|---|---|---|

| Flammable liquids | Category 4 (H227) | Not adopted | Considered to indicate negligible hazard level [7] |

| Acute toxicity | Category 5 (H303, H313, H333) | Not adopted | Considered to indicate negligible hazard level [7] |

| Skin irritation | Category 3 (H316) | Not adopted | Considered to indicate negligible hazard level [7] |

| Eye irritation | Category 2B (H320) | Not adopted | Considered to indicate negligible hazard level [7] |

| Aspiration hazard | Category 2 (H305) | Not adopted | Considered to indicate negligible hazard level [7] |

| Hazard to aquatic environment | Acute categories 2 & 3 (H401, H402) | Not adopted | Considered to indicate negligible hazard level [7] |

The CLP Regulation introduces several EU-specific hazard classes that have no direct equivalent in the UN GHS framework. These additional classifications address environmental and health concerns of particular relevance to European chemical safety policies.

Table 2: EU-Specific Hazard Classes under CLP

| Hazard Class | Categories | EUH Codes |

|---|---|---|

| Endocrine disruptors | For human health (Cat. 1 & 2) | EUH380, EUH381 [7] |

| Endocrine disruptors | For the environment (Cat. 1 & 2) | EUH430, EUH431 [7] |

| Persistent, Bioaccumulative, Toxic (PBT) | - | EUH440 [7] |

| Very Persistent, Very Bioaccumulative (vPvB) | - | EUH441 [7] |

| Persistent, Mobile, Toxic (PMT) | - | EUH450 [7] |

| Very Persistent, Very Mobile (vPvM) | - | EUH451 [7] |

Figure 1: GHS to CLP Implementation Pathway. CLP adopts selected GHS categories while introducing unique EU-specific hazard classifications.

CHEM21 Solvent Assessment Methodology

Integration of GHS/CLP in Greenness Evaluation

The CHEM21 solvent selection guide employs a sophisticated scoring system that directly incorporates GHS/CLP hazard statements to evaluate solvent sustainability. This methodology transforms qualitative hazard information into quantitative scores across three critical domains: safety, health, and environmental impact. Each domain is scored from 1-10, with higher values representing greater hazard levels, and color-coded (green=1-3, yellow=4-6, red=7-10) for rapid visual assessment [9].

The health score derivation relies extensively on GHS/CLP H3xx statements, which communicate specific health hazards. The scoring follows a structured hierarchy based on the severity of these statements.

Table 3: CHEM21 Health Score Criteria Based on GHS/CLP Statements

| Health Score | CMR Properties | STOT/Acute Toxicity | Irritation |

|---|---|---|---|

| 2 | H341, H351, H361 (CMR cat. 2) | - | - |

| 4 | H340, H350, H360 (CMR cat. 1) | - | - |

| 6 | - | H304, H371, H373 | H315, H317, H319, H335, EUH066 |

| 7 | - | H334 | H318 |

| 9 | - | H370, H372 | H314 |

CMR: Carcinogen, Mutagen, or Reprotoxic; STOT: Specific Target Organ Toxicity

For solvents with incomplete REACH registration data, the CHEM21 guide applies a default health score of 5 (if boiling point ≥85°C) or 6 (if boiling point <85°C), unless the supplier provides more stringent H3xx statements [9]. This approach ensures consistent assessment even with limited data availability.

Safety and Environmental Scoring Protocols

The safety score in the CHEM21 guide primarily derives from physical properties with contributions from specific GHS/CLP statements. The base safety score is determined by flash point ranges, with additional points added for specific hazardous properties.

Table 4: CHEM21 Safety Score Calculation Methodology

| Base Safety Score | Flash Point (°C) | GHS Statements |

|---|---|---|

| 1 | > 60 | - |

| 3 | 23 to 60 | H226 |

| 4 | 22 to 0 | - |

| 5 | -1 to -20 | - |

| 7 | < -20 | H225 or H224 |

Additional +1 to safety score for each: Auto-ignition temperature <200°C, Resistivity >10⸠ohm.m, Ability to form peroxides (EUH019)

The environmental score incorporates both the volatility of the solvent (based on boiling point) and GHS H4xx environmental hazard statements. The score reflects the most stringent of these factors, addressing both atmospheric impact and aquatic toxicity [9].

Figure 2: CHEM21 Solvent Assessment Workflow. The methodology integrates GHS/CLP data across three assessment domains to determine final solvent ranking.

The CHEM21 guide combines individual safety, health, and environmental scores to generate an overall solvent ranking that guides researchers toward more sustainable choices. The combination follows specific rules that emphasize the most hazardous properties.

Table 5: CHEM21 Overall Solvent Ranking Criteria

| Score Combination | Default Ranking | Examples After Review |

|---|---|---|

| One score ≥ 8 | Hazardous | Chloroform (Highly Hazardous) |

| Two "red" scores (7-10) | Hazardous | Pyridine (Hazardous) |

| One score = 7 | Problematic | Benzyl alcohol (Problematic) |

| Two "yellow" scores (4-6) | Problematic | Cyclohexanone (Problematic) |

| Other combinations | Recommended | Acetone, Ethanol (Recommended) |

The ranking system incorporates expert review to address limitations of purely GHS-based scoring. For instance, chloroform receives a default "Problematic" ranking but was elevated to "Highly Hazardous" based on its very low occupational threshold limits, demonstrating how professional judgment refines automated scoring [9].

Experimental Protocols for Solvent Assessment

Protocol 1: GHS/CLP-Based Hazard Scoring

This protocol provides a standardized methodology for determining CHEM21 safety, health, and environmental scores based on available GHS/CLP data.

Materials and Equipment:

- Safety Data Sheets (SDS) from supplier with GHS/CLP classification

- CHEM21 Solvent Selection Guide spreadsheet tool [9]

- Physical property data (flash point, boiling point, auto-ignition temperature)

Procedure:

- Compile GHS/CLP Statements: Extract all H-codes and EUH-codes from Section 2 of the SDS

- Determine Safety Score:

- Record flash point and identify base score from Table 4

- Add +1 for each: auto-ignition temperature <200°C, resistivity >10⸠ohm.m, peroxide formation (EUH019)

- Calculate Health Score:

- Identify the most severe H3xx statement using Table 3 hierarchy

- Add +1 if boiling point <85°C

- Establish Environmental Score:

- Determine score based on boiling point range (<50°C=7, 50-69°C=5, 70-139°C=3, etc.)

- Compare with H4xx statement score (H412/H413=5, H400/H410/H411=7)

- Apply the more stringent of the two scores

- Apply Defaults if Needed: Use default scores (Health=5/6, Environment=5) if REACH registration incomplete and no supplier statements available

Quality Control: Verify scores against the interactive CHEM21 solvent selection tool and consult occupational hygiene experts for final ranking decisions, particularly for solvents with limited data.

Protocol 2: Green Solvent Alternative Assessment

This protocol employs machine learning approaches to identify sustainable solvent alternatives while ensuring GHS/CLP compliance.

Materials and Equipment:

- GreenSolventDB database (10,189 solvent metrics) [10]

- Hansen solubility parameters for target and alternative solvents

- CHEM21 assessment tools [9]

Procedure:

- Profile Hazardous Solvent: Complete GHS/CLP-based hazard scoring per Protocol 1 for the solvent to be replaced

- Identify Alternatives:

- Query GreenSolventDB for solvents with similar Hansen solubility parameters

- Apply machine learning models (Gaussian Process Regression recommended) to predict greenness metrics [10]

- Rank Alternatives: Sort candidates by CHEM21 overall ranking, prioritizing "Recommended" solvents

- Verify Performance: Conduct laboratory testing to confirm solubility performance of top candidates

- Validate Compliance: Ensure final selection meets all CLP requirements for target market, including EU-specific hazard classes if applicable

Case Study Application: For benzene replacement, this methodology successfully identifies 2-methyltetrahydrofuran as a greener alternative with comparable solvation properties and improved GHS/CLP profile [10].

Research Toolkit for Solvent Assessment

Table 6: Essential Research Tools for GHS/CLP-Compliant Solvent Assessment

| Tool/Resource | Function | Source/Access |

|---|---|---|

| CHEM21 Solvent Selection Guide | Scores solvents based on safety, health, and environmental criteria from GHS/CLP data [9] | ACS GCI Pharmaceutical Roundtable |

| Interactive Solvent Selection Tool | Allows solvent selection based on Principal Component Analysis of physical properties [11] | ACS Green Chemistry Institute |

| GreenSolventDB | Machine learning-generated database of green solvent metrics for 10,189 solvents [10] | Adv Sci (Weinh.) 2025 |

| Process Mass Intensity (PMI) Calculator | Determines PMI value by accounting for raw material inputs and API outputs [11] | ACS GCI Pharmaceutical Roundtable |

| CLP Regulation Annex VI | Official list of harmonized classification and labelling of substances [8] | ECHA Website |

| GHS Revision 10 | Latest UN GHS standards informing future regulatory updates [12] | UNECE Website |

| 3-ethyl-2-methylhept-2-ene | 3-Ethyl-2-methylhept-2-ene|C10H20|CAS 19780-61-1 | |

| Gossyplure | (Z,Z)-Gossyplure|52207-99-5|Insect Pheromone | (Z,Z)-Gossyplure is a sex pheromone for pink bollworm mating disruption research. For Research Use Only. Not for human or veterinary use. |

The strategic alignment between GHS and CLP establishes a robust foundation for standardized chemical hazard assessment, while regional adaptations require careful navigation for global compliance. The CHEM21 solvent selection guide successfully leverages this aligned framework to transform GHS/CLP hazard statements into actionable green chemistry metrics. By integrating these protocols into solvent selection workflows, researchers and drug development professionals can systematically advance solvent sustainability while maintaining regulatory compliance across jurisdictions. The continued evolution of both GHS standards and assessment methodologies promises further refinement of green chemistry practices in pharmaceutical development and manufacturing.

Within the framework of the CHEM21 guide research, solvent selection is a critical component for advancing green chemistry in the pharmaceutical industry. Interpreting the final ranking of solvents—categorizing them as recommended, problematic, or hazardous—is not a trivial task and requires a multi-fetric evaluation. This assessment synthesizes data on environmental, health, and safety (EHS) profiles, life cycle impacts, and technical performance to guide researchers and drug development professionals toward more sustainable laboratory and manufacturing practices [13]. The goal is to move beyond historical, often short-sighted solvent substitution strategies, such as replacing benzene with toluene, without fully considering the latter's own suspected hazards, including potential damage to unborn children and organs [13]. A modern, comprehensive approach, as embodied by the CHEM21 project, seeks to provide a balanced and scientifically robust framework for these critical decisions, integrating regulatory compliance with fundamental green chemistry principles.

Quantitative Solvent Assessment and Classification

Structured Solvent Ranking Tables

A comprehensive solvent assessment involves scoring and ranking based on a suite of quantitative and qualitative indicators. The following tables provide a structured overview of how solvents can be classified, summarizing key hazard information and regulatory status to aid in interpretation.

Table 1: Classification of Common Solvents Based on Assessment Guides

| Solvent | CHEM21 / GSK Category | Key Health & Safety Hazards | Environmental Concerns | Common Regulatory Restrictions |

|---|---|---|---|---|

| Ethanol | Recommended | Flammable, Irritant [14] | Low cumulative energy demand (CED) [13] | Generally compliant |

| Heptane | Recommended | Flammable, Irritant [14] | Low CED, but high aquatic toxicity potential [13] [15] | Generally compliant |

| Acetone | Recommended | Flammable, Irritant [14] | - | Generally compliant; listed as F003 spent solvent [16] |

| Ethyl Acetate | Recommended | Flammable, Irritant [14] | - | Generally compliant; listed as F003 spent solvent [16] |

| Toluene | Problematic | Flammable, Irritant, Suspected reproductive toxicant [13] [14] | - | REACH restrictions; suspected of damaging the unborn child [13] |

| Diethyl Ether | Problematic | Flammable, Narcotic, Peroxide formation [14] | - | - |

| N-Methyl-2-pyrrolidone (NMP) | Problematic | Reproductive toxicity [13] | - | REACH Substance of Very High Concern (SVHC) [13] |

| Dichloromethane (DCM) | Hazardous | Carcinogenic, Irritant [14] | Ozone-depleting [13] | REACH SVHC; IARC likely carcinogen [13] |

| Benzene | Hazardous | Carcinogenic [14] | - | - |

| Chloroform | Hazardous | Narcotic, Irritant [14] | - | REACH SVHC; IARC likely carcinogen [13] |

| 1,4-Dioxane | Hazardous | - | - | Not recommendable from environmental perspective [15] |

| N,N-Dimethylformamide (DMF) | Hazardous | Reproductive toxicity [13] | - | REACH SVHC [13] |

Table 2: Quantitative Exposure and Hazard Limits for Selected Solvents

| Solvent | Workplace Exposure Limit (8-hr TWA) | Flash Point (°C) | Explosive Limits (% in air) | GHS Hazard Pictograms |

|---|---|---|---|---|

| Acetone | 500 ppm / 1500 ppm [14] | -20.7 [14] | 2.6 - 12.8 [14] | Flammable, Irritant |

| Methanol | Not specified | 11 [14] | 6.7 - 36.0 [14] | Flammable, Health Hazard, Toxic |

| Toluene | Not specified | 16 [14] | 1.2 - 7.1 [14] | Flammable, Irritant, Health Hazard |

| Dichloromethane | 100 ppm [14] | Above 100 [14] | Not specified | Irritant, Health Hazard |

| n-Hexane | 20 ppm [14] | -26 [14] | 1.2 - 7.4 [14] | Flammable, Irritant, Environ. Hazard |

Interpretation of Ranking Criteria

The classification of a solvent as "Recommended" hinges on a favorable balance across multiple domains. Simple alcohols (e.g., methanol, ethanol) and alkanes (e.g., heptane, hexane) are often placed in this category due to their relatively low environmental impact scores and well-understood safety profiles [15]. From a technical perspective, these solvents must also demonstrate effective performance in their intended application, such as sufficient solubility power for a given API synthesis.

Solvents are elevated to "Problematic" status when they possess significant, but often manageable, hazards. Toluene and diethyl ether are prime examples. Toluene's status as a suspected reproductive toxicant and ether's tendency to form explosive peroxides necessitate rigorous control measures [13] [14]. Their use often requires additional engineering controls, specialized personal protective equipment (PPE), and strict administrative procedures. The "Hazardous" category is reserved for solvents with severe and often irreversible impacts on human health or the environment. Dichloromethane (DCM), benzene, chloroform, and 1,4-dioxane fall into this group. DCM and benzene are recognized carcinogens, while DCM additionally contributes to ozone depletion [13] [14]. The use of these solvents is increasingly restricted under regulations like REACH, and their substitution is a high priority in green chemistry programs [13].

Experimental Protocols for Solvent Ranking and Validation

Protocol 1: Solvent Greenness Assessment Using Selection Guides

This protocol outlines the steps for systematically evaluating and ranking solvents for a specific chemical process using established guide.

- Objective: To assign a greenness category (Recommended, Problematic, Hazardous) to candidate solvents for a given synthesis or formulation step.

- Principles: The assessment is based on a combined evaluation of Environmental, Health, and Safety (EHS) criteria and Life Cycle Assessment (LCA) principles, as embodied by the CHEM21 and GSK solvent selection guides [13].

Step-by-Step Methodology:

- Define Solvent List: Compile a list of all solvents that are technically feasible for the intended chemical process (e.g., reaction, crystallization, extraction).

- Consult Selection Guide: Cross-reference the solvent list with a current solvent selection guide (e.g., CHEM21, GSK, Pfizer). Record the preliminary category for each solvent.

- Detailed Hazard Check: For each solvent, consult the Safety Data Sheet (SDS) and regulatory lists (e.g., REACH SVHC, EPA F-list [16] [13]). Document specific hazards:

- Health: Carcinogenicity, mutagenicity, reproductive toxicity (e.g., DMF, NMP), acute toxicity [13] [14].

- Safety: Flash point, explosive limits, peroxide formation potential (e.g., diethyl ether) [14].

- Environment: Biodegradability, aquatic toxicity, ozone depletion potential (e.g., DCM), global warming potential [13].

- Check Regulatory Status: Verify if the solvent is subject to usage restrictions or authorization requirements under regulations like REACH [13].

- Assign Final Category: Synthesize the information from steps 2-4 to assign a final category:

- Recommended: Low EHS burden, no major regulatory restrictions.

- Problematic: Significant but manageable hazards; requires specific controls.

- Hazardous: Severe health/environmental hazards; subject to regulatory restrictions; substitution is required.

- Documentation: Record the rationale for the categorization of each solvent, citing the specific hazards and regulatory findings.

Protocol 2: Computational Solvent Performance and Sustainability Screening

This protocol describes the use of data-driven platforms and machine learning models to predict solvent performance (e.g., solubility) and integrate this with sustainability metrics, as exemplified by the SolECOs platform [17].

- Objective: To identify an optimal solvent that balances high process efficiency (e.g., high API solubility) with a superior environmental profile.

- Principles: Leverage machine learning (ML) models trained on large solubility datasets and couple predictions with standardized LCA indicators [17] [18].

Step-by-Step Methodology:

- Input API Data: Define the target Active Pharmaceutical Ingredient (API) by its structure. Generate or calculate a set of molecular descriptors (e.g., using tools within the platform).

- Select Solvent Candidates: Choose from a pre-defined list of industrially relevant solvents and their binary mixtures within the platform (e.g., the 30 solvents in SolECOs) [17].

- Run Solubility Prediction: Execute the ML models (e.g., Polynomial Regression Model-based Multi-Task Learning Network - PRMMT, or FastSolv) to obtain predicted solubility profiles for the API in the candidate solvents across a temperature range [17] [18].

- Generate Sustainability Ranking: The platform automatically calculates sustainability scores for each solvent candidate using defined metrics (e.g., 23 Life Cycle Impact indicators from ReCiPe 2016 and the GSK sustainable solvent framework) [17].

- Multi-criteria Decision Analysis: Review the platform's output, which provides a multidimensional ranking of solvents based on both predicted solubility (performance) and sustainability score.

- Experimental Validation: For the top-ranked solvent(s), conduct laboratory-scale crystallization experiments to validate the predicted solubility and resulting crystal properties (e.g., yield, polymorphism). Compare results with predictions [17].

Visualization of the Solvent Assessment Workflow

The following diagram illustrates the logical sequence and decision points in a comprehensive solvent assessment process, integrating both guide-based and computational screening methods.

Solvent Assessment Workflow

This section details key databases, software tools, and regulatory resources essential for conducting a thorough solvent assessment.

Table 3: Essential Resources for Solvent Selection and Assessment

| Tool / Resource Name | Type | Primary Function in Solvent Assessment | Key Features / Data Provided |

|---|---|---|---|

| SolECOs Platform [17] | Data-Driven Software Platform | Sustainable solvent selection for pharmaceutical crystallization. | Predicts solubility for 1186 APIs in 30 solvents; integrates ML models & LCA indicators (ReCiPe 2016, GSK framework). |

| FastSolv / ChemProp Models [18] | Machine Learning Model | Predicts molecule solubility in organic solvents. | Uses molecular embeddings; accounts for temperature effects; publicly available. |

| BigSolDB [18] | Database | Training and benchmarking data for solubility prediction models. | Compiled solubility data from nearly 800 published papers for ~800 molecules in >100 solvents. |

| EPA F-List (e.g., F001-F005) [16] | Regulatory List | Identifies spent solvents classified as hazardous waste. | Lists common spent halogenated (e.g., trichloroethylene) and non-halogenated (e.g., xylene, acetone) solvents. |

| REACH SVHC List [13] | Regulatory List | Identifies Substances of Very High Concern subject to authorization. | Includes solvents like DMF, NMP, DMAc, and various chlorinated solvents. |

| GSK/Pfizer/CHEM21 Solvent Selection Guides [13] | Assessment Guide | Categorizes solvents based on EHS profiles. | Provides a ranked list of solvents from "Preferred" to "Undesirable". |

| EHS Assessment Tool (ETH Zurich) [13] | Spreadsheet Tool | Numerically ranks solvent greenness based on EHS criteria. | Free spreadsheet; combines hazard codes and exposure limits into a single score. |

The Critical Role of Solvent Selection in Sustainable Pharmaceutical Manufacturing

Solvent selection is a pivotal determinant of sustainability in pharmaceutical manufacturing, influencing process efficiency, environmental impact, and regulatory compliance. Solvents typically constitute 80-90% of the total mass utilization in active pharmaceutical ingredient (API) synthesis and can account for as much as 80% of the life cycle process waste [19] [20]. Driven by stringent regulations such as REACH and industry initiatives like the Green Pharmacy Initiative, pharmaceutical companies are increasingly adopting green chemistry principles that prioritize safer, more sustainable solvent systems [13] [17]. This application note details practical frameworks, experimental protocols, and assessment tools for implementing sustainable solvent selection within the context of the CHEM21 guide, providing scientists with methodologies to advance greener pharmaceutical manufacturing.

Solvent Greenness Assessment Frameworks

The CHEM21 Solvent Selection Guide

The CHEM21 Selection Guide represents a standardized approach for evaluating solvent environmental, health, and safety (EHS) profiles, aligned with the Globally Harmonized System (GHS) of Classification and Labelling of Chemicals [3]. This framework categorizes solvents into three tiers—Recommended, Problematic, or Hazardous—based on integrated safety, health, and environmental scores.

- Safety Scoring: Evaluates flammability (flash point), auto-ignition temperature, peroxide formation potential, and decomposition energy. For example, solvents with flash points >60°C score 1 (preferable), while those <-20°C score 7 (hazardous) [3].

- Health Scoring: Derived from GHS hazard statements, with additional points added for low boiling points (<85°C) indicating higher inhalation exposure risk [3].

- Environmental Scoring: Based on boiling point ranges and GHS environmental hazard statements (H400-H413), with scores of 3, 5, or 7 assigned accordingly [3].

Complementary Assessment Metrics

Multiple quantitative frameworks exist to complement the CHEM21 guide, providing holistic sustainability perspectives:

- Life Cycle Assessment (LCA): Comprehensive methodology evaluating environmental impacts across the solvent's entire life cycle, from raw material extraction to disposal [20]. The ReCiPe 2016 method incorporates 23 midpoint and endpoint impact indicators for robust comparative analysis [17].

- Process Mass Intensity (PMI): Preferred metric of the ACS Green Chemistry Institute Pharmaceutical Roundtable, calculated as the total mass of materials used per mass of product obtained, emphasizing resource efficiency [20].

- Cumulative Energy Demand (CED): Assesses the total energy required for solvent production, including credits for recycling via distillation or energy recovery via incineration [13].

- Green Environmental Assessment and Rating for Solvents (GEARS): Novel metric integrating ten parameters including toxicity, biodegradability, renewability, and cost into a single score [21].

Table 1: Comparison of Major Solvent Assessment Frameworks

| Framework | Key Metrics | Output | Primary Application |

|---|---|---|---|

| CHEM21 Guide | Safety, Health, Environment | Categorical (Recommended/Problematic/Hazardous) | Initial solvent screening |

| EHS (ETH Zurich) | Environmental, Health, Safety hazards | Numerical score (0-9, lower=greener) | Process development |

| GSK SSG | Environmental, Health, Safety, Waste | Score (0-10, lower=greener) | Pharmaceutical process design |

| GEARS | Ten parameters including renewability, efficiency, cost | Overall score (0-100, higher=greener) | Comprehensive solvent evaluation |

| LCA | Multiple impact categories (ReCiPe 2016) | Environmental impact profiles | Comparative sustainability analysis |

Experimental Protocols for Sustainable Solvent Selection

Computational Screening Workflow

Purpose: To efficiently identify potential green solvent candidates for API crystallization using predictive modeling before experimental verification.

Materials:

- Solubility database (e.g., SolECOs platform containing 30,000+ data points for 1186 APIs in 30 solvents) [17]

- Machine learning models (Polynomial Regression Model-based Multi-Task Learning Network/PRMMT, Point-Adjusted Prediction Network/PAPN, Modified Jouyban-Acree-based Neural Network/MJANN for binary systems) [17]

- Hansen Solubility Parameters data

- CHEM21 Solvent Selection Guide

- Life Cycle Assessment software (e.g., SimaPro)

Procedure:

- Input API Characterization: Calculate 347 molecular descriptors from 3D molecular structure of target API [17].

- Solubility Prediction: Apply appropriate ML model (PRMMT for general screening, PAPN for specific temperatures, MJANN for binary solvent systems) to predict API solubility in candidate solvents [17].

- Sustainability Assessment: Rank solvent candidates using integrated sustainability metrics (CHEM21, GSK SSG, LCA indicators) [17].

- Uncertainty Quantification: Evaluate prediction reliability through probability distributions of residuals [17].

- Candidate Selection: Identify optimal solvents balancing solubility performance and sustainability metrics.

Laboratory-Scale Green Solvent Validation

Purpose: Experimentally verify computational predictions for API crystallization in selected green solvents.

Materials:

- API compound (e.g., paracetamol, meloxicam, piroxicam, cytarabine) [17]

- Candidate green solvents (e.g., ethyl lactate, dimethyl isosorbide, ethanol-water mixtures) [22]

- Standard laboratory equipment: jacketed reactor, temperature control system, vacuum filtration apparatus, analytical HPLC

- CHEM21 Solvent Selection Guide for reference

Procedure:

- Solvent Preparation: Obtain and characterize purity of candidate green solvents. For binary mixtures, prepare precise volumetric ratios.

- Solubility Determination: Use shake-flask method at controlled temperatures (typically 10-50°C) to establish experimental saturation concentrations [17].

- Crystallization Trials: Conduct cooling crystallization with controlled temperature ramp (0.1-1.0°C/min) from saturation point [17].

- Product Characterization: Analyze crystal form (polymorphism) by PXRD, purity by HPLC, yield by gravimetric analysis [17].

- Solvent Recovery: Implement distillation to recover and reuse solvent, calculating recovery efficiency [13].

- Green Metrics Calculation: Determine Process Mass Intensity (PMI), E-factor, and applicable sustainability scores for the process [20].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Green Solvent Research

| Reagent/Material | Function/Application | Green Credentials | CHEM21 Category |

|---|---|---|---|

| Ethyl Lactate | Bio-based solvent for reactions and extraction | Derived from renewable resources, biodegradable [22] | Recommended |

| Dimethyl Isosorbide | Green solvent for synthesis, particularly semicarbazones [22] | Renewable origin, low toxicity, used in cosmetics [22] | Recommended |

| Ethanol-Water Mixtures | Crystallization medium | Reduced toxicity, lower VOC emissions vs pure organic solvents [3] | Recommended |

| Supercritical COâ‚‚ | Extraction and separation medium | Non-flammable, non-toxic, easily recyclable [23] | Recommended |

| Ionic Liquids | Tunable solvents for specialized applications | Negligible vapor pressure, highly customizable [23] | Case-dependent |

| Deep Eutectic Solvents (DES) | Biorenewable solvents for synthesis | Low toxicity, biodegradable, inexpensive components [23] | Recommended |

| Neomenthoglycol | Neomenthoglycol (CAS 3564-95-2) - High-Purity Standard | High-purity Neomenthoglycol (cis-p-Menthane-3,8-diol), a natural compound. For Research Use Only. Not for human or veterinary use. | Bench Chemicals |

| 2-(3-Mercaptophenyl)acetic acid | 2-(3-Mercaptophenyl)acetic Acid|CAS 63271-86-3 | 2-(3-Mercaptophenyl)acetic acid (CAS 63271-86-3) is a key aryl thioether carboxylic acid for research. This product is for Research Use Only. Not for human or veterinary use. | Bench Chemicals |

Implementation in Pharmaceutical Development

Integrating Assessment Tools

Successful implementation of sustainable solvent strategies requires leveraging multiple complementary tools:

- ACS GCI Solvent Selection Tool: Interactive platform featuring 272 solvents with PCA analysis of 70 physical properties, ICH classification, and environmental impact categories [24].

- Data-Driven Platforms: SolECOs integrates predictive modeling with sustainability assessment for both single and binary solvent systems [17].

- Machine Learning Expansion: Gaussian Process Regression models trained on GSK Solvent Sustainability Guide data can predict greenness metrics for over 10,000 solvents, dramatically expanding options beyond traditional guides [10].

Case Study: Semicarbazone Synthesis in Green Solvents

Research demonstrates the successful application of green solvent principles to pharmaceutical synthesis. Semicarbazones, molecules with anticonvulsant and anti-tumor activity, were synthesized quantitatively at room temperature within minutes using the green solvents ethyl lactate and dimethyl isosorbide, replacing traditional toxic reagents and high-energy conditions [22]. This approach satisfied green chemistry requirements while maintaining excellent efficiency, demonstrating the practical viability of green solvent implementation for pharmaceutical production.

Strategic solvent selection represents a critical opportunity to advance sustainable pharmaceutical manufacturing. By integrating robust assessment frameworks like the CHEM21 guide with predictive computational tools and experimental validation, researchers can significantly reduce the environmental footprint of pharmaceutical processes while maintaining efficiency and product quality. The methodologies outlined in this application note provide a structured approach for scientists to systematically evaluate and implement greener solvent systems throughout drug development and manufacturing.

A Step-by-Step Guide to Applying the CHEM21 Scoring System in Your Lab

Within the context of the CHEM21 solvent selection guide, the evaluation of a solvent's greenness is based on a combined assessment of Safety, Health, and Environment (SHE) criteria. The safety score, a critical component of this assessment, provides researchers and drug development professionals with a standardized measure of the potential physical hazards associated with a solvent during laboratory use and industrial processing. This application note details the quantitative methodology and experimental protocols for determining the safety score, focusing on its core determinants: flash point, auto-ignition temperature, resistivity, and peroxide formation tendency [9].

The primary goal is to equip scientists with the knowledge to accurately calculate this score, thereby enabling informed, safer solvent choices in alignment with the principles of green chemistry. The procedural guidelines outlined herein are derived from the CHEM21 consensus methodology, which aligns with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) to ensure international relevance and applicability [9].

Core Concepts and Definitions

Understanding the specific terms used in the safety scoring system is fundamental to its correct application. Below are the key definitions:

- Flash Point: The lowest temperature at which a liquid gives off vapors in sufficient concentration to form an ignitable mixture with air near the surface of the liquid upon application of an ignition source [25]. It is not to be confused with the auto-ignition temperature or the fire point. The flash point is the primary determinant of the base safety score.

- Auto-ignition Temperature (AIT): The minimum temperature required to initiate self-sustained combustion in a substance in the absence of an external ignition source, such as a spark or flame [25]. A low AIT contributes to a higher safety hazard.

- Peroxide Formation: The ability of certain solvents, particularly ethers, to form unstable and highly explosive peroxides upon exposure to air and light. This property is identified by the GHS hazard statement EUH019 [9].

- Resistivity: A measure of a liquid's ability to resist the flow of electric current. Solvents with high resistivity (e.g., > 10^8 ohm.m) are prone to the accumulation of static charge, which can act as an ignition source for flammable vapors [9].

Quantitative Safety Scoring Methodology

The CHEM21 safety score is calculated on a scale of 1 to 10, where a higher score indicates a greater hazard level [9]. The overall score is an aggregate of a base score (derived from the flash point) and additional penalty points.

Base Safety Score from Flash Point

The foundation of the safety score is the solvent's flash point, which determines its base hazard rating as shown in Table 1.

Table 1: Determination of Base Safety Score from Flash Point

| Base Safety Score | Flash Point (°C) | Relevant GHS Hazard Statement(s) |

|---|---|---|

| 1 | > 60 | None |

| 3 | 23 to 60 | H226: Flammable liquid and vapor |

| 4 | 22 to 0 | H226: Flammable liquid and vapor |

| 5 | -1 to -20 | H224: Extremely flammable liquid and vapor |

| 7 | < -20 | H225: Highly flammable liquid and vapor |

Additional Hazard Penalties

After establishing the base score, one point is added to the safety score for each of the following secondary hazards that apply to the solvent [9]:

- Auto-ignition Temperature (AIT) < 200°C

- Resistivity > 10^8 ohm.m

- Ability to form explosive peroxides (GHS Statement EUH019)

Workflow for Safety Score Determination

The following diagram illustrates the logical procedure for calculating the final CHEM21 safety score.

Calculation Example: Diethyl Ether

To illustrate the methodology, consider the safety scoring for diethyl ether [9]:

- Flash Point: -45°C → According to Table 1, this corresponds to a base safety score of 7.

- Auto-ignition Temperature: 160°C (< 200°C) → Add 1 point.

- Resistivity: 3 x 10^11 ohm.m (> 10^8 ohm.m) → Add 1 point.

- Peroxide Formation: Has GHS statement EUH019 → Add 1 point.

Final Safety Score = 7 + 1 + 1 + 1 = 10

Experimental Protocols for Data Acquisition

The following sections provide detailed methodologies for obtaining the key experimental data required for the safety score calculation.

Flash Point Measurement

The flash point can be measured using two main approaches: Closed Cup or Open Cup methods. The closed cup method is generally preferred for product specifications and regulatory reporting as it provides a more conservative (lower) value by containing the vapors, better simulating conditions in a closed container [25] [26].

Table 2: Standardized Flash Point Test Methods

| Test Method | Type | Governing Standard(s) | Typical Application Scope |

|---|---|---|---|

| Pensky-Martens | Closed Cup | ASTM D93-20, IP 34, ISO 2719:2016 | Petroleum products; Flash point range: 40°C to 370°C [25] |

| Cleveland Open Cup (COC) | Open Cup | ASTM D92-18, IP36, ISO 2592:2017 | Petroleum products with flash points above 79°C (175°F) and below 400°C (752°F) [25] |

| Small Scale Closed Cup | Closed Cup | ASTM D3828 | Pass/fail testing; requires only 2-4 mL sample [25] |

Detailed Protocol: Flash Point by Pensky-Martens Closed Cup Tester (ASTM D93)

Principle: A sample is heated in a closed cup at a controlled rate and with periodic stirring. A small test flame is applied at regular intervals through a shutter opening. The flash point is the lowest temperature at which the application of the test flame causes the vapor above the sample to ignite momentarily [25].

Materials and Equipment:

- Pensky-Martens Closed Cup Tester (manual or automated), including cup, lid, shutter mechanism, ignition source, and heater

- Thermometer or temperature sensor

- Barometer

- Syringe or pipette for sample transfer

- Cooling medium (if needed)

Procedure:

- Preparation: Ensure the cup and its components are clean and dry. Place the tester in a draft-free location.

- Sample Introduction: Fill the test cup with the sample to the appropriate level (typically 75 mL) using a syringe or pipette, avoiding air bubble formation [25].

- Assembly: Secure the lid onto the cup, ensuring a tight seal. The thermometer and stirrer should be correctly positioned.

- Heating and Stirring: Begin heating the sample at a specified rate (e.g., 5-6°C/min) while stirring the sample at a prescribed speed (e.g., 90-120 rpm) [25].

- Ignition Test: For every 1°C rise in temperature, stop stirring and open the shutter to apply the test flame. Observe if a flash occurs within the cup. The test flame should be applied smoothly and consistently.

- Endpoint Determination: The temperature at which a distinct flash is observed inside the cup is recorded as the flash point. The flame application should be a swift, not slow, rocking motion.

- Correction: Correct the observed flash point to standard atmospheric pressure (101.3 kPa) as per the calculation method provided in the standard.

Safety Considerations:

- Perform the test in a fume hood or well-ventilated area.

- Wear appropriate Personal Protective Equipment (PPE) including safety glasses and lab coat.

- Have a Class B fire extinguisher readily available.

- Pre-warn the laboratory if testing samples suspected of having low flash points or fuel dilution [25].

Assessment of Peroxide Formation Tendency

Principle: The primary indicator for a solvent's tendency to form peroxides is the assignment of the GHS hazard statement EUH019: "May form explosive peroxides" [9]. Laboratory testing can be performed to detect and quantify peroxides in suspect solvents.

Materials and Equipment:

- Test strips (e.g., peroxide test strips for organic solvents)

- Alternatively, potassium iodide (KI) solution and acetic acid

- Spectrophotometer or visual color comparison chart

- Glass test tubes

Procedure (Qualitative/Semi-Quantitative using Test Strips):

- Sampling: Dip a peroxide test strip into the solvent sample for the duration specified by the manufacturer.

- Development: Remove the strip and allow the solvent to evaporate.

- Reading: Observe the color change on the test pad and compare it to the provided calibration chart to determine the approximate peroxide concentration.

Interpretation: A positive test indicates the presence of peroxides, confirming the hazard associated with the solvent. For the purpose of the CHEM21 safety score, the official GHS classification (EUH019) is the definitive source. Experimental testing is crucial for monitoring aged solvents in the laboratory, even if the solvent is not classified with EUH019.

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table lists key equipment and reagents required for performing the assessments described in this application note.

Table 3: Essential Materials for Safety Parameter Assessment

| Item | Function/Application |

|---|---|

| Pensky-Martens Flash Point Tester | Standardized equipment for determining the closed-cup flash point of solvents, especially for regulatory and specification purposes [25]. |

| Cleveland Open Cup Tester | Standardized equipment for determining the open-cup flash point and fire point of less volatile petroleum products [25] [26]. |

| Small Scale Closed Cup Tester (e.g., Setaflash) | Rapid, pass/fail flash point testing requiring minimal sample volume (2-4 mL), ideal for quality assurance and screening [25] [26]. |

| Peroxide Test Strips | Simple, semi-quantitative detection of peroxide formation in stored solvents, a key safety monitoring activity [9]. |

| Barometer | Essential for measuring atmospheric pressure to correct the observed flash point value to standard pressure (101.3 kPa) [25]. |

| Static Dissipative Containers | Safe storage and transfer of high-resistivity solvents to prevent the accumulation of static charge, a known ignition source [9]. |

| N'-Nitrosopentyl-(2-picolyl)amine | N'-Nitrosopentyl-(2-picolyl)amine|C11H17N3O|Research Compound |

| N6,7-Dimethylquinoline-5,6-diamine | N6,7-Dimethylquinoline-5,6-diamine|CAS 83407-42-5 |

The calculated safety score is one of three pillars in the CHEM21 assessment framework. It is combined with the health score and environment score to produce an overall solvent ranking. According to the CHEM21 guide, the following combinations determine the preliminary ranking [9]:

- Recommended: No single score is ≥ 7 and no more than one score is in the "yellow" (4-6) range.

- Problematic: One score is 7, OR two scores are in the "yellow" (4-6) range.

- Hazardous: Any one score is ≥ 8, OR two or more scores are in the "red" (7-10) range.

This integrated approach ensures that a solvent is evaluated not just on its flammability and physical hazards, but also on its toxicity and environmental impact, providing a holistic view of its greenness for use in research and pharmaceutical development.

Within the framework of the CHEM21 selection guide, the assessment of a solvent's environmental and safety profile is a multi-factorial process [9] [1]. A critical component of this assessment is the Health Score, a quantitative measure of the potential occupational health hazards associated with a solvent [1]. This score provides researchers, scientists, and drug development professionals with a standardized metric to quickly identify and prioritize safer solvents during process development [3]. The methodology for determining the Health Score is deliberately aligned with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) and European regulations, ensuring a consistent and internationally recognized approach to hazard communication [9] [1]. This application note details the protocol for determining the Health Score based on GHS H3xx hazard statements and the pivotal adjustment for solvent volatility based on boiling point.

The Health Score Calculation Framework

The CHEM21 Health Score is derived primarily from the most severe GHS H3xx statement assigned to a solvent, with an additional adjustment factor for volatility [9]. The final score is an integer ranging from 1 to 10, where a higher score indicates a greater health hazard [9] [1]. A color code is typically associated with this scoring: green for scores of 1-3 (low hazard), yellow for 4-6 (moderate hazard), and red for 7-10 (high hazard) [1].

Table 1: Health Score Based on GHS H3xx Hazard Statements

| Health Score | Carcinogenicity, Mutagenicity, or Reproductive Toxicity (CMR) | Specific Target Organ Toxicity (STOT) | Acute Toxicity | Irritation |

|---|---|---|---|---|

| 2 | H341, H351, H361 (Suspected CMR, Category 2) | |||

| 4 | H340, H350, H360 (CMR, Category 1) | |||

| 6 | H371, H373 (May cause damage to organs/through prolonged exposure) | H302, H312, H332, H336, EUH070 (Harmful) | H315, H319, H335 (Causes skin or eye irritation, respiratory irritation) | |

| 7 | H334 (May cause allergy or asthma symptoms) | H301, H311, H331 (Toxic) | H318 (Causes serious eye damage) | |

| 9 | H370, H372 (Causes damage to organs/through prolonged exposure) | H300, H310, H330 (Fatal) | H314 (Causes severe skin burns and eye damage) |

Boiling Point Adjustment: After assigning the base score from Table 1, 1 point is added to the health score if the solvent's boiling point is below 85°C [9]. This adjustment accounts for the increased occupational risk from inhalation exposure due to higher volatility at room temperature [1].

Default and Ideal Scores:

- A solvent with a boiling point ≥85°C and no H3xx statements after a full REACH registration is assigned a health score of 1 [9].

- For newer solvents with incomplete REACH registration data and no H3xx statements attributed by the supplier, a default health score of 5 is assigned if the boiling point is ≥85°C, or 6 if the boiling point is <85°C [9].

Experimental Protocol for Health Score Determination

Objective

To systematically determine the CHEM21 Health Score for a given solvent based on its GHS H3xx hazard statements and its boiling point.

Materials and Equipment

Table 2: Research Reagent Solutions and Essential Materials

| Item | Function/Description |

|---|---|

| Safety Data Sheet (SDS) | The primary source for GHS classification, hazard statements, and physical property data for the solvent [27]. |

| REACH Registration Dossier | Provides authoritative toxicological and eco-toxicological data, confirming hazard classifications [1]. |

| Boiling Point Apparatus | For experimental determination of boiling point if literature/data sheet values are unavailable or require verification. |

| CHEM21 Solvent Selection Guide | Reference document containing the scoring tables and methodology for final ranking [9] [1]. |

Step-by-Step Procedure

Solvent Identification: Record the solvent name and its CAS Registry Number to ensure precise identification.

Data Collection:

- Obtain the most recent Safety Data Sheet (SDS) for the solvent from a reliable supplier or database.

- Locate the Hazard Statements (H-codes) in Section 2 of the SDS. Identify all H3xx codes related to health hazards [27].

- Locate the solvent's boiling point in Section 9 of the SDS.

Base Health Score Assignment:

- Review the identified H3xx statements.

- Consult Table 1 of this document. Assign the base health score corresponding to the most severe H3xx statement present.

Volatility Adjustment:

- Compare the solvent's boiling point to the 85°C threshold.

- If the boiling point is <85°C, add 1 point to the base health score.

Final Score and Ranking:

- The resulting value is the final Health Score (1-10).

- Classify the solvent's health hazard level based on its score and color code (Green: 1-3; Yellow: 4-6; Red: 7-10).

The following workflow diagram illustrates this deterministic process:

Worked Examples

Example 1: Determining the Health Score for Methanol

- H3xx Statements: H301 (Toxic if swallowed) [9].

- Boiling Point: 65°C [9].

- Base Score Assignment: H301 corresponds to a base health score of 7 (see Table 1, Acute Toxicity).

- Volatility Adjustment: Boiling point (65°C) is <85°C; therefore, add 1 point.

- Final Health Score: 7 + 1 = 8.

Example 2: Determining the Health Score forn-Butanol

- H3xx Statements: H318 (Causes serious eye damage) [9].

- Boiling Point: 118°C [9].

- Base Score Assignment: H318 corresponds to a base health score of 7 (see Table 1, Irritation).

- Volatility Adjustment: Boiling point (118°C) is >85°C; therefore, no points are added.

- Final Health Score: 7.

Table 3: Health Score Examples from the CHEM21 Guide

| Solvent | CAS | Boiling Point (°C) | Relevant H3xx Statements | Base Score | BP Adj. | Final Health Score |

|---|---|---|---|---|---|---|

| Water | 7732-18-5 | 100 | None | 1 | No | 1 [9] |

| Ethanol | 64-17-5 | 78 | H319 | 3 | Yes (+1) | 4 [9] |

| Acetone | 67-64-1 | 56 | H319 | 3 | Yes (+1) | 4 [9] |

| Ethyl Acetate | 141-78-6 | 77 | H319 | 3 | Yes (+1) | 4 [9] |

| i-Propanol | 67-63-0 | 82 | H319 | 3 | Yes (+1) | 4 [9] |

| n-Butanol | 71-36-3 | 118 | H318 | 7 | No | 7 [9] |

| Methanol | 67-56-1 | 65 | H301 | 7 | Yes (+1) | 8 [9] |

The protocol for determining the CHEM21 Health Score provides a robust, standardized method for evaluating solvent health hazards. By integrating the severity of GHS H3xx statements with a quantitative adjustment for volatility, it effectively captures both the intrinsic toxicity and the exposure risk potential of a solvent. This enables researchers in drug development and other chemical industries to make informed, safer choices, thereby supporting the overarching goal of incorporating green chemistry principles into sustainable manufacturing processes. This Health Score, when combined with separate Safety and Environment scores, forms the tripartite foundation of the comprehensive CHEM21 solvent selection and ranking system [9] [1].

The transition towards sustainable chemistry in the pharmaceutical and specialty chemicals industries necessitates robust, quantitative tools for evaluating solvent environmental impact. Framed within the broader CHEM21 guide research context—a leading framework for green metrics in the pharmaceutical industry—this application note addresses the critical need for standardized assessment of key physicochemical parameters affecting environmental and human health [19]. Volatility, boiling point, and eco-toxicity (often indicated by hazard codes like H4xx) are interconnected properties that fundamentally determine a solvent's emission potential, exposure risk, and overall environmental footprint.

Understanding these parameters enables researchers to make informed substitutions, such as replacing hazardous conventional solvents like acetonitrile or benzene with safer, bio-based alternatives, thereby aligning industrial processes with the principles of green chemistry [28] [29]. This document provides detailed methodologies for measuring and interpreting these properties, supported by quantitative data and practical protocols, to guide solvent selection in drug development and other laboratory settings.

Quantitative Parameter Comparison

The following tables summarize key physicochemical and toxicological data for a selection of conventional and green solvents, providing a basis for comparative assessment.

Table 1: Physicochemical and Toxicological Properties of Common Solvents [28] [30] [29]

| Solvent | Boiling Point (°C) | Volatility Class | LD50 (mg/kg) | Common Hazard Codes | Greenness Score (GEARS) |

|---|---|---|---|---|---|

| Acetonitrile | 82 | High (VOC) | 2460 | H312, H319, H332 | 48 |

| Methanol | 65 | High (VOC) | 5628 | H301, H311, H331 | 51 |

| Ethanol | 78 | High (VOC) | 7060 | H319 | 81 |

| Benzene | 80 | High (VOC) | 930 | H350, H340, H372 | 21 |

| Glycerol | 290 | Low | >5000 | - | 93 |

| Dimethyl Carbonate | 90 | Moderate (VOC) | >5000 | H319 | 82 |

| Ethyl Lactate | 154 | Moderate (VOC) | >5000 | H319 | 85 |

Table 2: Green Solvent Classification by Boiling Point and Source [31] [32]

| Green Solvent | Boiling Point Range (°C) | Renewable Source | Primary Application |

|---|---|---|---|